Expansion joint holder and a method of pouring concrete sections

a technology of expansion joint and concrete section, which is applied in the direction of bridges, roads, constructions, etc., can solve the problems of large area concrete slabs that are prone to cracks, joints that can easily float, time-consuming and inefficient processes, etc., and achieve the effect of more efficient pouring of concr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The phrase “resulting joint is substantially straight” as used herein means the expansion joint is linear and not wavy or curved.

[0027] The phrase “substantially parallel” as used herein means planes which are less than about 10 degrees, preferably less than about 5 degrees and more preferably less than about 2 degrees off of parallel.

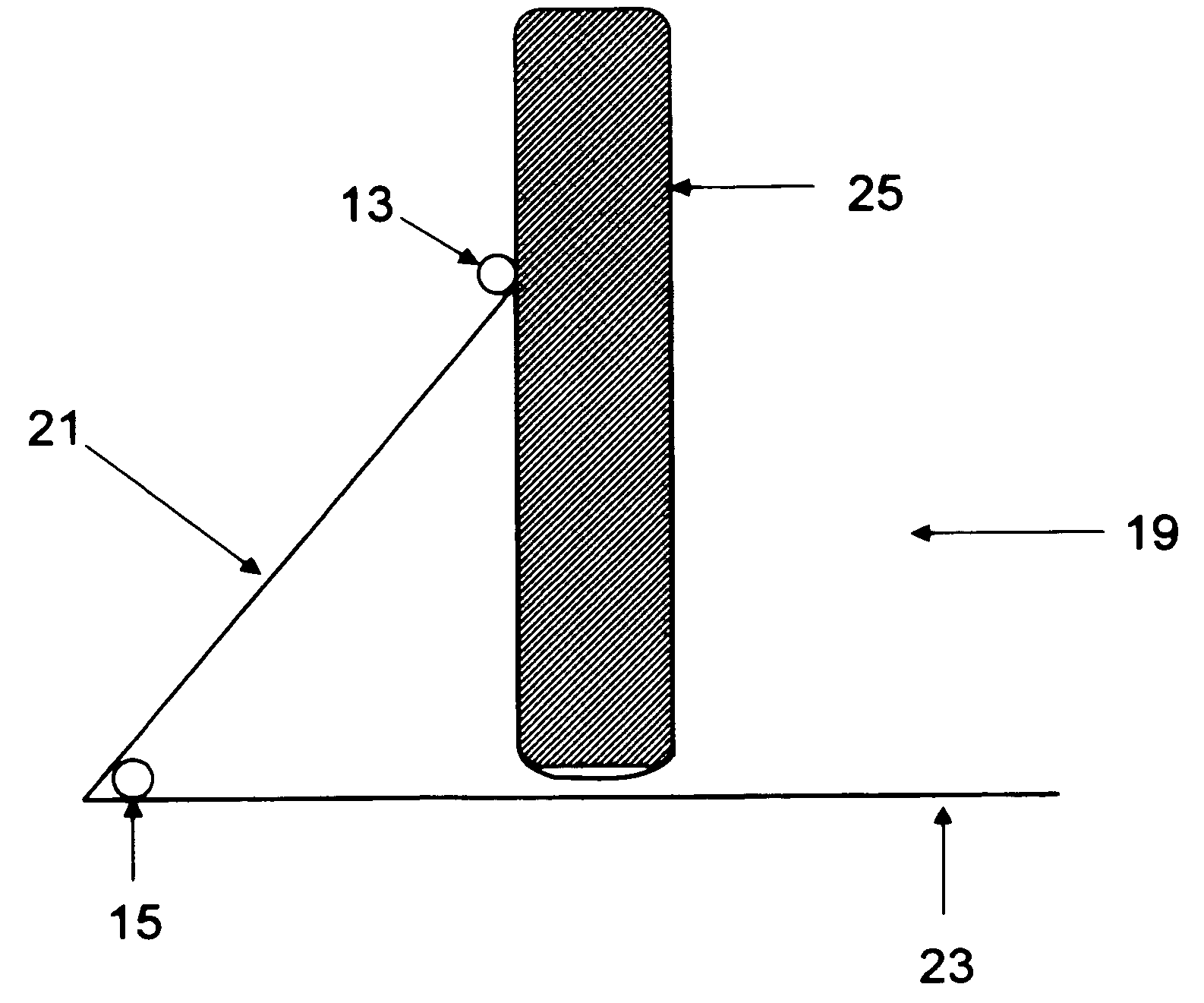

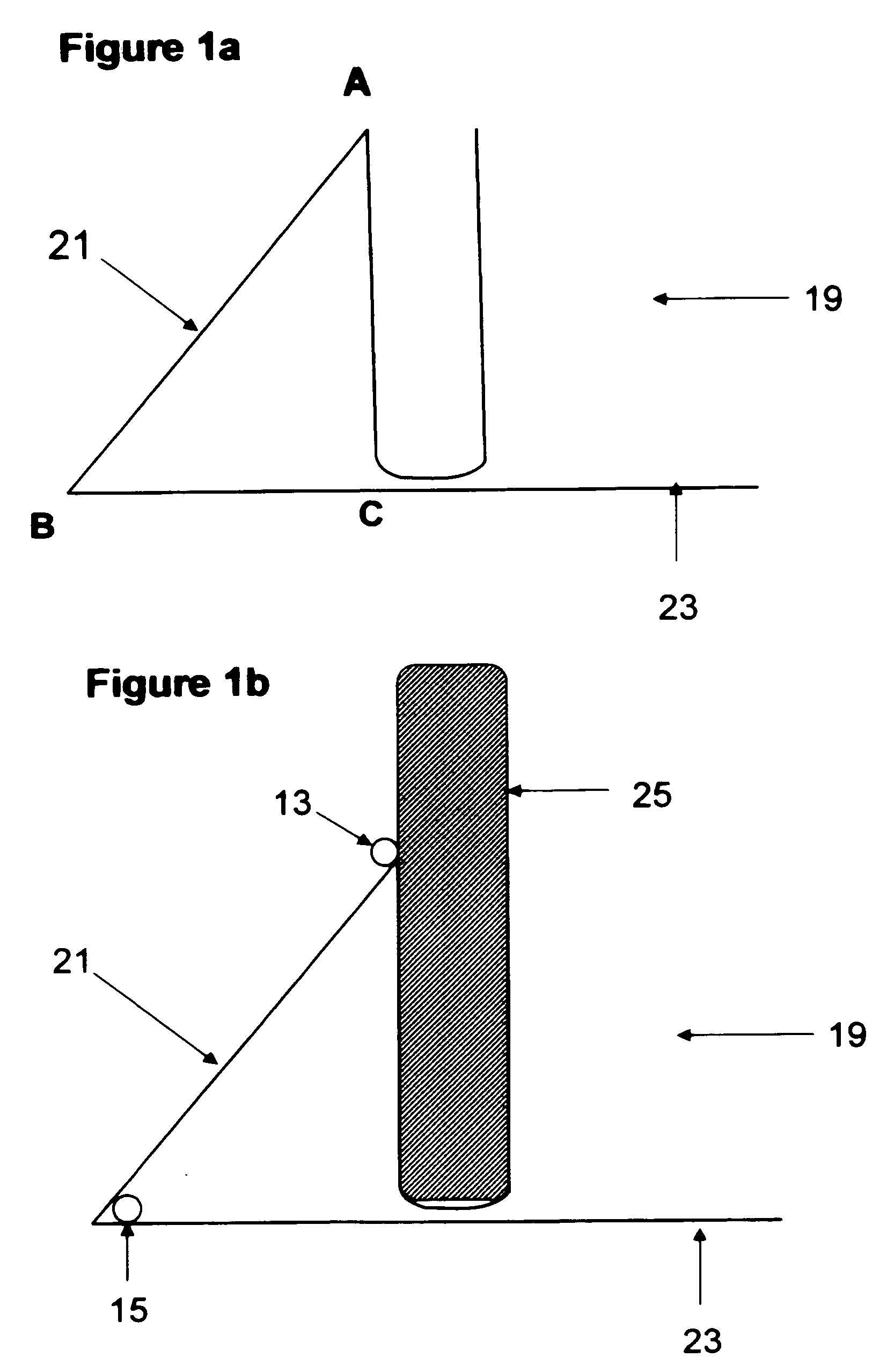

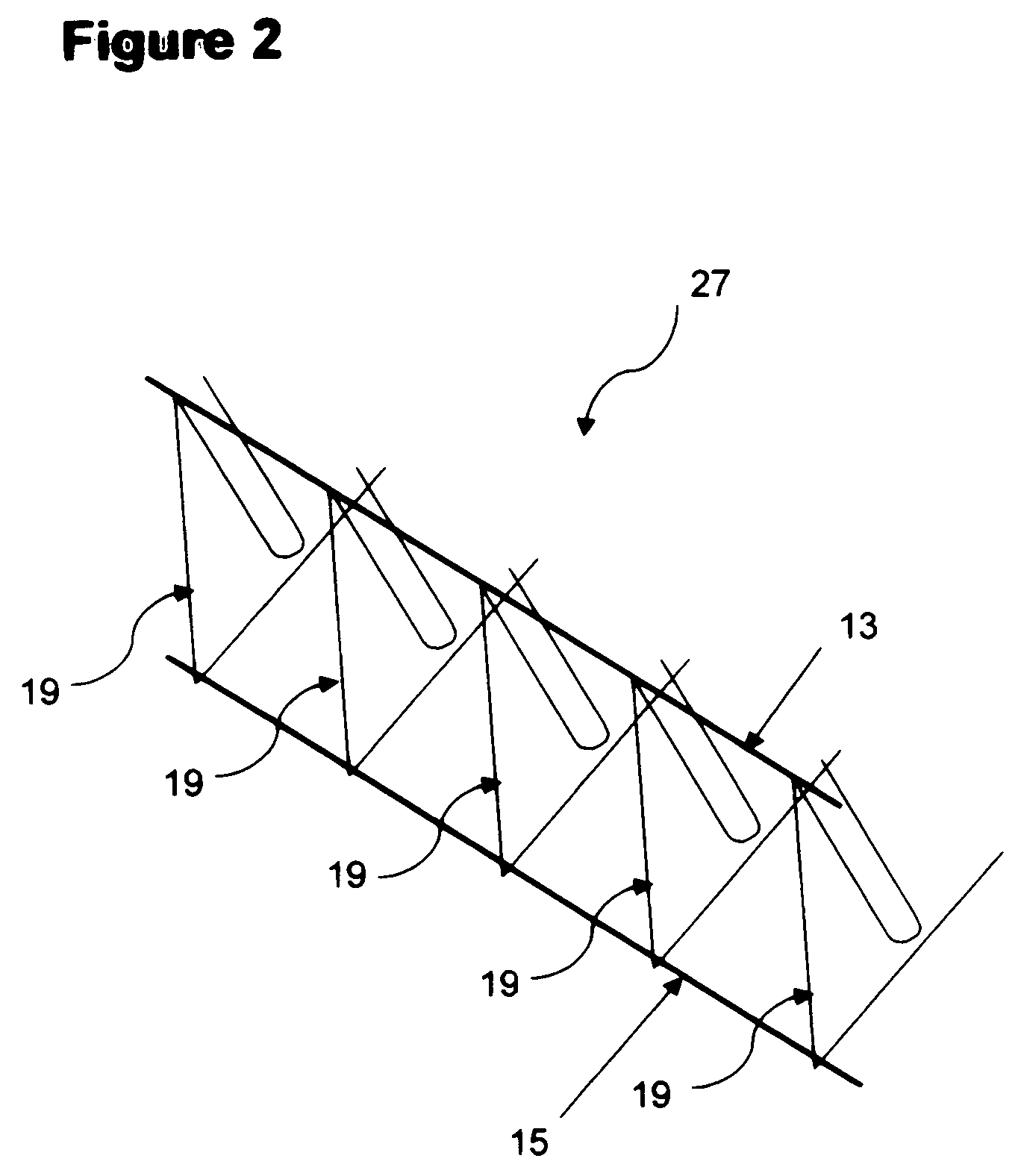

[0028]FIG. 1a shows a support component 19 which is integral to the instant invention.

[0029] Each shaped support component 19 comprises two legs (21 and 23) angled at an acute angle with respect to each other and continuous with each other. The two legs are continuous with and in the same plane as a substantially U-shape that serves as a slot for insertion of an expansion joint. One side of the U-shape forms one side of substantially a right triangle having vertexes A, B and C wherein leg 21 connects vertices A and B and part of leg 23 connects vertices B and C. This right triangle is in the same plane as the U-shape. The bottom of the U-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com