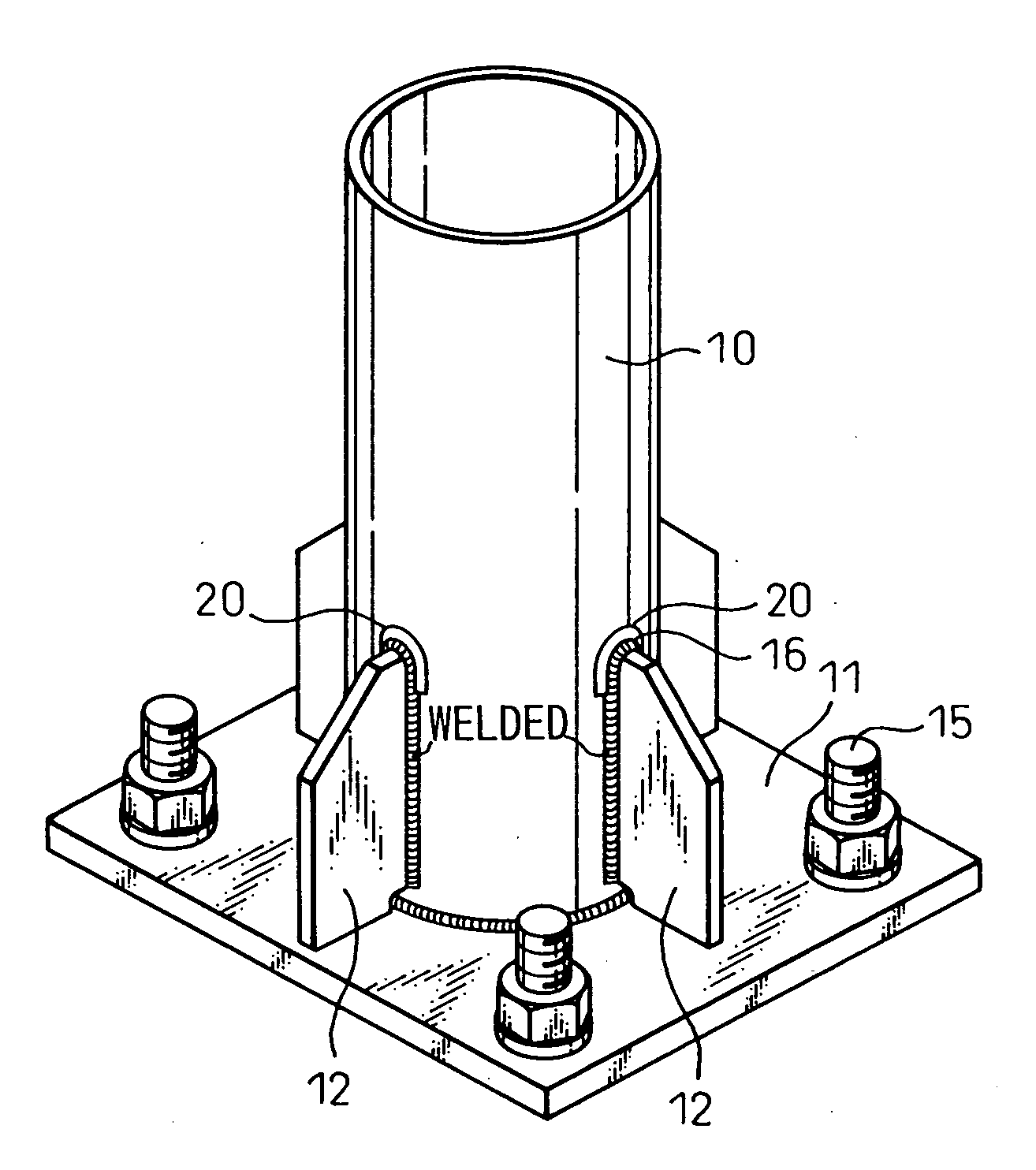

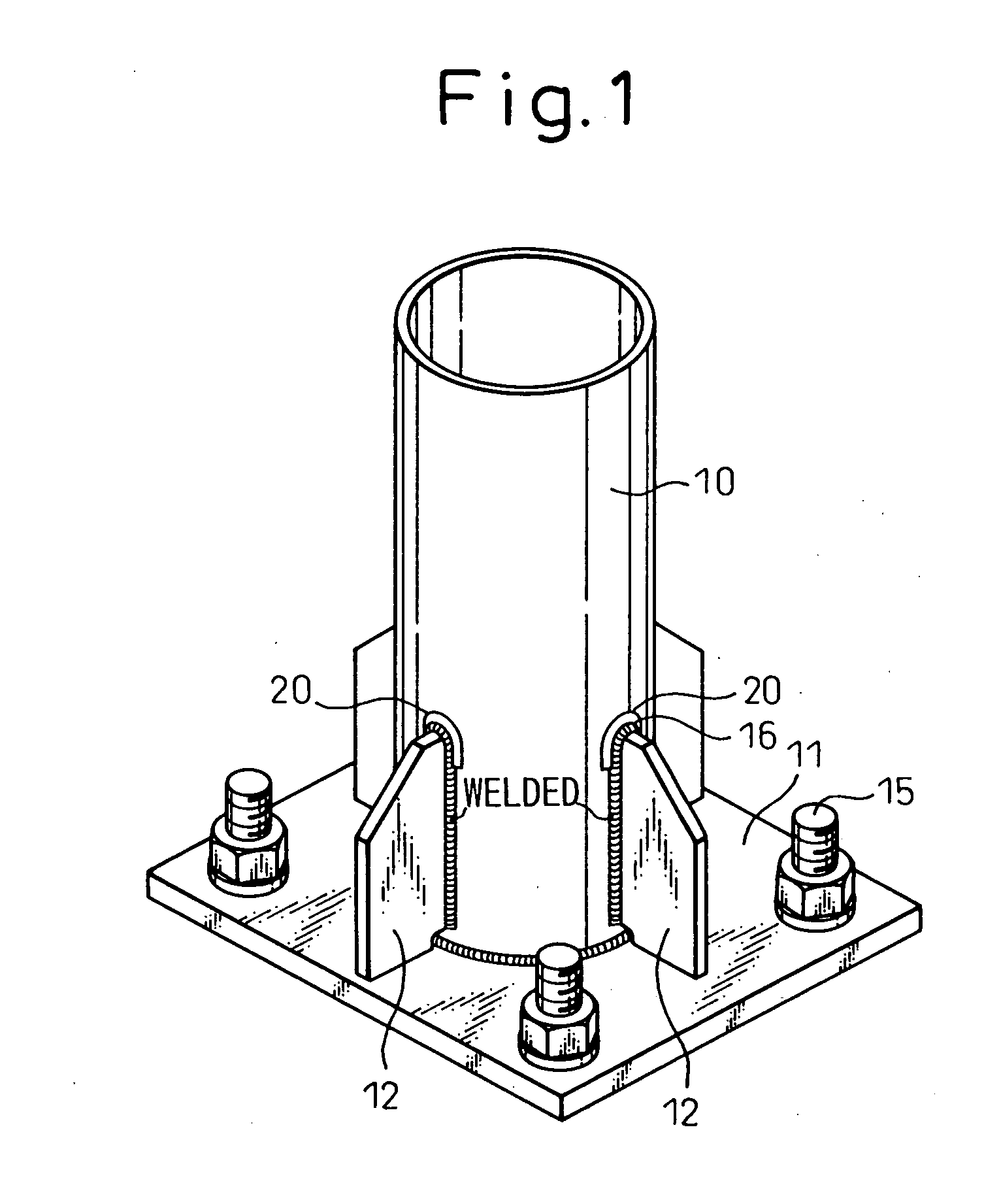

Steel pipe pole base and reinforcing method thereof

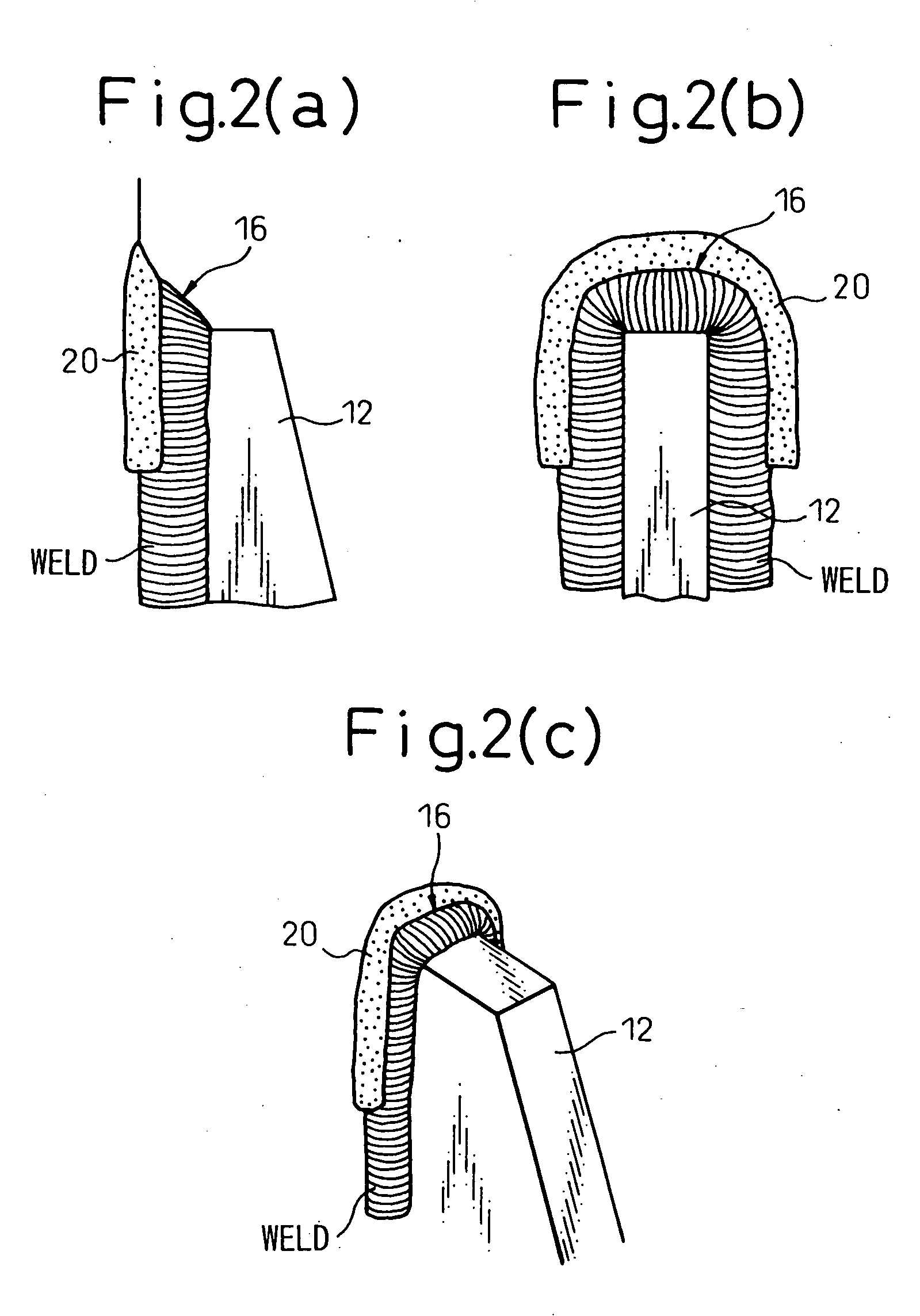

a technology of steel pipe and pole base, which is applied in the direction of buildings, buildings, buildings, etc., can solve the problems of deterioration of strength at the portions, proof of stress and fatigue properties, and likely structural defects in boxing welded portions at the upper end portions of the ribs, etc., to achieve relaxation of stress concentration, imposing residual compressive stress, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Fatigue strength tests were carried out by imposing repeated tensile stress on partial specimens around steel pipe ribs having the construction shown in FIG. 1. The material used for both the steel pipes and the ribs was SM 490. The fatigue property of the conventional construction having as-welded ribs as shown in FIG. 10 corresponded to the E to D grades of the design life curves in the “Railway Bridge Design Guideline” as shown by the black round marks in FIG. 7. On the contrary, the fatigue property of the invention construction wherein peening treatment was applied to weld toes by ultrasonic vibration markedly improved up to the grade B or higher of the design life curves as shown by the white round marks in the figure. Here, the amplitude of the tool tip was 40 μm and the frequency thereof was 30 kHz.

[0046] Further, when peening treatment was applied by ultrasonic vibration while a load for applying tensile stress was imposed on a steel pipe pole base, the fatigue prop...

example 2

[0047] Fatigue strength tests were carried out by using a test device and imposing repeated tensile stress on the steel pipe pole bases according to the present invention as shown in FIGS. 3 and 4. The material used for both the steel pipes and the ribs was SM 490. In comparison, fatigue strength tests were carried out by imposing repeated tensile stress on partial specimens around steel pipe base ribs having the construction shown in FIG. 10. As a result, the fatigue property of the conventional construction shown in FIG. 10 corresponded to the E to D grades of the design life curves in the “Railway Bridge Design Guideline” as shown by the black round marks in FIG. 8. On the contrary, the fatigue property of the invention construction markedly improved up to the grade A of the design life curves as shown by the white round marks in the figure. Here, the amplitude of the tool tip was 40 μm and the frequency thereof was 30 kHz.

[0048] Further, when peening treatment was applied by ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com