Liquid circulation type cooling system

a cooling system and liquid circulation technology, applied in the direction of lighting and heating apparatus, semiconductor/solid-state device details, domestic cooling apparatus, etc., can solve the problems of increasing the size of the cooling device, increasing the heat-generating amount of the cpu, and achieving the limit of heat radiation performance in the cooling devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

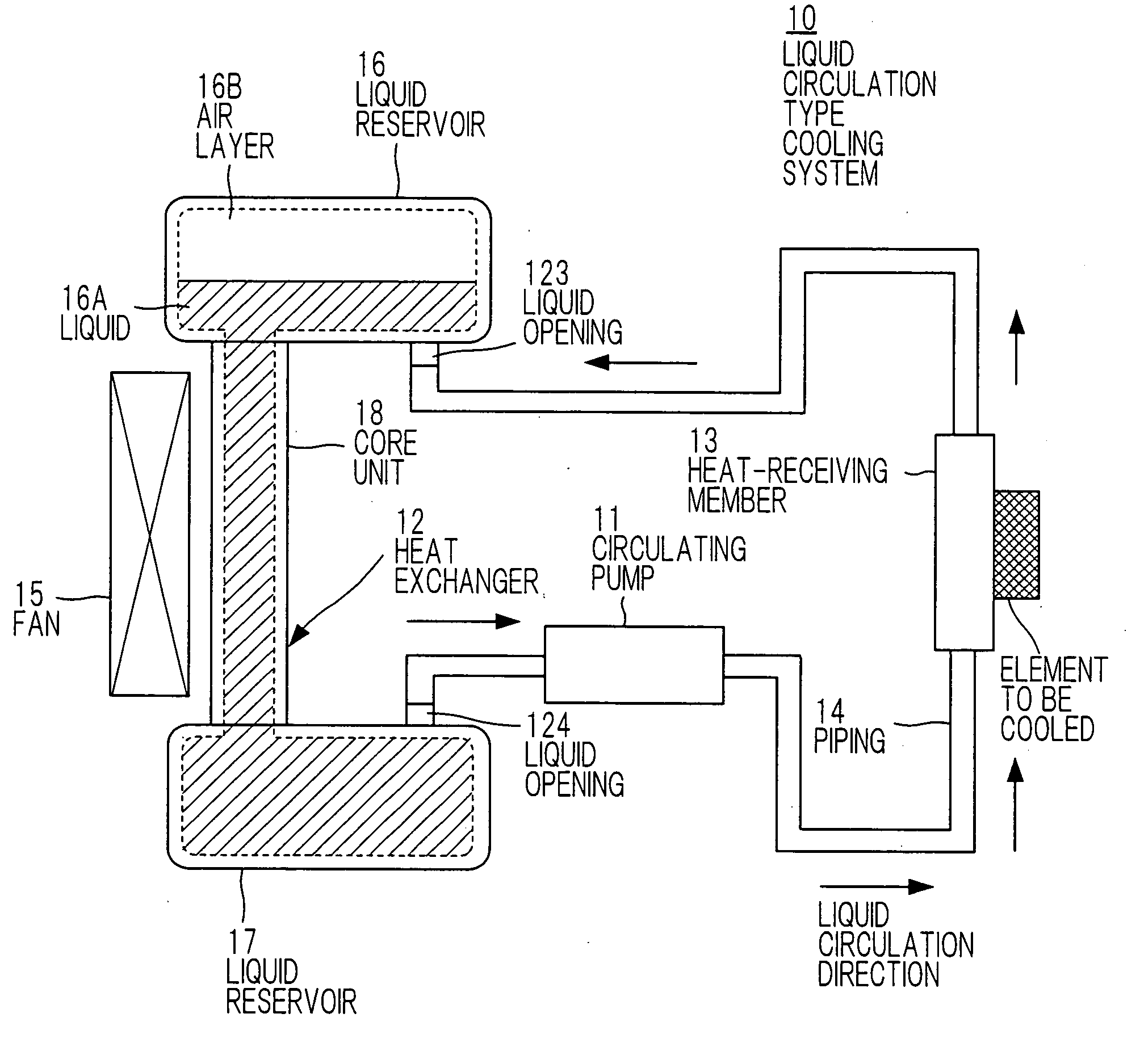

[0040]FIG. 3 is a schematic diagram showing a circuit of a liquid circulation type cooling system according to a first embodiment of the present invention wherein the liquid circulation type cooling system 10 includes a circulating pump 11 for circulating a liquid such as water, a heat exchanger 12 for radiating heat outside a casing for the system, the heat exchanger being disposed in a heat radiation space, a heat-receiving member 13 attached to an element to be cooled such as a heat-generating element, the heat-receiving member being served for transferring efficiently heat from the element to be cooled to the liquid, a piping 14 for connecting the above-mentioned components with each other, the piping being composed of a flexible tube or a fixed piping, and a fan 15 for supplying air to the heat exchanger 12 to achieve forced-air cooling.

[0041] The heat exchanger 12 has a core unit 18, a liquid reservoir 16 formed at the top of the core unit 18 in the vertical direction in the ...

second embodiment

[0058]FIG. 6 is a schematic diagram showing a circuit of a liquid circulation type cooling system according to a second embodiment of the present invention wherein the liquid circulation type cooling system 20 includes a circulating pump 21, for circulating a liquid, a heat exchanger 22 for radiating heat outside a casing for the system, the heat exchanger being disposed in a heat radiation space, a heat-receiving member 23 attached to an element to be cooled such as a heat-generating element, the heat-receiving member being served for transferring efficiently heat from the element to be cooled to the liquid, a piping 24 for connecting the above-mentioned components with each other, the piping being composed of a flexible tube or a fixed piping, and a fan 25 for supplying wind to the heat exchanger 22 to achieve forced-air cooling.

[0059] The heat exchanger 22 has a core unit 18, a liquid reservoir 26 formed on the left side with respect to the core unit 18 in the drawing, and anoth...

third embodiment

[0071]FIG. 9A is a side view showing a structure of a heat exchanger 32 used in a liquid circulation type cooling system according to a third embodiment of the present invention, and FIG. 9B is a plan view showing the heat exchanger 32 wherein the heat exchanger 32 is the one having a “corrugated straight fin core” type structure, which is composed of a core unit 18, a liquid reservoir 36 positioned on the left side to the core unit 18 in the drawing, and another liquid reservoir 37 positioned on the right side to the core unit 18.

[0072] The heat exchanger 32 has the same structure as that of the heat exchanger 22 except that the liquid reservoir 36 has a liquid opening 323 into and from which a liquid may be introduced and discharged on a side of the liquid reservoir 36 perpendicular to the side to which the core unit 18 is connected, while a liquid opening 324 which is the same as the liquid opening 323 is provided on a side of the liquid reservoir 37 perpendicular to the side to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com