Aviatorial valve assembly

a valve assembly and valve body technology, applied in the field of aircraft valve assembly, can solve the problems of limited stress on instrument air sources, and achieve the effects of preventing spikes, back pressure, and stressing on instrument air sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

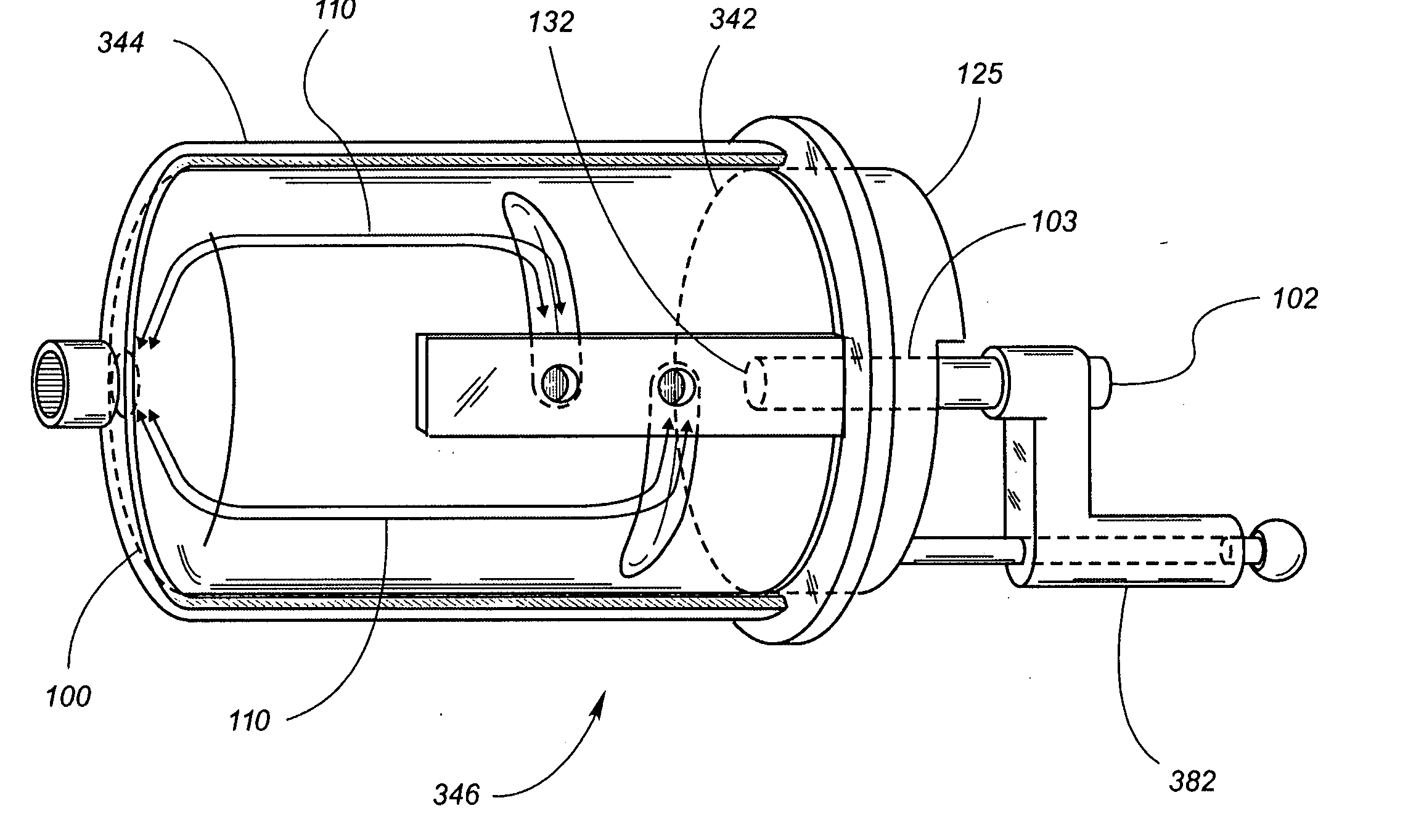

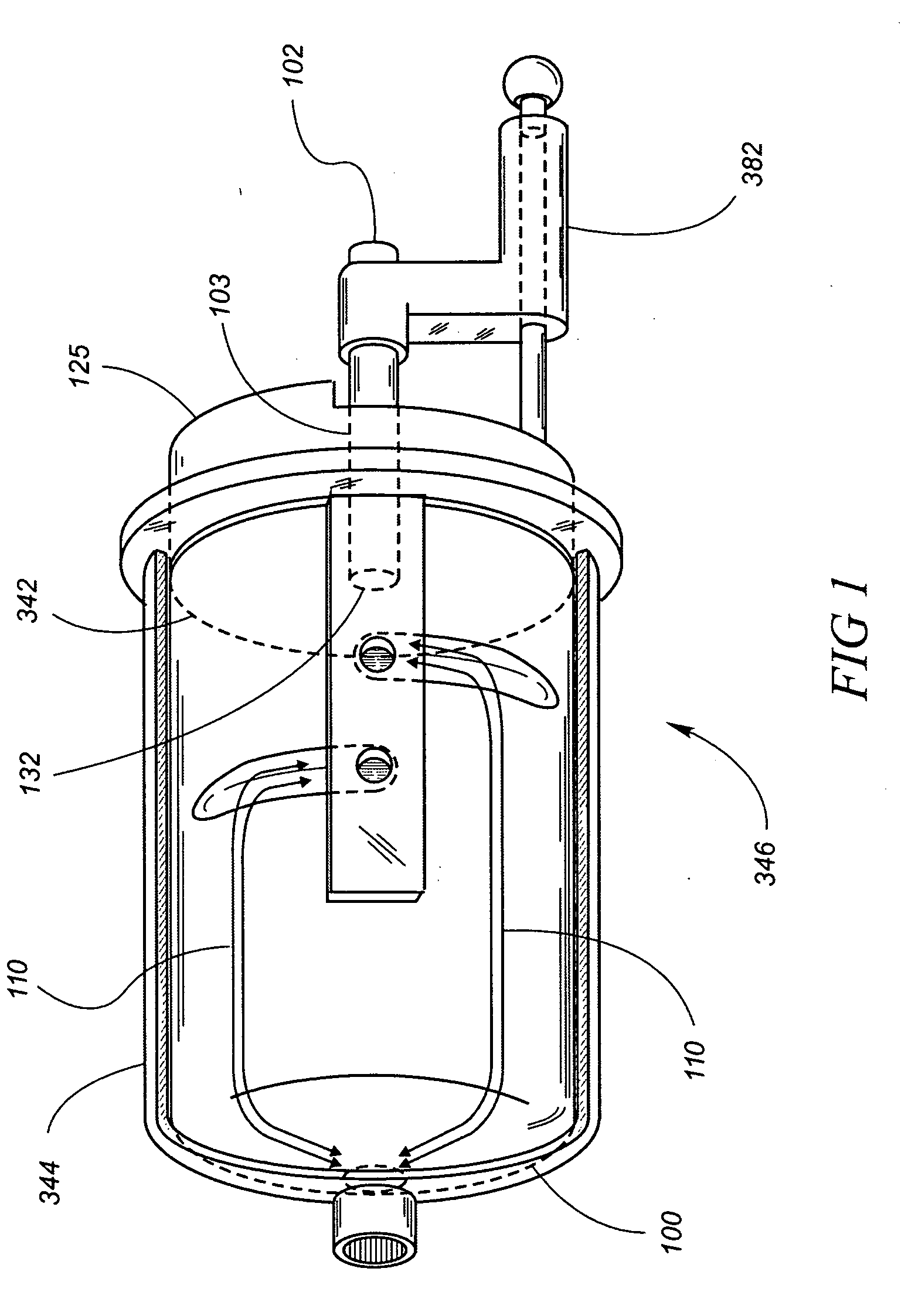

[0045] A first aspect of invention, as seen in FIG. 1, is a valve (346) for use in aircraft. One embodiment of the valve (346) includes a body (344) and a seat (342) comprising a selective interrupter (100) and an arm (102), wherein the arm (102) is connected to a first end (132) of the selective interrupter (100). The selective interrupter (100) is positioned inside the body (344) for rotation therein. A flow arrangement (110) exists between the selective interrupter (100) and the body (344). A bonnet (125) connects to the body (344) and the bonnet (125) is also in contact with the first end (132) of the selective interrupter (100). An actuator (382) is movably connected to the arm (102), and the arm (102) extends through a bonnet hole (103) in the bonnet (125).

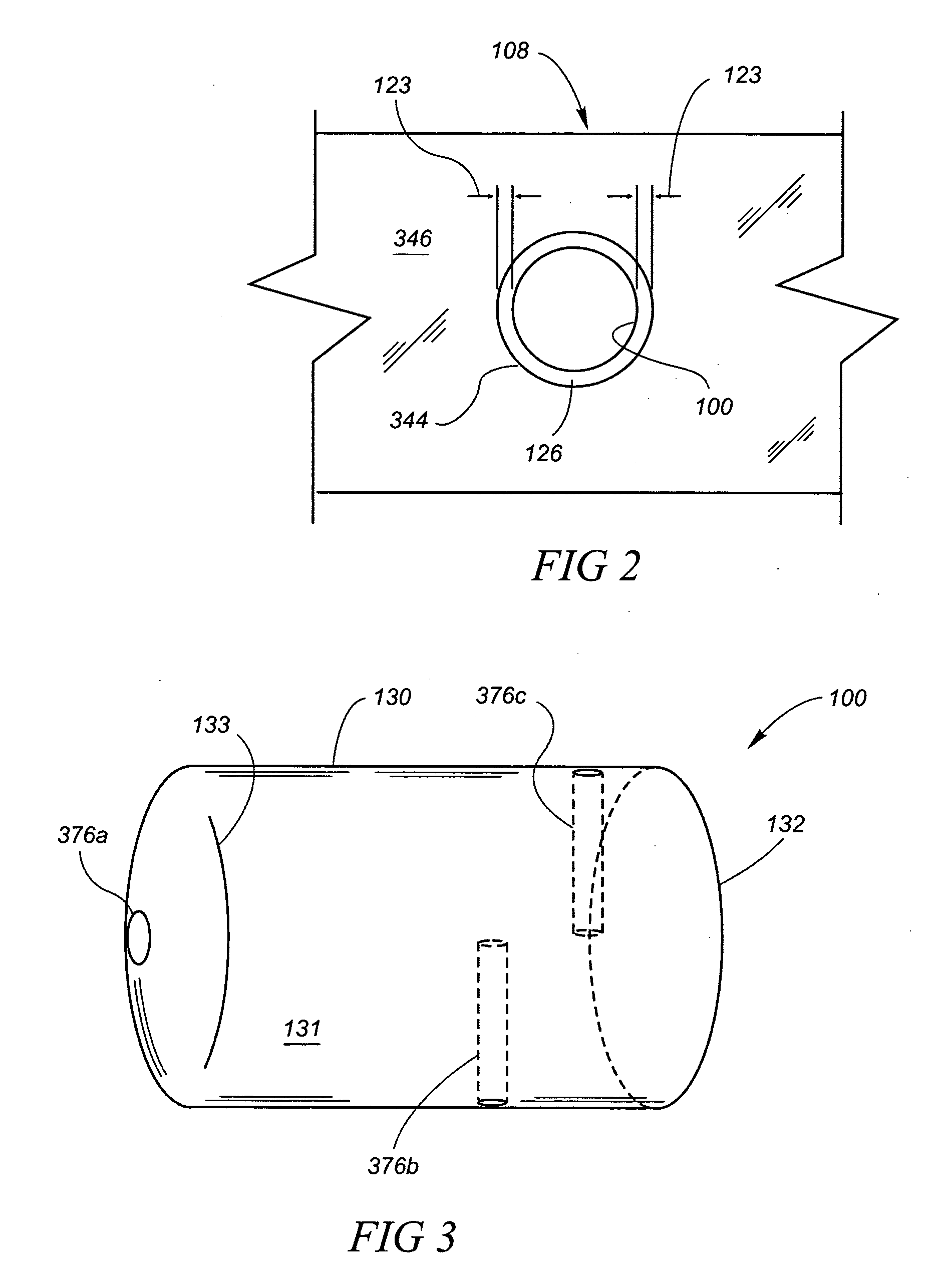

[0046] A further embodiment, as shown in FIG. 2, includes the valve (346) being installed into an aircraft instrument panel (108). A still further embodiment includes the valve (346) being installed into a standard hole wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com