Structure for expanding thermal conducting performance of heat sink

a technology of thermal conductivity and heat sink, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of restricting the heat dissipation effect of the fins, obstructing the heat conductance of the heat sink, etc., and achieves the effect of expanding the thermal conductivity performance of the heat sink and enhancing the applicability and value of the heat sink having improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

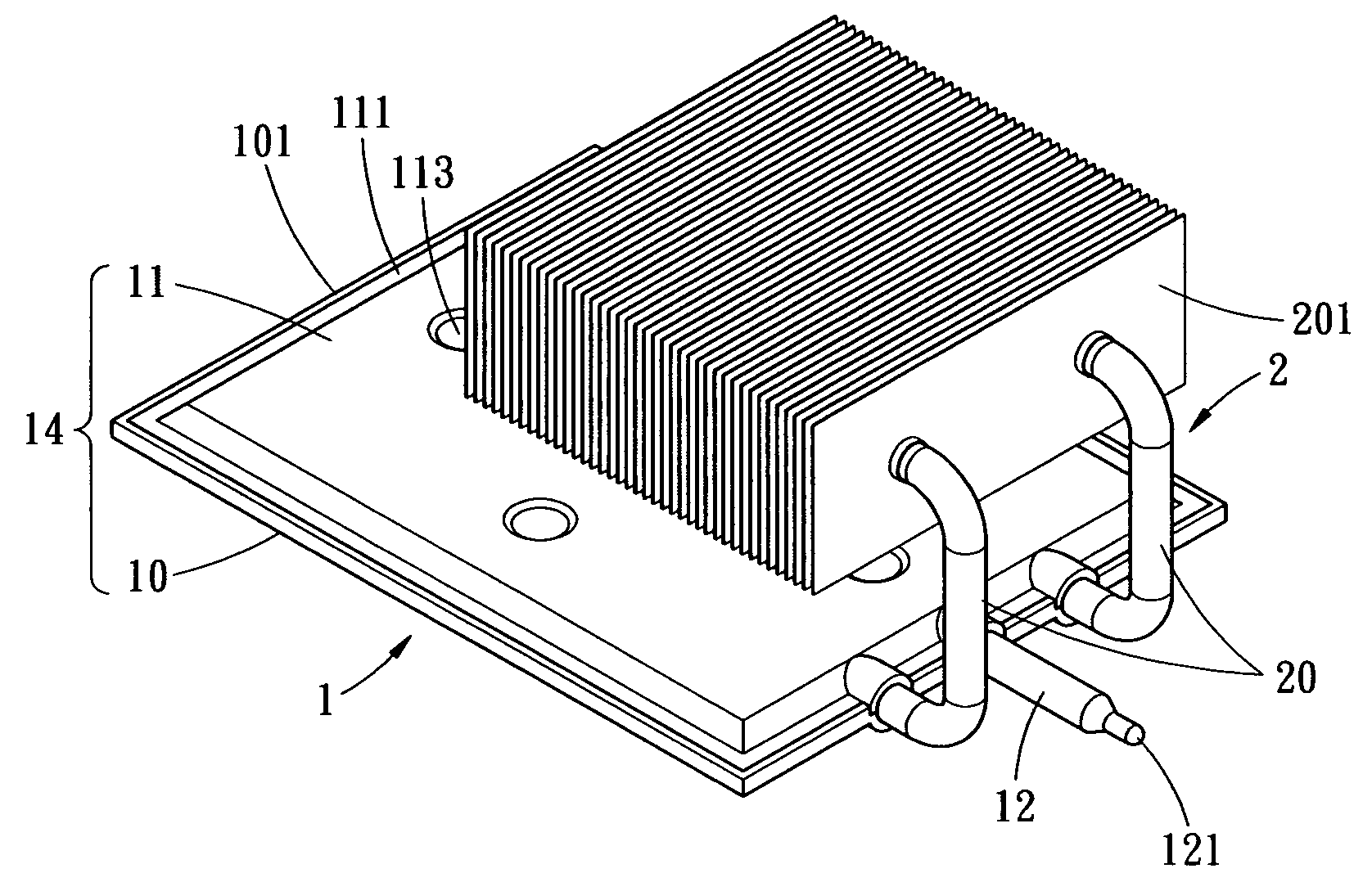

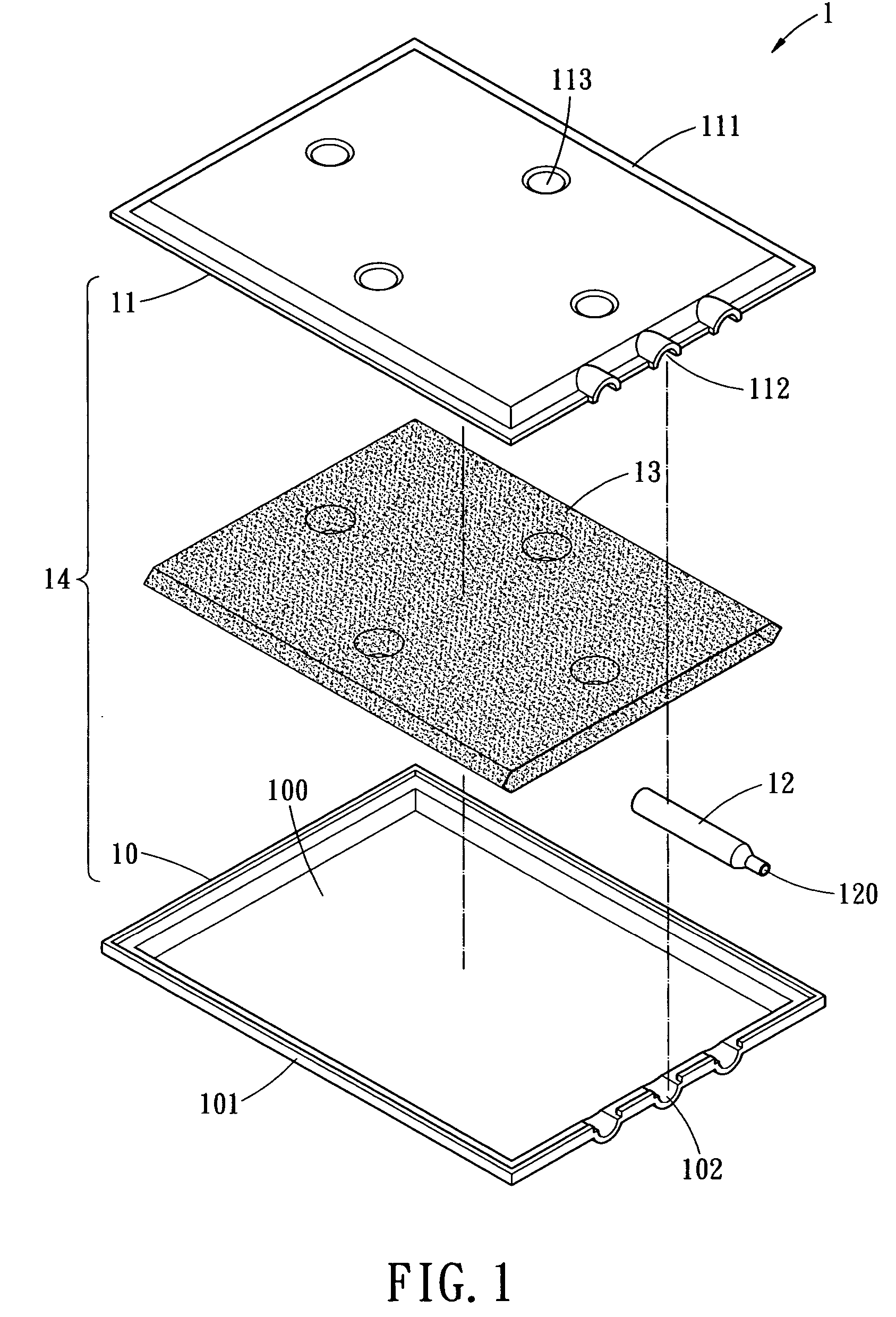

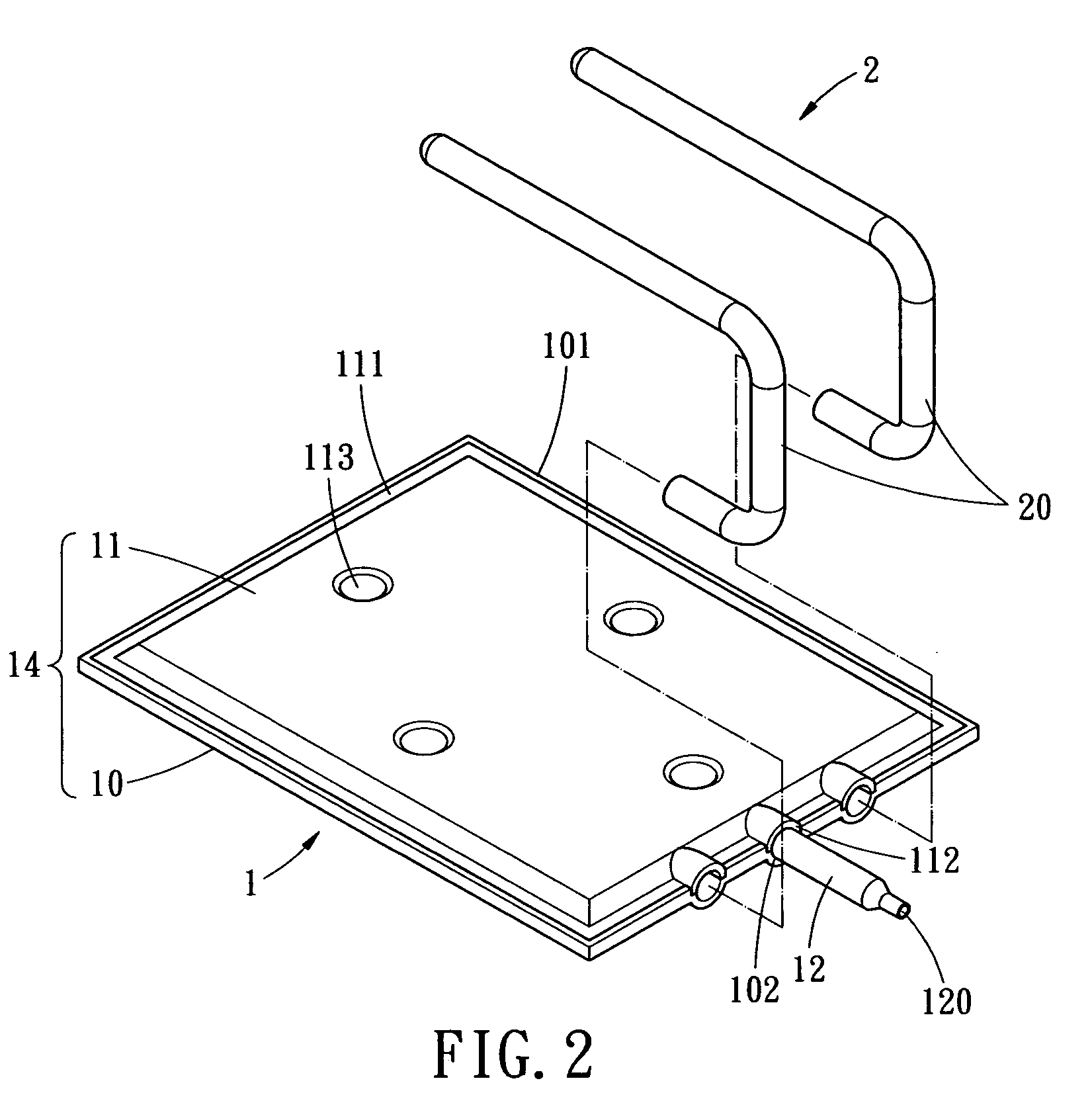

[0019] As shown in FIGS. 1 to 3, an exploded of a heat sink body, an exploded view and a perspective view of a structure for expanding thermal conducting performance of the heat sink are illustrated. The structure includes a thermal expansion conductor 2 embedded in the heat sink 1. The thermal expansion conductor 2 has good thermal conducting efficiency. The thermal expansion conductor 2 is hollow and is in fluid communication with an internal space of the heat sink 1. Therefore, the thermal expansion conductor 2 serves as an extension of the heat 1 for thermal conduction. By the thermal expansion conductor 2, heat is absorbed and dissipated away from the heat sink, or conducted and delivered to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com