Plasma display panel (PDP)

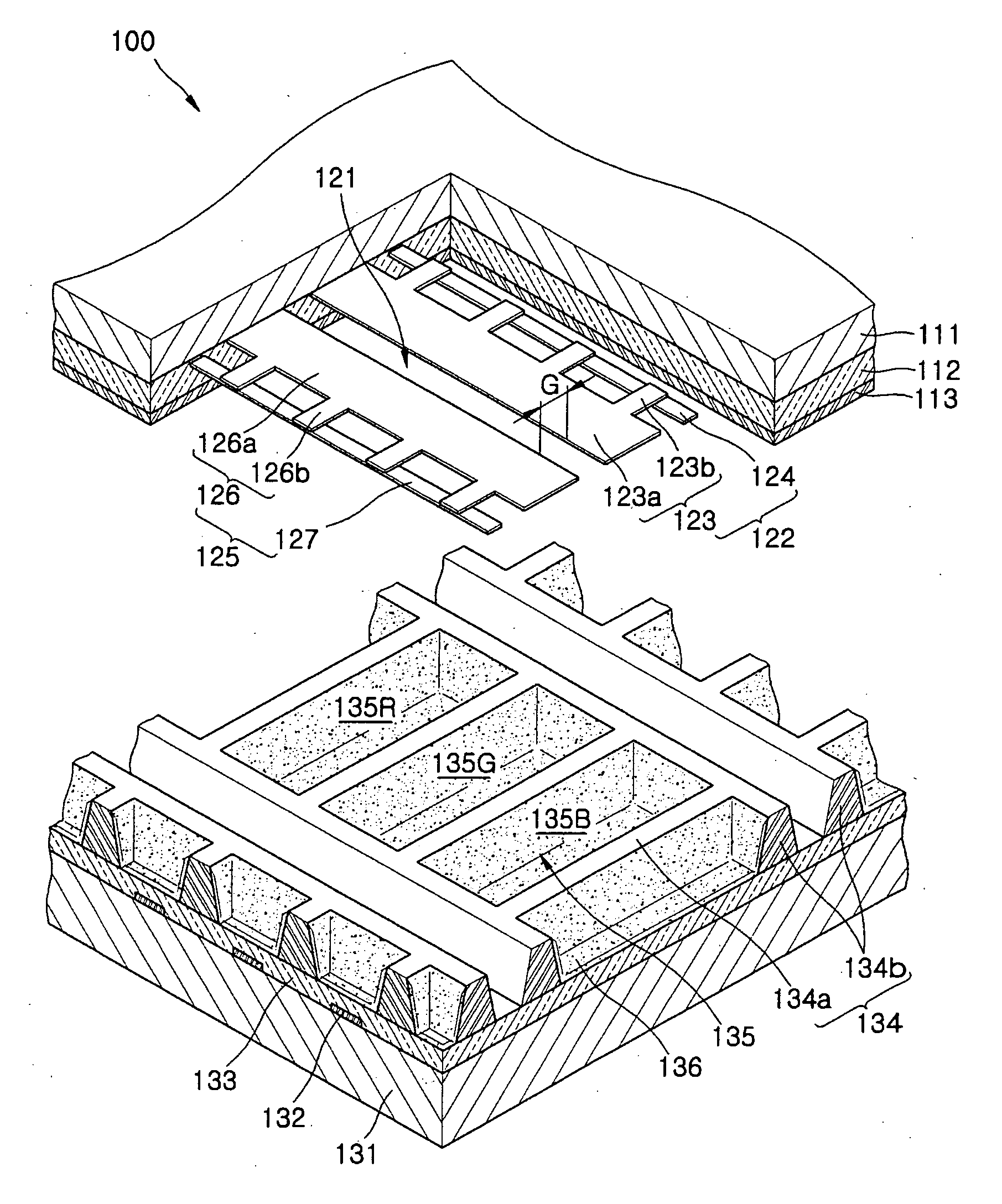

a technology of display panel and plasma, which is applied in the direction of gas discharge vessel/container, gas-filled discharge tube, electrodes, etc., can solve the problems of easy control of wall charges, unnecessary wall charges, and easy accumulation of wall charges, so as to improve the pdp discharge efficiency and the effect of maintaining electrode structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

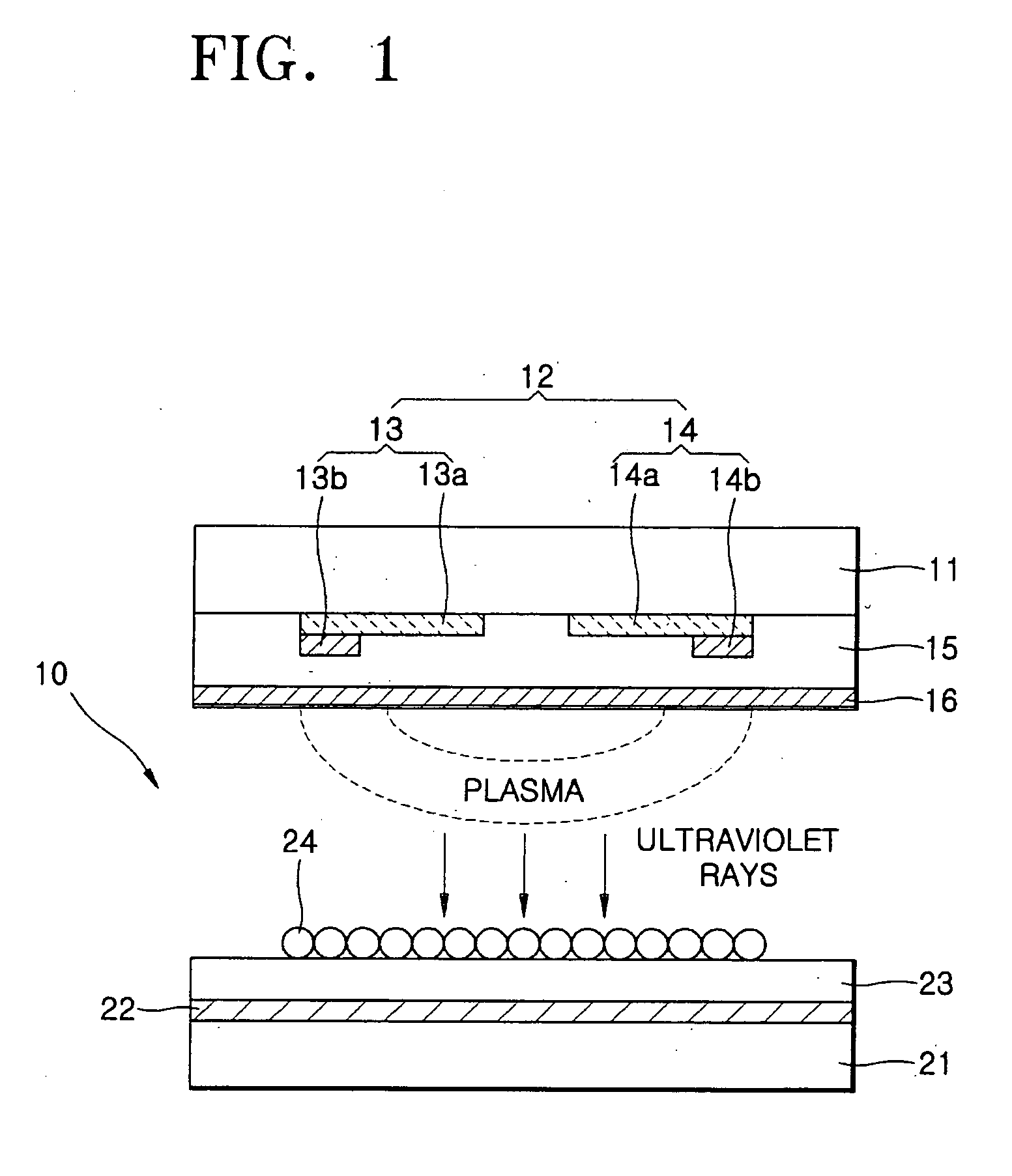

[0038]FIG. 1 is a cross-sectional view of a unit discharge cell.

[0039] Referring to FIG. 1, a sustain electrode 12 including an X electrode 13 and a Y electrode 14 is formed on a lower surface of a first substrate 11 arranged at an upper portion of a discharge cell 10. The X electrode 13 and the Y electrode 14 respectively function as a common electrode and a scan electrode, and are separated from each other by a discharge gap. The X electrode 13 and the Y electrode 14 respectively include transparent electrodes 13a and 14a and bus electrodes 13b and 14b formed on lower surfaces of the transparent electrodes 13a and 14a. The sustain electrode 12 is covered by a first dielectric layer 15, and a protective layer 16 is formed on a lower surface of the first dielectric layer 15.

[0040] In addition, a second substrate 21 is disposed to face the first substrate 11, and an address electrode 22 is formed on an upper surface of the second substrate 21. The address electrode 22 is covered by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com