Fan assembly and method

a technology of fan assembly and fan body, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of less desirable, inefficient fans that require a different rotor geometry, and consume more power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

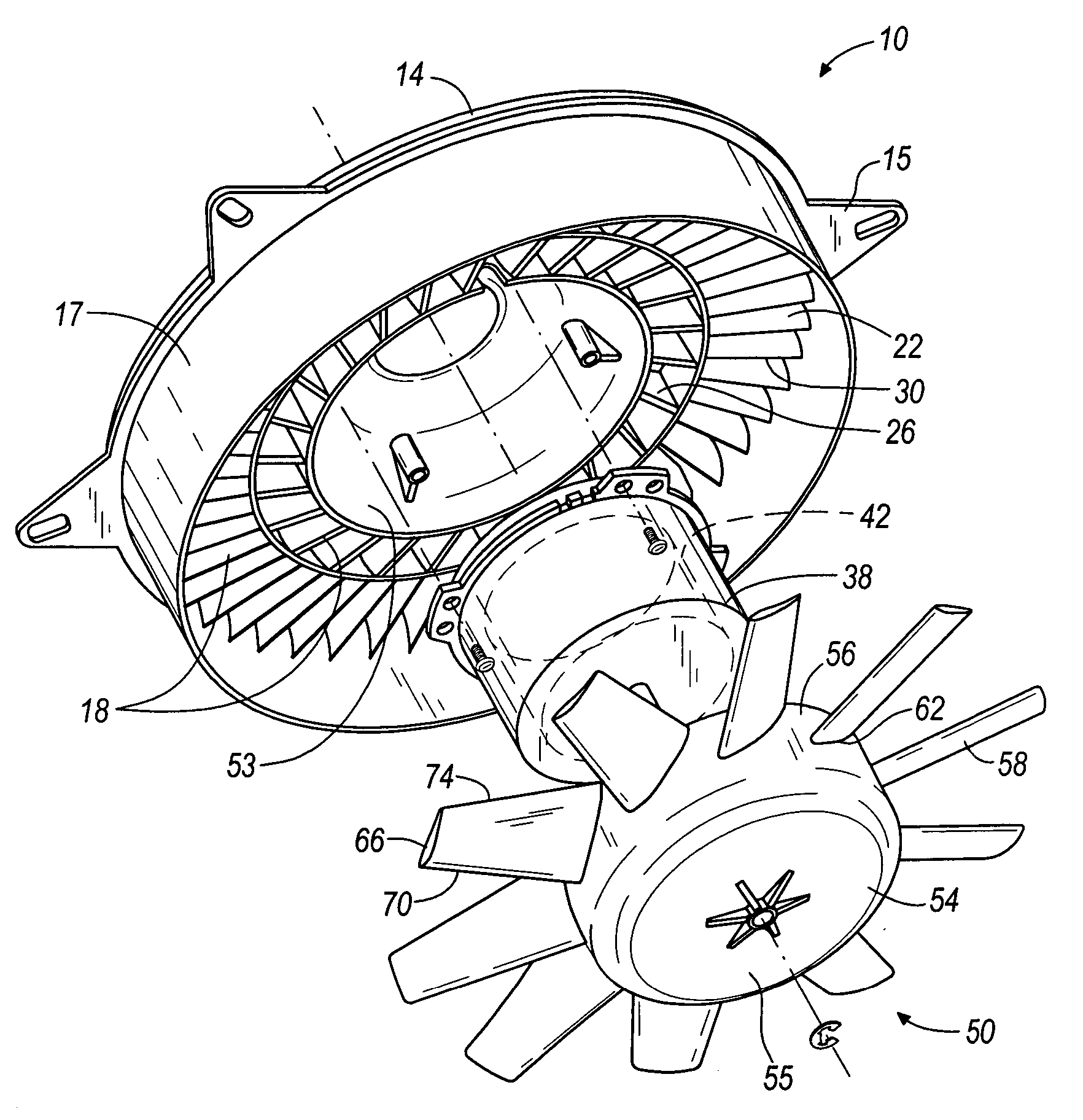

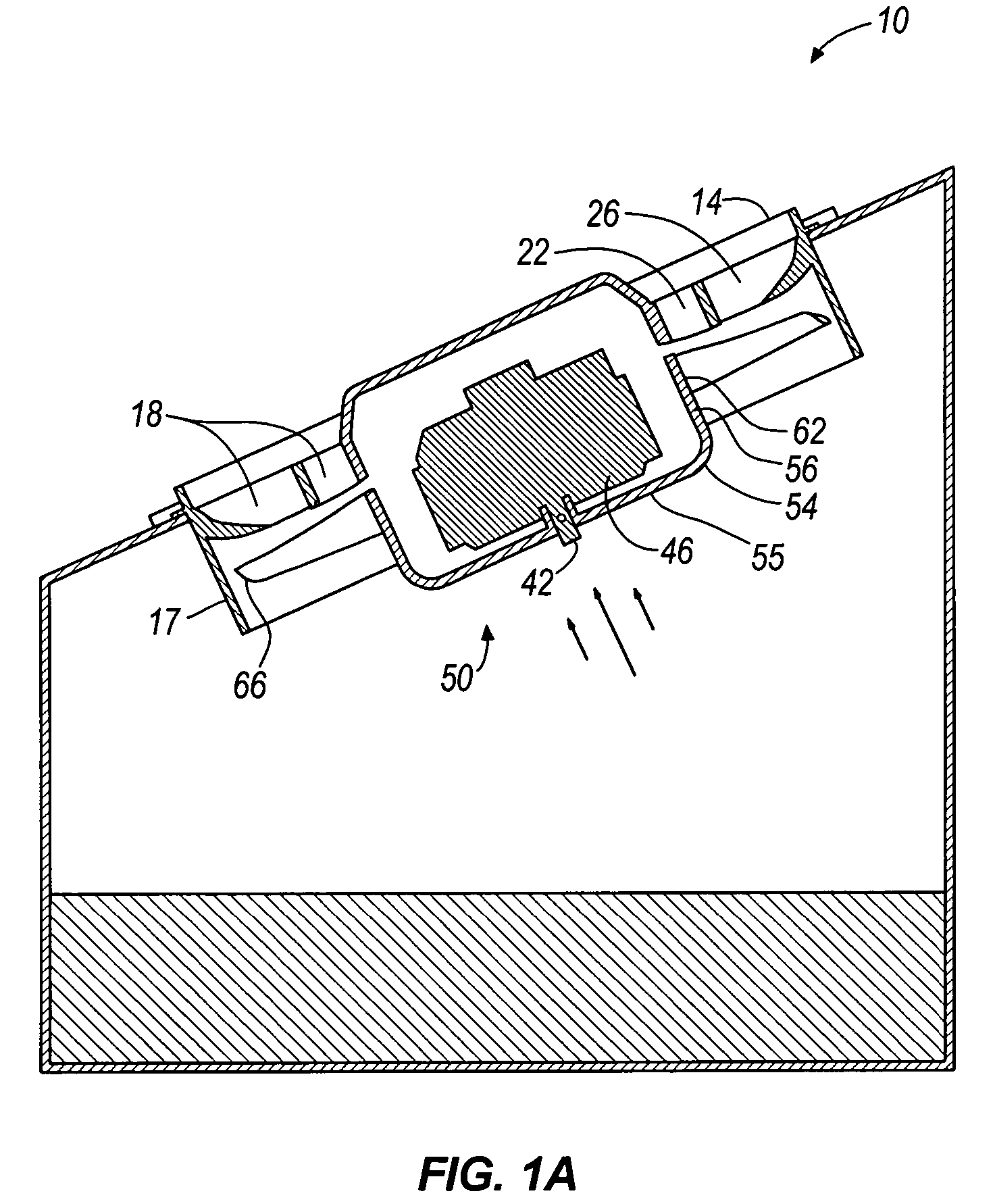

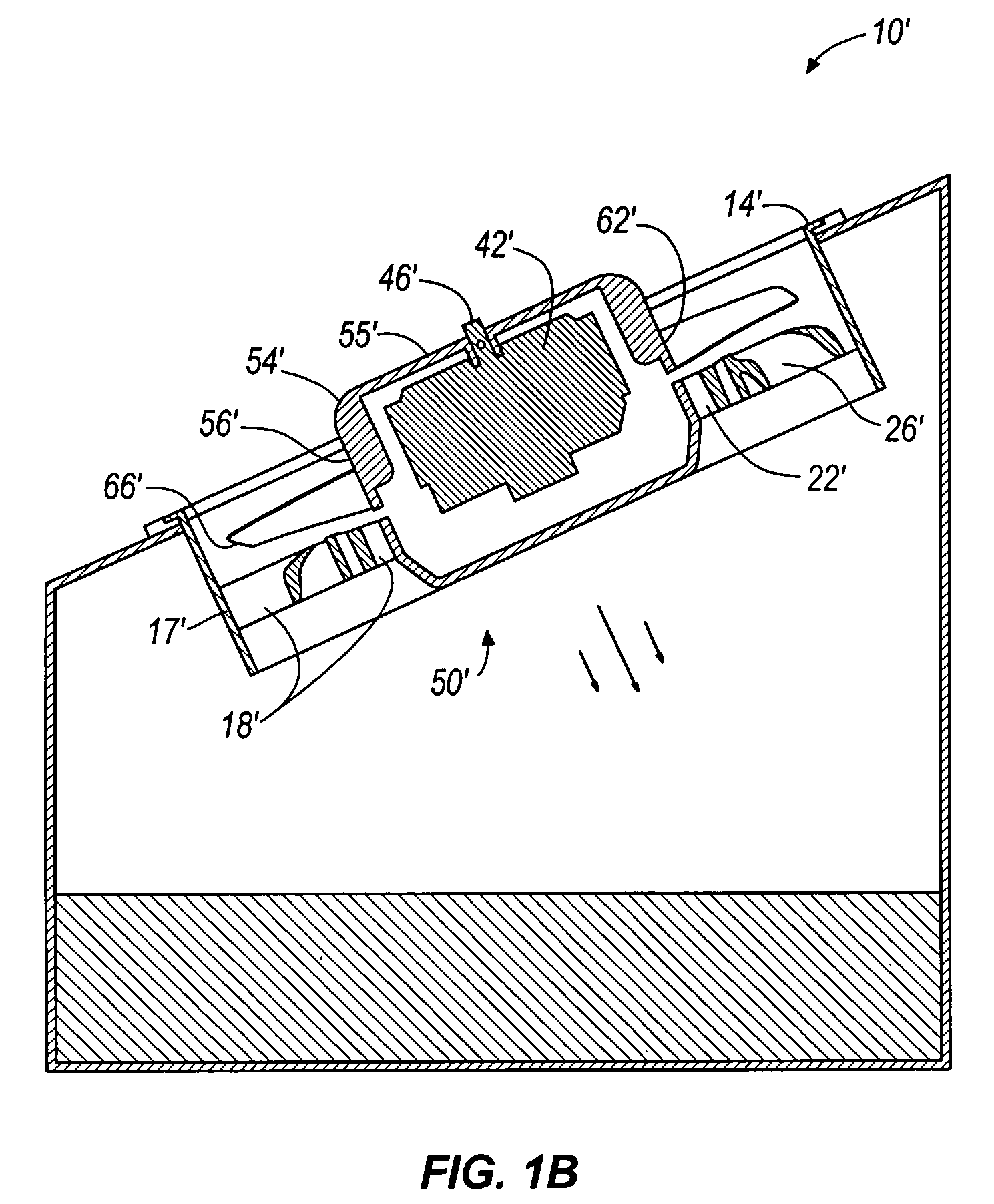

[0028] An exemplary embodiment of an axial flow fan assembly 10 according to the present invention is illustrated in FIGS. 1-10. The exemplary fan assembly 10 in FIGS. 1-10 has a shroud 14, a motor 42 coupled to the shroud 14, and a fan 50 coupled to the motor 42. In operation, the motor 42 rotates a drive shaft 46 coupled to the fan 50. As the drive shaft 46 rotates, it powers the fan 50 to rotate within the shroud 14, and generates air movement. FIGS. 1A and 1B illustrate the fan in an exemplary environment. As illustrated, the fan is mounted to generate a stream of air to remove heat from condensing coils. This is just one of the many possible uses of this fan. Although a heat exchange environment is described herein and illustrated in FIGS. 1A and 1B, the fan of the present invention can be employed in any air moving application. Other uses known by those having ordinary skill in the art fall within the spirit and scope of the present invention.

[0029] As illustrated in FIGS. 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com