Self tying shoe

a self-tying and shoe technology, applied in the field of shoes, can solve the problem of adding undue complexity to shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

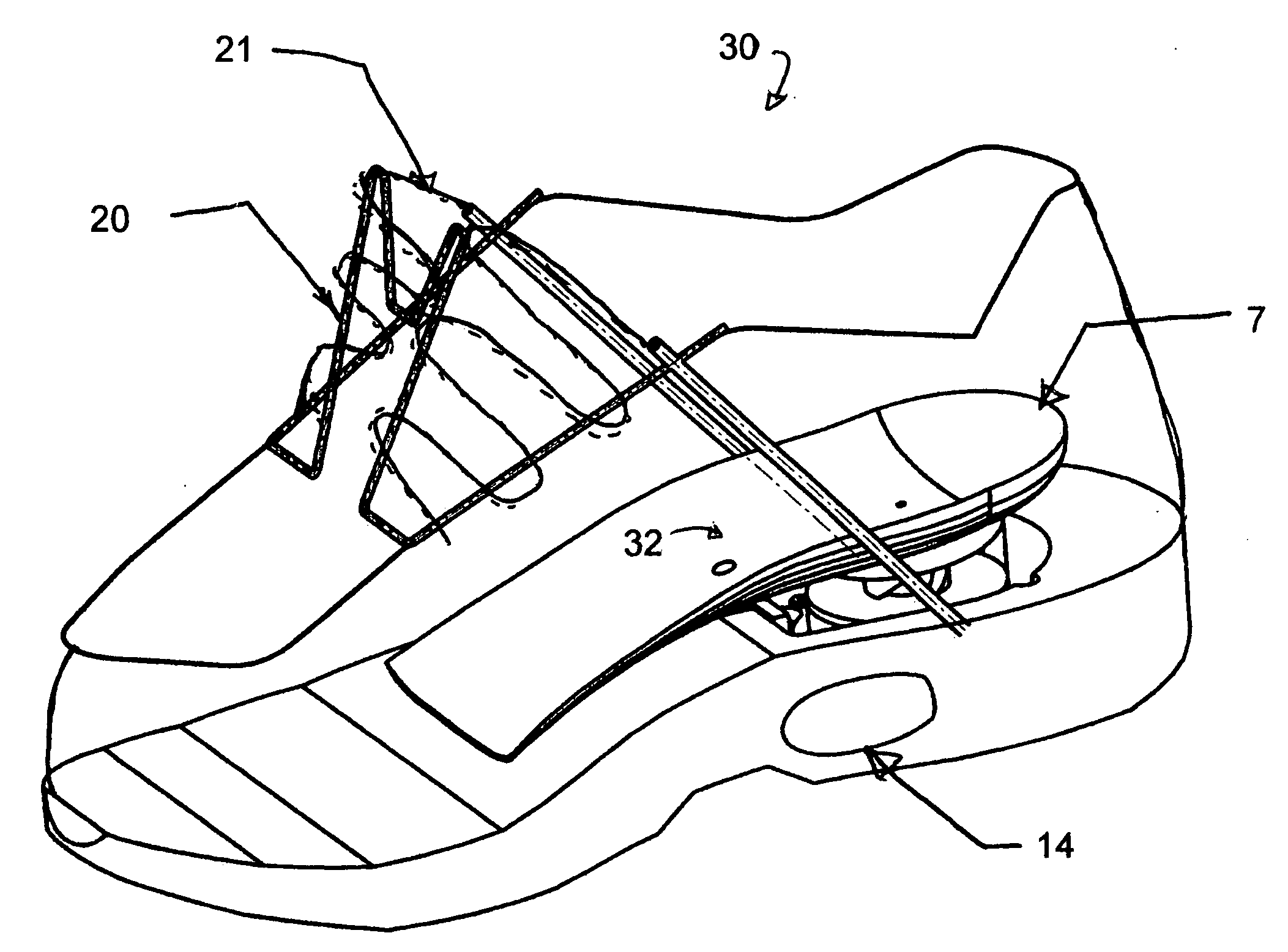

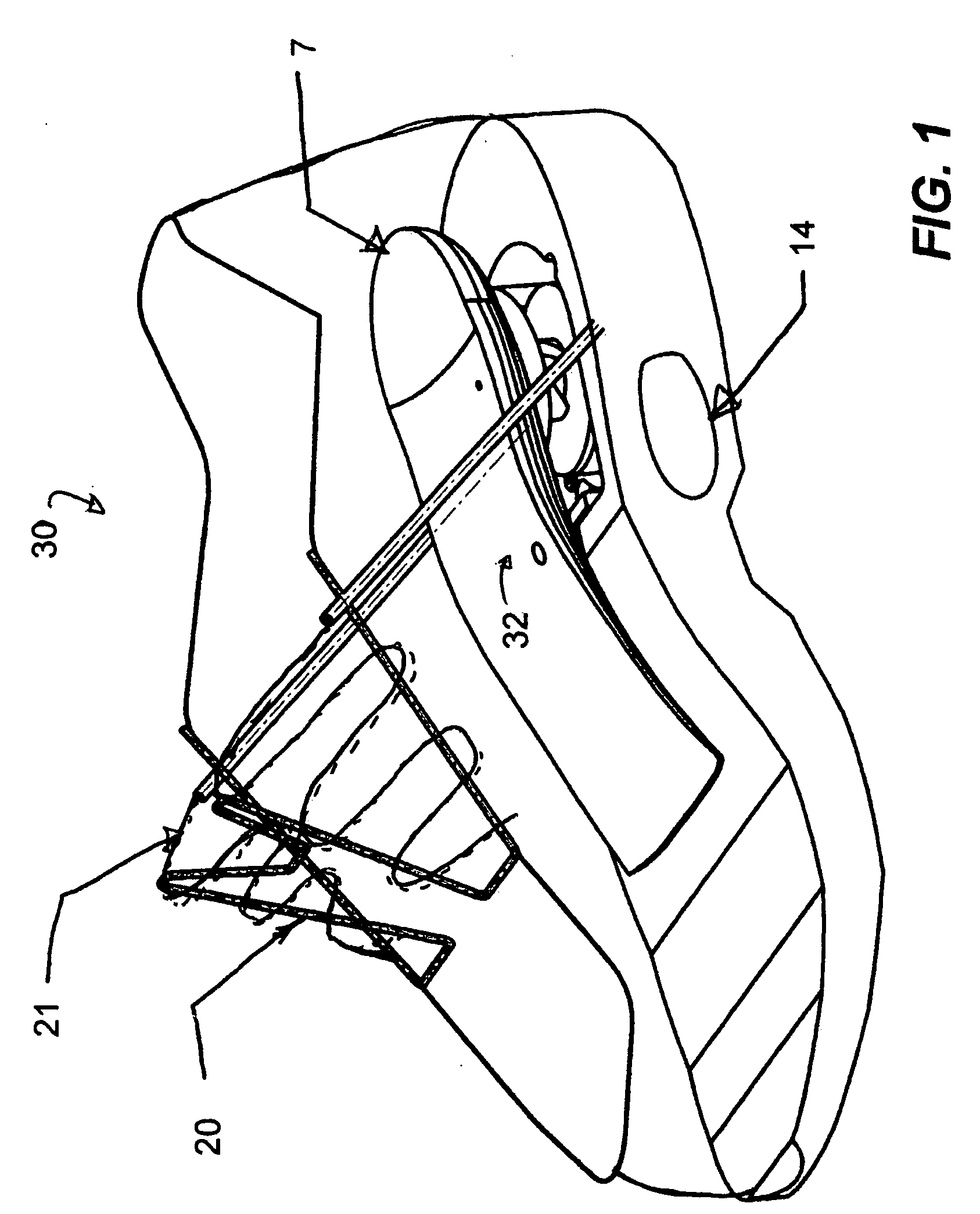

[0023]FIG. 1 See through isometric view of the shoe unlaced with the inner sole in an upward position.

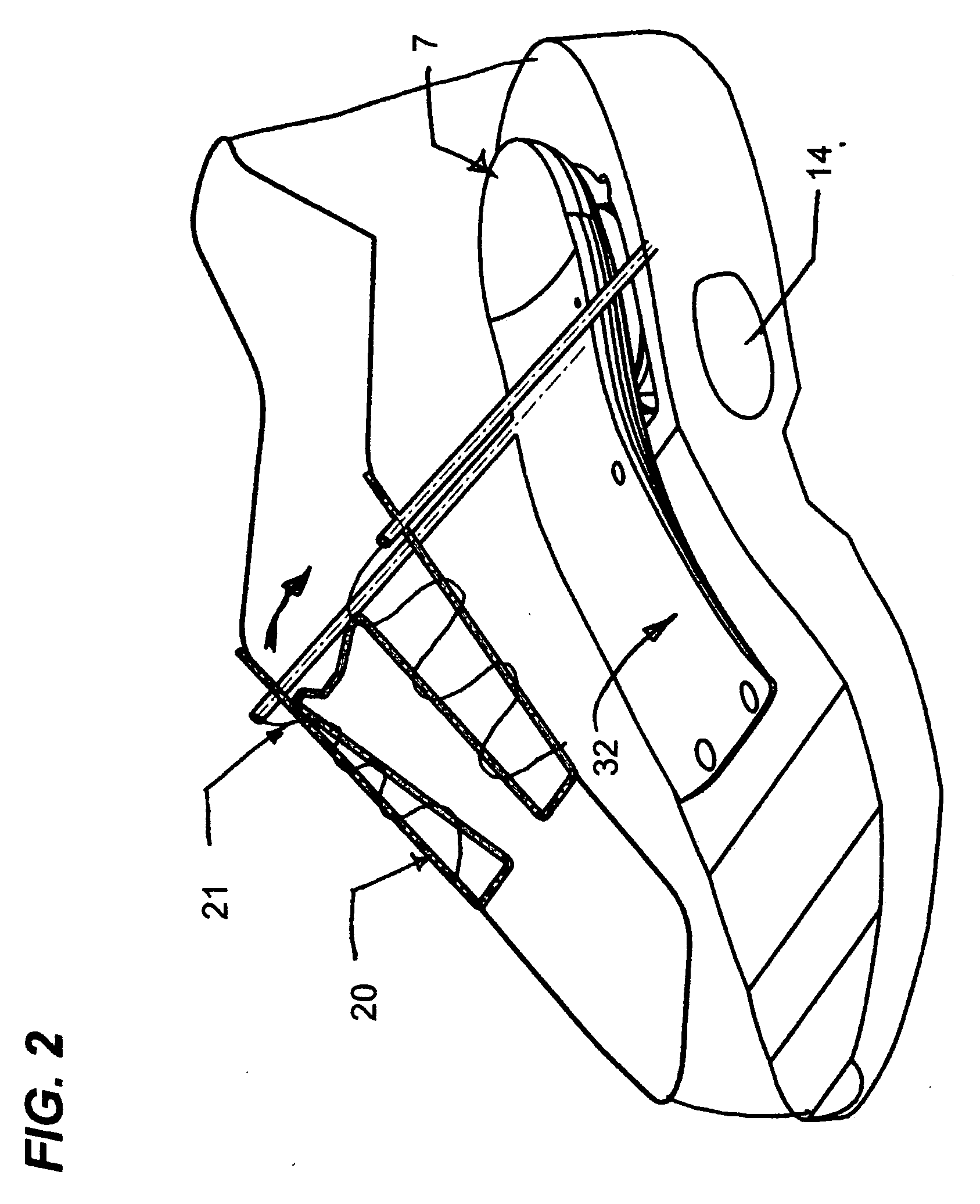

[0024]FIG. 2 See through isometric view of the shoe laced with the inner sole in a downward position.

[0025]FIG. 3 Isometric view of the interior mechanism with the inner sole in an upward position.

[0026]FIG. 4 Isometric view of the interior mechanism with the inner sole in a downward position.

[0027]FIG. 5 See through side elevation with the inner sole in a downward position.

[0028]FIG. 6 See through side elevation with the inner sole in an upward position.

[0029]FIG. 7 Exploded view of the interior mechanism.

[0030]FIG. 7bc Side cutaway detail of the peg and sleeve showing the open and closed positions respectively

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0031]FIG. 1 A self tying shoe (30) has an interior mechanism (32) which consists of visible elements such as an inner sole (7) hingedly attached to a base (1) set inside the shoe (30). in this illustration, the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com