Packaging material roll, packing machine using the roll, and commercial goods processing system with the machine

a technology of commercial goods and packaging materials, which is applied in the direction of packaging, packaging goods type, transportation and packaging, etc., can solve the problems of increasing the cost of production, so as to shorten the downtime. the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0129] A third technique for reading packaging related information will now be described. FIG. 5e is a diagram showing the structure of a housing unit 310 and a film roll 100 using the third technique. Description below will be focused on differences between this technique and the first technique.

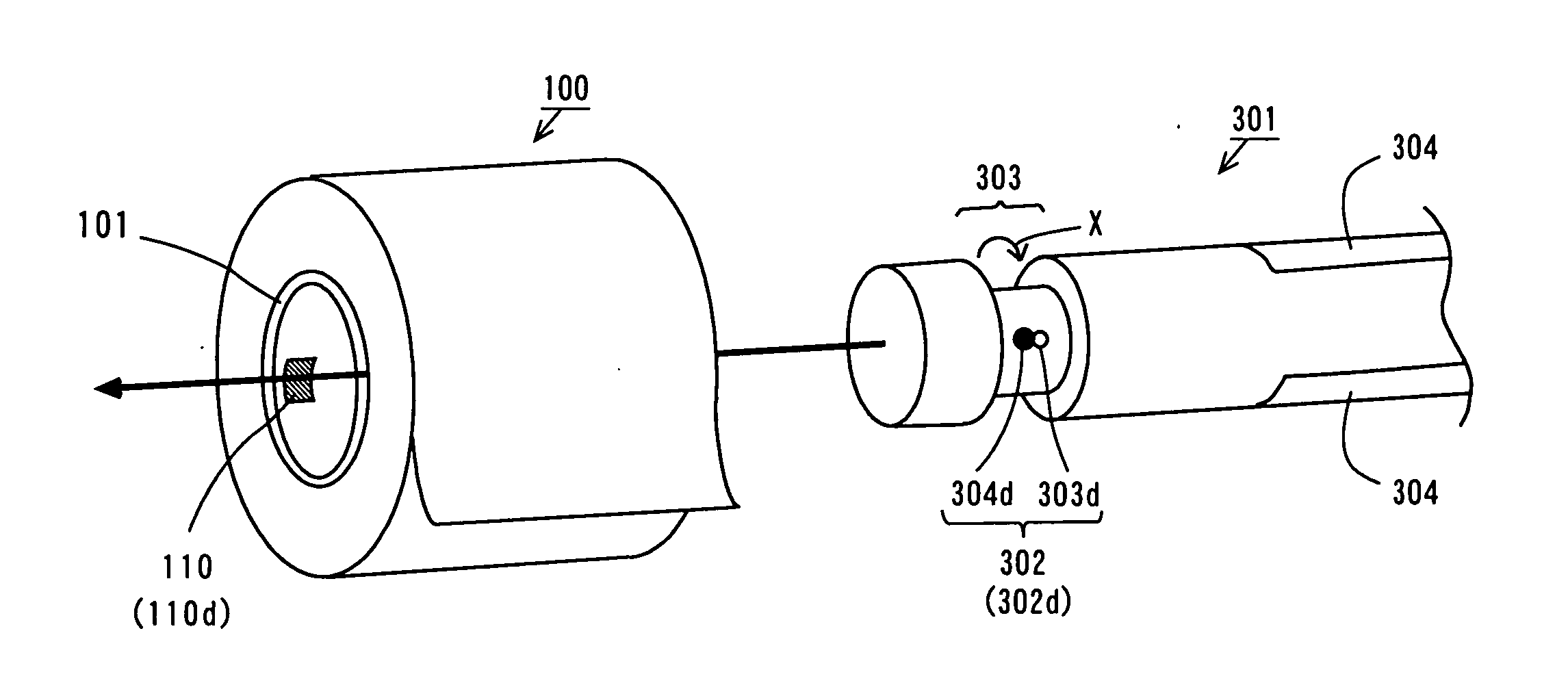

[0130] In this technique, a ring-like ID (identifier) tag (hereinafter, “a ring-like tag”) 110c having a round opening is adopted. While having a different shape, the ring-like tag 110c is in principle similar in structure and function to that of the aforementioned plate-like tag 110a or the rod-like tag 110b.

[0131] The diameter of the opening of the ring-like tag 110c coincides with the inside diameter of the paper tube 101, and the outside diameter of the ring-like tag 110c coincides with the outside diameter of the paper tube 101. The ring-like tag 110c is attached on the side of the paper tube 101 in contact with the stop plate 311. The ring-like tag 110c is attached as a final step i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com