Sensor device

a sensor and circuit chip technology, applied in the direction of acceleration measurement using interia force, film/foil adhesives without carriers, vehicular safety arrangments, etc., can solve the problems of circuit chip malfunction, lower side of sensor chip damage to circuit chip, and decrease in performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a description of an embodiment of the present invention with reference to the drawings.

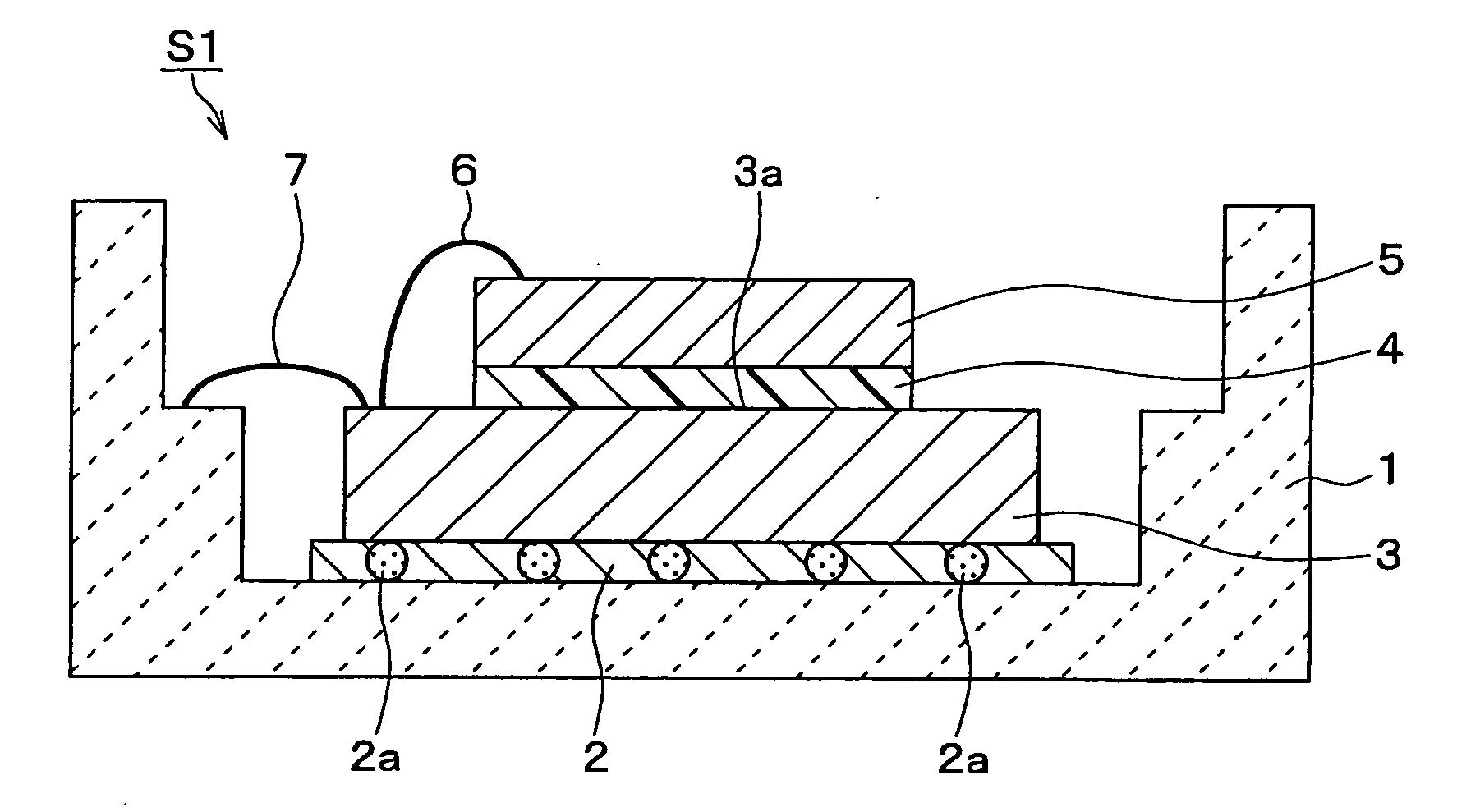

[0023] A sensor device used as an acceleration sensor S1 is shown in FIG. 1 in cross-sectional view. The acceleration sensor S1 is, for example, used for an automotive air-bag device.

[0024] A ceramic package 1 is used as a base of the acceleration sensor S1 as well as an attachment used for attaching the sensor S1 at a suitable place for measurement (e.g. at a bottom of a driver's seat of a vehicle). The accelerator sensor S1 includes a circuit chip 3 disposed on the ceramic package 1. A liquid adhesive 2 made of a silicon-type resin is interposed between the ceramic package 1 and the circuit chip 3.

[0025] In this embodiment, the adhesive 2 contains beads 2a made of resin or the like. The beads 2a serve to establish the thickness of the adhesive 2 in order to level the upper surface of the circuit chip 3 relative to the ceramic package 1. In other words, the beads 2a act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com