Current collector for polymer electrochemical cells and eclectrochemical generators thereof

a technology of polymer electrochemical cells and current collectors, which is applied in the direction of sustainable manufacturing/processing, carpet cleaners, hand devices, etc., can solve the problems of increasing the internal resistance of the electrochemical cell, reducing the power density and cycle life of such rechargeable batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

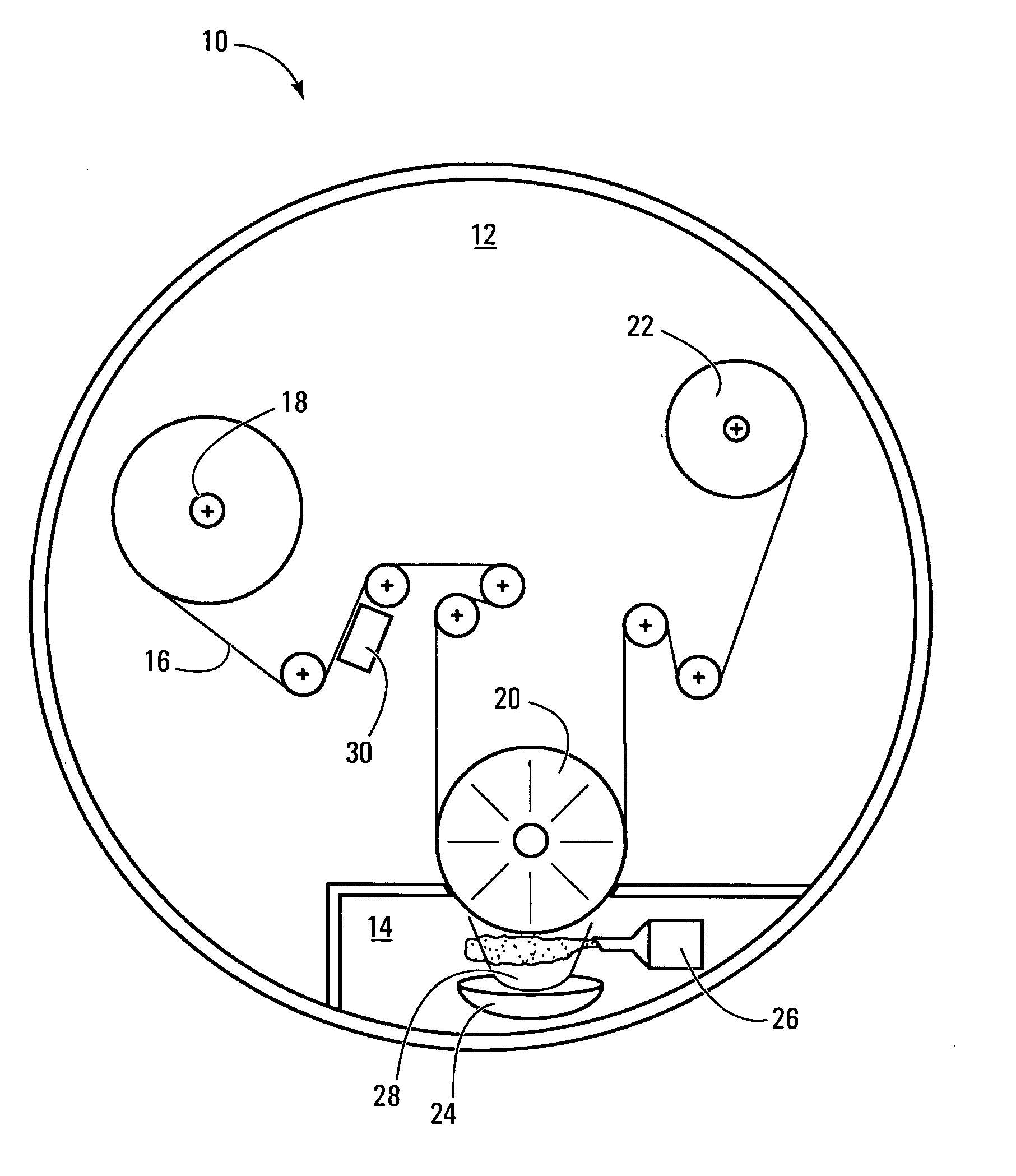

[0021] As previously mentioned, current collectors in electrochemical (EC) cells are passive components that transport currents generated by the chemical reaction between the anode and the cathode. Current collectors also act as mechanical supports for paste-like anodes or cathodes, and as such should be as strong and as thin as practicable to reduce the weight and volumetric penalty of the current collector to the overall weight and volume of the EC cell.

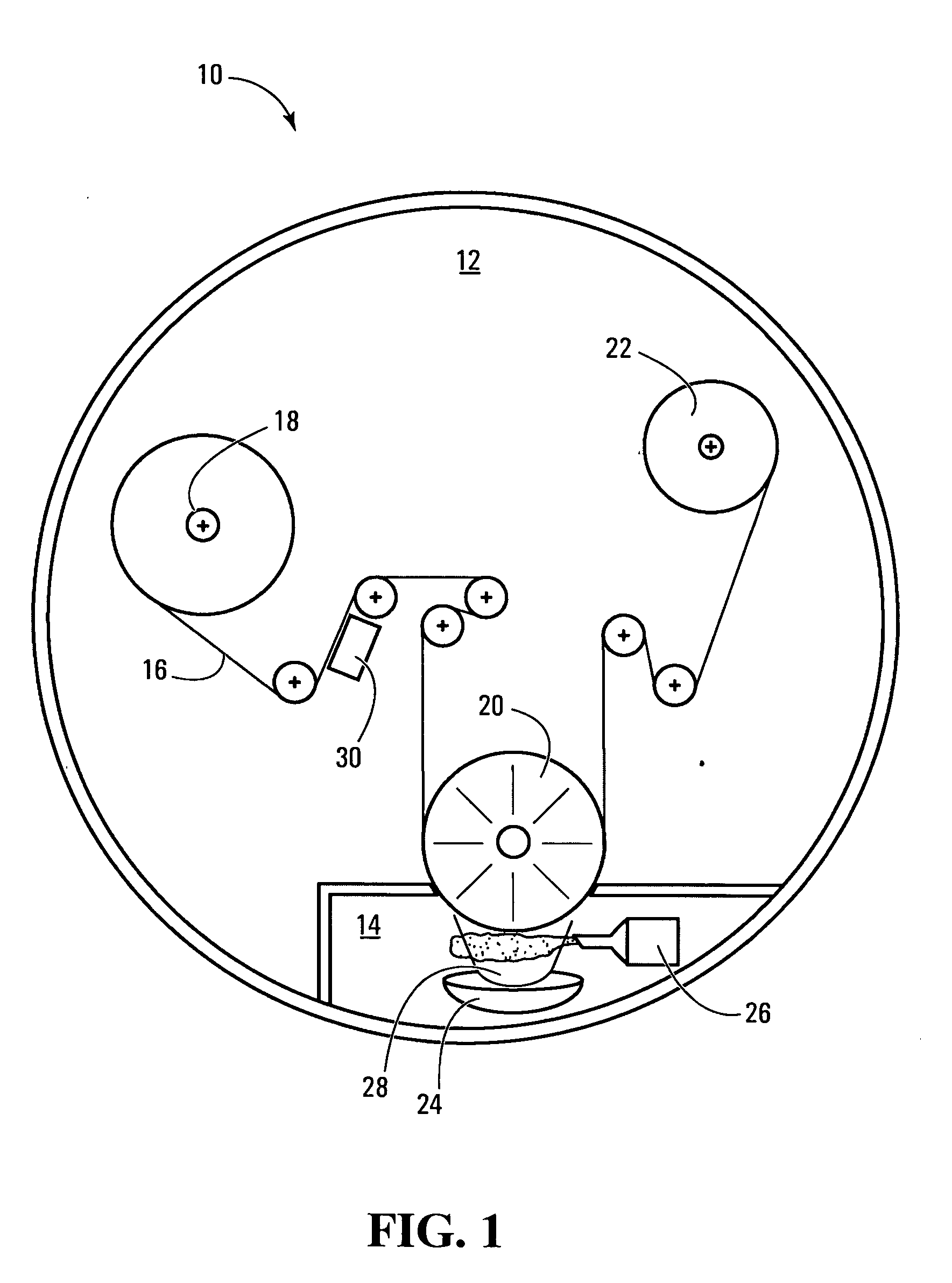

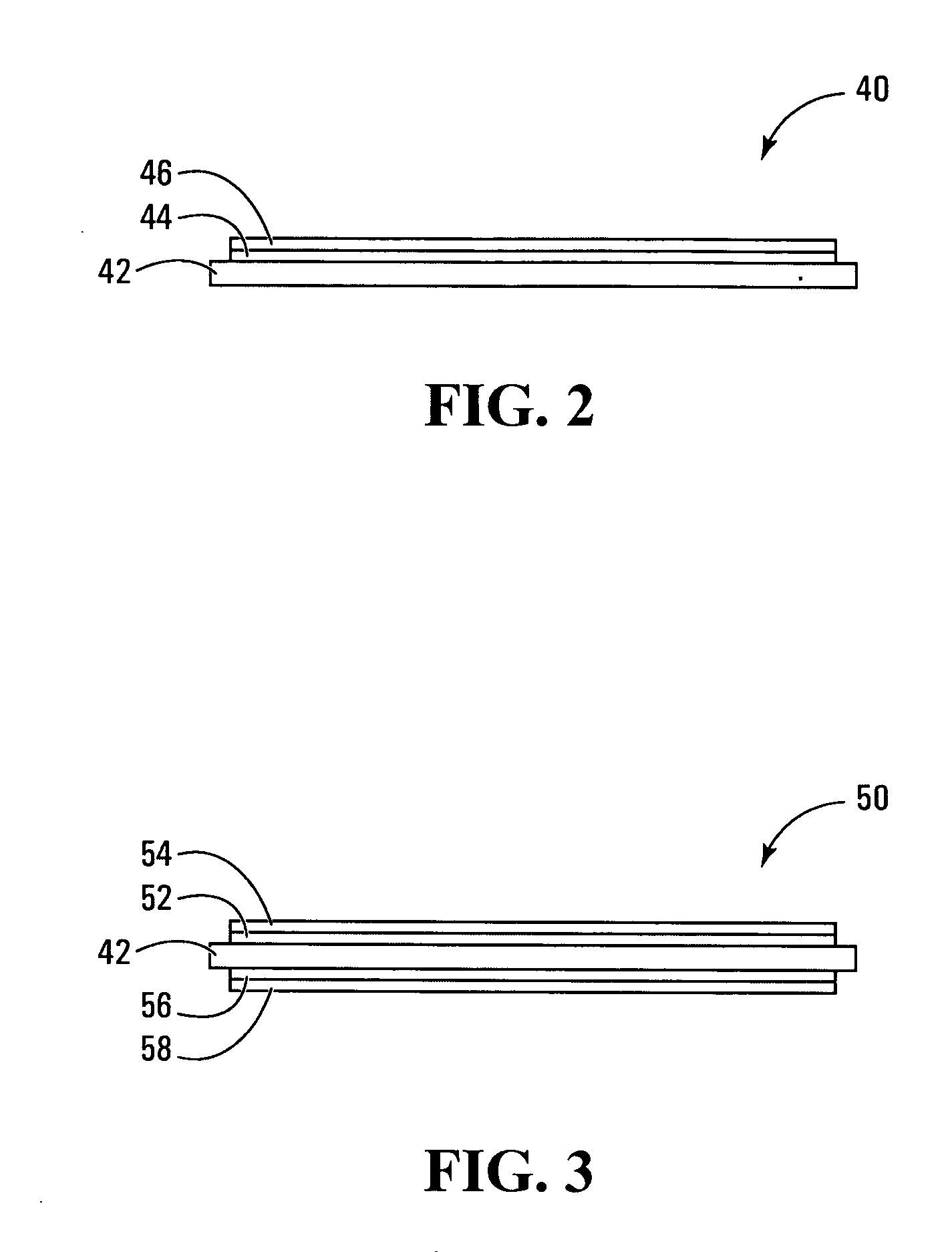

[0022] To achieve these goals, a current collector in accordance with one embodiment comprises a polymer support film having a thickness of between about 1 and 15 microns, preferably less than about 10 microns, onto which is deposited by vacuum evaporation a conductive metallic layer having a thickness of less than 3 microns, and preferably less than 1 micron. The conductive metallic layer is thereafter protected against corrosion by a protective metallic layer having a thickness of between about 5 and 500 nanometers, and preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com