Wash attenuator for a moored vessel

a technology for mooring vessels and attenuators, which is applied in the direction of waterborne vessels, vessel cleaning, and vessel movement reduction by wave damping, etc. it can solve the problems of increased noise, difficulty for persons occupying the vessel and attempting to sleep, and vessel is not able to move freely to reorient itself, so as to achieve lateral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

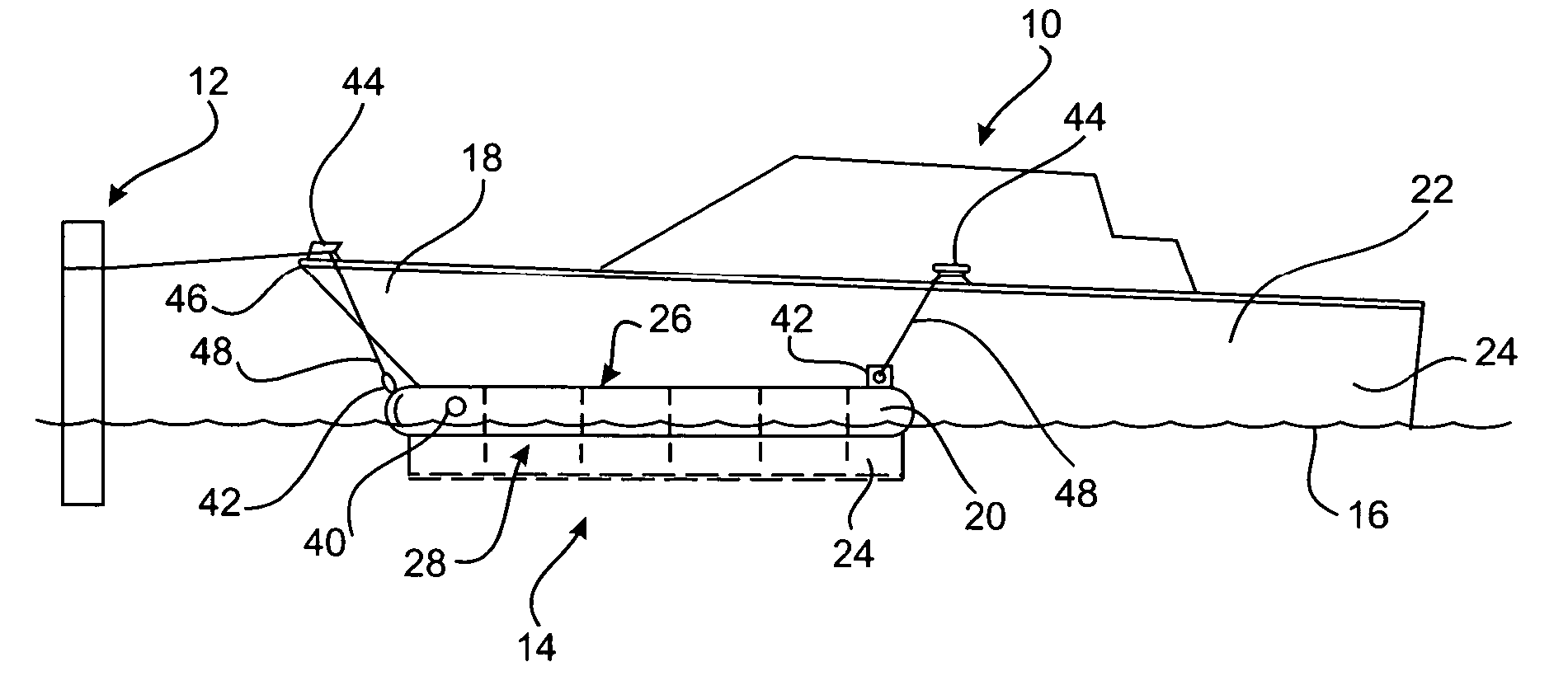

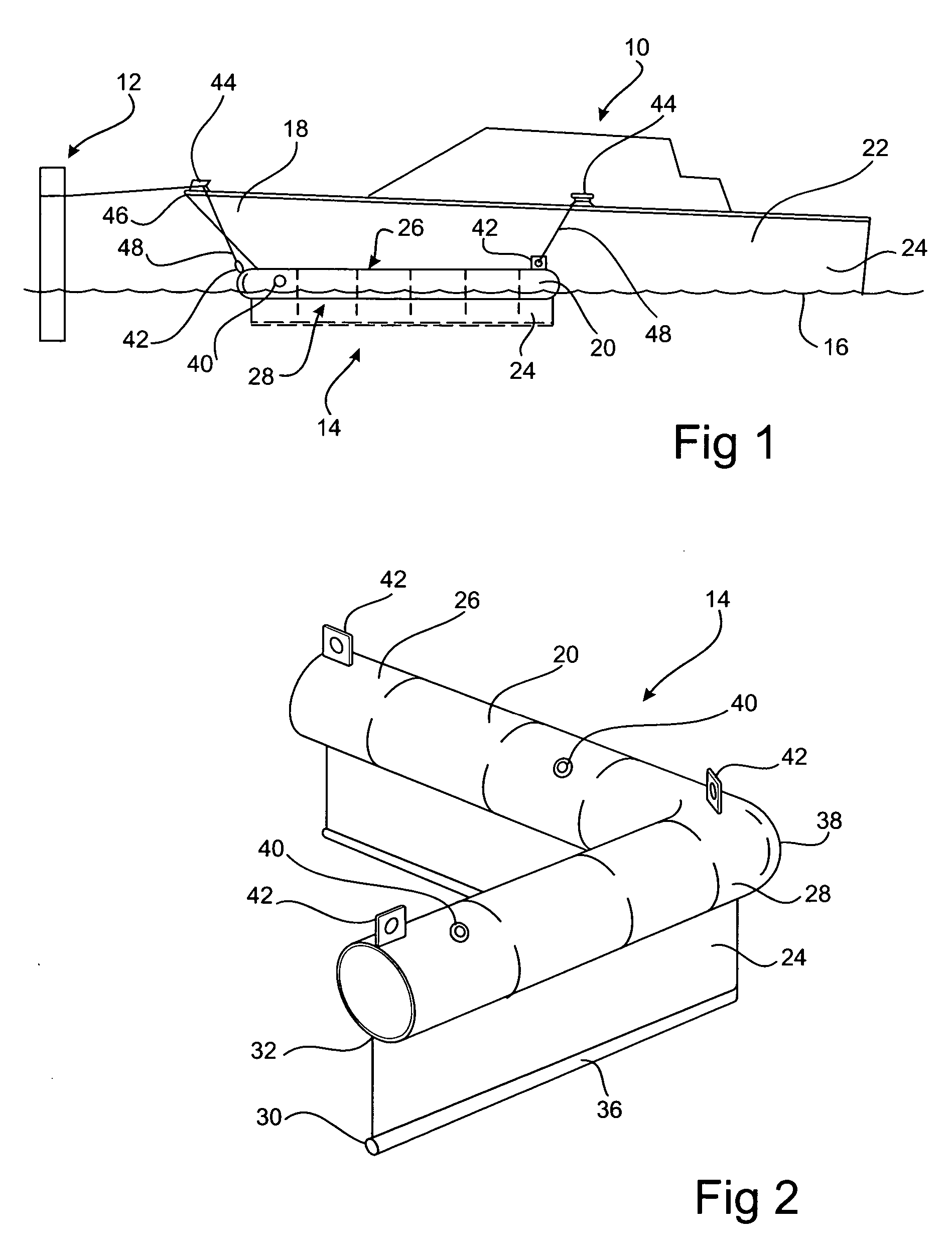

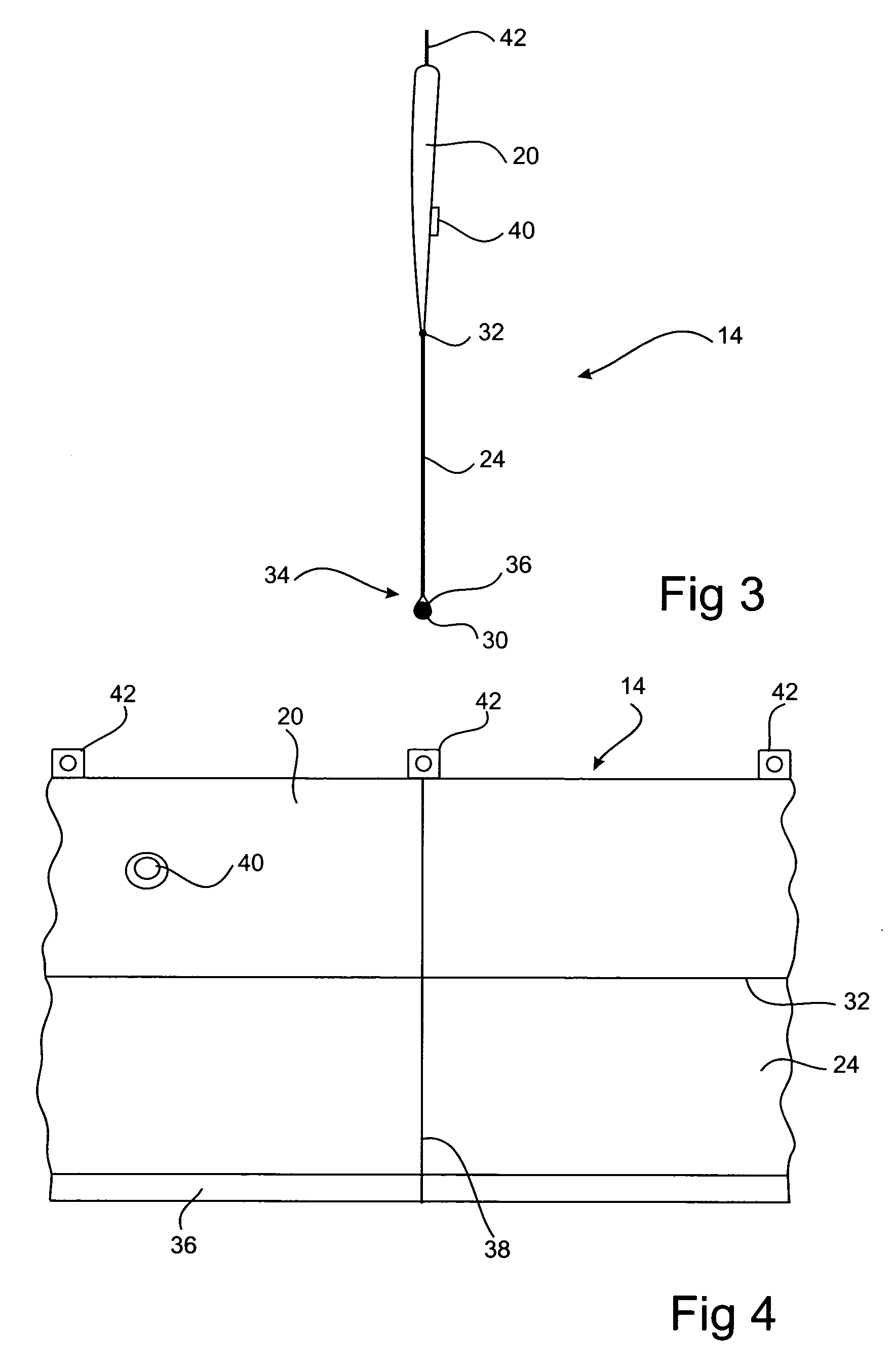

[0045] the present invention is illustrated in FIGS. 1 to 4 in which a vessel 10 in the form of a V-bottom boat is moored to a mooring 12 and is thus able to re-orient itself in response to changes in the direction of wind, wash, current or swell. In this example, the prevailing wind direction can be assumed to be from the left hand side of the page towards the right hand side of the page in relation to FIG. 1. A wash attenuator 14 is releasably connected to the boat 10 to isolate the waterline 16 at the bow section 18 of the boat 10 from the action of the wash of the water upon which the boat when moored.

[0046] The wash attenuator 14 comprises a buoyant member 20 adapted to extend along the waterline 16 of the bow section 18 of the boat 10 and along at least a portion of the each side 22 of the hull 24 of the boat 10. The buoyant member 20 has a first section 26 extending above the waterline and a second section 28 extending below the waterline. The wash attenuator 14 further compr...

second embodiment

[0061] In the present invention illustrated in FIGS. 5 and 6, the buoyant member 20 is provided with one or more spacing means 60 in the form of rubber projections for holding the buoyant member 20 in a spaced apart relationship from the hull of the vessel 10. It is to be understood that the buoyant member 20 need not be spaced apart from the vessel 10 in order to attenuate the wash that is incident on the vessel, the spacing means being used to reducing wear or noise associated with rubbing of the buoyant member 20 on the hull of the vessel 10. The buoyant member 20 is not coupled directly to the vessel 10 but is rather releasably coupled to one or more bollards 64 provided on the pen 50 using securing lines 48 extending from the attachment points 42 to the bollards 64.

third embodiment

[0062] the present invention is illustrated in FIGS. 9 and 10 for which like reference numerals refer to like parts. In this embodiment, the vessel 10 a multi-hull vessel and more particularly a trimaran. The trimaran has a centre hull 70 positioned between two outermost hulls 72. Each of the three hulls of the trimaran 10 has a bow section 18 and in this example, the buoyant member is arranged to extend around the bow 46 of the trimaran and along at least a portion of the waterline of the outermost hulls 72. Alternatively, a plurality of smaller wash attenuators 14 could be positioned around each of the outermost hulls 72 and / or the centre hull 70.

[0063] In this example, the buoyant member 20 is held in a spaced apart relationship away from the trimaran 10 indirectly using a spacer 74 positioned at the base 76 of the securing line 48 extending from the bow 46 of the centre hull 70 of the trimaran to a mooring 80. The spacer 74 effectively pulls the buoyant member 20 away from the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com