Bed foundation having a structural foam perimeter utilizing mechanical interlocking

a technology of structural foam and perimeter, which is applied in the direction of fluid mattresses, beds, sofas, etc., can solve the problems of affecting the comfort of sleep, so as to reduce the occurrence of “edge roll” and reduce the occurrence of “edge roll”. , the effect of inherently cushioning feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

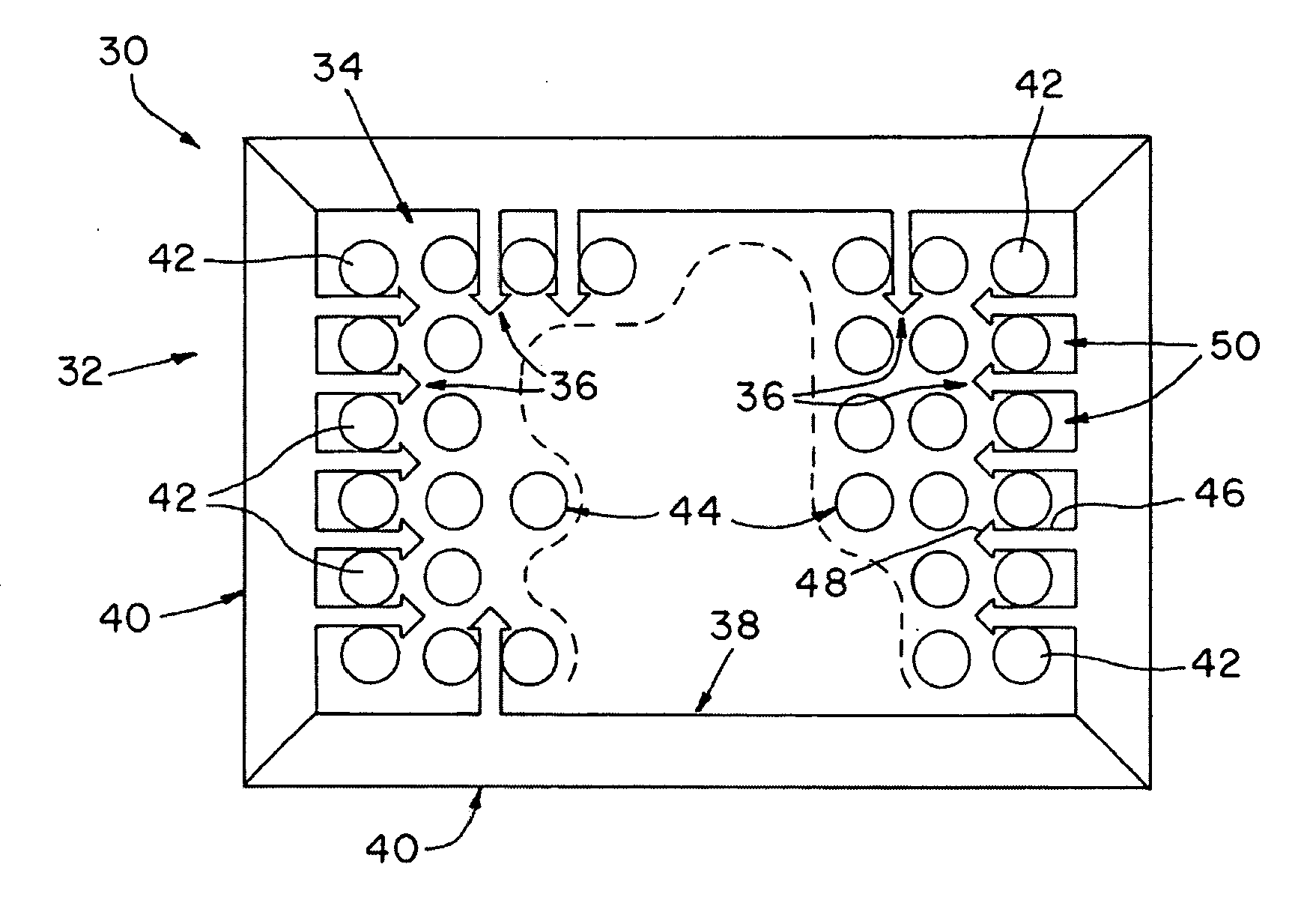

[0028] The first aspect of the present invention is illustrated in FIGS. 1a-1h, illustrating the concept of interlocking frame members for creating a frame / perimeter of a bed foundation according to the present invention. Frame assemblies 10a-10h each include, respectively, a first spring member 12a-12h and a second frame member 14a-14h. First spring member 12a-12h is in turn supplied with a male connecting portion 16a-16h, respectively, while second frame member 14a-14h is supplied with a female connector portion 18a-18h, respectively. Such connector portions 16a-16h are able to snap fit and / or slideably connect with respective female member 18a-18h.

[0029] As illustrated, any of a variety of connection configurations may be employed with respect to the interconnecting portions, so long as a sufficient interlocking is achieved between the two portions. By creating interlocking portions, it is possible to avoid the need to further glue such portions together in order to maintain a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com