Apparatus and method

a technology of apparatus and well, which is applied in the direction of piston pumps, positive displacement liquid engines, borehole/well accessories, etc., can solve the problems of uneconomical wells with low production levels, and it is not feasible to deploy certain traditional pumping apparatuses to their subterranean depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

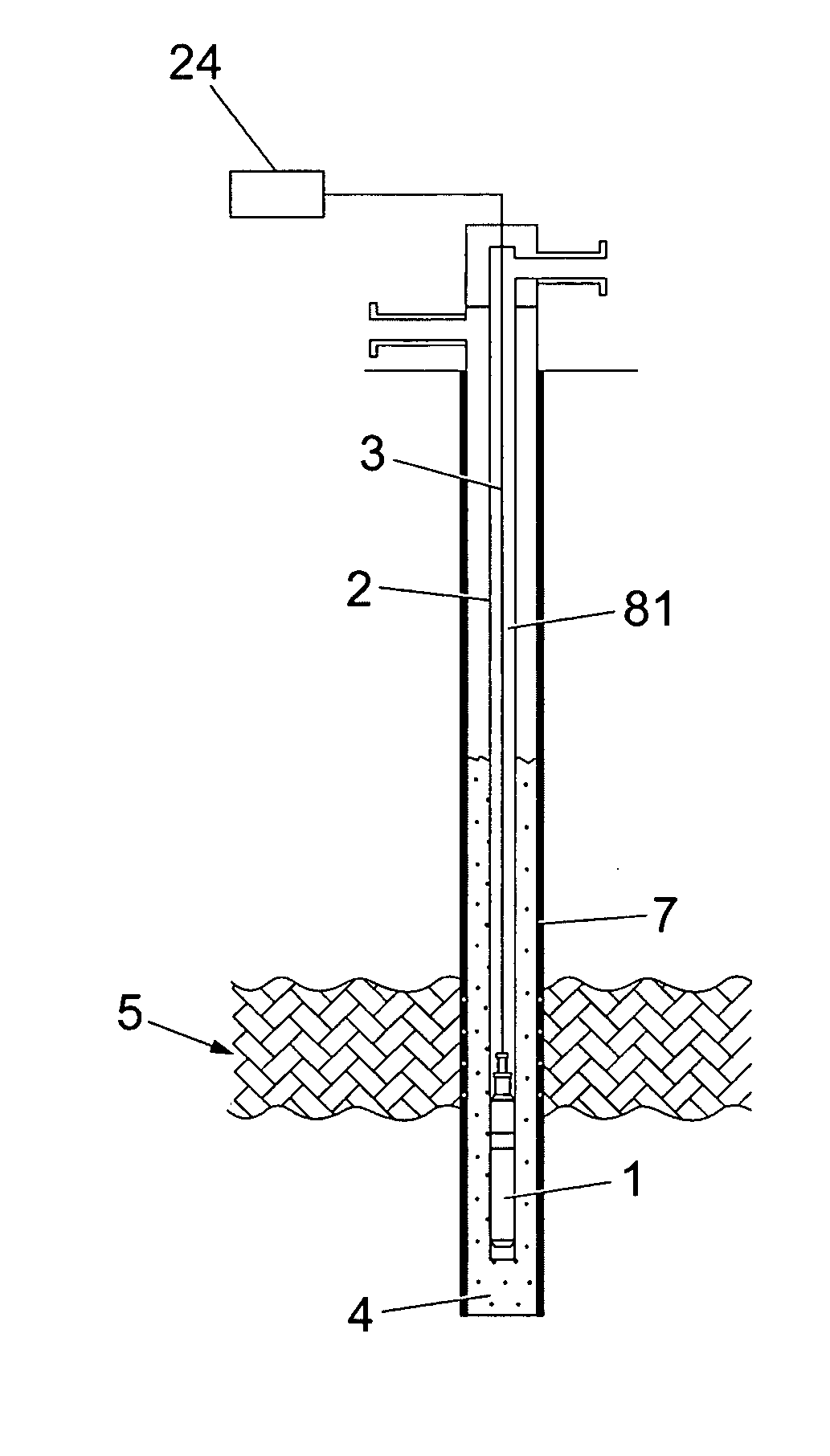

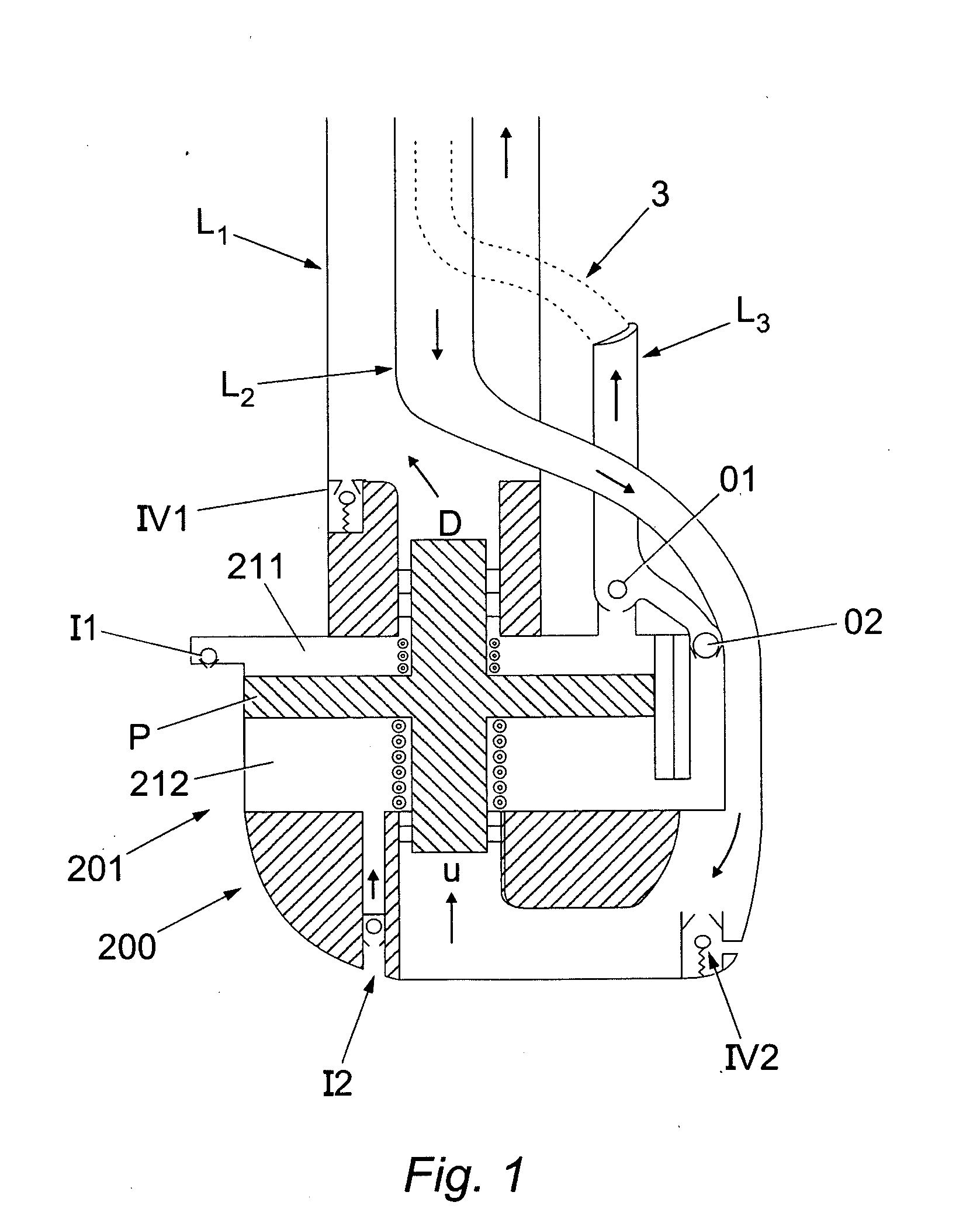

[0088] Referring initially to FIG. 1, a schematic hydraulic pump assembly 200 is shown. Pump assembly 200 preferably includes three hydraulic lines, L1, L2, and L3. L1 is shown as a hydraulic down-stroke operation line, L2 is shown as a hydraulic up-stroke operation line, and L3 is shown as a production fluid return line. While the lines are shown as three distinct lines, it should be understood by one of ordinary skill in the art that lines L1, L2, and L3 may be constructed as a single co-axial line having three distinct fluid flow passages. Pump assembly 200 includes a pump 201 with a hydraulic piston assembly P that reciprocates up and down within a housing of pump assembly 200. Piston P defines two pumping chambers, 211 and 212 and two pressure actuation surfaces U and D. Pressure from line L1 engages surface D and drives piston P down. As piston P is driven down, chamber 211 fills with production fluids through inlet valve I1 and production fluids within chamber 212 are forced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com