Under deck drainage system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

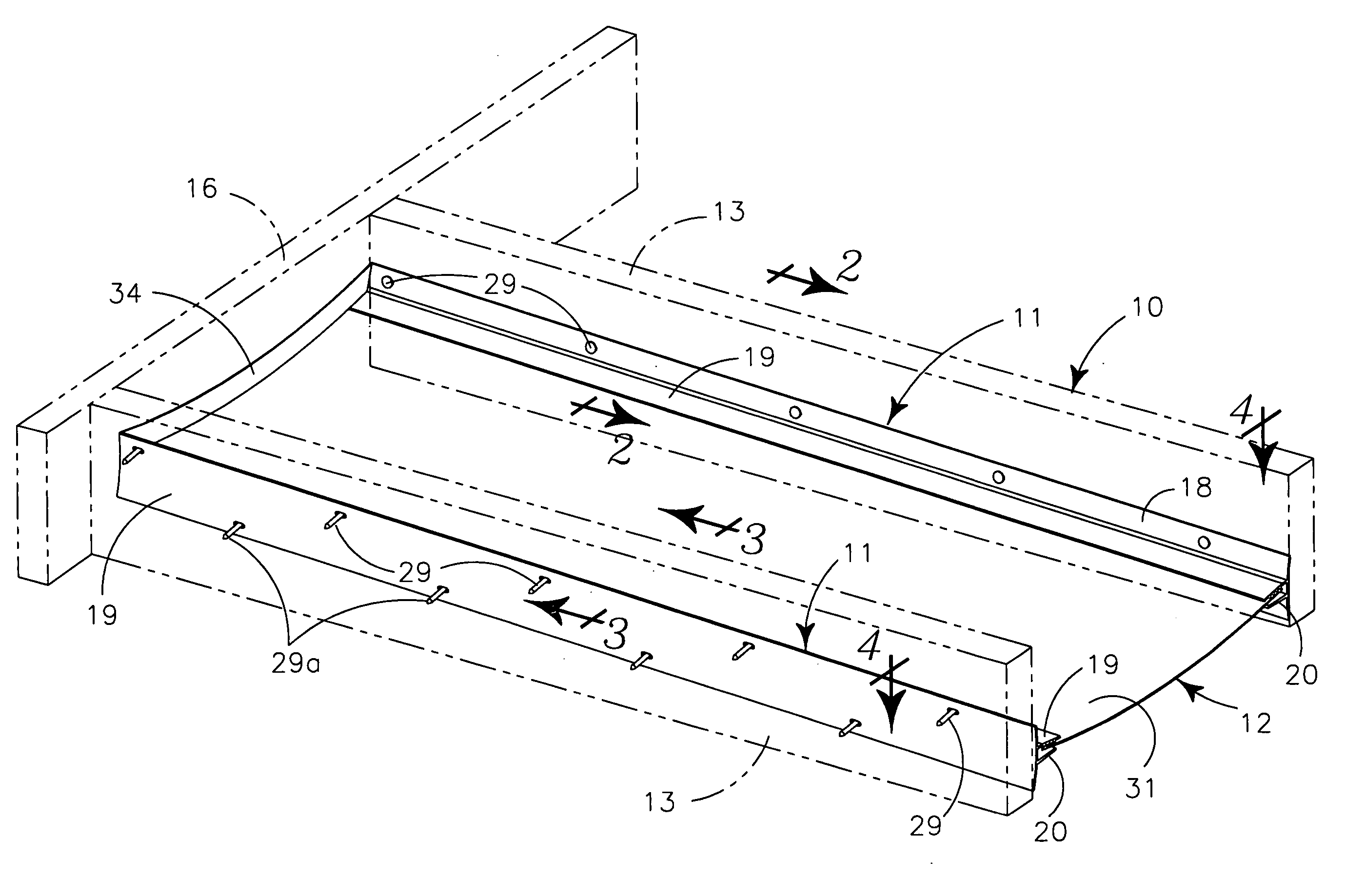

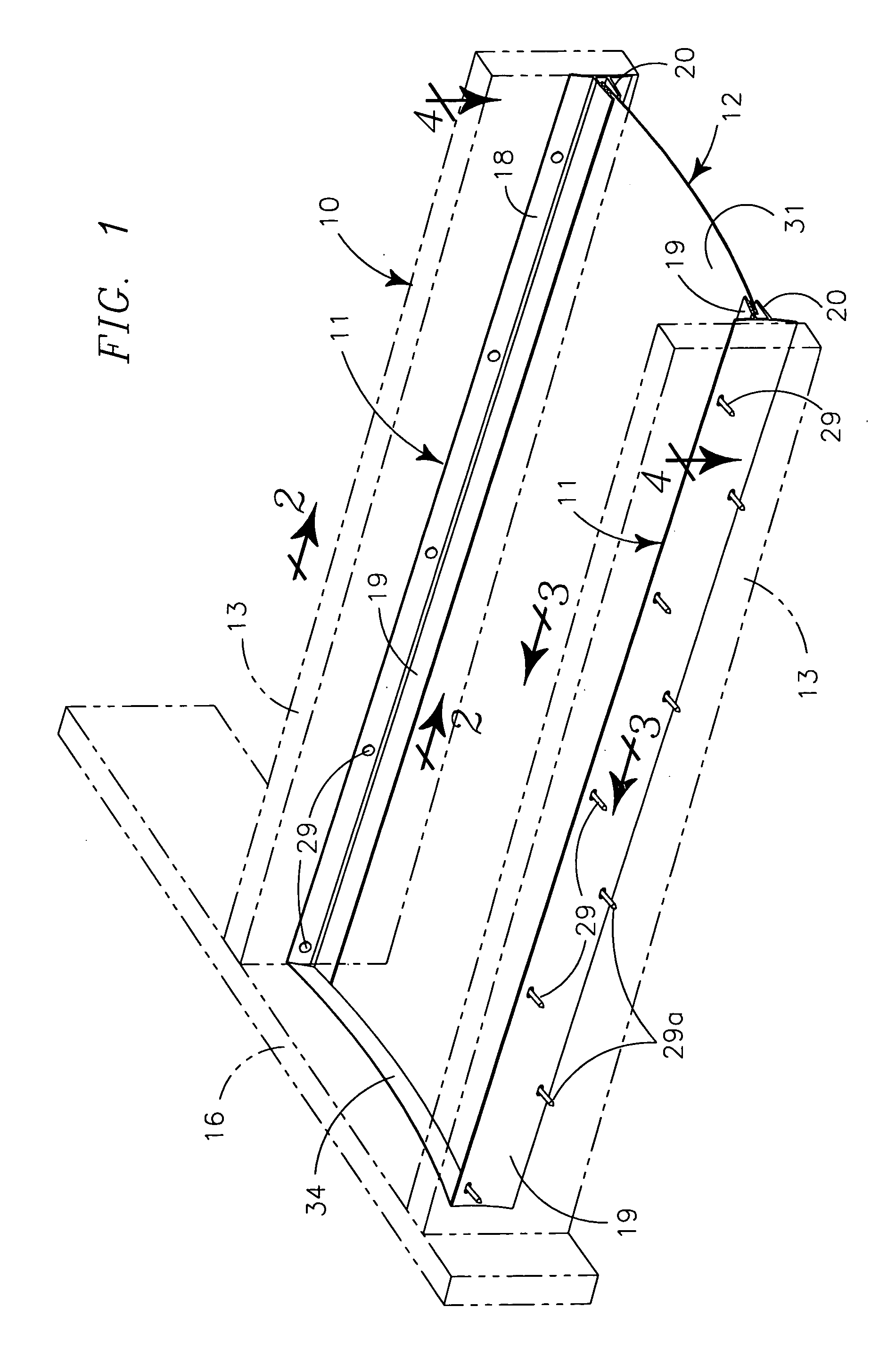

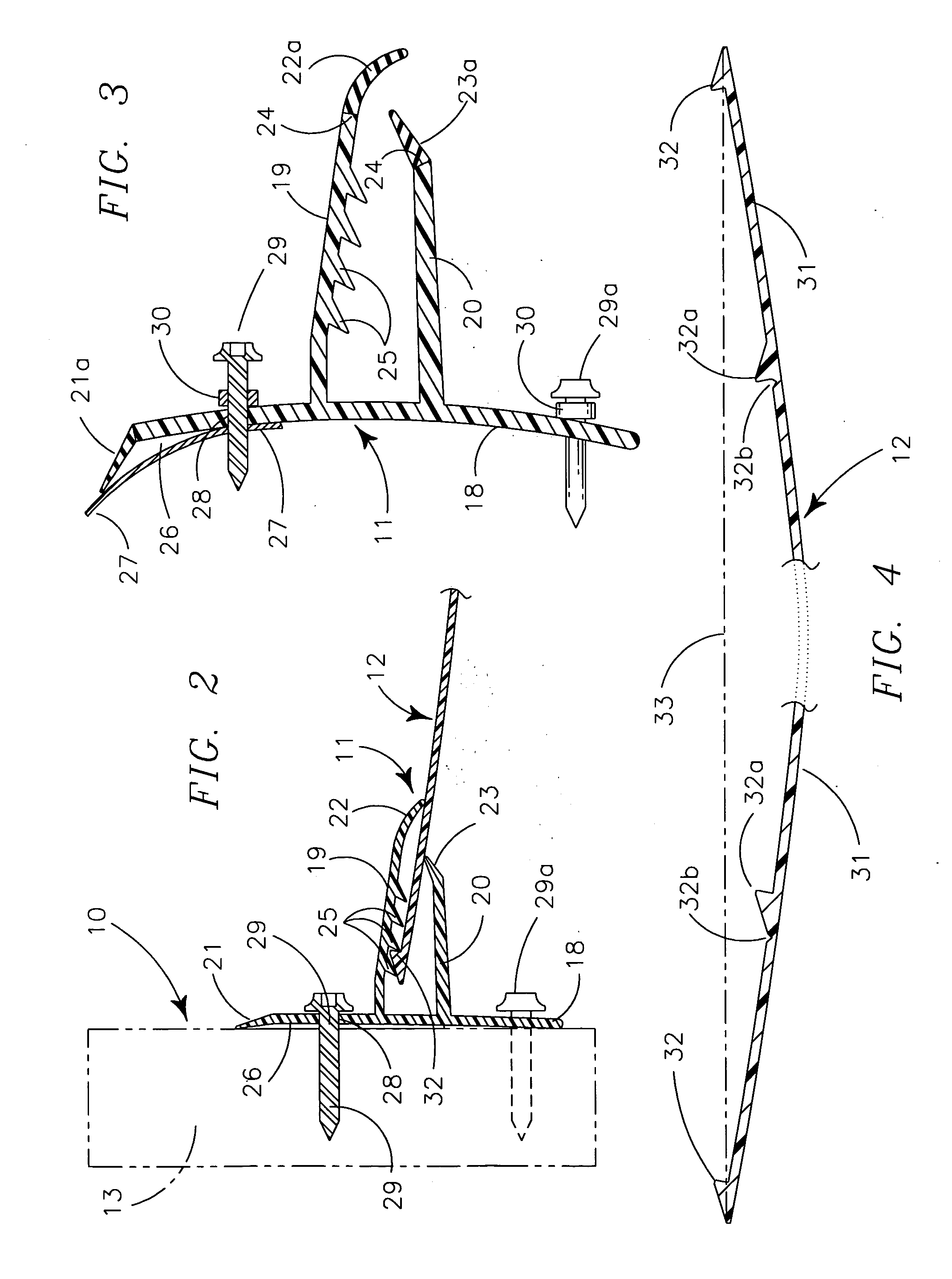

[0031] My invention generally provides a plurality of elongate fastening brackets 11 supported in cooperating pairs on adjacent vertical surfaces of each adjacent pair of joists of deck 10 to carry drainage panels 12 between each cooperating pair of the fastening brackets 11 to drain fluidic material passing downwardly through the surface of deck 10 and transport the drained fluidic material to a deck edge at the outer ends of the joists for further disposition.

[0032] A portion of the type of deck 10 with which my drainage system may be used is shown in FIGS. 1 and 5. The deck 10 provides a plurality of parallel spaced joists 13, extending outwardly from support on an associated support structure (not shown) that extends spacedly above the earth or other supporting structure beneath the deck. The joists 13 normally extend substantially perpendicularly outwardly from the associated support structure and may be supported in cantilever fashion from the associated support structure, by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com