Leadless lower temperature co-crystal phase transition metal heat conductive device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order that those skilled in the art can further understand the present invention, a description will be described in the following in details. However, these descriptions and the appended drawings are only used to cause those skilled in the art to understand the objects, features, and characteristics of the present invention, but not to be used to confine the scope and spirit of the present invention defined in the appended claims.

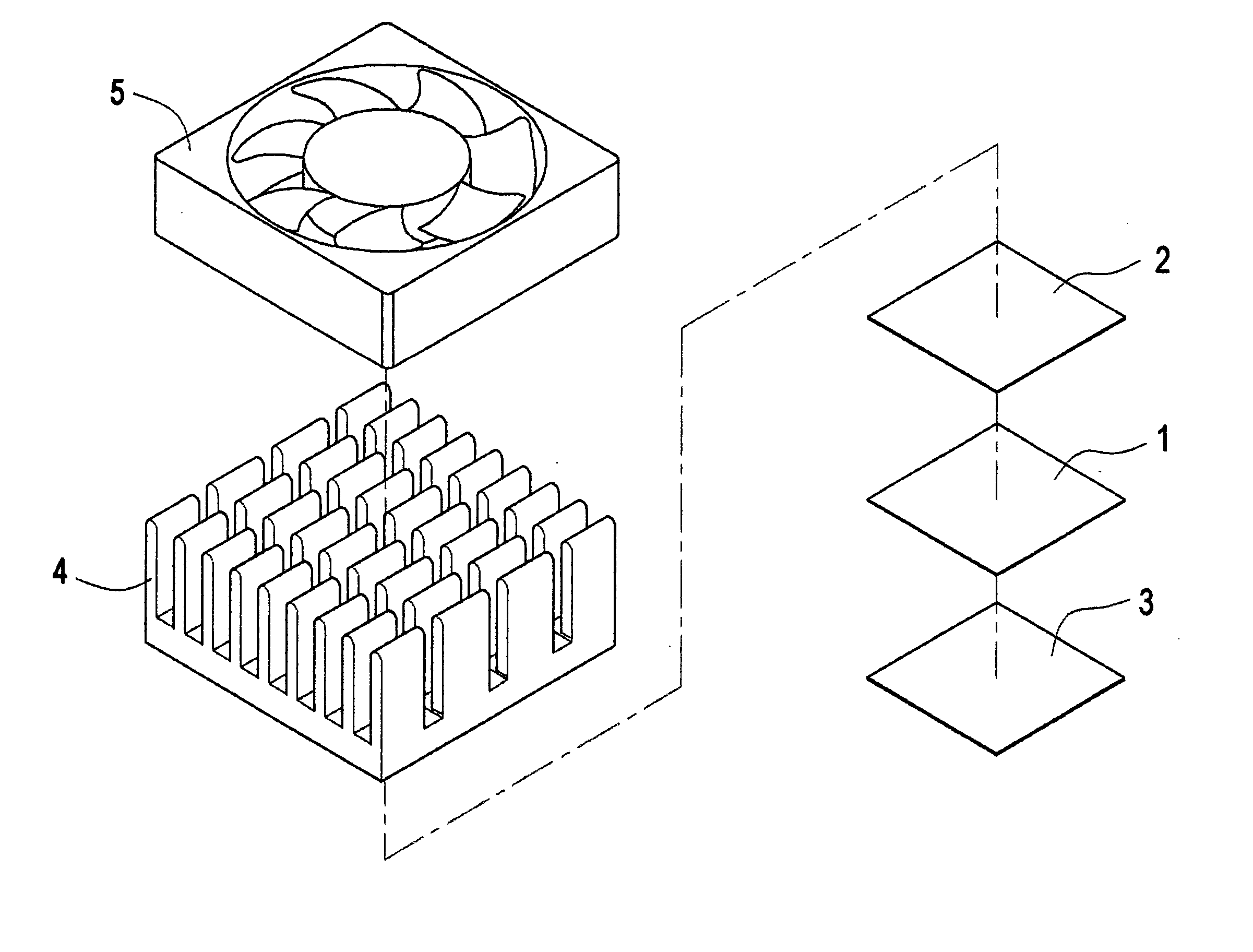

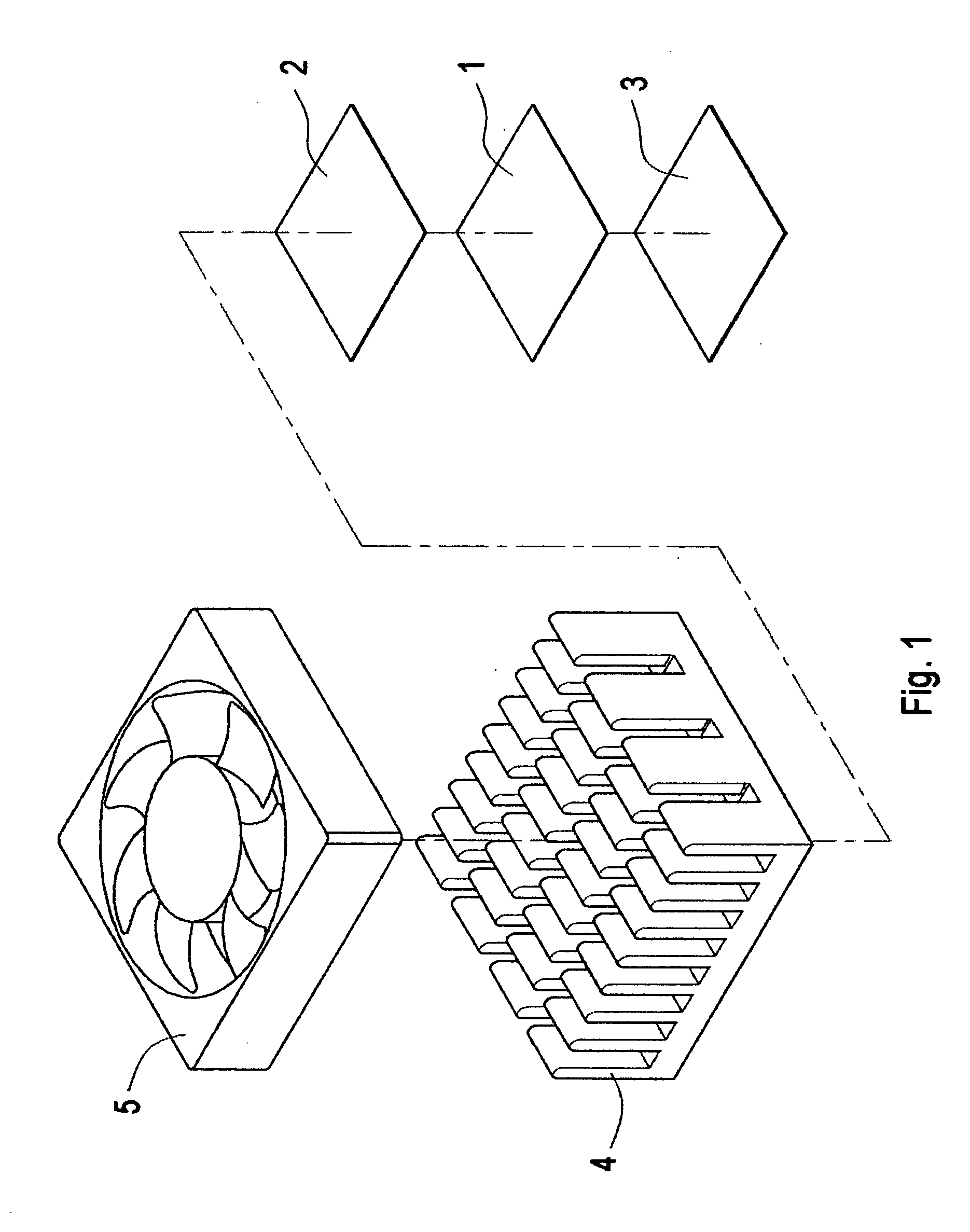

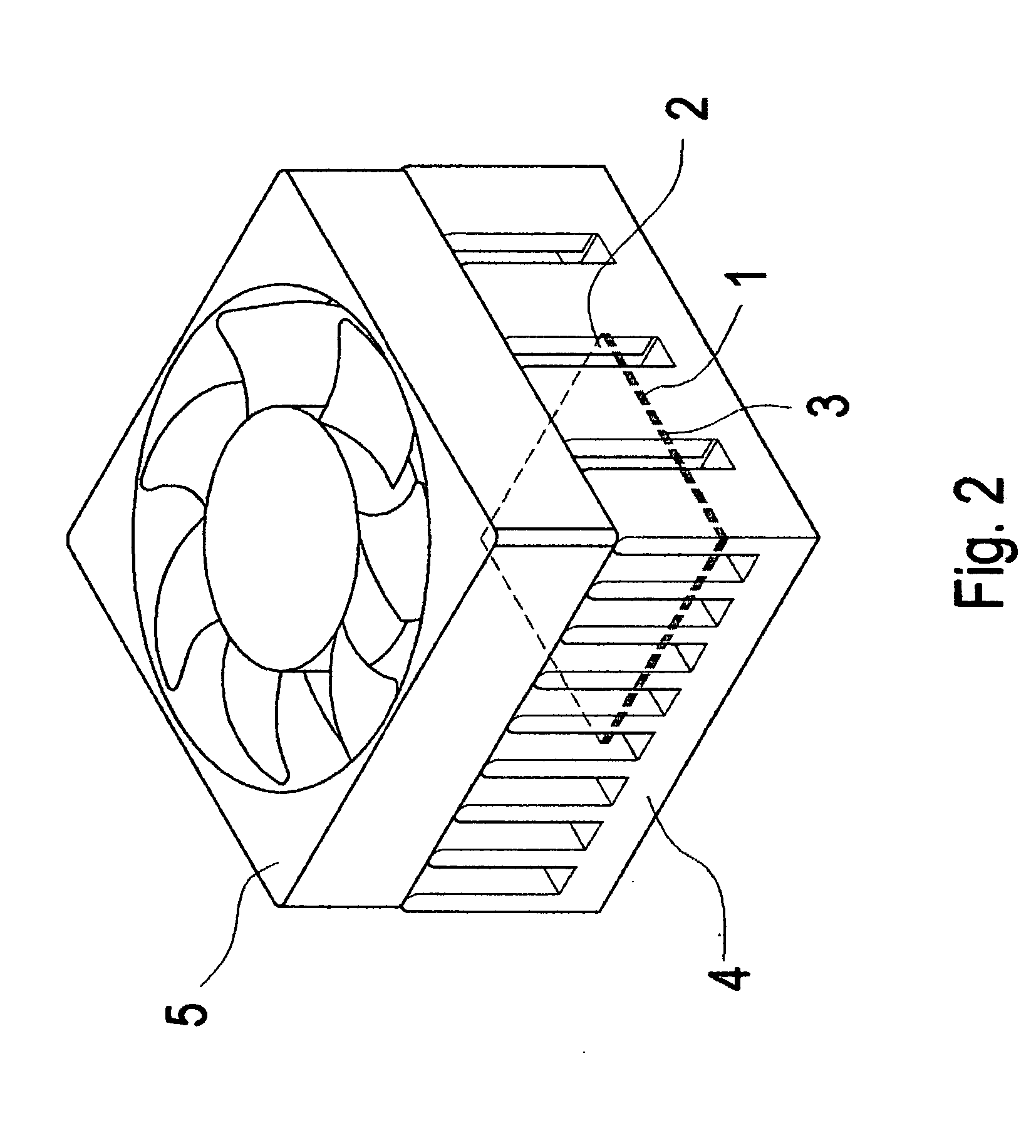

[0011] With reference to FIGS. 1, 2 and 3, the leadless lower temperature co-crystal phase transition metal heat conductive sheet. The present invention mainly comprises the following elements.

[0012] Two metal substrates 2 and 3 are made from tin, indium, bismuth and a little other elements.

[0013] A metal heat conductive sheet 1 is installed between the two metal substrates 2 and 3, where the metal substrates 2 and 3 have the effect of increasing heat dissipating ability of the metal heat conductive sheet 1.

[0014] A heat dissipation device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com