Dosing device for mounting on a container

a technology for mounting devices and dosing devices, which is applied in the direction of liquid dispensing, containers, pliable tubular containers, etc., can solve the problems of large volume, inability to apply a solution to a dosing device that is not mounted, and complicated structure of this known dosing device, etc., to achieve the effect of simple and compact structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

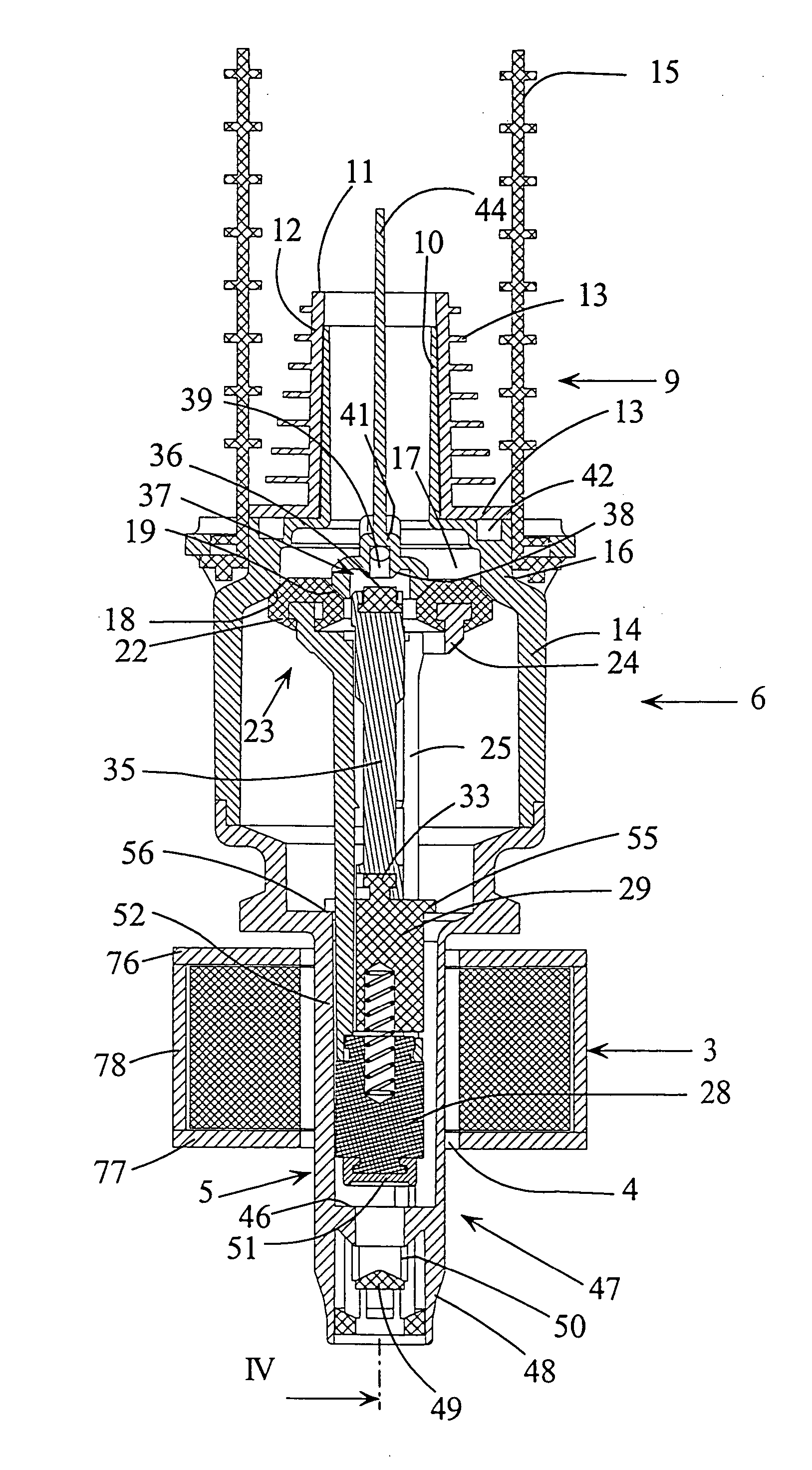

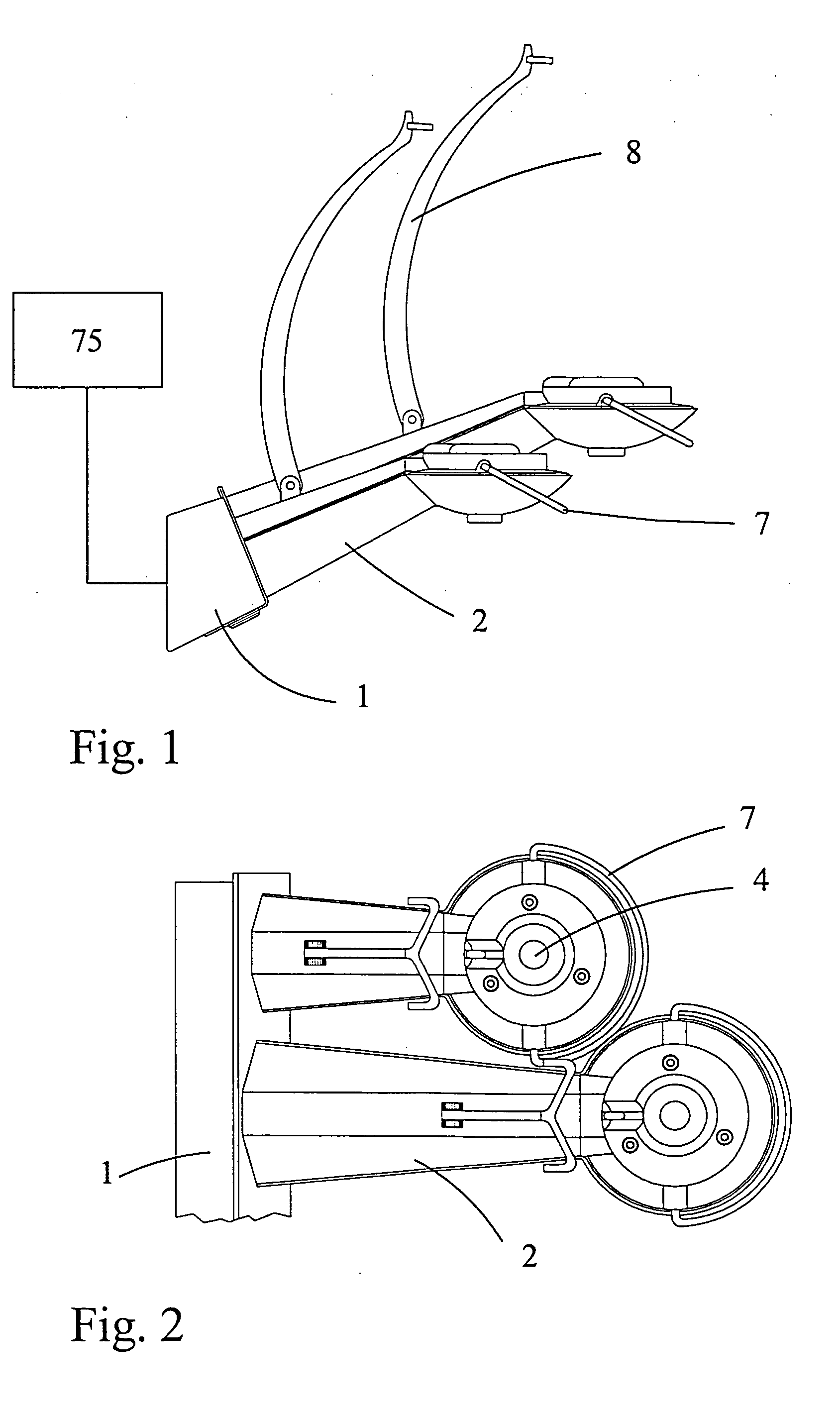

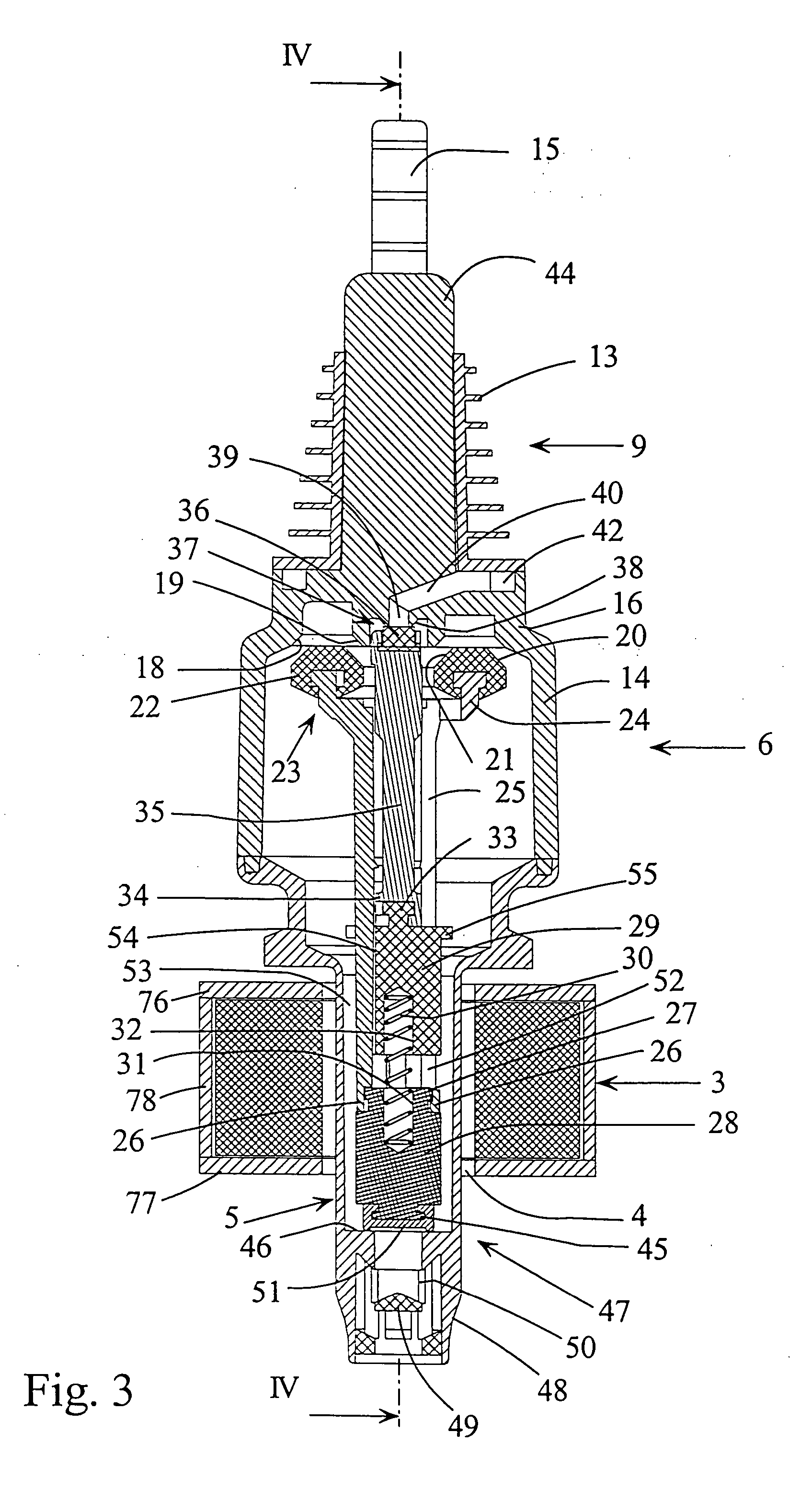

[0044]FIG. 1 is a side view of a panel I comprising several bottle holders 2, of which only two are shown, provided with an electromagnetic coil 3, shown in FIGS. 3 and 4, located around a central opening 4 in the bottle holder 2. An outlet spout 5 of a dosing device 6 according to the invention, mounted on the neck of a bottle, may be inserted into the opening 4 from above, so that the bottle may be supported upside down on the bottle holder 2. In this position, the spout 5 will project from the bottom side of the bottle holder 2, so that liquor may be dispensed from the spout 5 upon activation of the electromagnetic coil 3. The activation of the coil 3 may be initiated by pressing a switch in the form of a lever arm 7 on the bottle holder 2. The bottle holders 2 are provided with supplementary support arms 8 for the bottles.

[0045] The dosing device according to the invention is not only suitable for dispensing of liquor, but can advantageously be applied for many different purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com