AC/DC portable wet/dry vacuum having improved portability and convenience

a portable, wet/dry vacuum technology, applied in the field of vacuum appliances, can solve the problems of placing significant cost pressure on the commercially available wet/dry vacuum, the relatively long time that is necessary, and the known wet/dry vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

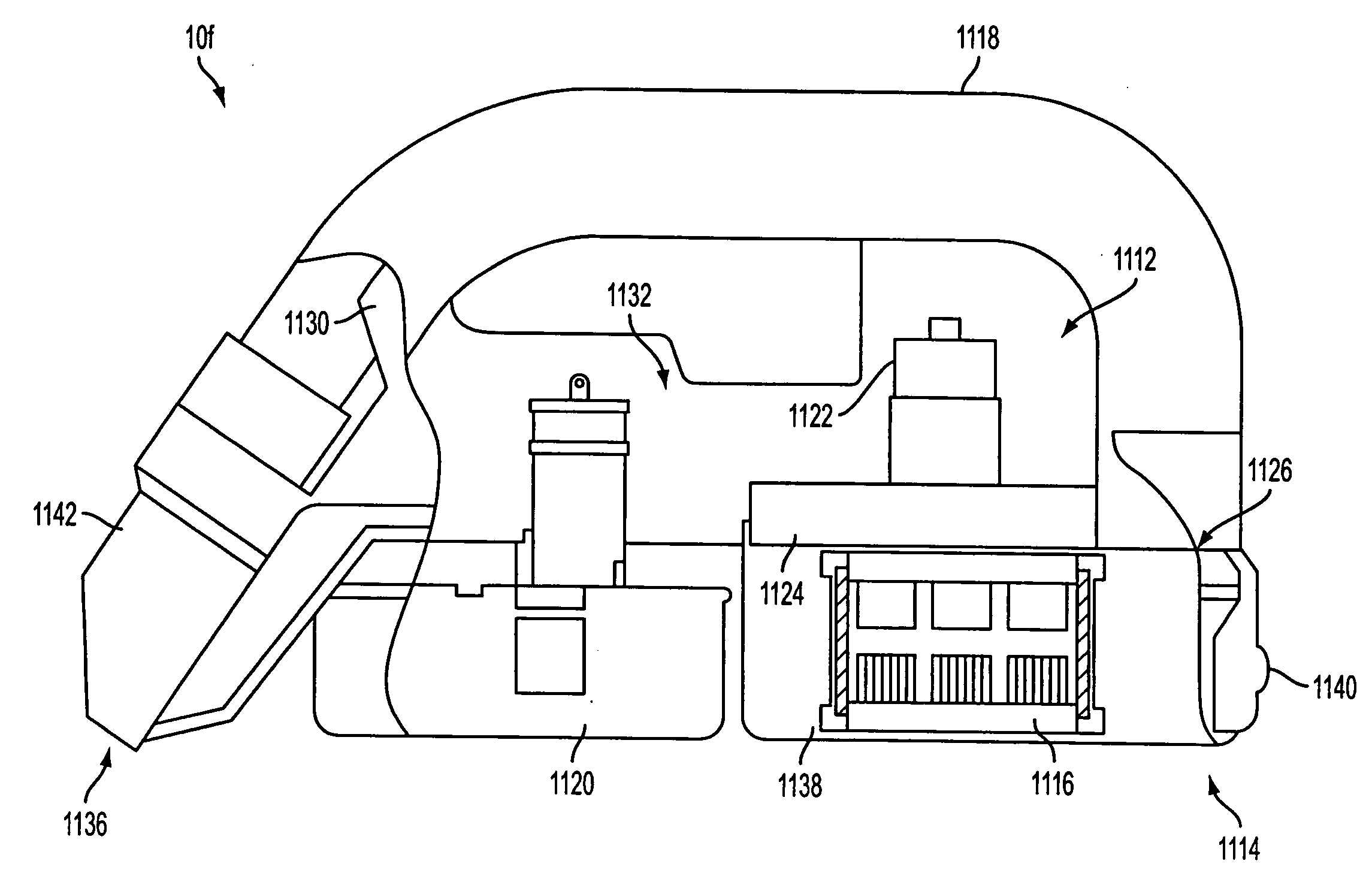

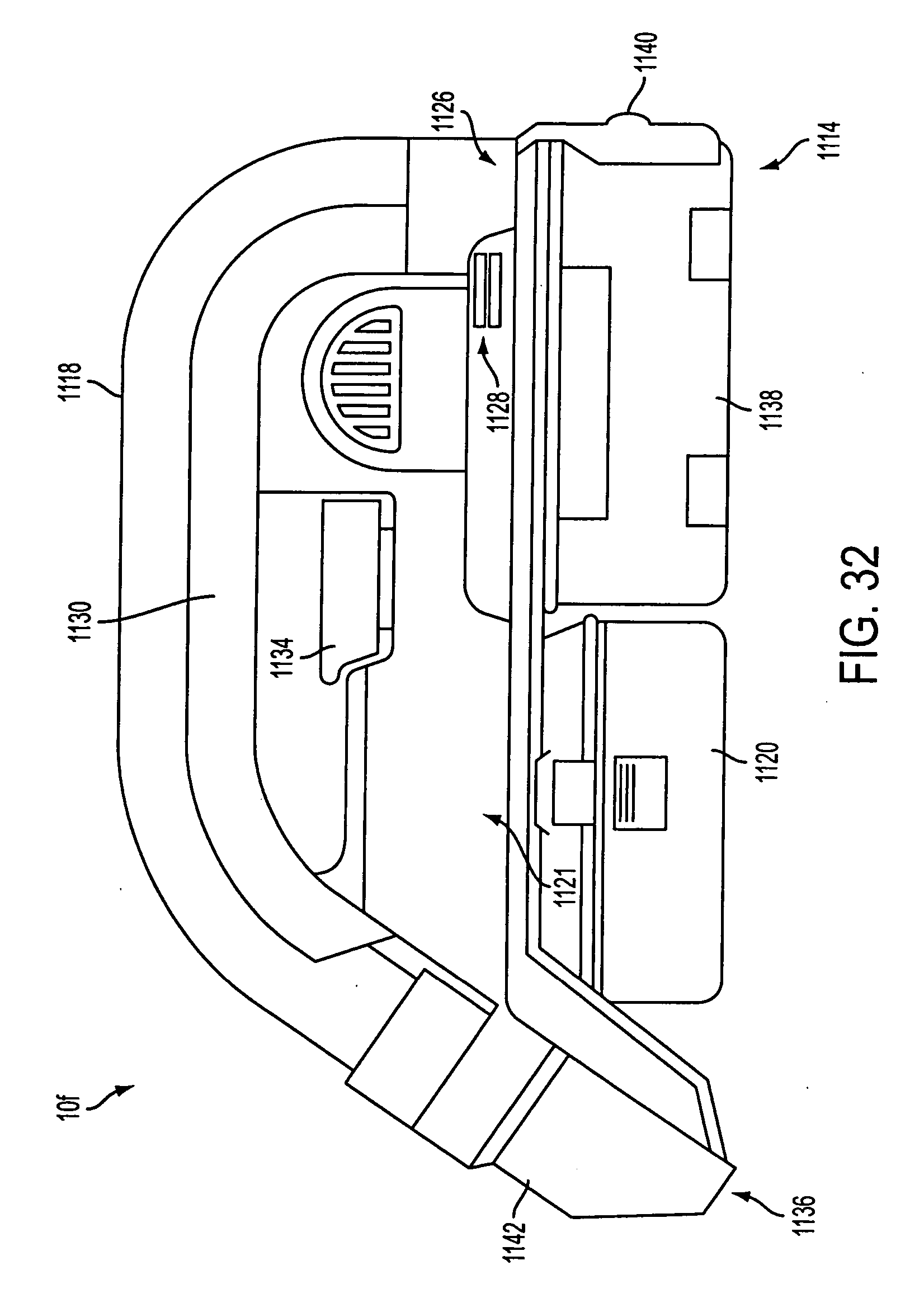

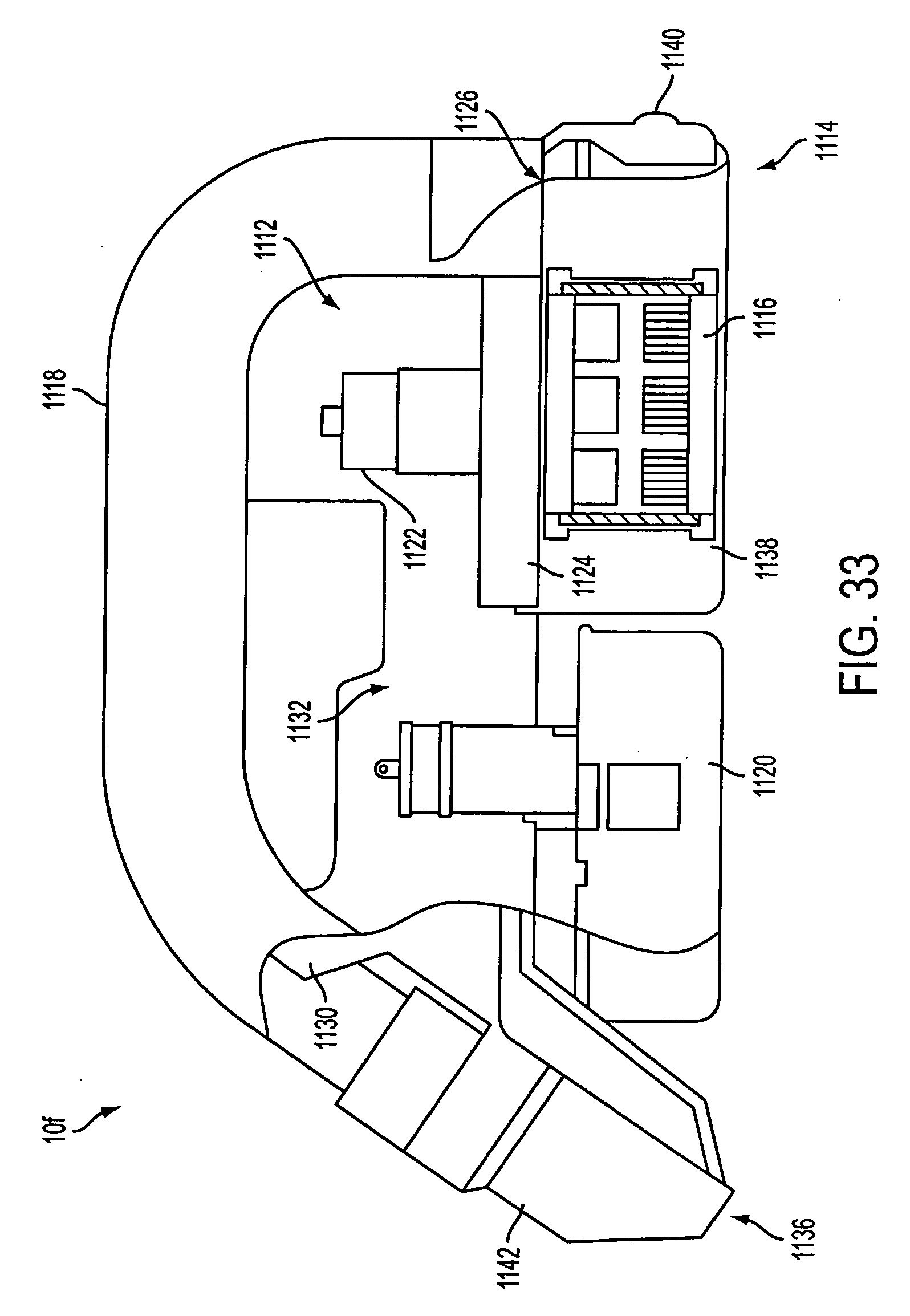

[0050] With reference to FIG. 1 of the drawings, a hand-portable wet / dry vacuum constructed in accordance with the teachings of the present invention is generally indicated by reference numeral 10. In the particular example illustrated, the vacuum 10 is shown to include a powerhead assembly 12, a canister assembly 14, a filter system 16, a hose assembly 18, a plurality of conventional hose-end attachments 20, a shoulder strap 22, a first electrical cord 24, a second electrical cord 26 and a battery pack 28.

[0051] With additional reference to FIG. 2, the powerhead assembly 12 may be removably attached to the canister assembly 14 and includes a housing 40, a motor 42, a fan 44 and a controller 46. The housing 40 defines an inlet port 50, an outlet port 52, a handle 54 and a central cavity 56 into which the motor 42, fan 44 and controller 46 are housed. The inlet port 50 may be routed to the canister assembly 14 on a first side of the filter system 16 while the outlet port 52 may be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com