Cellulosic and para-aramid pulp and processes of making same

a technology of para-aramid and cellulosic, which is applied in the field of cellulosic and para-aramid pulp, and can solve the problems of asbestos replacement products that do not perform as well as asbestos in one way, products that are not adequately used, and cost significantly more than currently commercial products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

I. First Embodiment of the Inventive Process

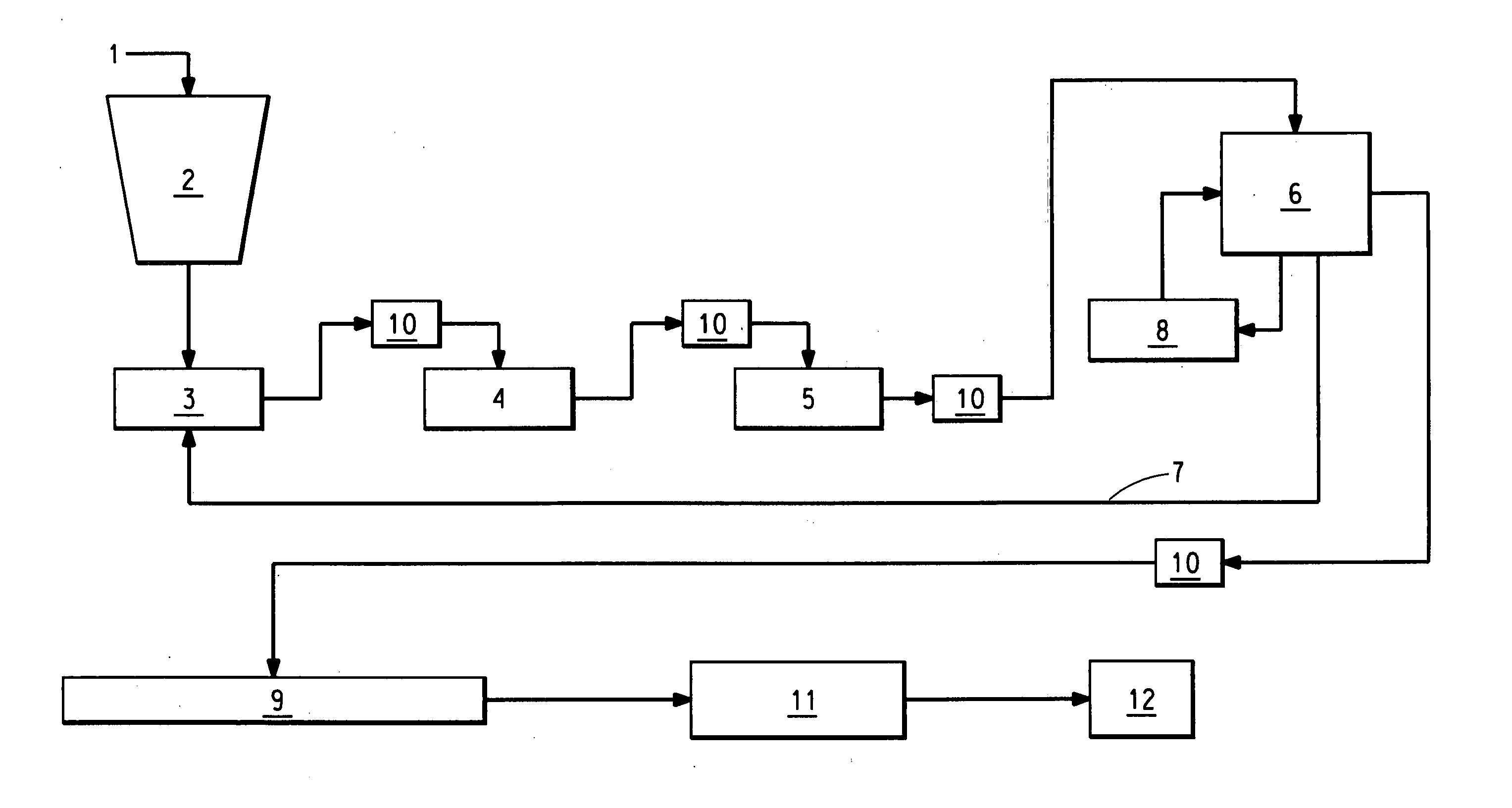

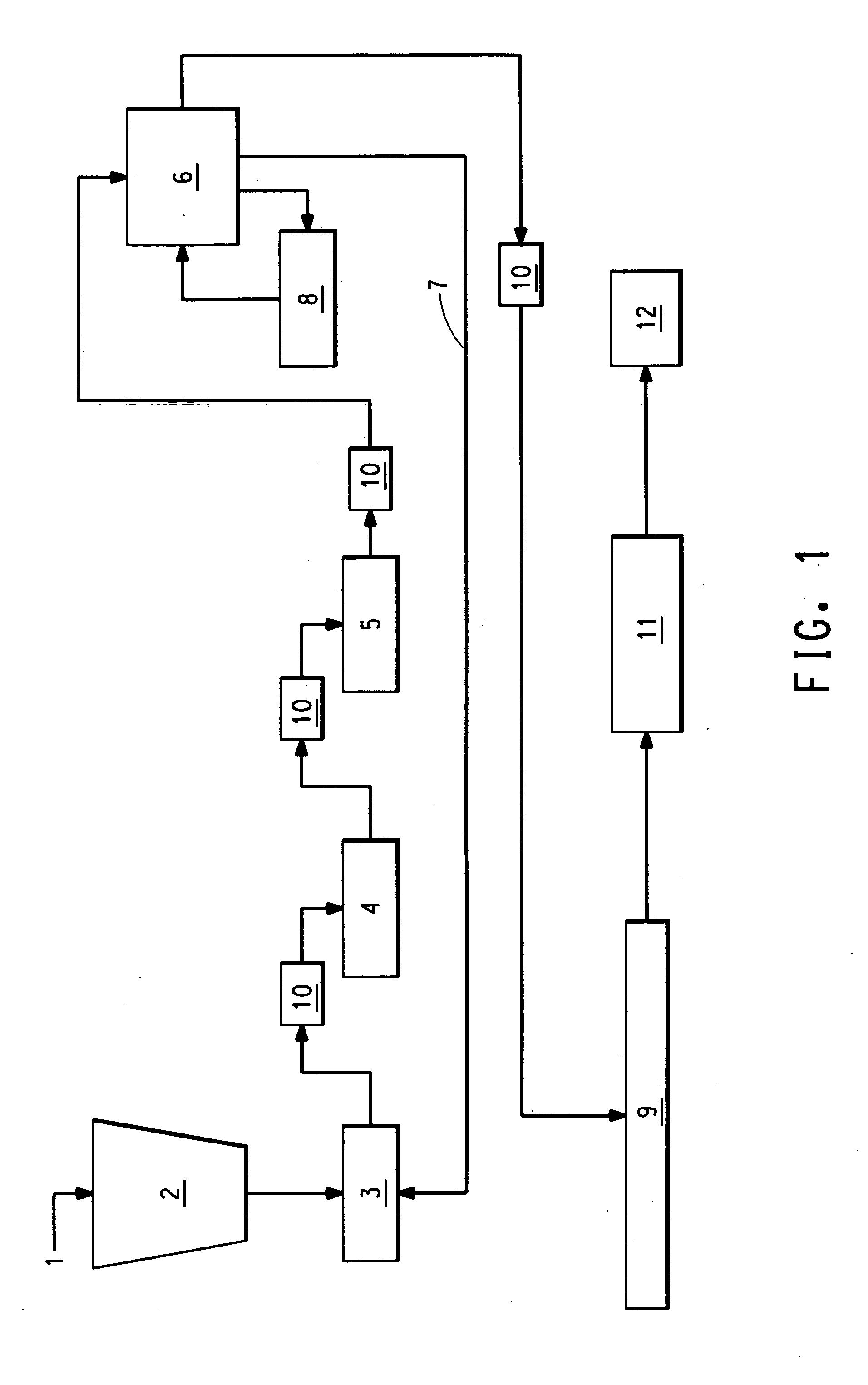

[0055] In a first embodiment, the process for making a cellulosic and para-aramid pulp comprises the following steps. First, pulp ingredients are combined, added or contacted together. Second, the combined pulp ingredients are mixed to a substantially uniform slurry. Third, the slurry is simultaneously refined or co-refined. Fourth, water is removed from the refined slurry.

Combining Step

[0056] In the combining step, the pulp ingredients are preferably added together in a container. The pulp ingredients include (1) cellulosic fiber, (2) para-aramid fiber, (3) optionally substantially or completely fibril-free, granular, para-aramid particles, (4) optionally other minor additives, and (5) water.

Cellulosic Fiber

[0057] The cellulosic fiber is added to a concentration of 10 to 90 wt % of the total solids in the ingredients, preferably 25 to 60 wt % of the total solids in the ingredients, and most preferably 25 to 55 wt % of the total solid...

second embodiment

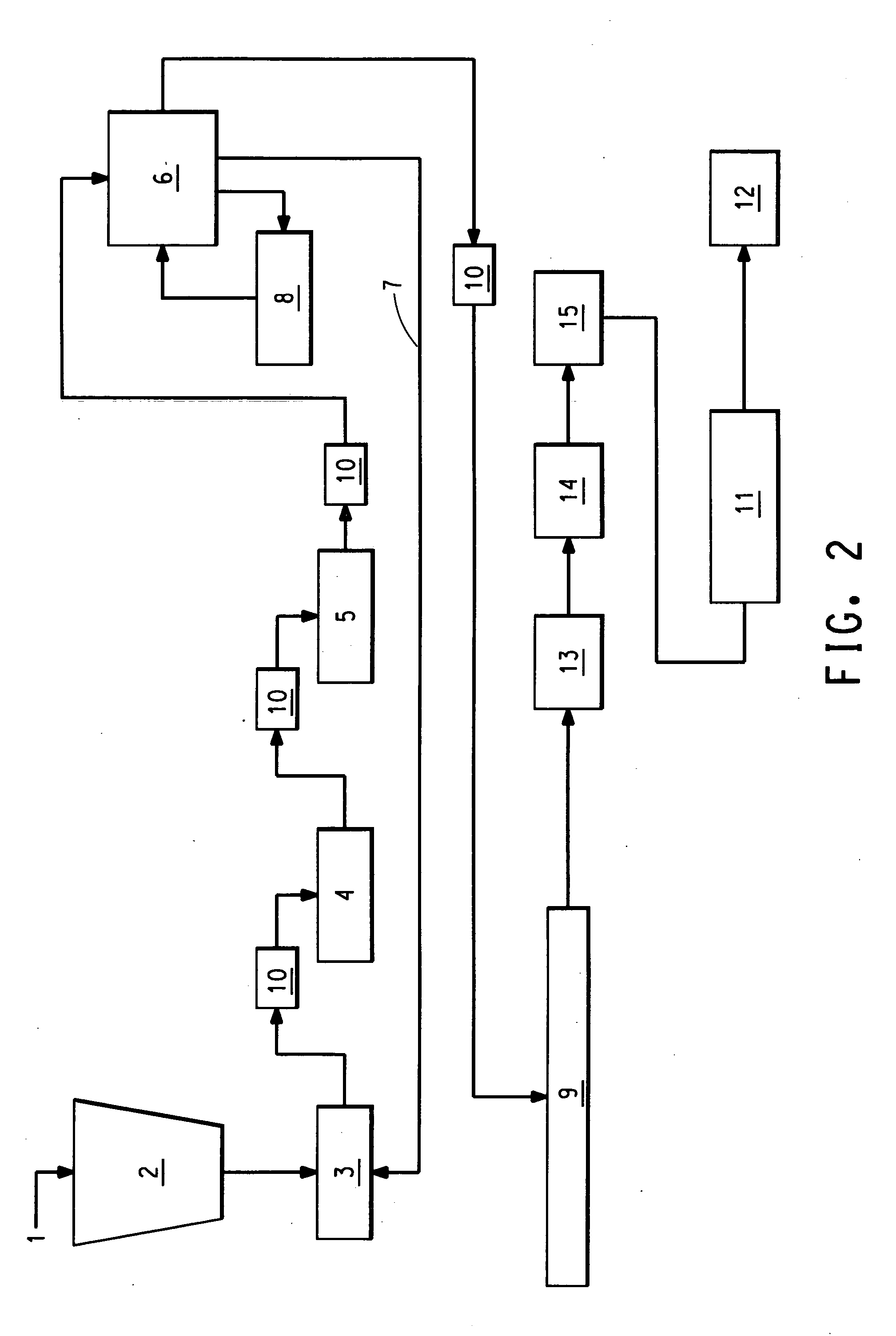

II. Second Embodiment of the Inventive Process

[0073] In a second embodiment, the process for making the cellulosic fiber and para-aramid pulp is the same as the first embodiment of the process described above with the following differences.

[0074] Prior to combining all ingredients together, either the cellulosic fiber or the para-aramid fiber, or both the cellulosic fiber and the para-aramid fiber, may need to be shortened. This can be done by combining water with either the cellulosic fiber or the para-aramid fiber. Then the water and fiber can be mixed to form a first suspension and processed through a first disc refiner to shorten the fiber. The refiner cuts the fiber to have an average length of no more than 10 cm, The refiner will also partially fibrillate and partially masticate the fiber. The other fiber, that was not previously added, can optionally be shortened this way too forming a second processed suspension. Then the other fiber having an average length of no more than...

example 1

[0100] In this example of the invention, the pulp of this invention was produced from a feedstock of para-aramid fiber and cellulosic staple. VISIL® brand staple having a cut length of 2 inches and having a filament linear density of 3 dpf (3.3 dtex per filament) was obtained from Sateri Oy of Finland. Para-aramid fiber in the form of commercially available KEVLAR® brand floc, Style 1F178, having a ¼″ cut length, was obtained from E. I. de Pont de Nemours and Company with offices in Wilmington, Del., USA.

[0101] The cellulosic staple, para-aramid fiber, and water were fed simultaneously into a highly agitated tank and then simultaneously pumped through a Sprout-Waldron 12″ Single Disc Refiner for approximately five (5) minutes. Cellulosic staple and water together were fed directly into a Sprout-Waldron 12″ Single Disc Refiner using a 3 mil plate gap setting and pre-pulped to reach an acceptable processing length in the range of 13 mm.

[0102] The pre-pulped cellulosic fiber and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com