Method of manufacturing a tank of thermoplastic material including a portion in relief for mounting an attachment, and a tank manufactured thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

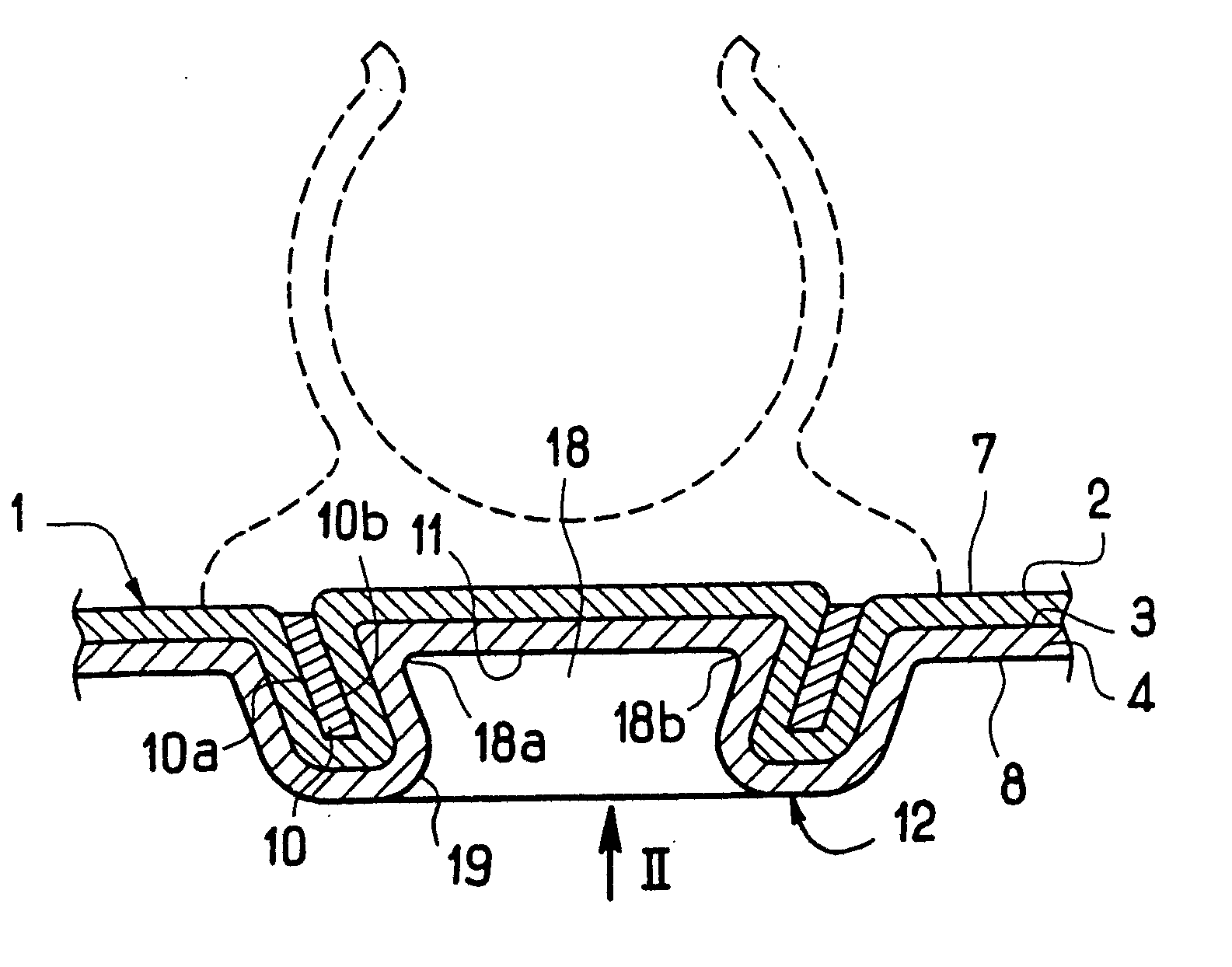

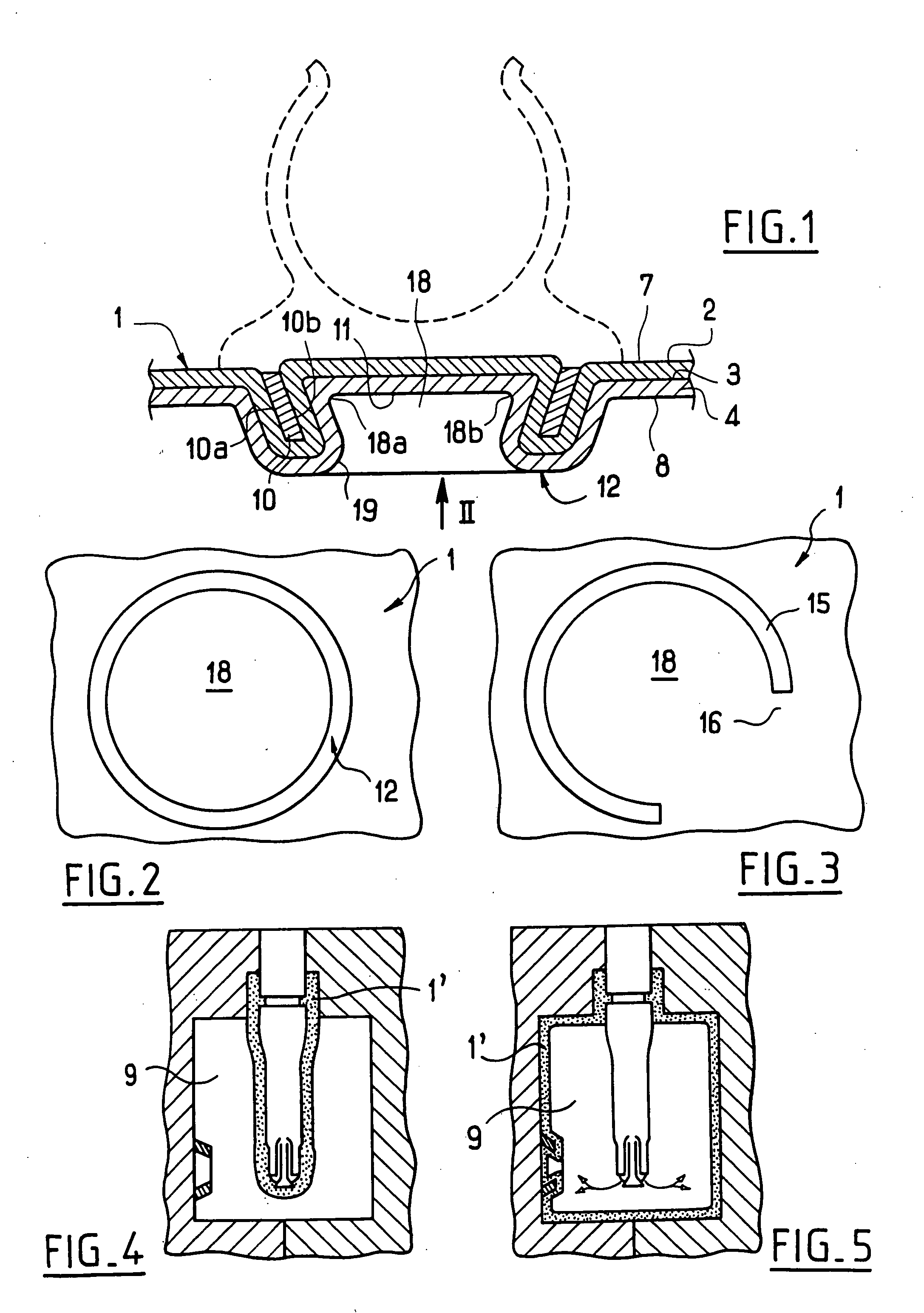

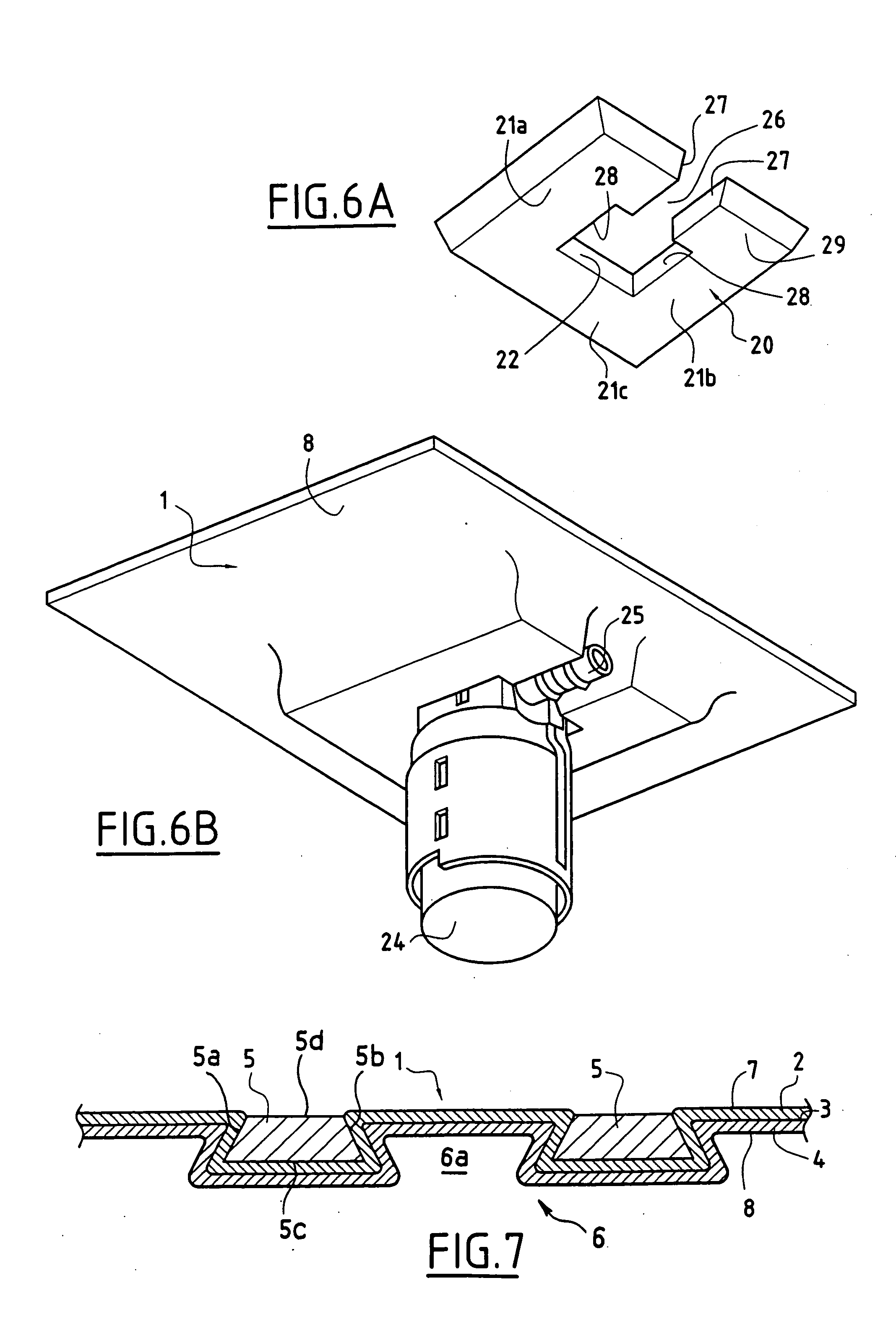

[0069]FIG. 1 shows a portion of the wall 1 of the body of a motor vehicle fuel tank.

[0070] This wall 1 has a multi-layer structure, comprising in succession: an outer layer 2 which defines practically the entire outside face 7 of the tank (and made of polyethylene in this example); an intermediate layer 3 forming a barrier against hydrocarbons (and made of EVOH in this example; and an inner layer 4 defining the inside face 8 of the tank (and made of polyethylene in this example).

[0071] In the embodiment described, the multi-layer structure includes a layer of adhesive between each inner or outer layer 4 or 2 and the intermediate layer 3 in order to improve the cohesion of the tank as a whole.

[0072] In this embodiment, an annularly shaped insert 10 is integrated in the wall 1 of the tank.

[0073] The insert 10 it used for providing mounting means 12 defining a housing 18 inside the tank and having an opening 19 of smaller diameter than its end wall 11.

[0074] The housing 18 is desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat | aaaaa | aaaaa |

| Thermoplasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com