Microplate storage apparatus and method

a micro-plate and storage device technology, applied in the direction of supporting apparatus, chemistry apparatus and processes, domestic applications, etc., can solve the problems of a significant fraction of the total cost of the crystallizer, the manual process of protein crystallization experiments is labor and time-intensive, and the crystallization rate is often very slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will now be described with reference to the drawing figures, in which like reference numerals refer to like parts throughout. An embodiment in accordance with the present invention provides a way to store microplates in a high density and cost effective manner in a complex instrument. Furthermore, some embodiments also provide a way to determine the position, alignment and registration of a microplate storage hotel relative to other hotels and to the instrument's frame.

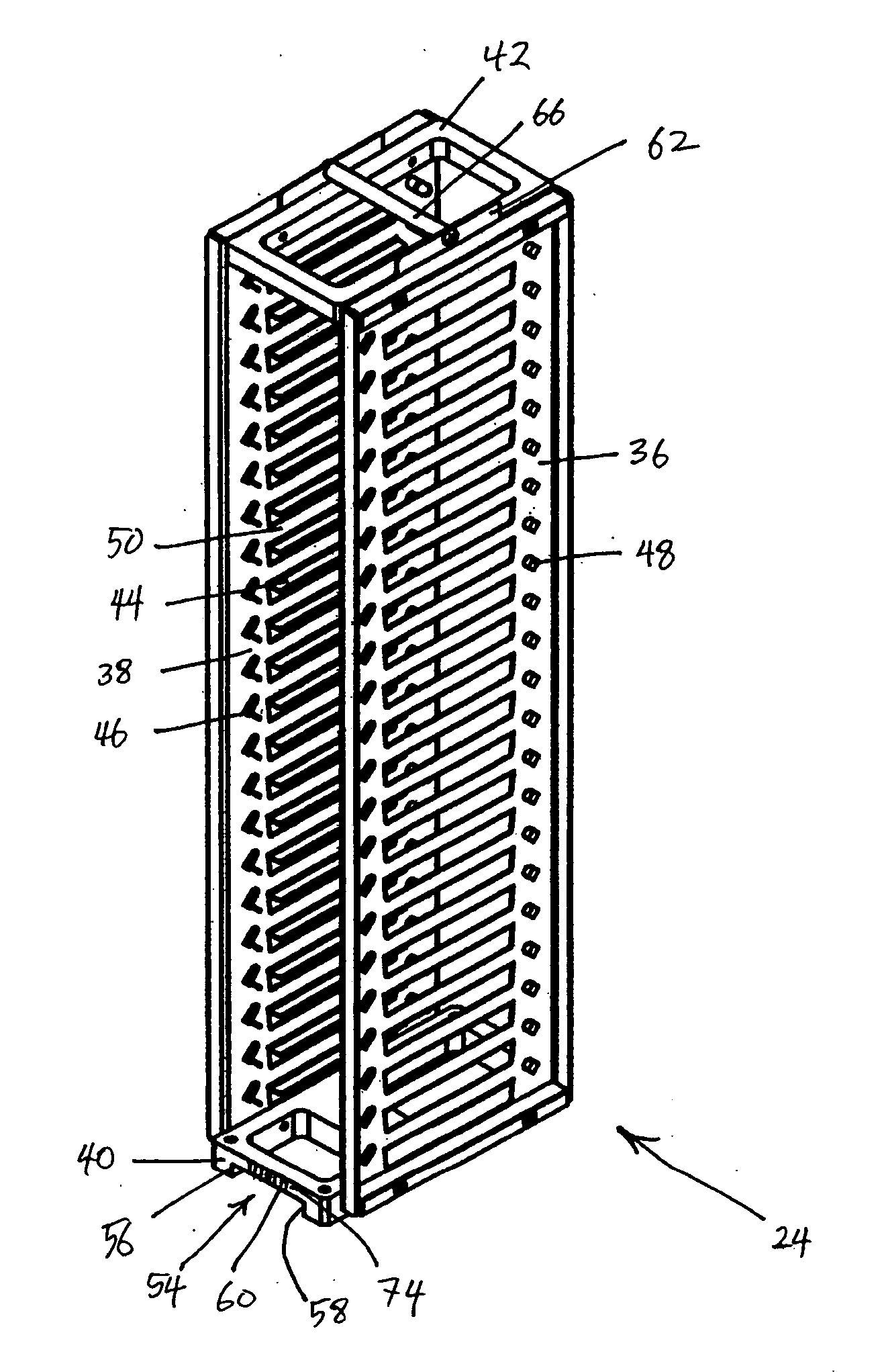

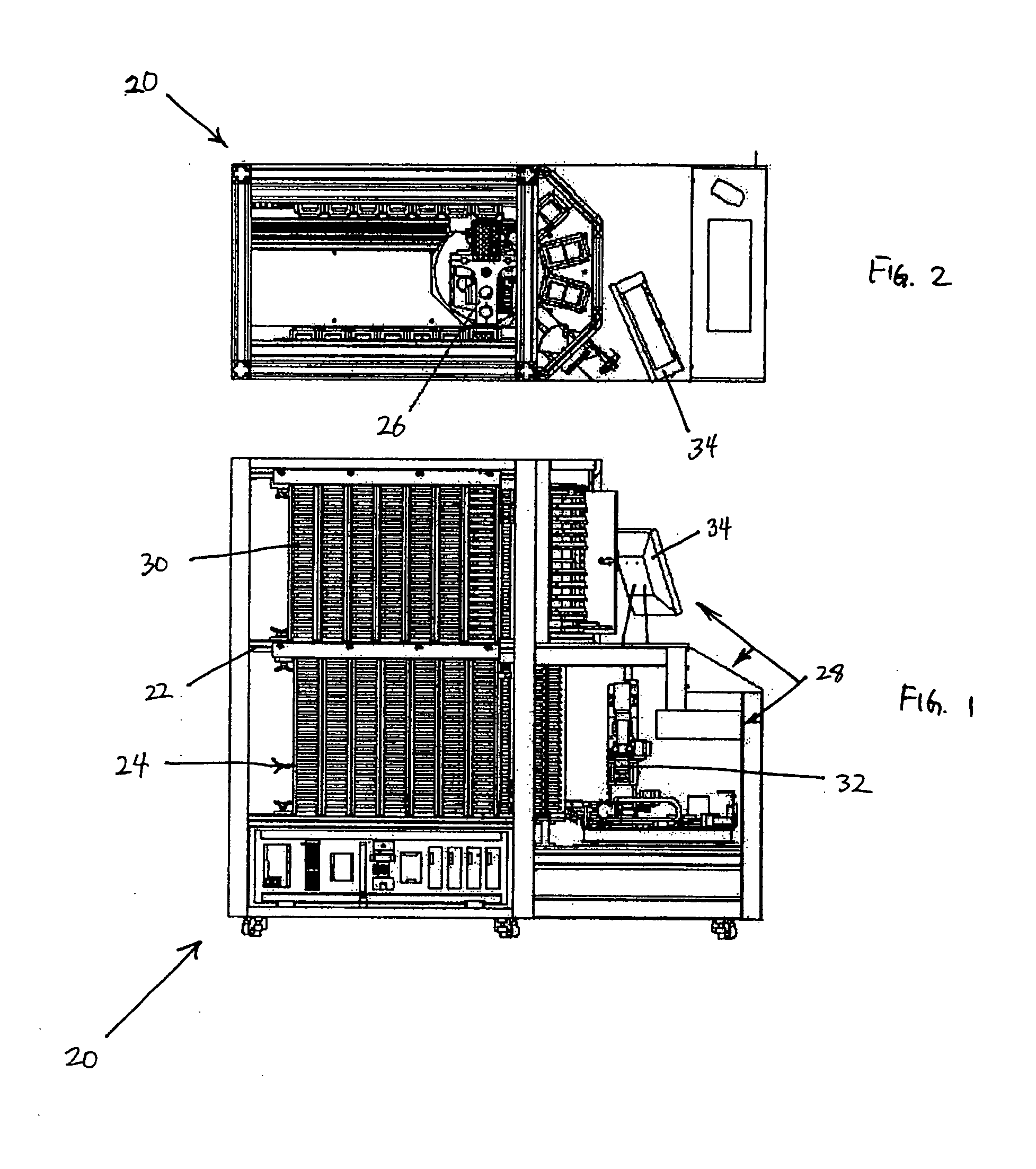

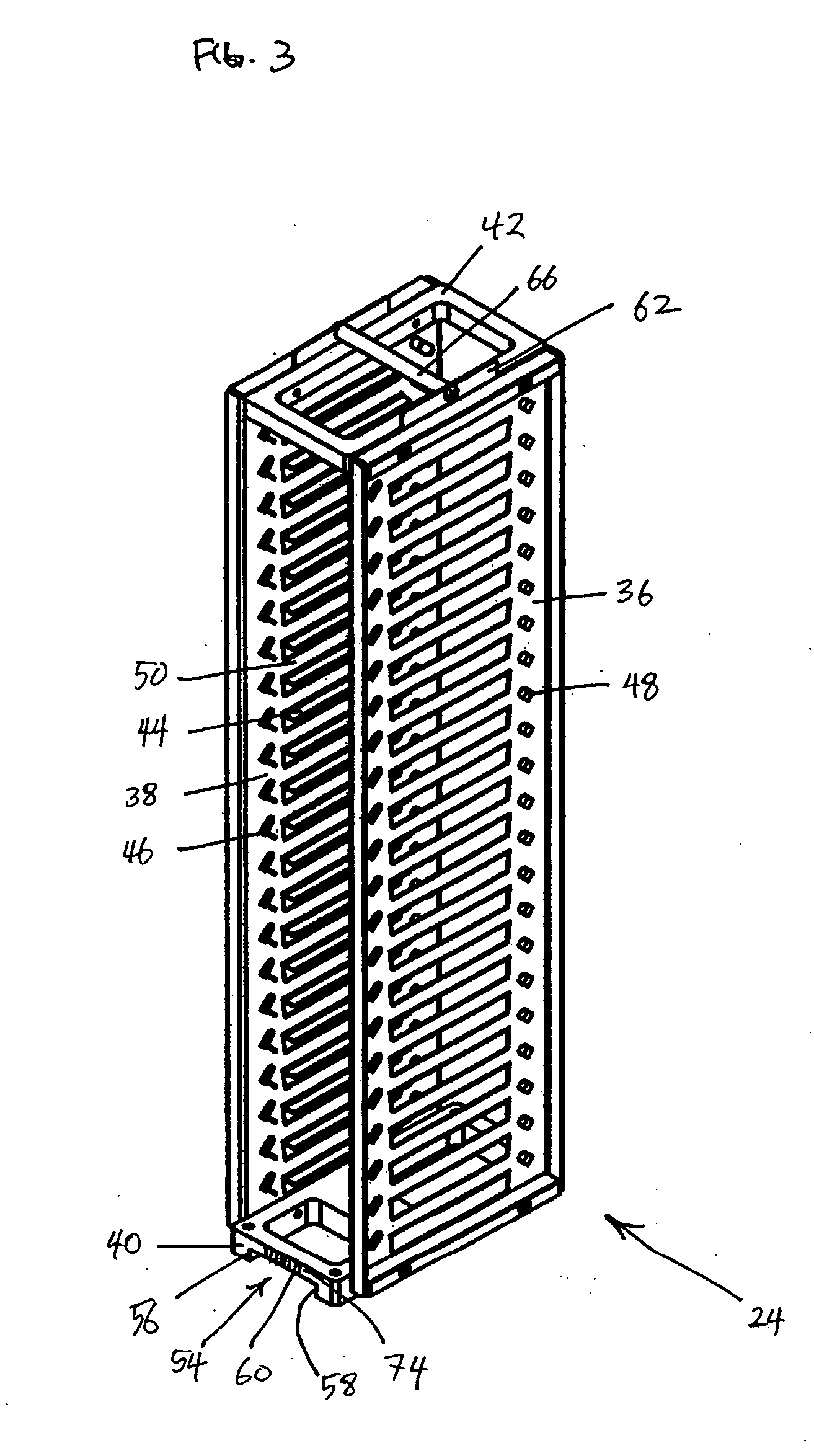

[0026]FIG. 1 shows a side view of an automated plate storage and imaging apparatus 20 for protein crystallization. The apparatus 20 has a system frame 22 that supports the housing of multiple microplate storage hotels 24. A robotic microplate handler 26 shown in FIG. 2, controlled by a computer system 28, is used to transfer a microplate 30 to the imager 32. The computer system 28 has a monitor 34 and is used to analyze the data collected by the imager 32. The imager 32 can take images under brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com