Controlled release metformin compositions

a composition and metformin technology, applied in the field of oral dosage, can solve the problems of no fixed dosage regimen, little research in the field of controlled or sustained release compositions that employ antihyperglycemic drugs, etc., and achieve the effect of effective control of blood glucose levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

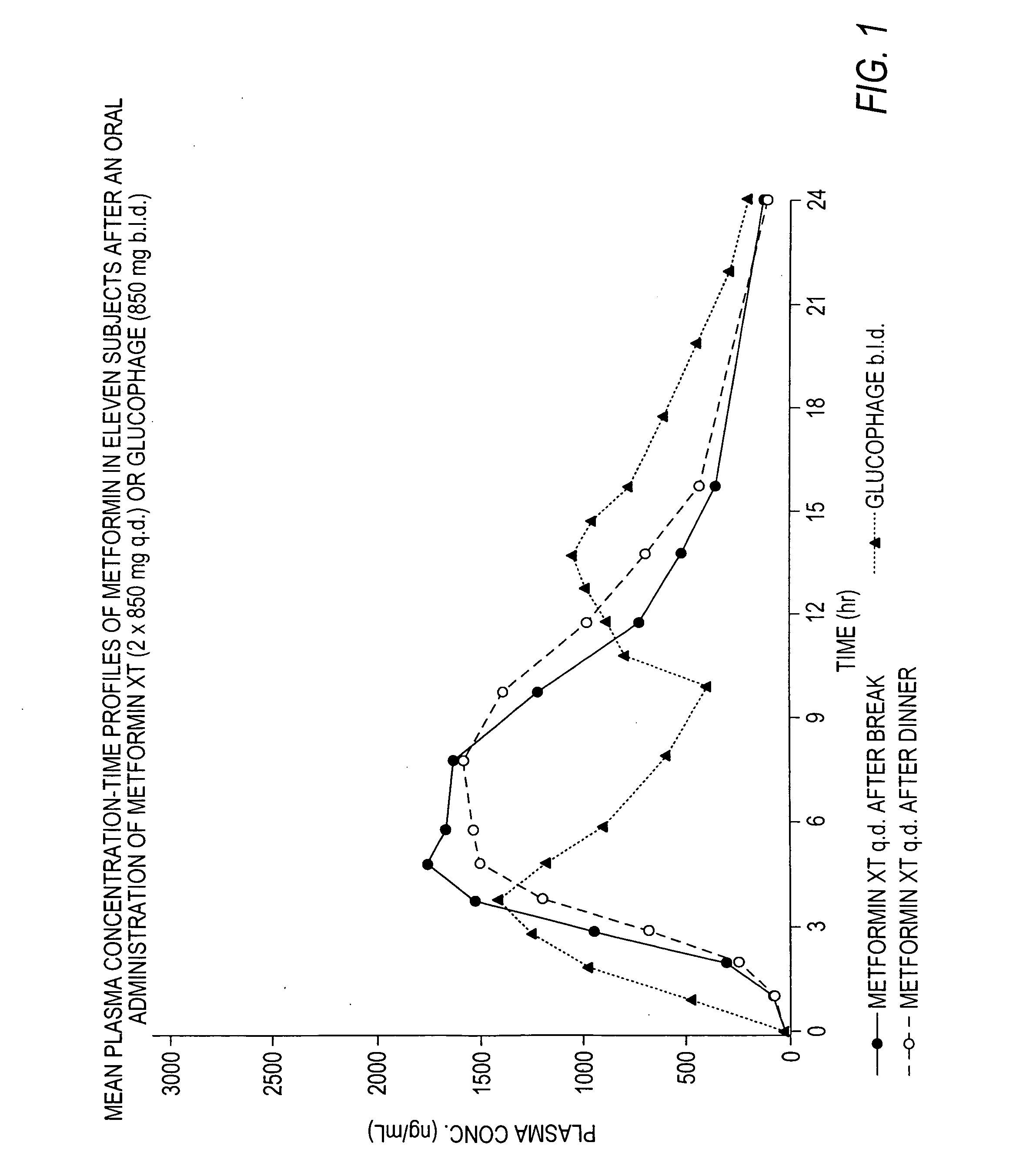

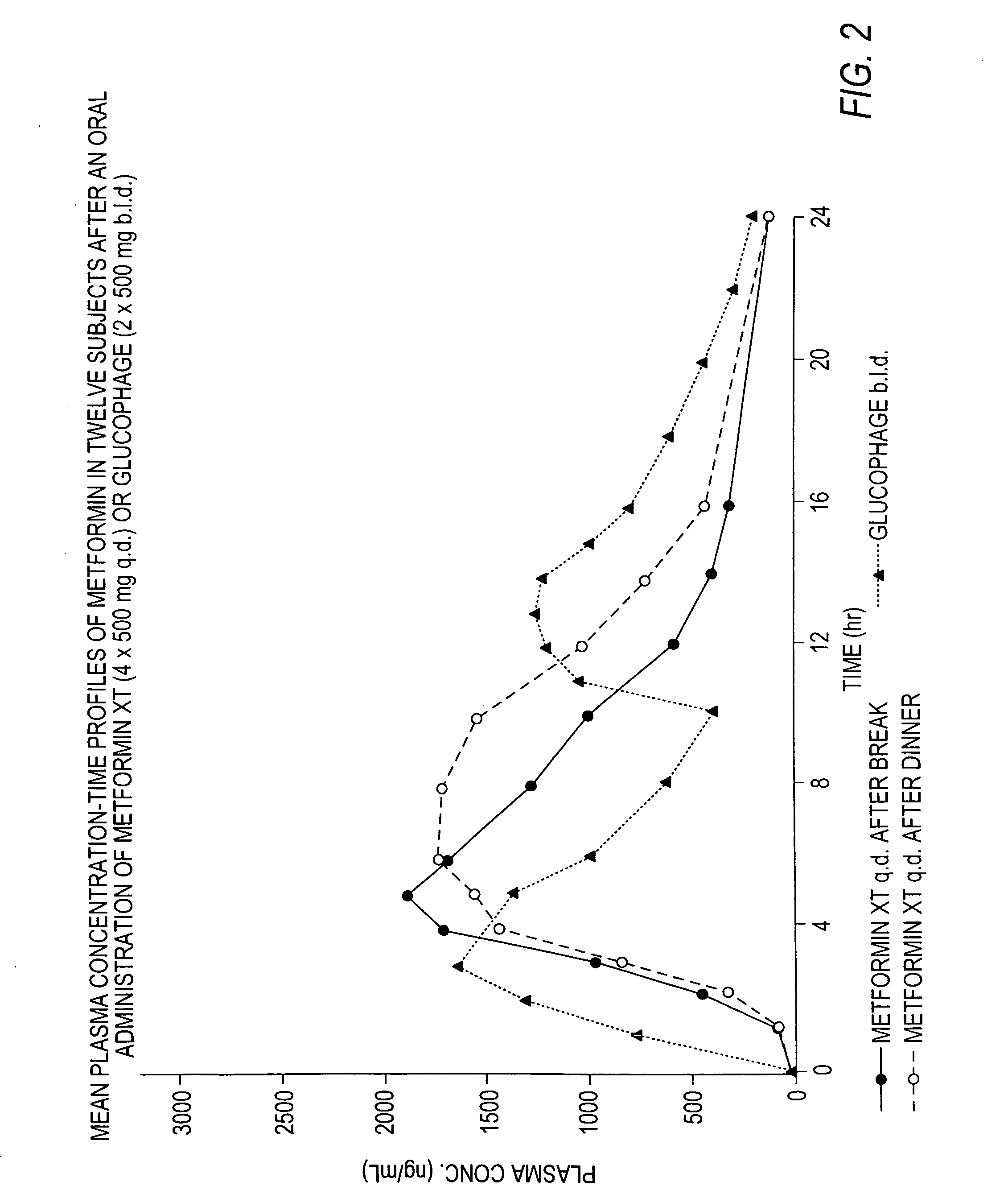

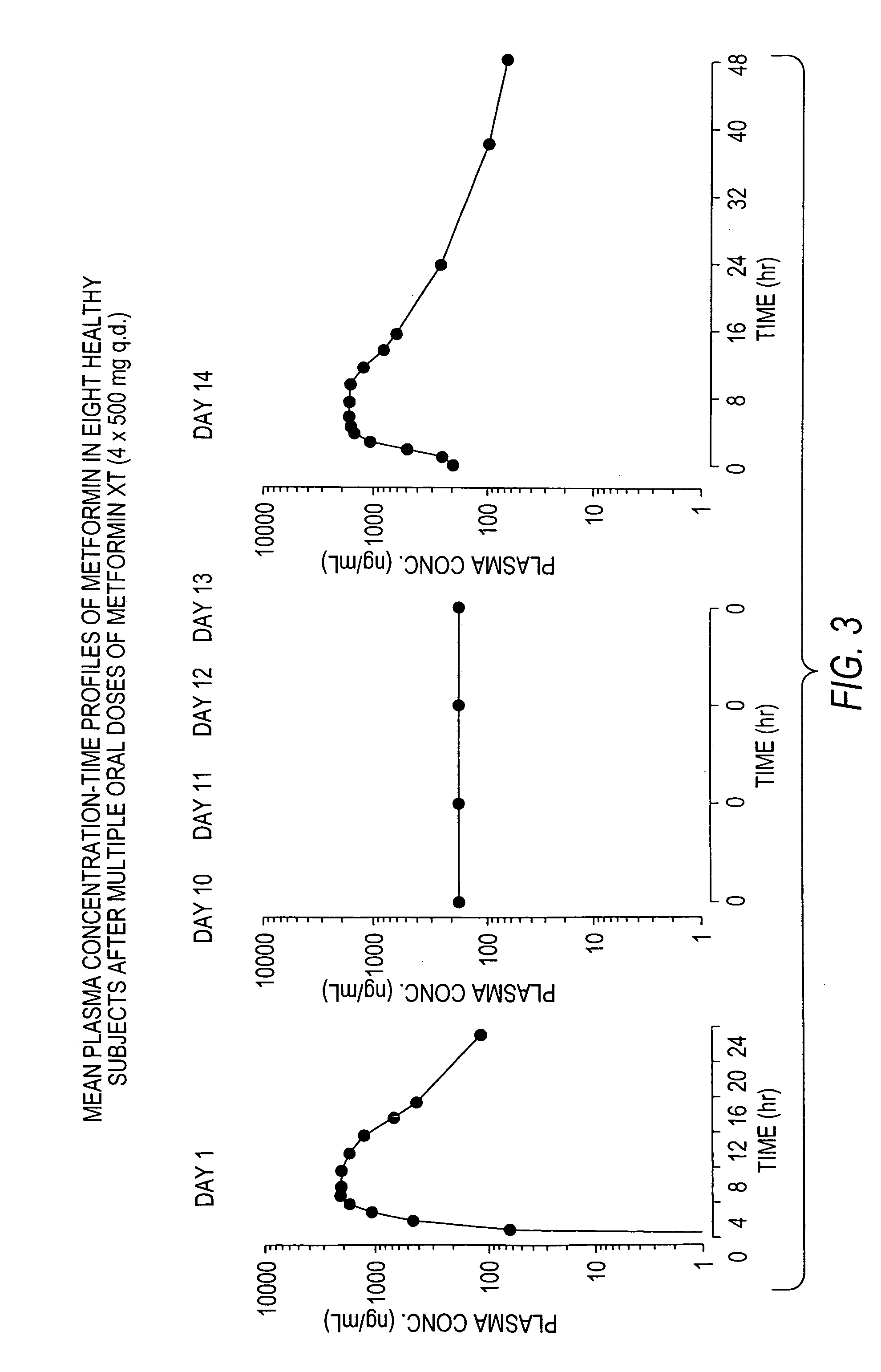

Image

Examples

example 1

[0117] A controlled release tablet containing 500 mg of metformin HCl and having the following formula is prepared as follows:

I. CoreIngredientsAmount (mg / tab)Metformin HCl500.0Povidone3, USP36.0Sodium Lauryl Sulfate25.8Magnesium Stearate2.8

3approximate molecular weight = 1,000,000; dynamic viscosity (10% w / v solution at 20° C.) = 300-700 m Pa s.

[0118] (a) Granulation

[0119] The metformin HCl and sodium lauryl sulfate are delumped by passing them through a 40 mesh screen and collecting them in a clean, polyethylene-lined container. The povidone, K-90-F is dissolved in purified water. The delumped metformin HCl and sodium lauryl sulfate are then added to a top-spray fluidized bed granulator and granulated by spraying with the binding solution of povidone under the following conditions: inlet air temperature of 50-70° C.; atomization air pressure of 1-3 bars; and spray rate of 10-100 m / min.

[0120] Once the binding solution is depleted, the granules are dried in the granulator until...

example 2

[0128] A controlled release tablet containing 850 mg of metformin HCl and having the following formula is prepared as follows:

I. CoreIngredientsAmount (mg / tab)Metformin HCl850.0Povidone3, USP61.1Sodium Lauryl Sulfate43.9Magnesium Stearate4.8

3approximate molecular weight = 1,000,000; dynamic viscosity (10% w / v solution at 20° C.) = 300-700 m Pa s.

[0129] (a) Granulation

[0130] The metformin HCl and sodium lauryl sulfate are delumped by passing them through a 40 mesh screen and collecting them in a clean, polyethylene-lined container. The povidone, K-90-F is dissolved in purified water. The delumped metformin HCl and sodium lauryl sulfate are then added to a top-spray fluidized bed granulator and granulated by spraying with the binding solution of povidone under the following conditions: inlet air temperature of 50-70° C.; atomization air pressure of 1-3 bars; and spray rate of 10-100 m / min.

[0131] Once the binding solution is depleted, the granules are dried in the granulator until...

example 3

[0139] A controlled release tablet containing 1000 mg of metformin HCl and having the following formula is prepared as follows:

I. CoreIngredientsAmount (mg / tablet)Metformin HCl1000.0Povidone3, USP71.9Sodium Lauryl Sulfate51.7Magnesium Stearate5.6

3approximate molecular weight = 1,000,000; dynamic viscosity (10% w / v solution at 20° C.) = 300-700 m Pa s.

[0140] (a) Granulation

[0141] The metformin HCl and sodium lauryl sulfate are delumped by passing them through a 40 mesh screen and collecting them in a clean, polyethylene-lined container. The povidone, K-90-F is dissolved in purified water. The delumped metformin HCl and sodium lauryl sulfate are then added to a fluidized bed granulator and granulated by spraying with the binding solution of povidone under the following conditions: inlet air temperature of 50-70° C.; atomization air pressure of 1-3 bars; and spray rate of 10-100 ml / min.

[0142] Once the binding solution is depleted, the granules are dried in the granulator until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com