Axial field electric machine

a technology of axial field and electric machine, which is applied in the direction of magnetic circuits characterised by magnetic materials, magnetic circuit shapes/forms/construction, magnetic circuit rotating parts, etc., can solve the problems of motor performance not using materials, design steps or construction techniques, and poor efficiency of motor performance, so as to maximize efficiency and motor constant, reduce cost, and maximize efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

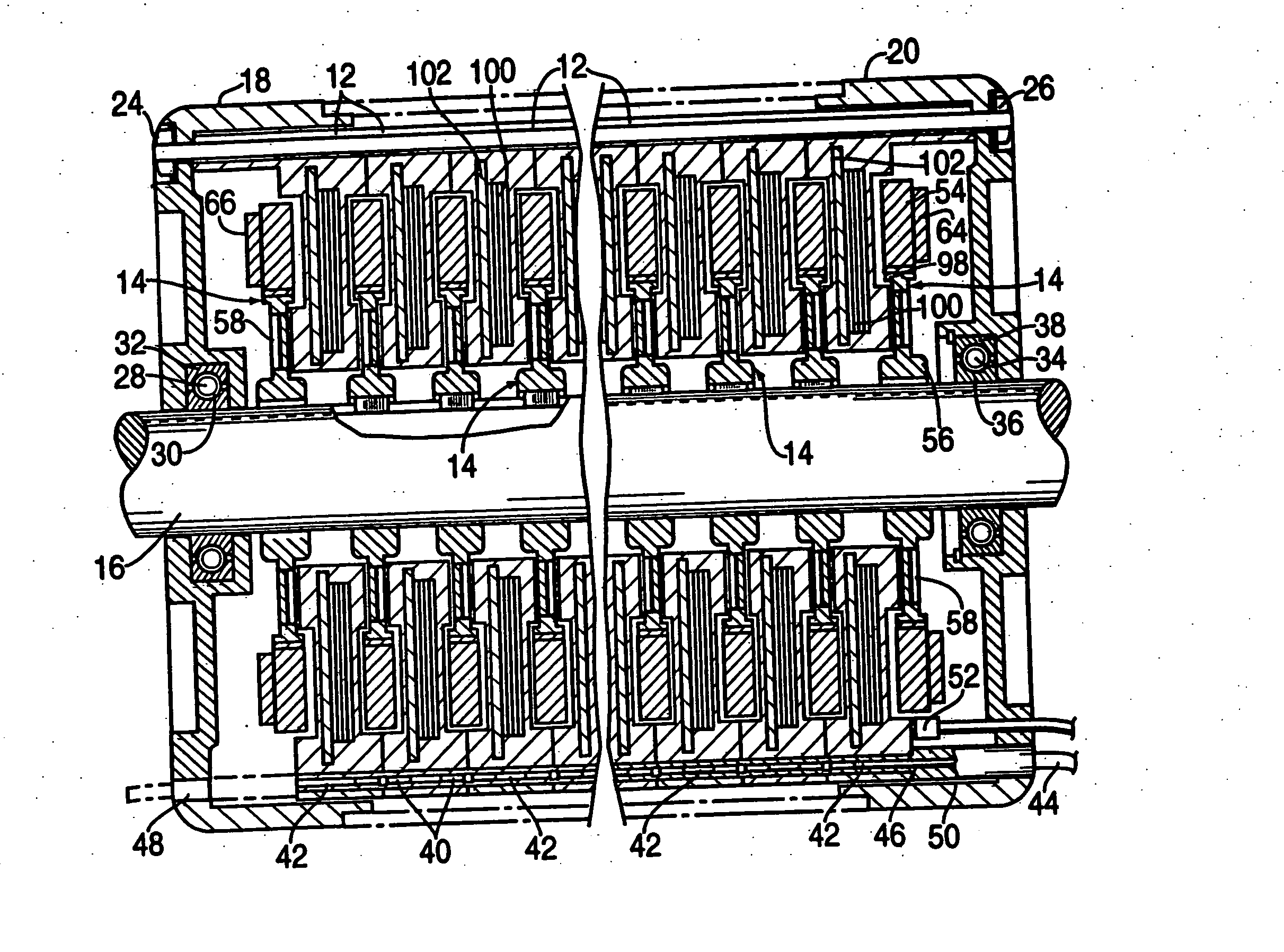

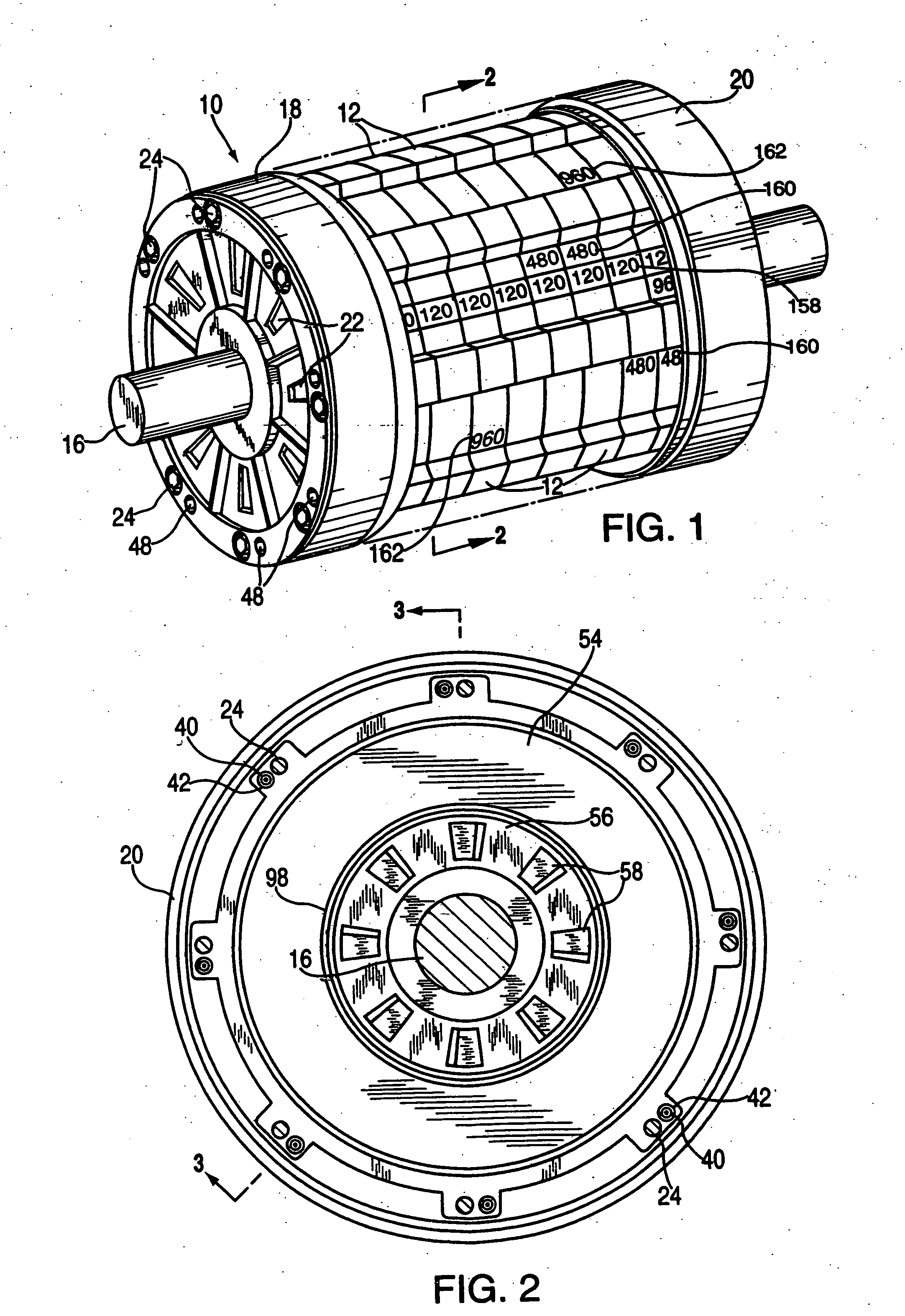

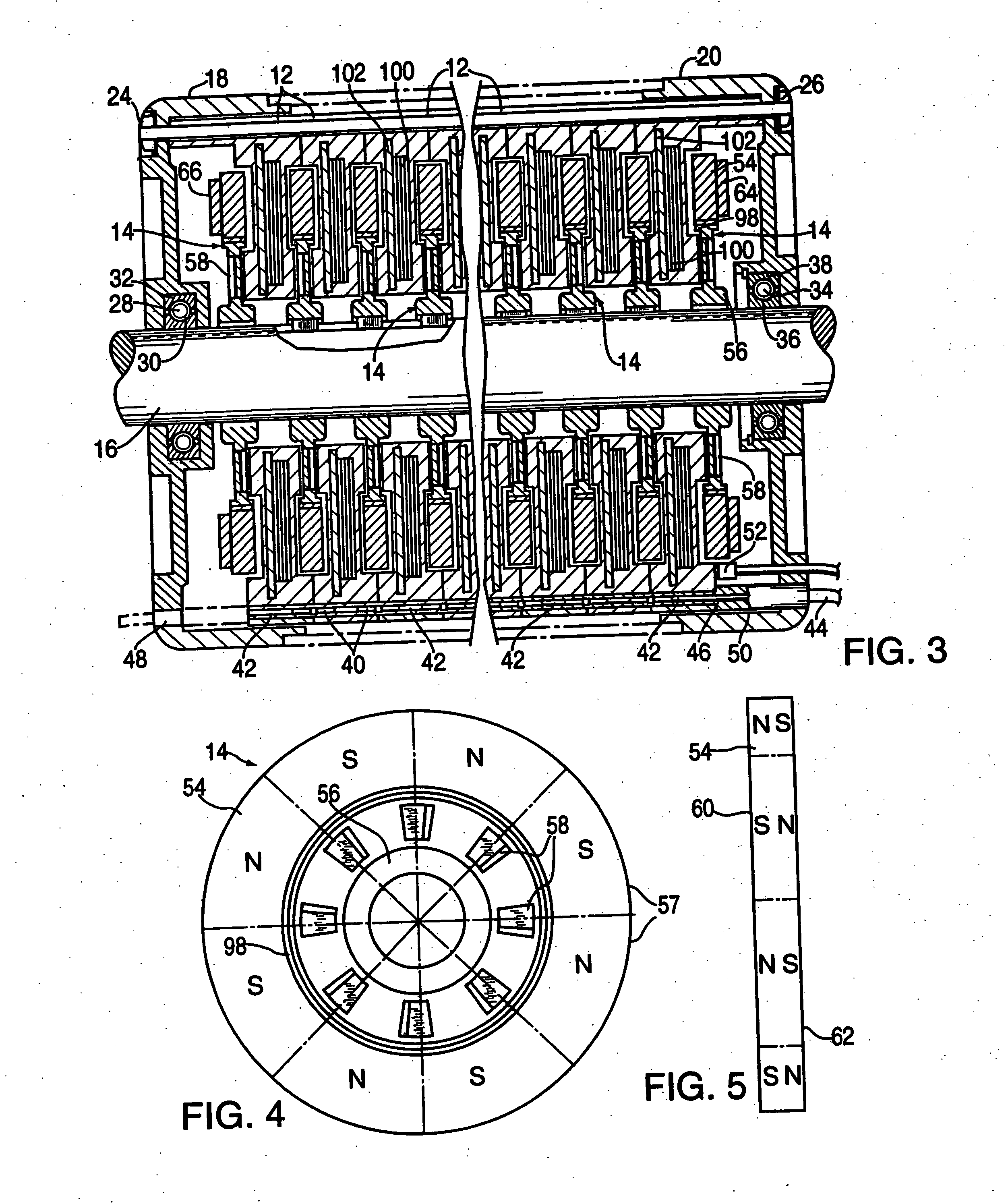

[0077] As illustrated in FIGS. 1-3, a first embodiment of the axial field electric machine designed according to an embodiment of the present invention is shown. The axial field electric machine includes a housing 10 (the center section of which is shown removed), multiple stator assemblies 12 (e.g., each including a conductor element similar to the one shown in FIG. 14) connected to one another and disposed within housing 10, and magnetic elements 14 (e.g., similar to the one shown in FIG. 4) connected to a shaft 16 that extends axially through housing 10. In this example, the conductor elements make up the stator of the electric machine and the magnetic elements make up the rotor. One skilled in the art will appreciate that in an alternative embodiment, conductor elements can serve as the rotor and the magnetic elements can serve as the stator in the electric machine.

[0078] Housing 10 includes two endpieces 18 and 20, each having multiple housing ventilation openings 22. Housing ...

second embodiment

[0089] A second embodiment of the electric machine of the present invention is shown in FIGS. 12, 27-29 using the conductor element of FIGS. 16-20. Referring to FIG. 12, a cross section of this axial field electric machine is shown. The axial field electric machine 200 is similar in construction to the electric machine of FIGS. 1 and 3. Electric machine 200 includes a plurality of magnetic elements 201, such as rotor disks, attached to a shaft 205. In this example, shaft 205 has a configuration similar to that which is shown in FIG. 9. Hubs of axially adjacent magnetic elements are separated by a ring separator 209. Electric machine 200 includes a plurality of conductor elements 202 and connector support elements 203, the construction of which is described in further detail below. As with the electric machine design of FIGS. 1 and 3, electric machine 200 has a modular design in that any number of conductor elements 202 (and connector support elements 203) and magnetic elements 201 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com