Method for controlling a vacuum packaging machine and vacuum packaging machine

a vacuum packaging machine and vacuum technology, applied in packaging, packaging protection, packaging under special atmospheric conditions, etc., can solve the problems of significant reduction in the efficiency of vacuum packaging machines, low accuracy of end results obtained by this method, and low accuracy of final pressure at the end of evacuation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

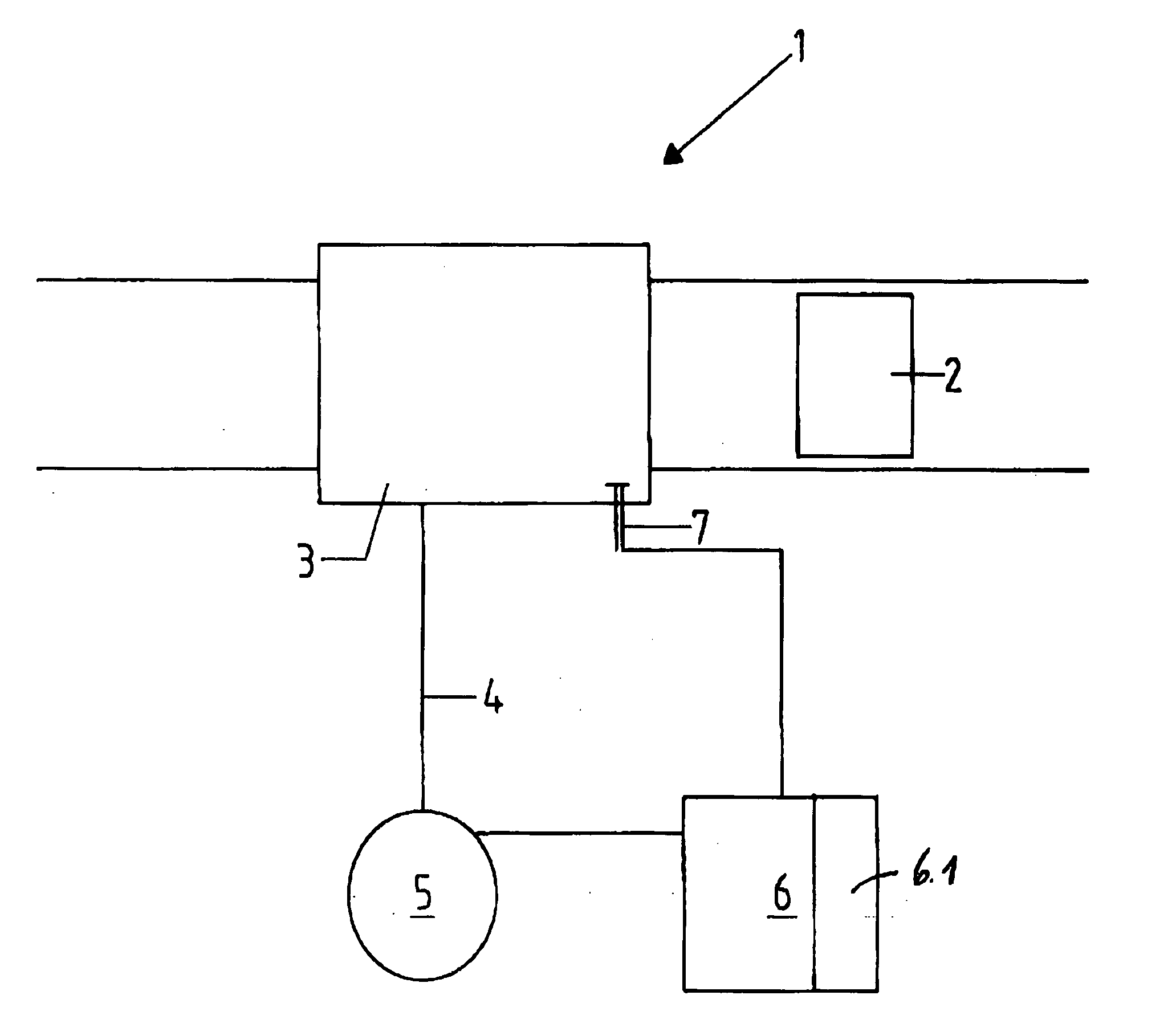

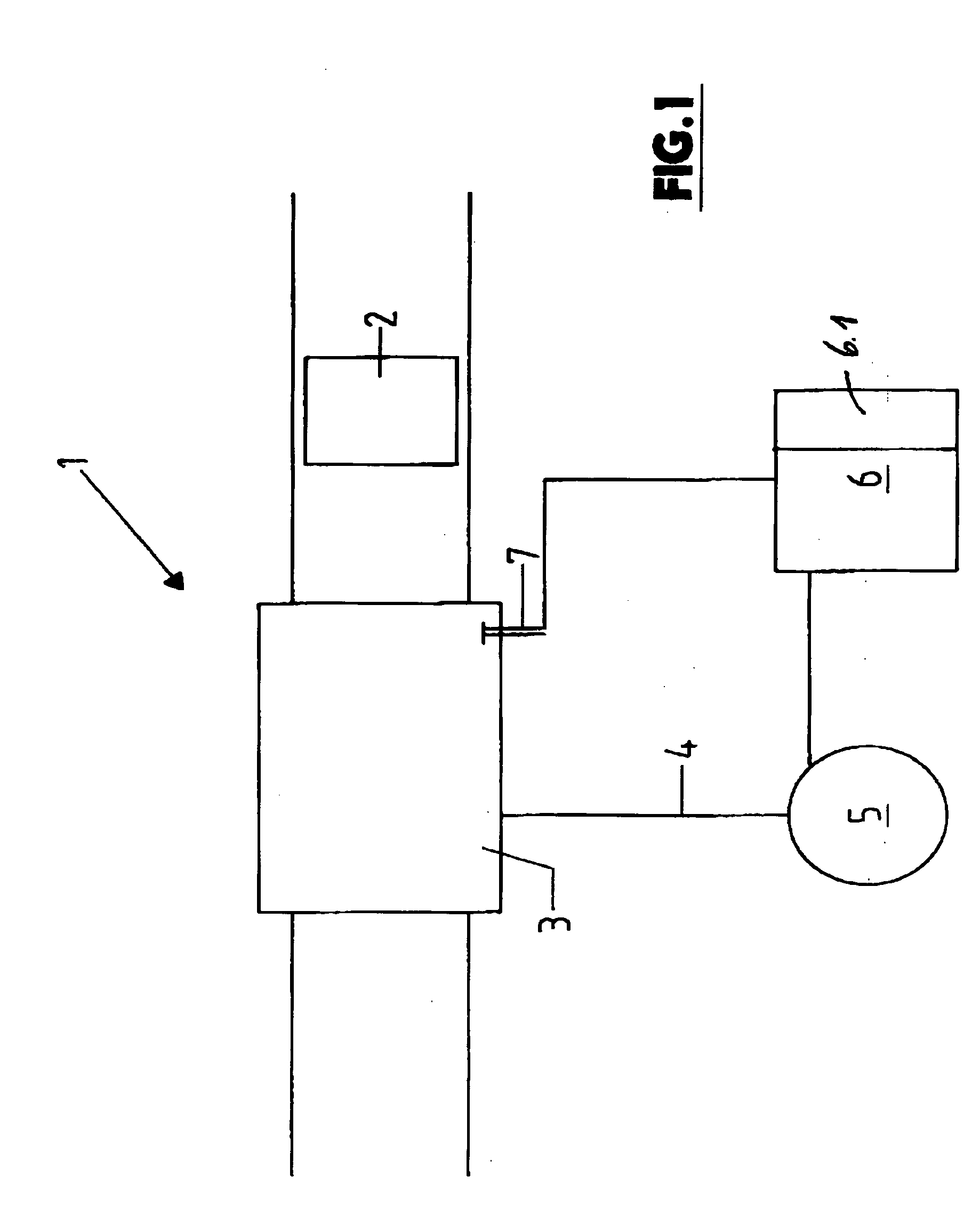

[0012] The vacuum packaging machine 1 depicted very schematically in FIG. 1 and used for packaging foods in vacuum-tight packages or containers 2, has a vacuum chamber 3 located in a packaging line, in which the containers 2 to be packaged are inserted and then sealed after evacuation. The vacuum chamber 3 is connected by means of a vacuum line 4 with a source for the vacuum, e.g. with a vacuum pump 5.

[0013] The evacuation time is controlled by means of an electronic analysis and control unit 6 and the signal of a pressure sensor 7, which in the depicted embodiment is provided at the vacuum chamber 3 and responds to the prevailing negative pressure in the vacuum chamber 3. Of course, the sensor 7 can also be located elsewhere, for example in the vacuum line 4 or in a separate measuring line connected with the interior of the chamber 3.

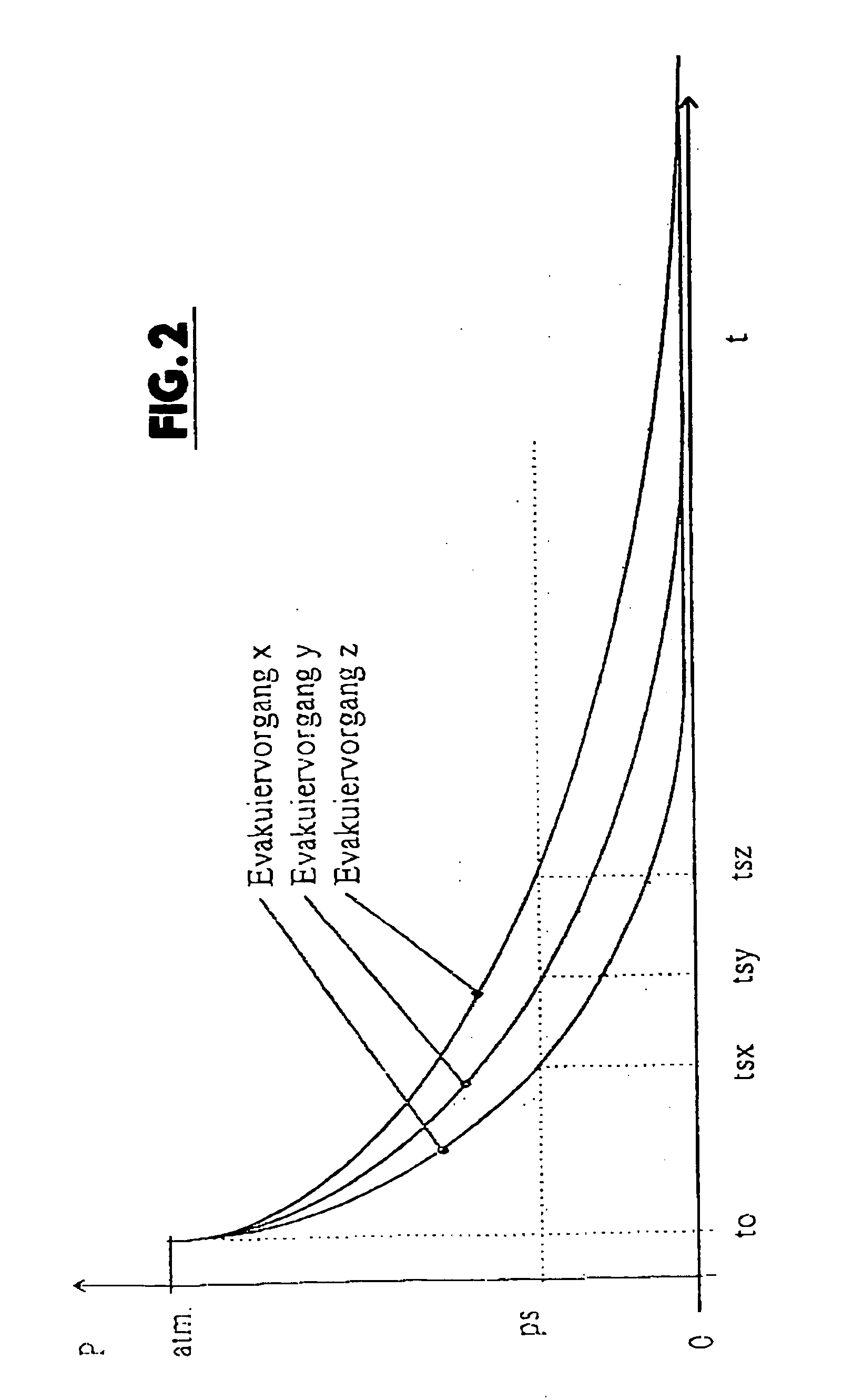

[0014] The sensor 7 is designed as a simple switch that responds to a negative pressure or a threshold pressure or a switching pressure ps and that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com