Ultrasonic optical cleaning system

a cleaning system and ultrasonic technology, applied in the direction of cleaning processes and apparatus, cleaning using liquids, instruments, etc., can solve the problems of user inconvenience, time-consuming and inefficient, and erroneous readings,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Other objects, features and advantages will occur from the following description of a preferred embodiment and the accompanying drawings, in which:

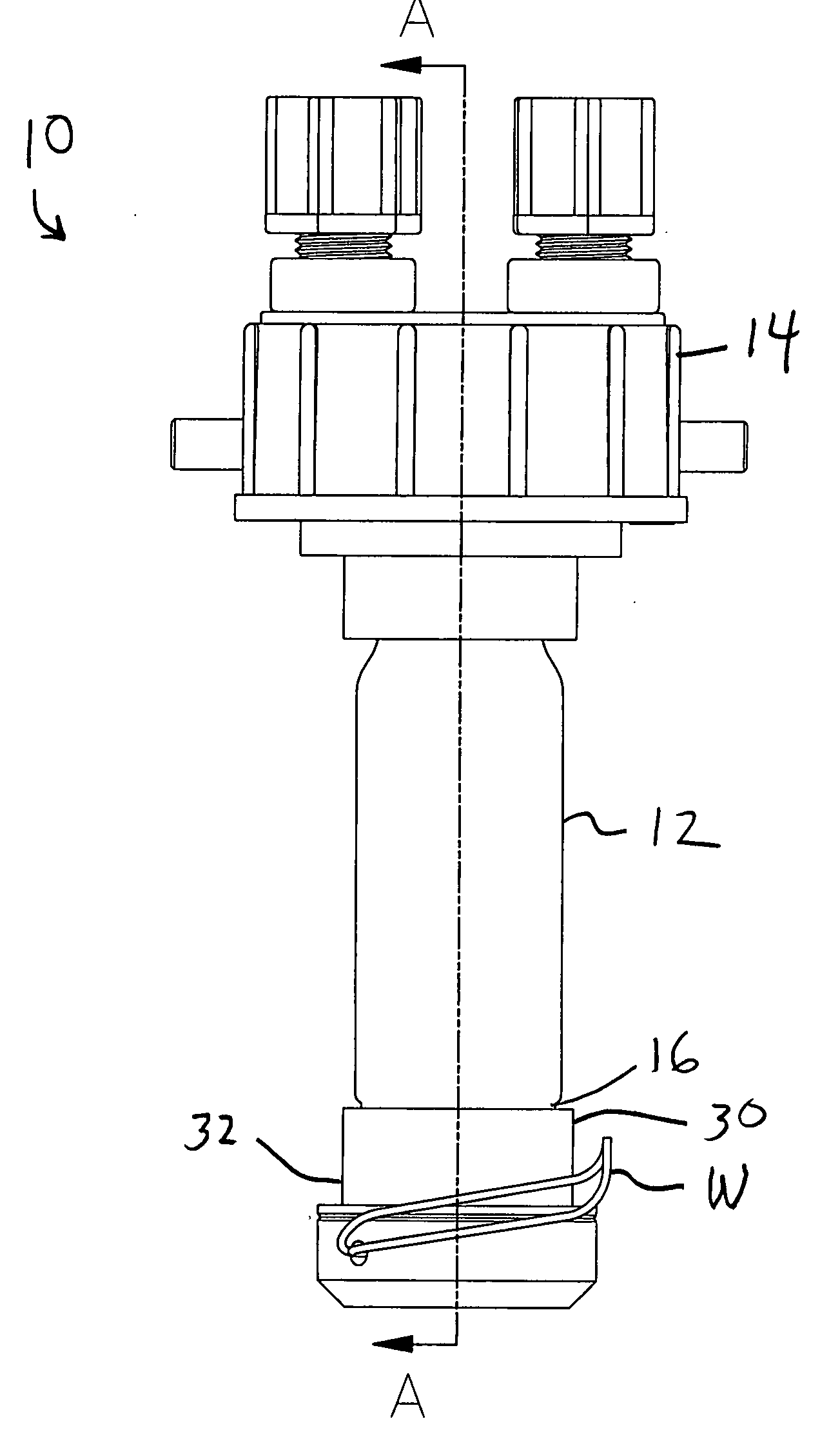

[0016]FIG. 1A is side elevational view of the ultrasonic optical cleaning system of this invention as used with a turbidimeter;

[0017]FIG. 1 B is a cross sectional view of the cleaning system;

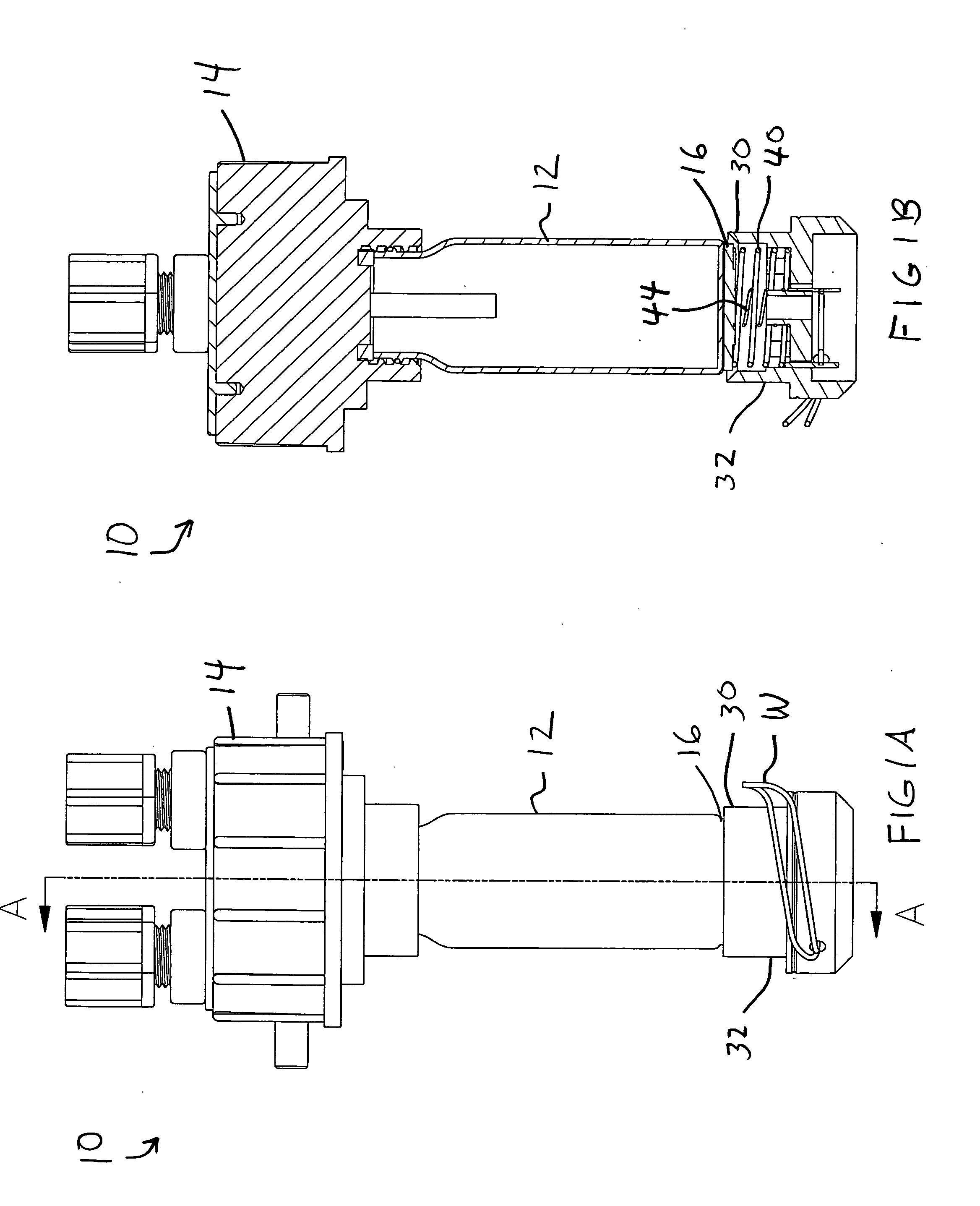

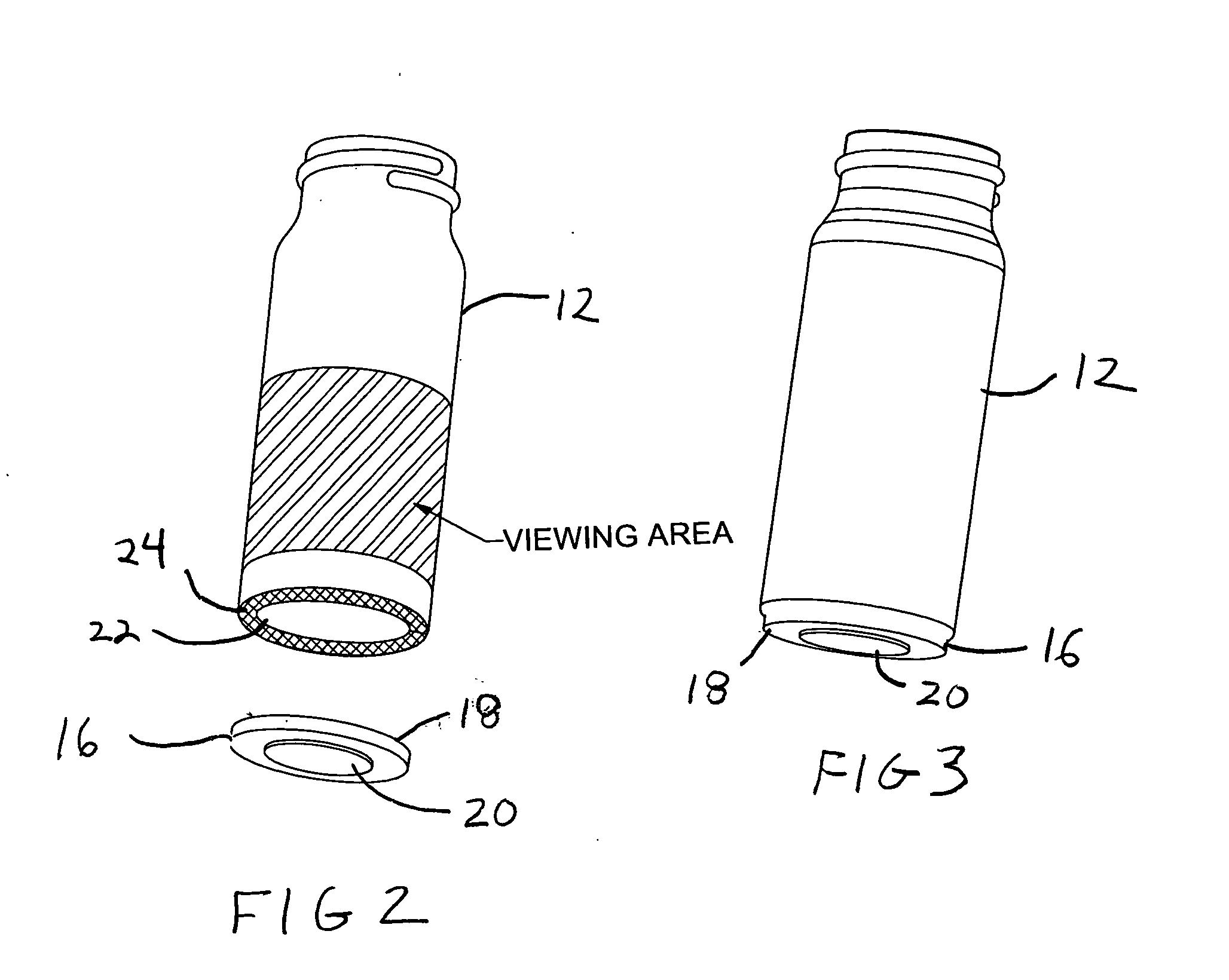

[0018]FIG. 2 is a perspective view of glassware comprising a cuvette and the ultrasonic transducer in position to be applied to the cuvette;

[0019]FIG. 3 is a view similar to FIG. 2 with the ultrasonic transducer bonded to a lower surface of glassware;

[0020]FIG. 4 is a perspective top view of the connector cap;

[0021]FIG. 4A is an exploded view of the connector cap;

[0022]FIG. 5 is a bottom perspective view of the connector cap;

[0023]FIG. 6 is a plan view of the upper, component side of the main printed circuit board employed in a turbidimeter featuring the cleaning system of this invention; the ultrasonic printed circuit board is depicted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com