Modular deck structure

a modular, deck technology, applied in the direction of stairs, floors, treads, etc., can solve the problems of difficult to combine wood and concrete, difficult to build, and difficult to build prior art patios,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

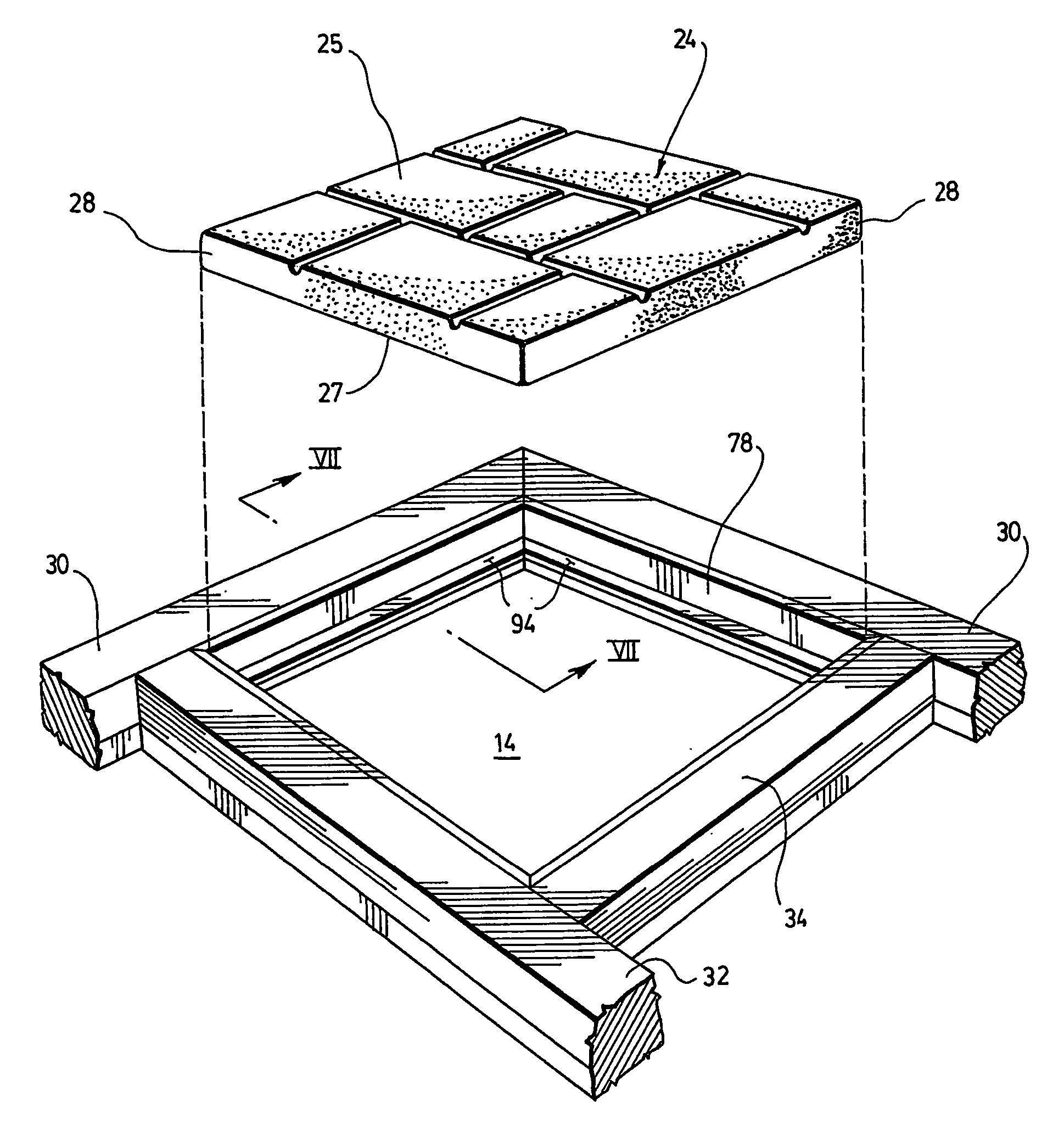

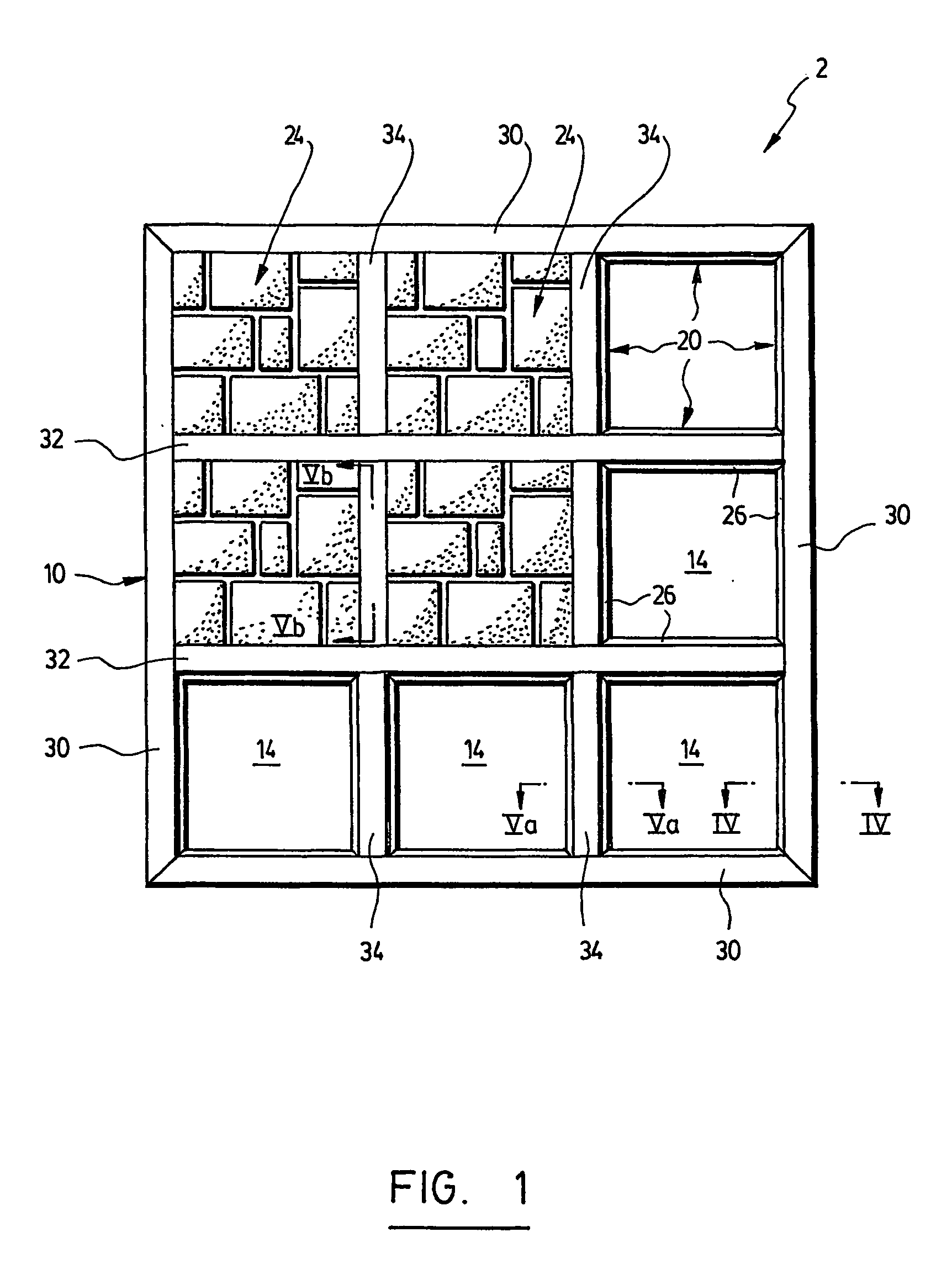

[0044] Referring to FIG. 9a, there is shown a first embodiment comprising the flagstones 24 having a sloping shape on their side edges 28. The sloping shape is complementary to the sloping portion 26 of the inner wall 20 of the cells 14. These side edges 28 are needed to conform the flagstones 24 to the inner wall 20. Since the sloping portion 26 is flaring upwardly, it provides a strong support to the flagstones 24. To have a nice looking deck, the height of the flagstones 24 must be approximately of the same height as the slanted side edges in order for the top edges 48 of the flagstones 24 to be flush or a little higher than the top edges 48 of the border 30, transverse 32 and cross 34 planks.

third embodiment

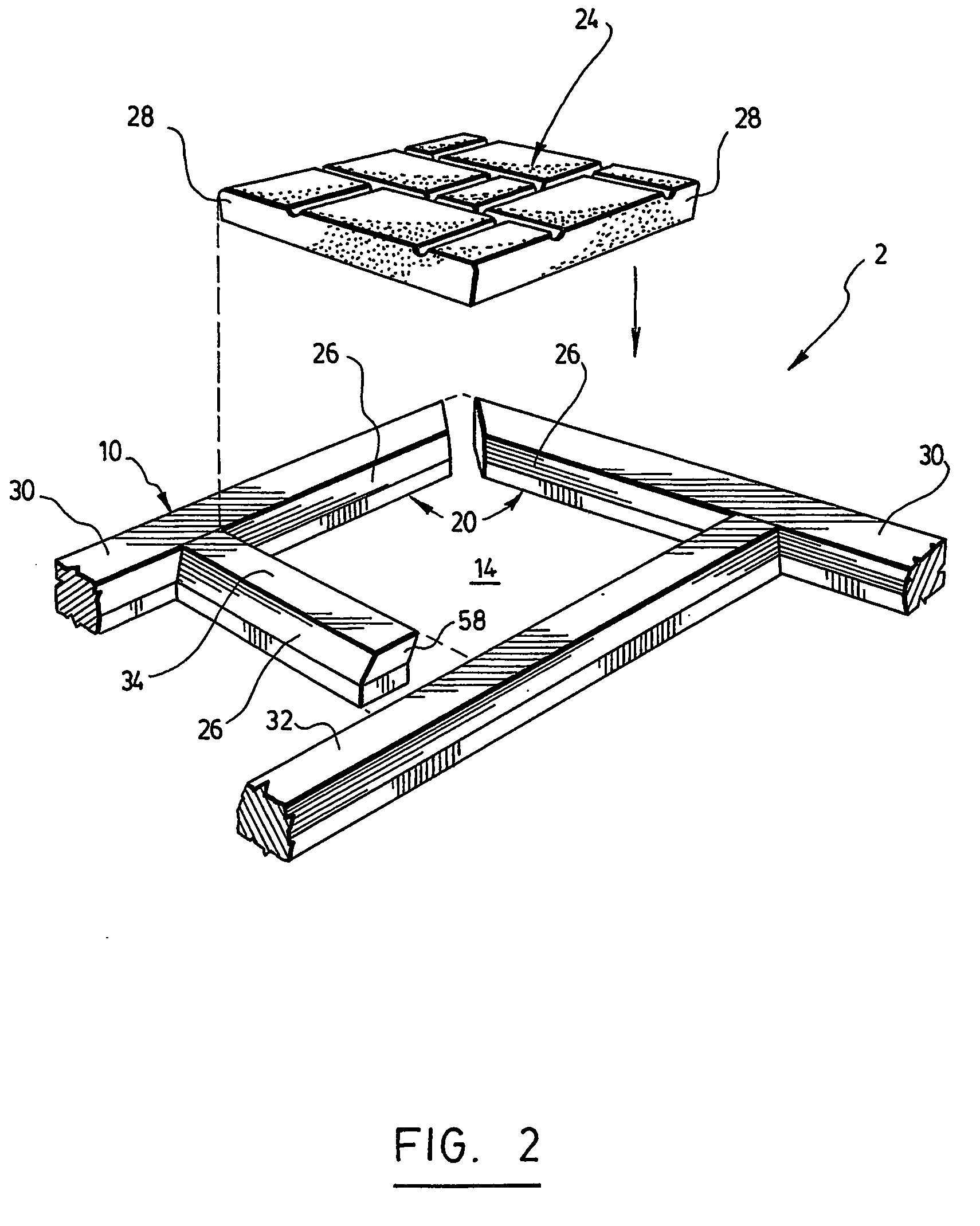

[0045] Referring to FIGS. 6, 7, 9b, 12 and 13, there are shown a second and the present invention using already available flagstones 24 to fit within the cells 14.

second embodiment

[0046] In the second embodiment, as shown in FIG. 12, the flagstone 24 can be sitting directly on the sloping portion 26 of the inner wall 20. The side edge 28 of the flagstone 24 leans in a close-fitting manner against a vertical portion of the inner wall 20 and the flagstone 24 sits on a superior end of the sloping portion 26. Again, the sloping portion 26 drains water out of the border plank and prevents water accumulation between the side edge 28 of the flagstone 24 and the inner wall 20.

[0047] In the third embodiment, as shown in FIGS. 6, 7, 9b and 13, a device to conform the side edges 28 of the flagstones 24 to the inner wall 20 of the cells 14 can be used. With this conforming device, the flagstones 24 can easily fit within the cells 14 while being supported by the inner walls 20. The device can be needed because since the side edges 28 of the flagstones 24 are generally perpendicular to the top and bottom ends 25, 27 of the flagstones 24, the flagstones 24 will not be suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com