Capacitively coupled power supply

a capacitive voltage divider and power supply technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of large devices, bulky, and relatively high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

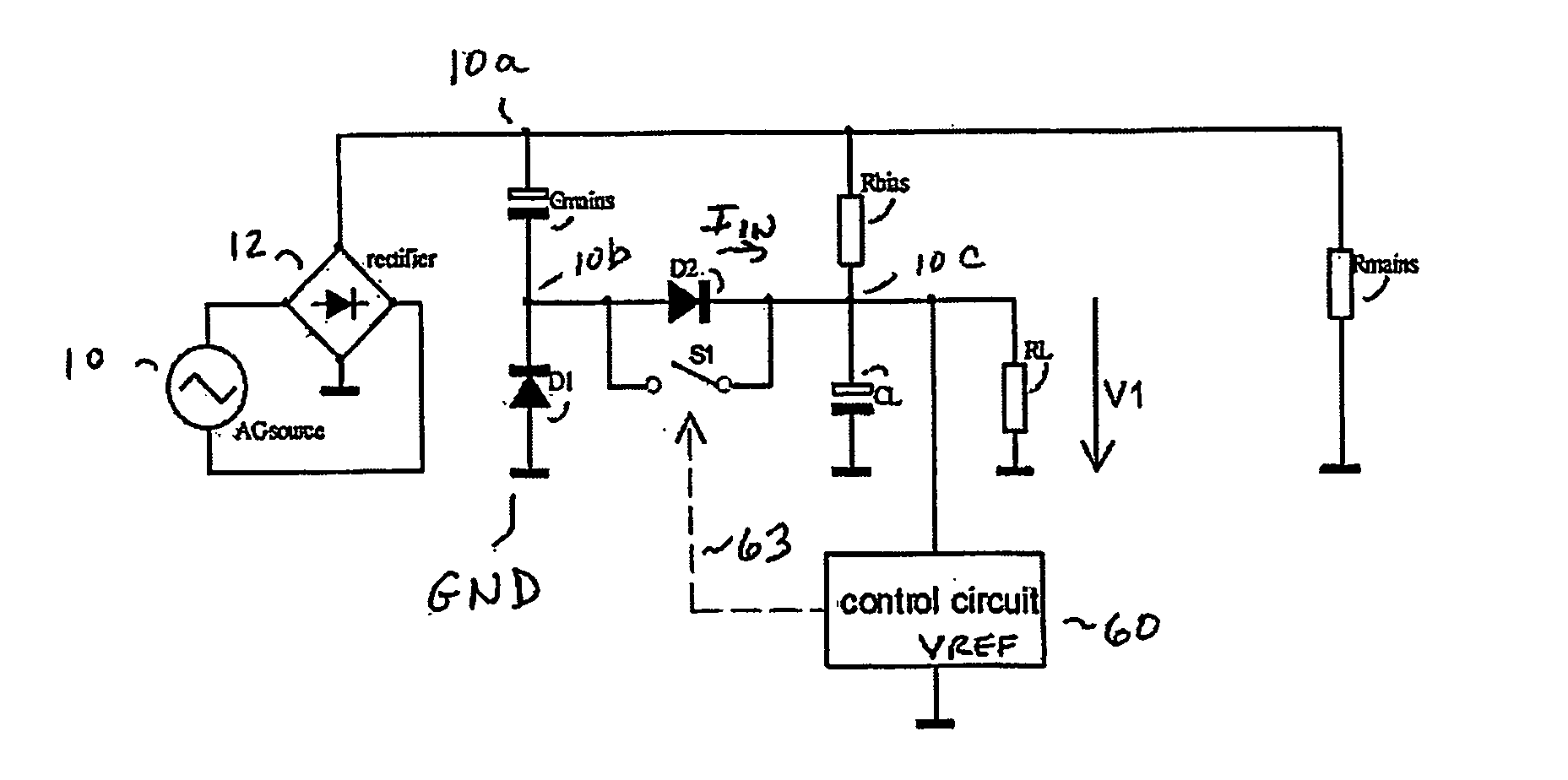

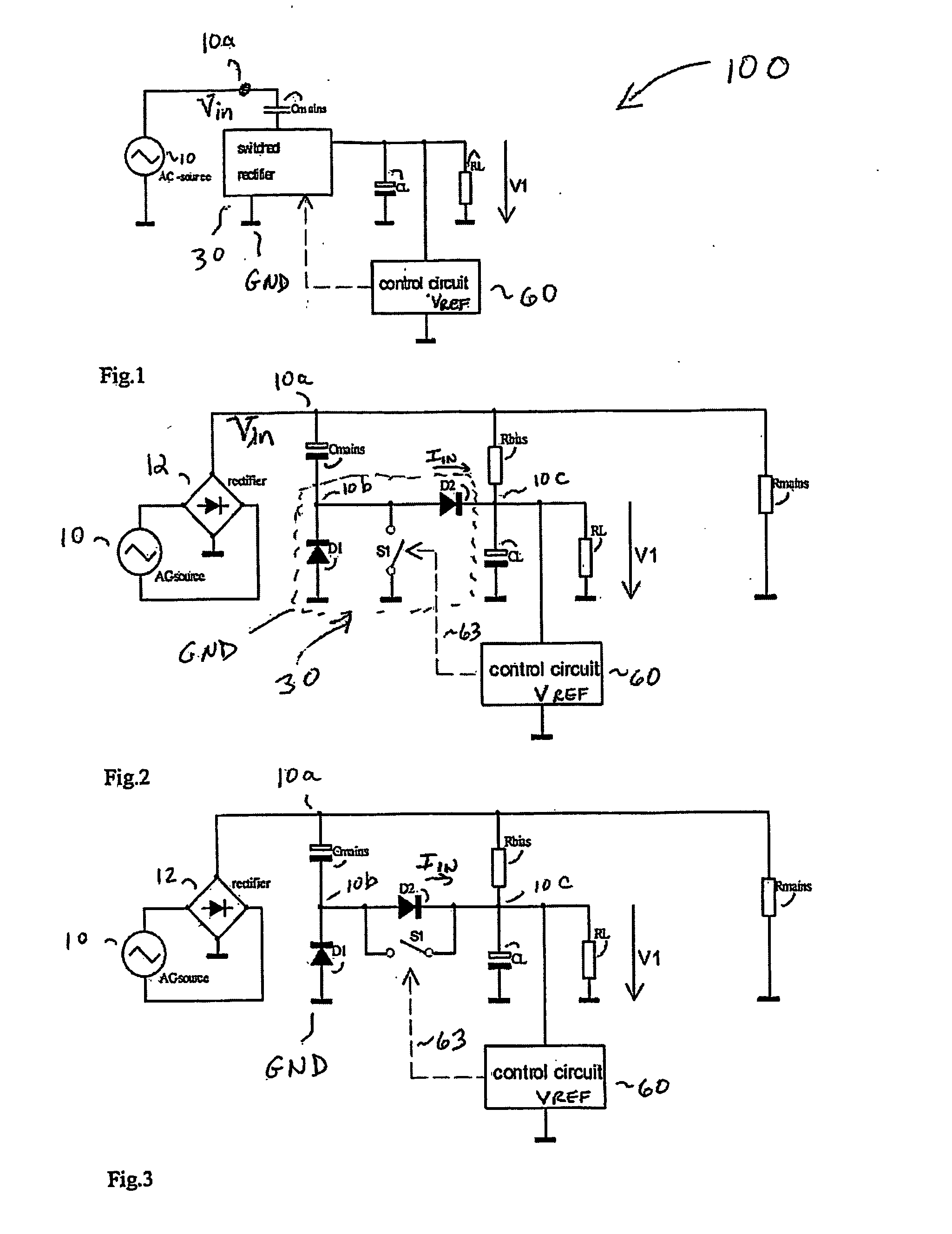

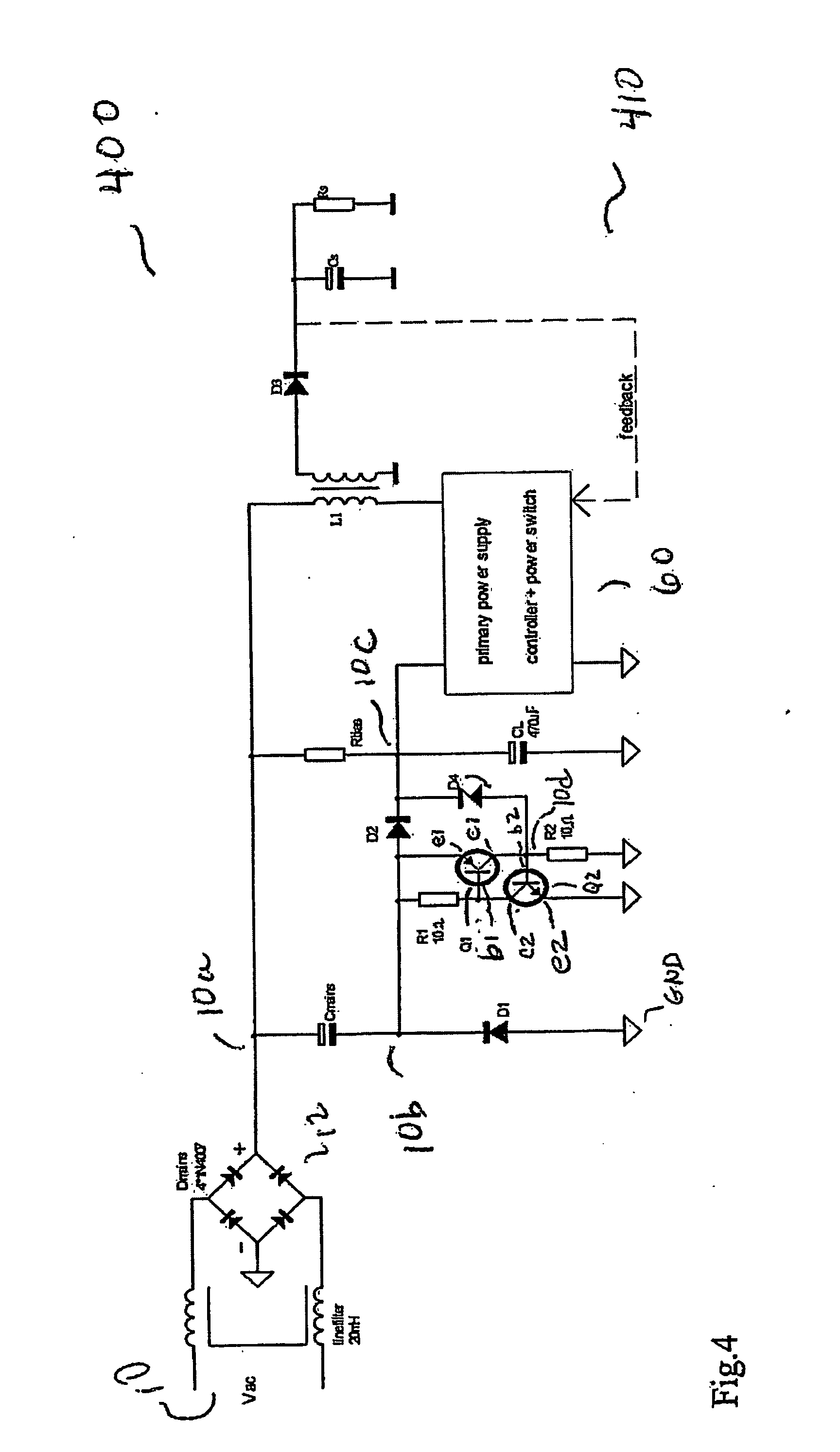

[0011]FIG. 1 is a block diagram illustrating a circuit 100 for generating a regulated supply voltage using a capacitive divider according to the general principles embodying the present invention. Throughout the drawings, like reference numerals are used to indicate like parts. The circuit 100 includes a source 10 of AC power applied at node 10a. A voltage or a current source may be used, however, in case of a mains application, it is understood that the source comprise an AC power line input A capacitive divider comprising capacitor Cmains and capacitor CL connected in series, is used to transform the input voltage (Vin) at node 10a to the desired output voltage level V1 across load device RL. Since the energy transfer is determined by the capacitor Cmains, a voltage source can automatically be considered as a current source.

[0012] Control circuit 60 coupled to the voltage divider arrangement measures the output voltage V1 and compares the measured output voltage with a reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com