Nonaqueous electrolyte secondary battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

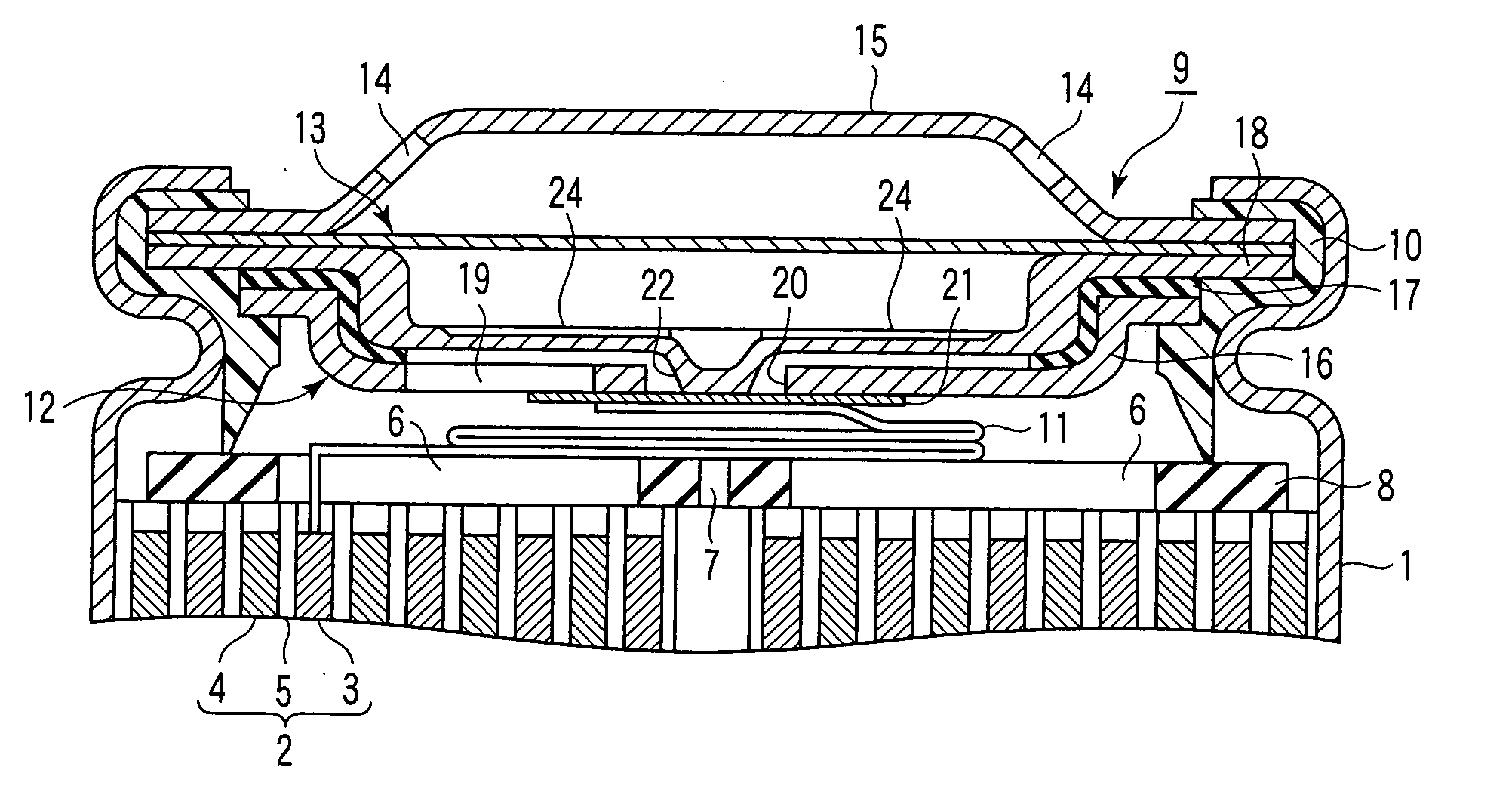

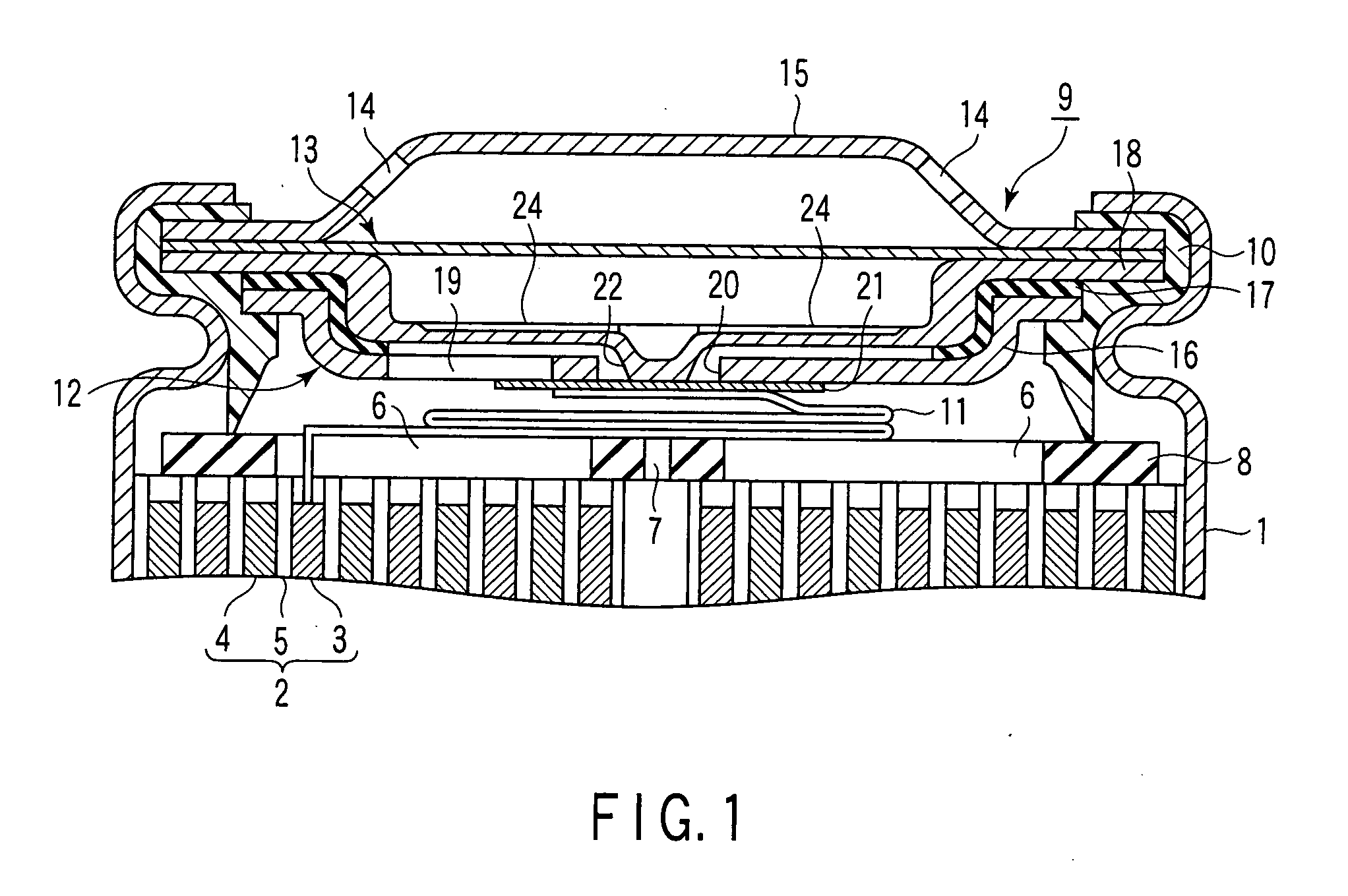

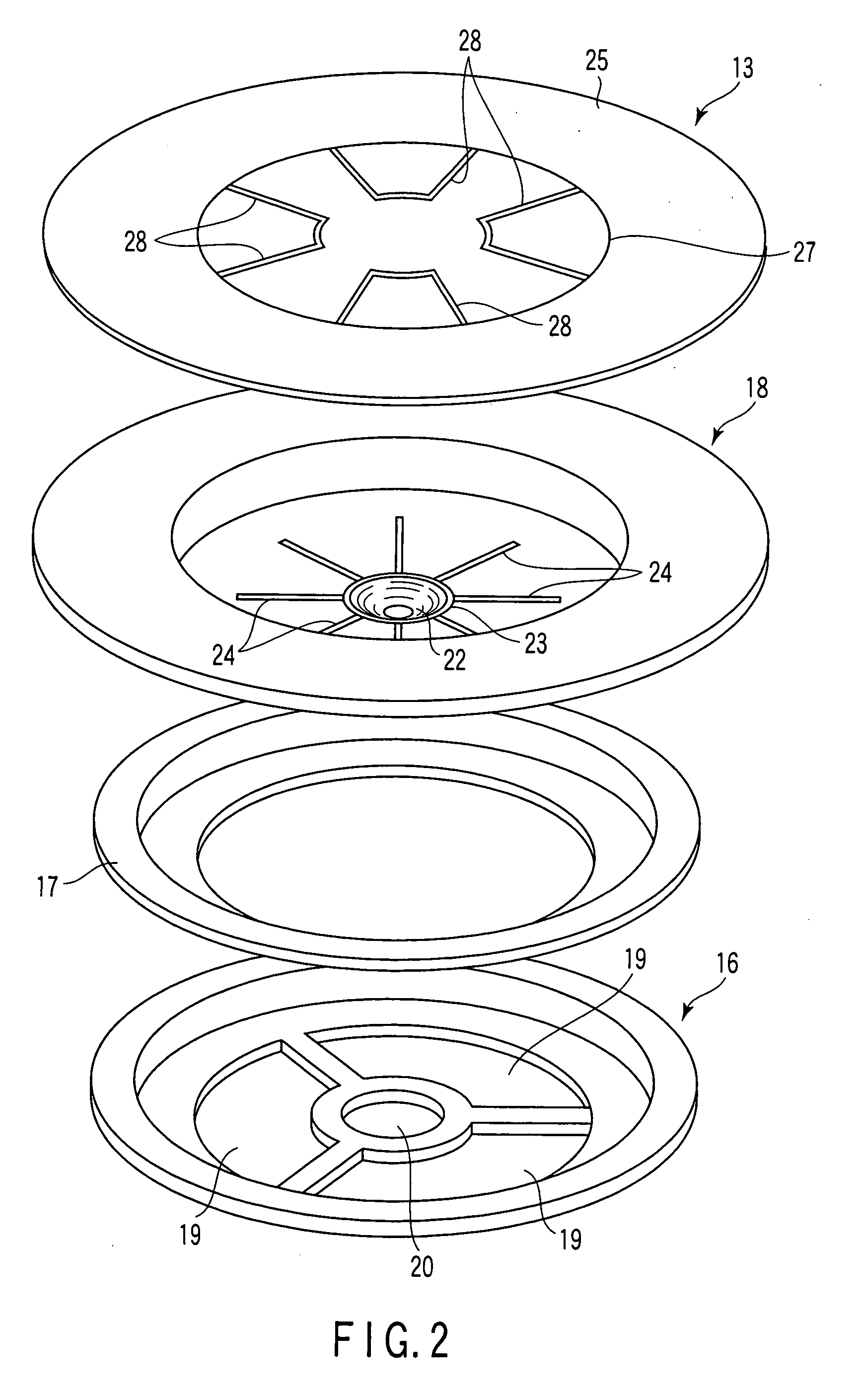

[0040]FIG. 1 is a partial sectional view showing a cylindrical nonaqueous electrolyte secondary battery according to a first embodiment of the invention; FIG. 2 is an exploded perspective view showing essential parts of a sealing lid group assembled in the cylindrical nonaqueous electrolyte secondary battery in FIG. 1; FIG. 3 is a plan view showing a PTC element assembled in the cylindrical nonaqueous electrolyte secondary battery in FIG. 1; and FIG. 4 is a sectional view taken along line IV-IV in FIG. 3.

[0041] As shown in FIG. 1, an external can 1 of cylindrical shape with a bottom is made of, for example, stainless steel or iron, and also functions as one polar terminal (for example, negative electrode terminal). In the bottom of the external can 1, an insulator (not shown) is disposed. An electrode assembly 2 is contained in the external can 1. The electrode assembly 2 is constituted of a positive electrode 3, a negative electrode 4, and a separator 5 interposed therebetween to ...

second embodiment

[0128]FIG. 11 is a partial sectional view showing a cylindrical nonaqueous electrolyte secondary battery according to a second embodiment of the invention, and FIG. 12 is an exploded perspective view showing essential parts of a sealing lid group assembled in the cylindrical nonaqueous electrolyte secondary battery in FIG. 11. In FIGS. 11 and 12, the same members as in FIGS. 1 and 2 are identified with same reference numerals, and explanation thereof is omitted.

[0129] In FIGS. 11 and 12, the sealing lid group 9 is composed of a conductive current breaking member 61, an insulating ring 62, a rupture plate 63, and a hat-shaped terminal plate 15 having a PTC element 13 and gas vents 14 and serving as the other polarity terminal (for example, positive electrode terminal), which are crimped and fixed in this order by the insulating gasket 10 at their peripheral edges.

[0130] The current breaking member 61 is formed like a dish as shown in FIG. 12, and a peripheral edge of the current br...

third embodiment

[0139]FIG. 13 is a partial sectional view showing a cylindrical nonaqueous electrolyte secondary battery according to a third embodiment of the invention, and FIG. 14 is an exploded perspective view showing essential parts of a sealing lid group assembled in the cylindrical nonaqueous electrolyte secondary battery in FIG. 13. In FIGS. 13 and 14, the same members as in FIGS. 1 and 2 are identified with same reference numerals, and explanation thereof is omitted.

[0140] In FIGS. 13 and 14, the sealing lid group 9 is composed of a rupture plate 71, a PTC element 13, a first half insulating ring 72, a current breaking member 73, a second half insulating ring 74, and a hat-shaped terminal plate 15 having gas vents 14 opened and serving as the other polarity terminal (for example, positive electrode terminal), which are crimped and fixed in this order from the electrode assembly 2 side by the insulating gasket 10 at their peripheral edges.

[0141] The rupture plate 71 is formed like a dish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com