Turbine-tip arrowhead

a turbine-tip arrowhead and arrow head technology, applied in the field of arrowheads, can solve the problems of additional damage caused by rifling, and achieve the effect of excellent rotation of the arrow shaft and no large amount of aerodynamic drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

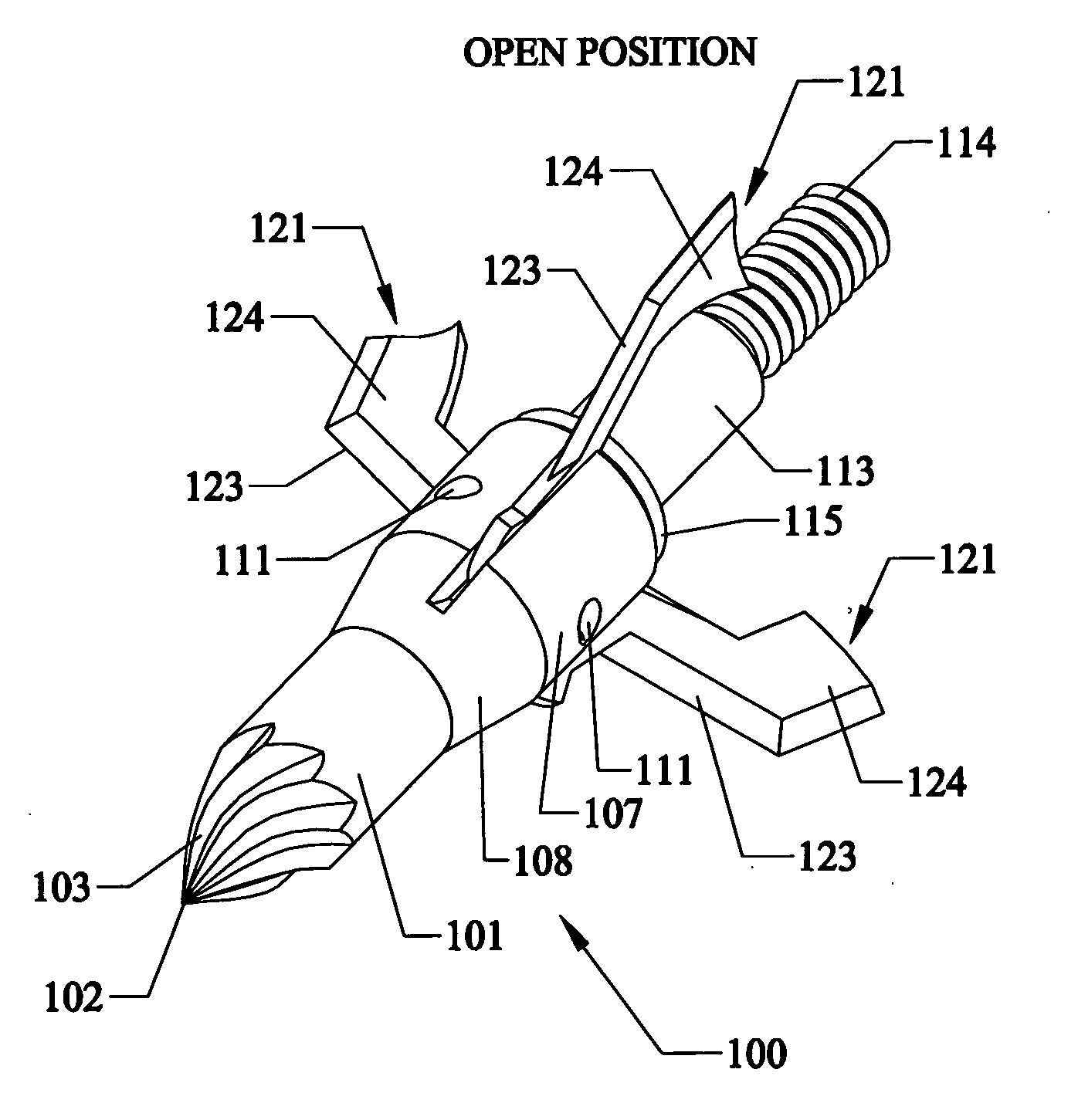

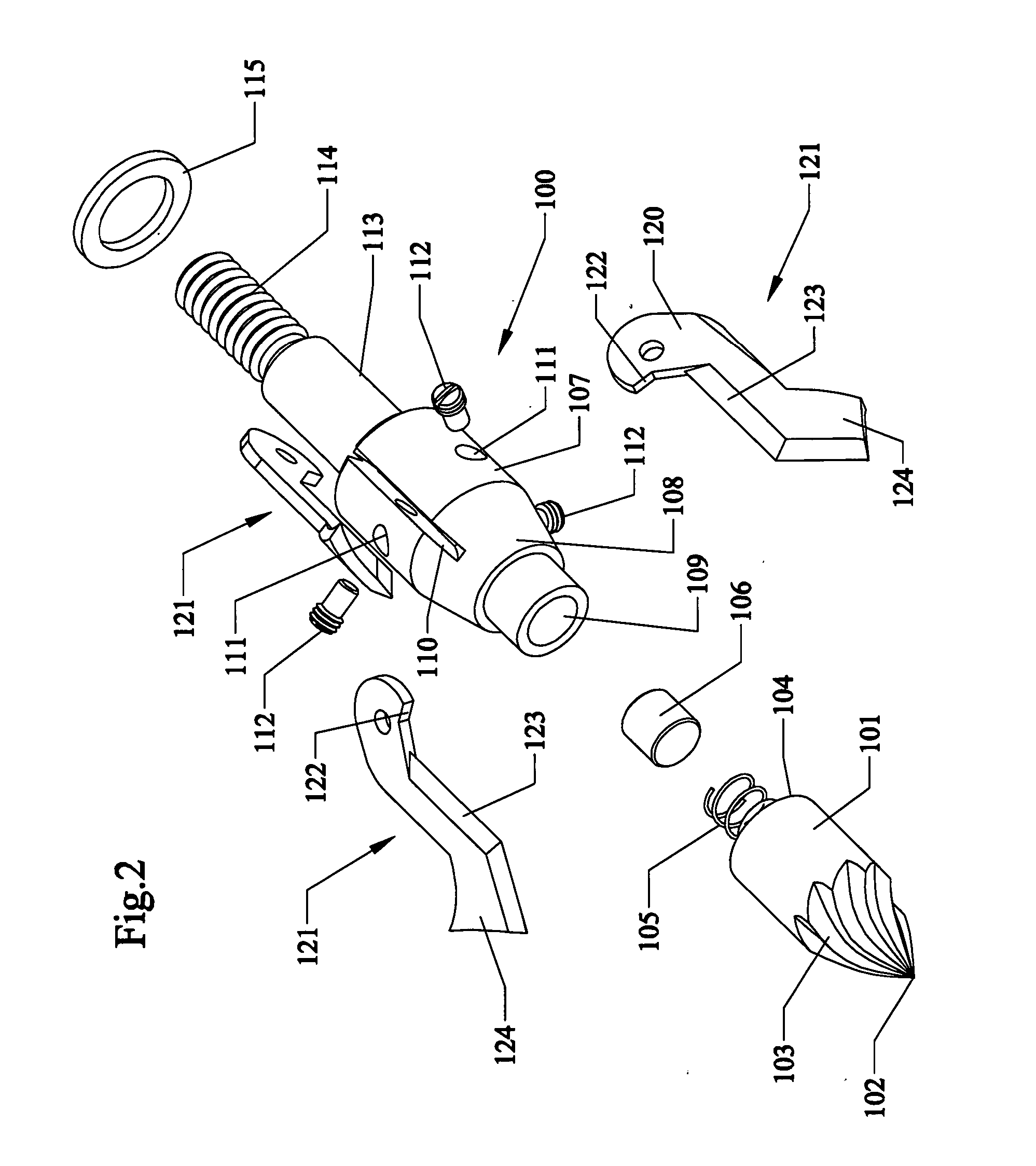

Embodiment Construction

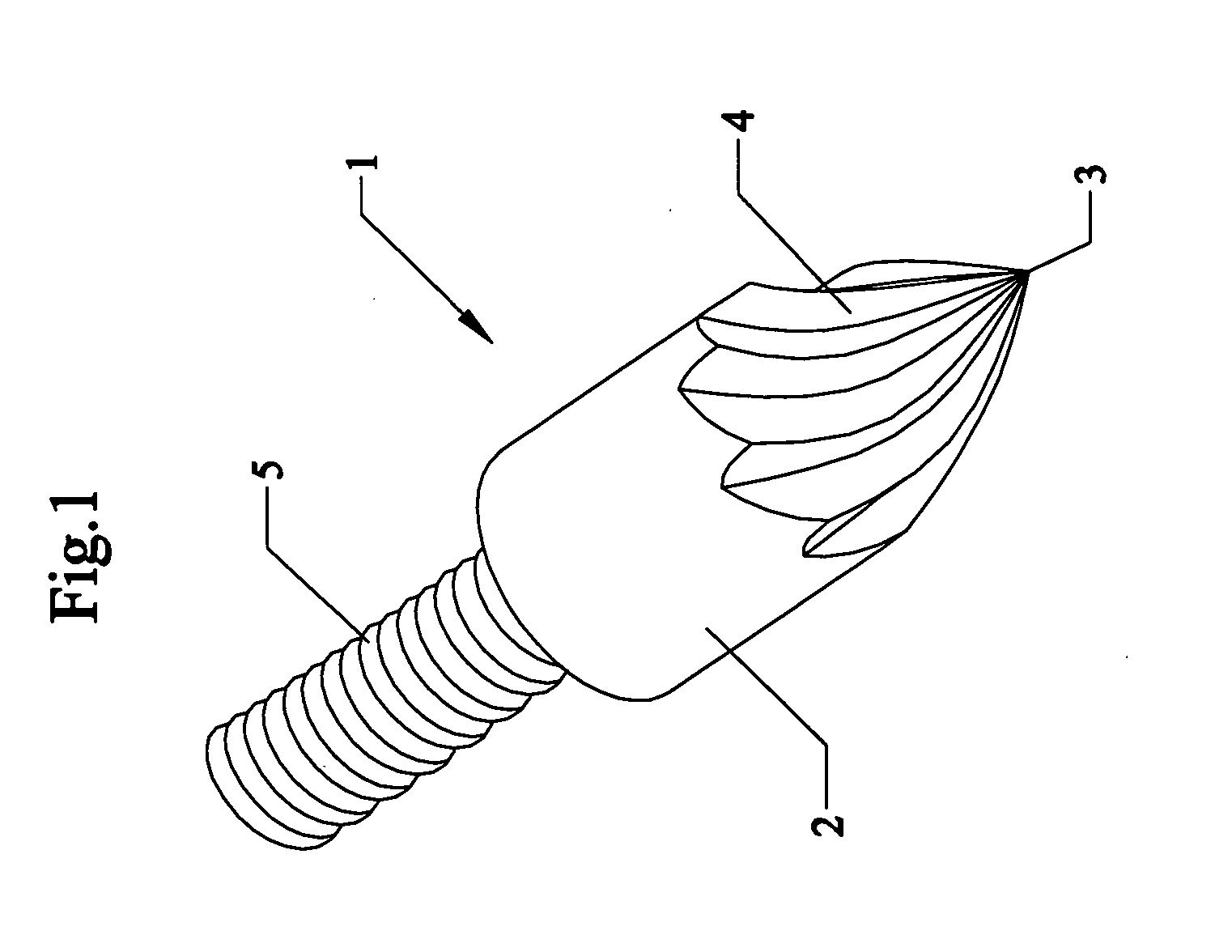

[0016] With reference to FIG. 1, field point 1 of this invention comprises a typically cylindrical body 2 with a maximum diameter approximately equal to the maximum diameter of an arrow shaft. Body 2 is typically symmetrical about a longitudinal axis. A portion of body 2 tapers to a point 3 at one end. A plurality of helical rifles 4, consisting of either grooves or ridges, begin at point 3 of the field point 1 and spiral down the longitudinal axis of body 2. Rifles 4 may spiral down the entire axial length of body 2 or may terminate partially down a portion of the axial length of body 2. All rifles 4 spiral in the same rotational direction giving the appearance of a turbine. In the preferred embodiment, rifles 4 are placed close together around body 2 so that they contact each other down their entire helical length.

[0017] In the preferred embodiment there are between about three and about ten rifles 4 located symmetrically about the longitudinal axis of body 2. There are optimally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com