Optical viewing system for monitoring a wide angle area of interest exposed to high temperature

a wide angle, monitoring system technology, applied in the direction of burners, combustion regulation, liquid fuel evaporation burners, etc., can solve the problems of local flow blockage, significant damage to turbine components, labor-intensive procedures, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

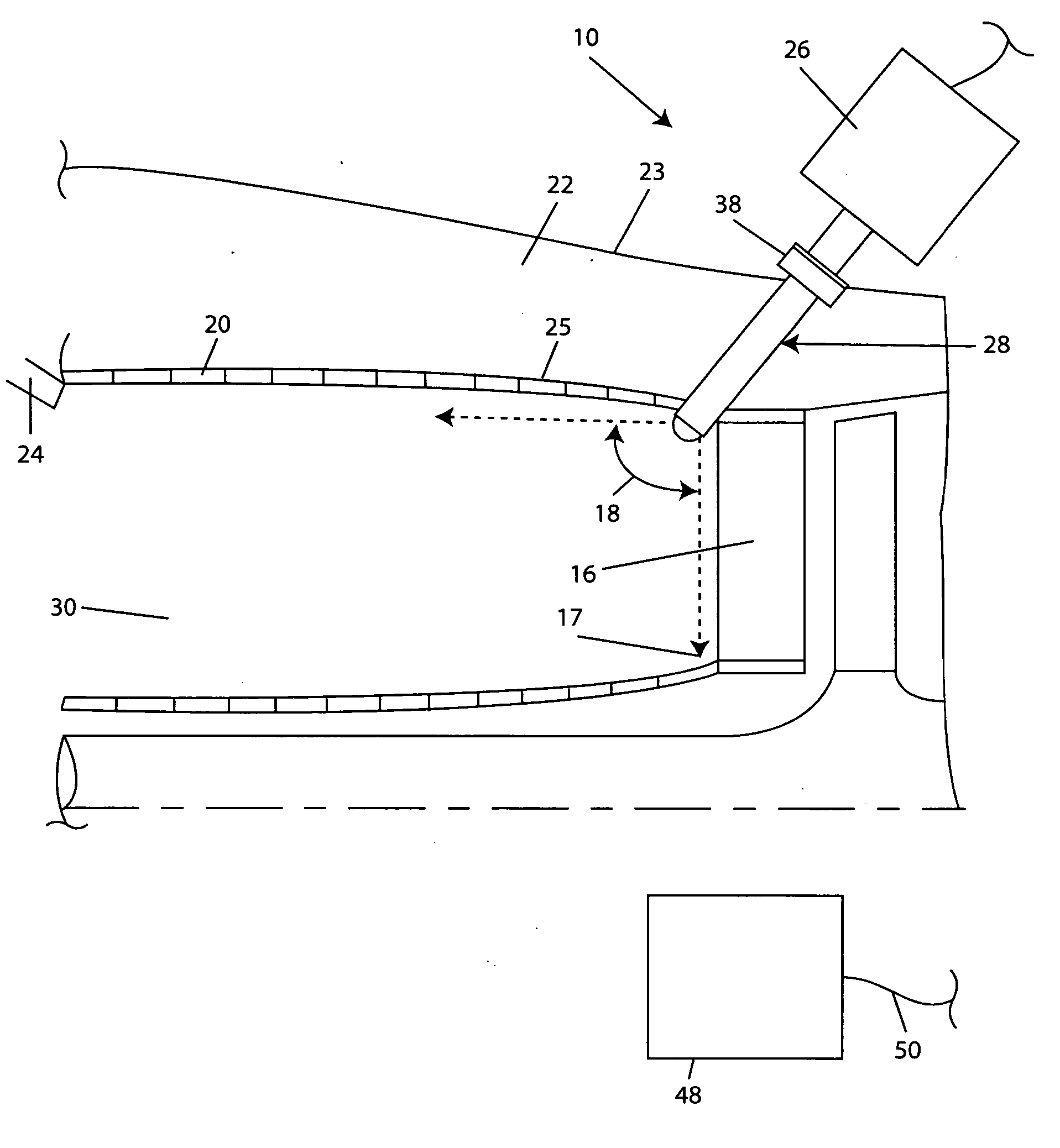

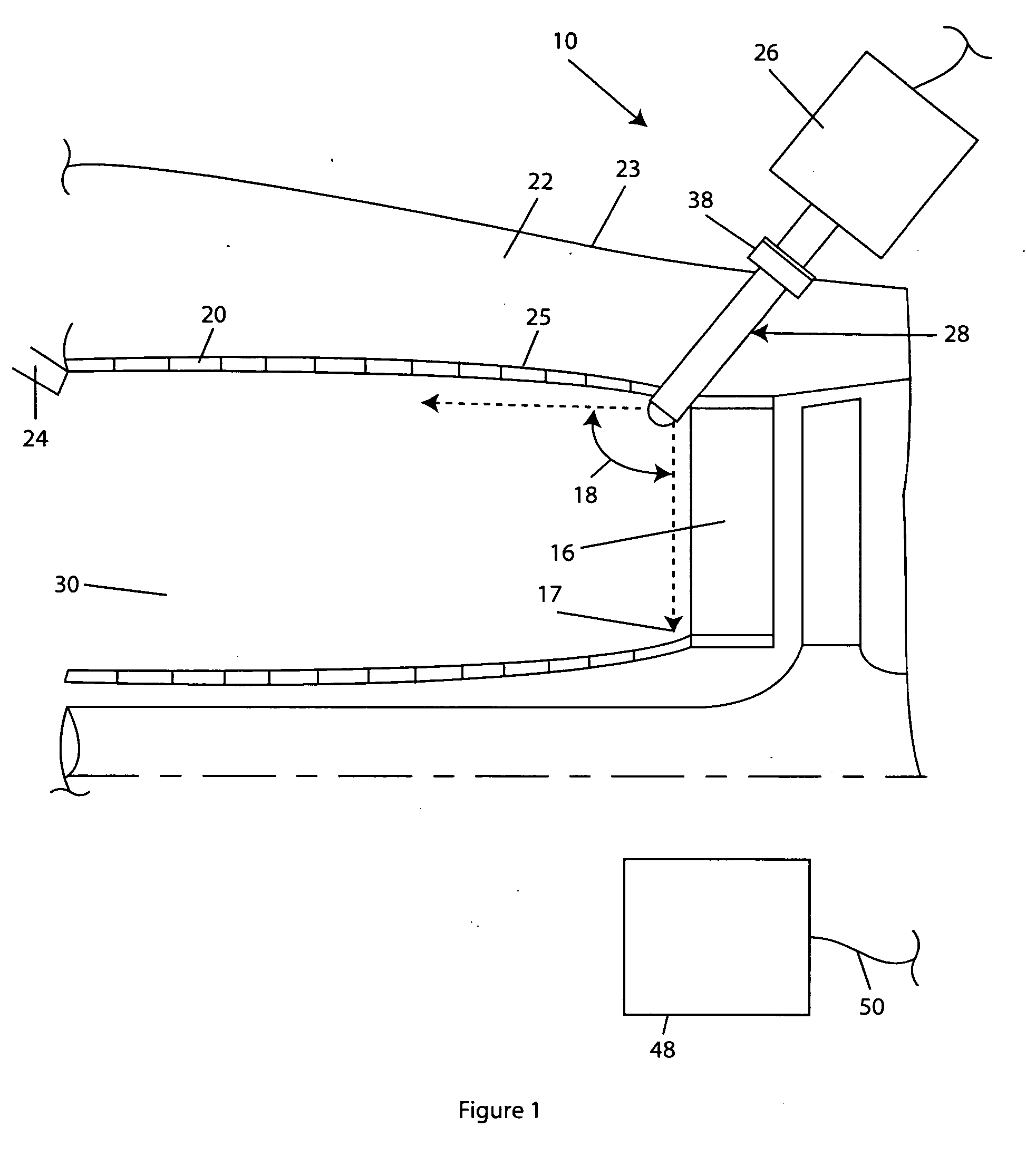

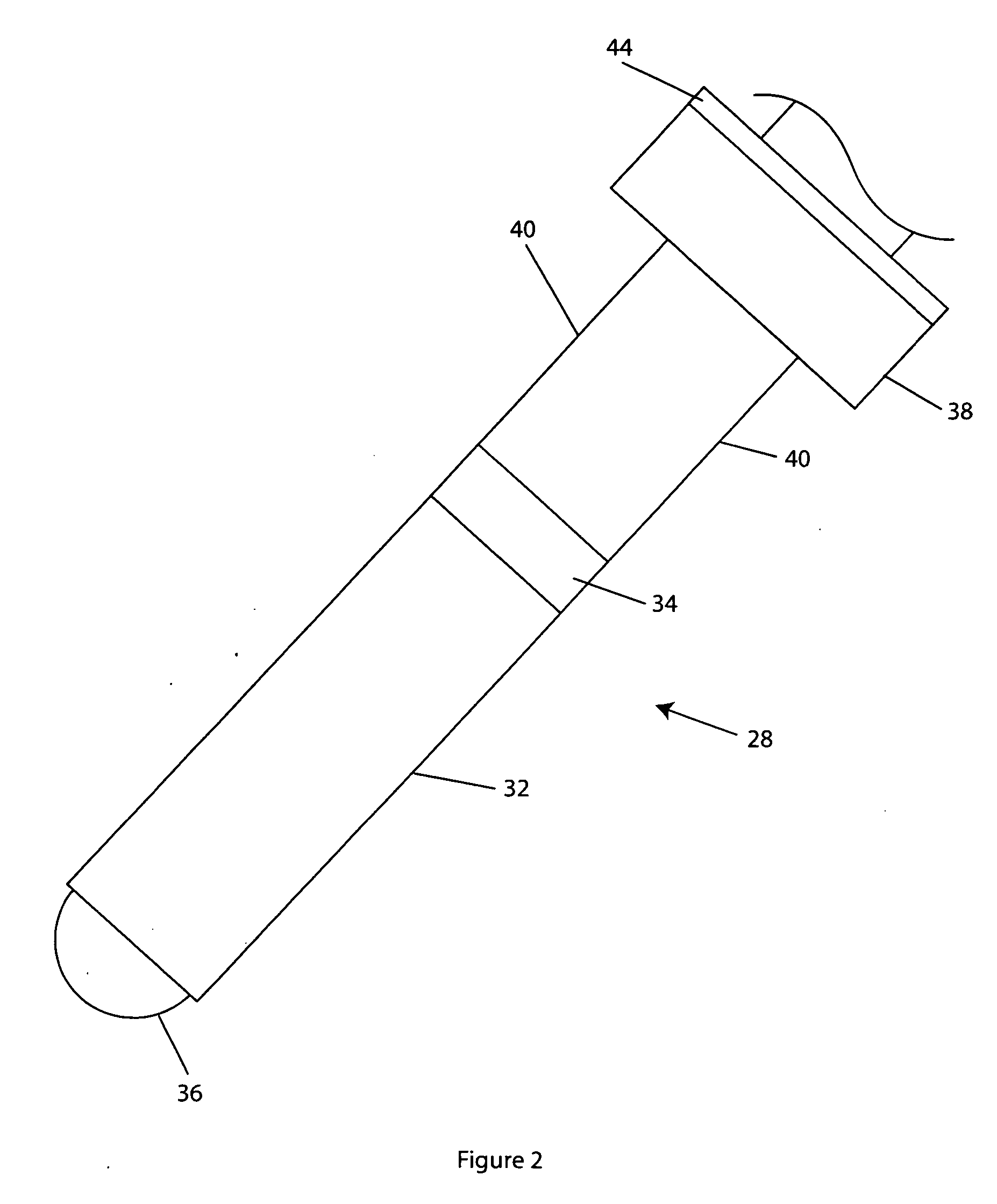

[0016] The invention described herein employs several basic concepts. For example, one concept relates a wide angle viewing system that is cooled by active cooling for use in a high temperature environment. Another concept relates a device and a method for monitoring ceramic tile integrity on the inner wall of an annular combustion chamber. Another concept relates to the monitoring of an area of interest where wide-angle viewing of a high temperature region through a confined access space is needed.

[0017] It is advantageous to define the term “area of interest” before describing the invention. “Area of interest” refers to any region where viewing or monitoring is desired. For example, the interface between the row 1 vane and the combustion chamber in an annular combustor in a gas turbine would be an area of interest.

[0018] The present invention is disclosed in context of use of a wide-angle infrared (IR) optical viewing system within a gas turbine engine for monitoring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com