Tool display rack having holding and rotation test functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

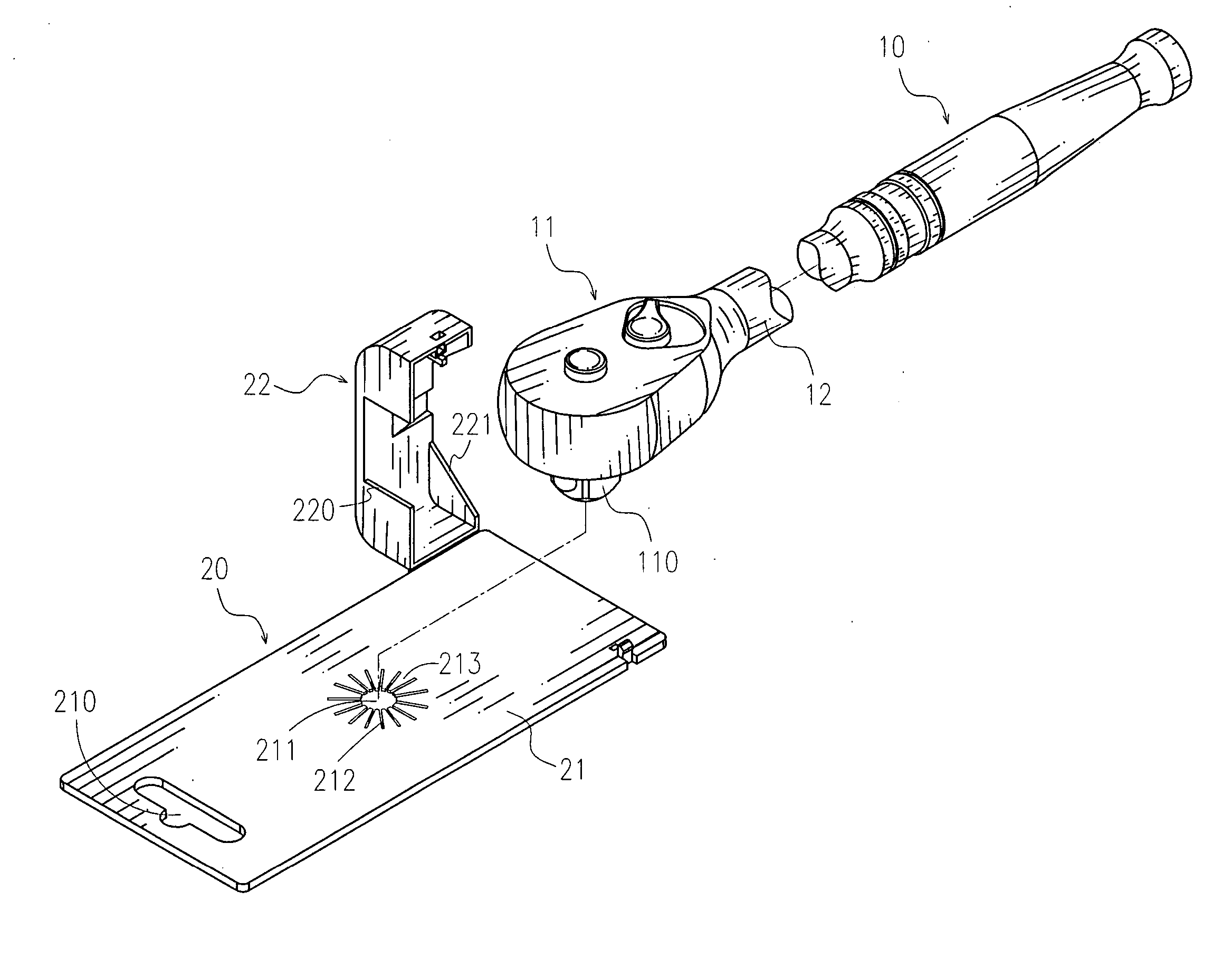

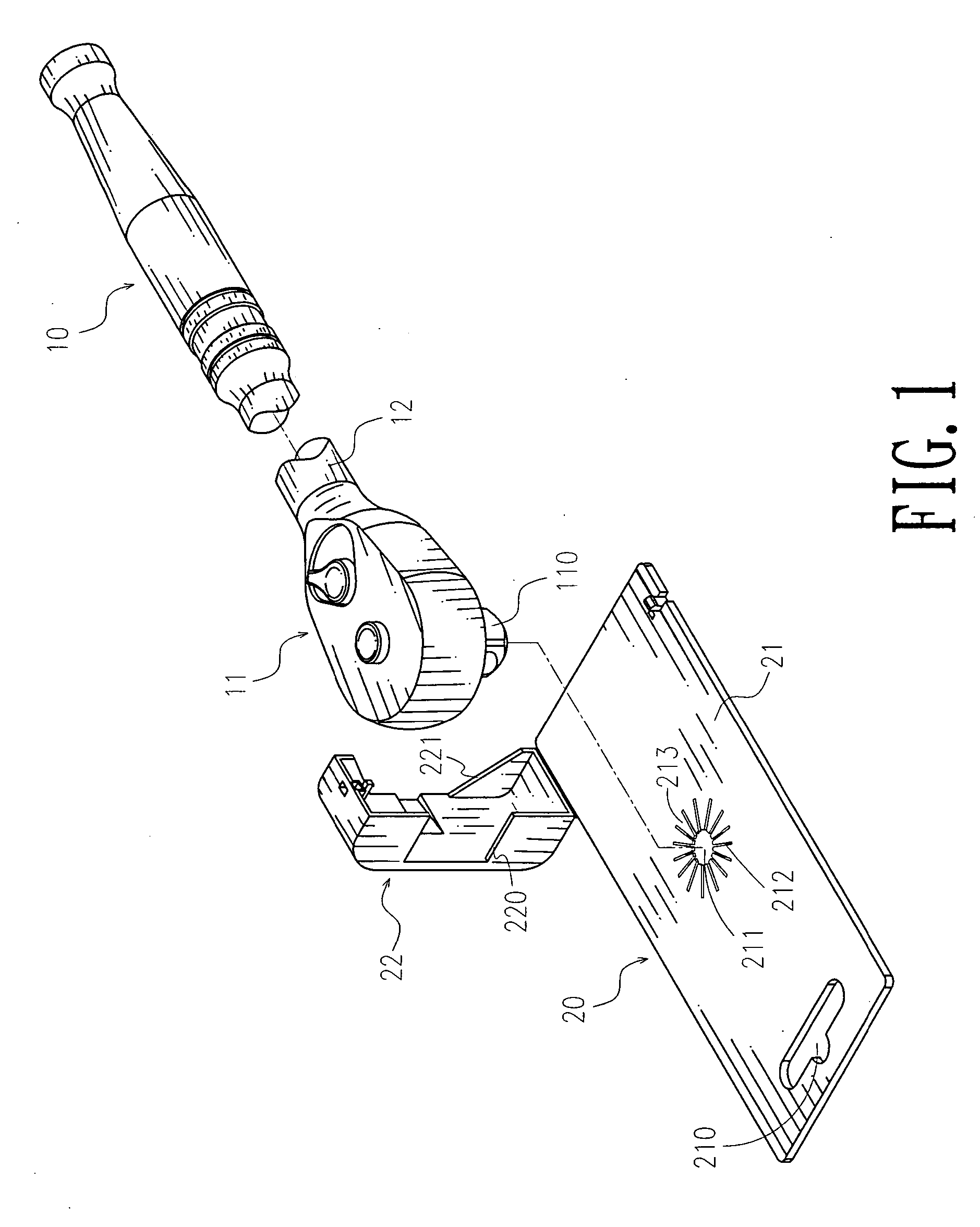

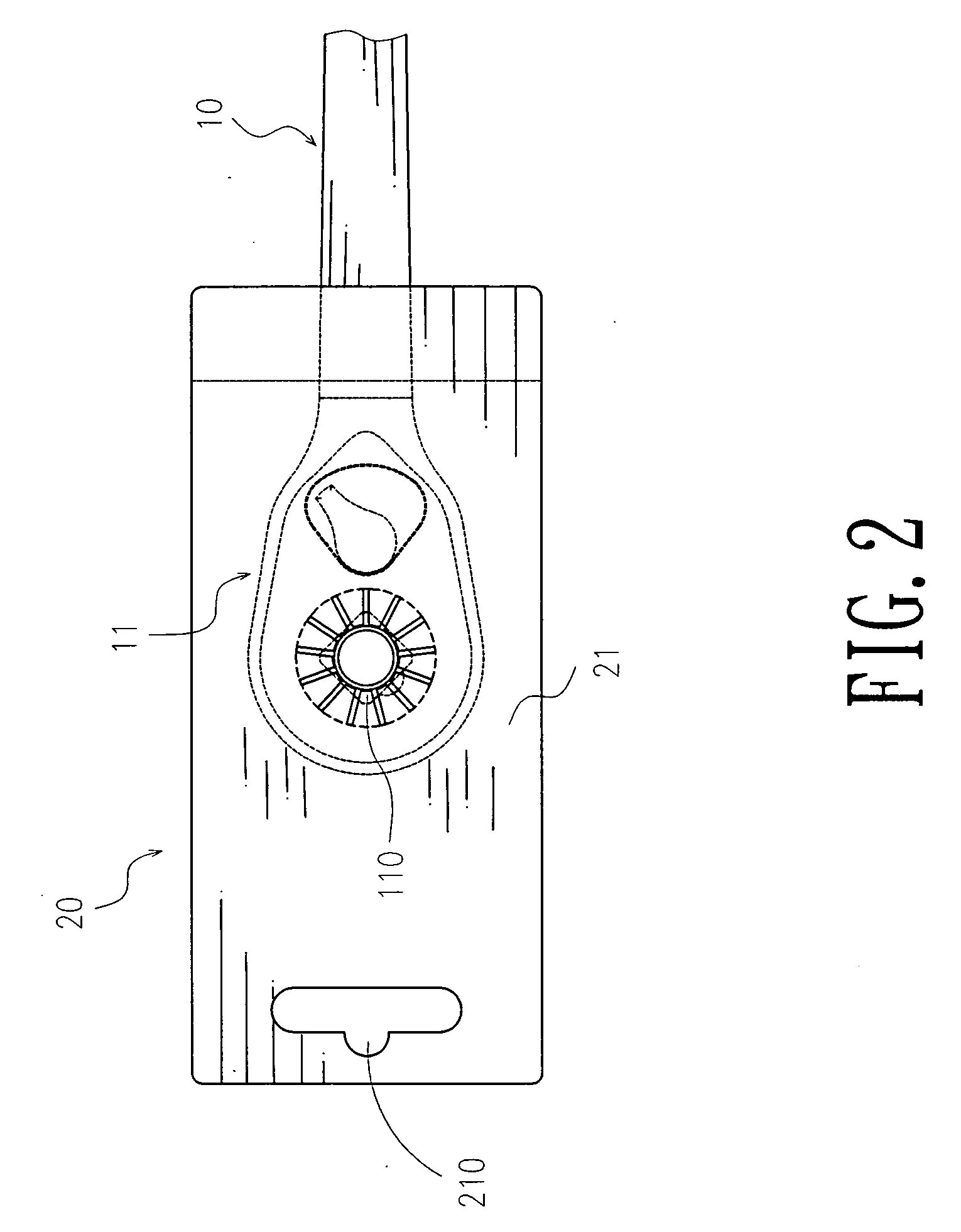

[0026] Referring to the drawings and initially to FIGS. 1-4, a tool display rack 20 in accordance with a first embodiment of the present invention is used for mounting a tool 10. The tool 10 has a drive head 11 and a neck portion 12. The drive head 11 of the tool 10 has a square drive stud 110.

[0027] The tool display rack comprises a main body 21, a mounting portion 211 mounted on the main body 21 to allow passage of the drive stud 110 of the tool 10 and having an inner edge closely urged on a peripheral wall of the drive stud 110 of the tool 10 to produce a contact friction therebetween, and a pressing member 22 pivotally mounted on the main body 21 and urged on the neck portion 12 of the tool 10.

[0028] The main body 21 has a first end formed with a hanging portion 210 for hanging the main body 21. The mounting portion 211 is mounted on a mediate portion of the main body 21 and is preferably a through hole having a diameter slightly smaller than a size of the drive stud 110 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com