Load cell and seat occupant weight sensing system

a load cell and occupant technology, applied in the field of load cell and seat occupant weight sensing system, can solve the problems of high cost of airbags of occupant protection systems, damage to seats or car floors, and inability to deploy airbags, so as to increase the volume available, and reduce the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

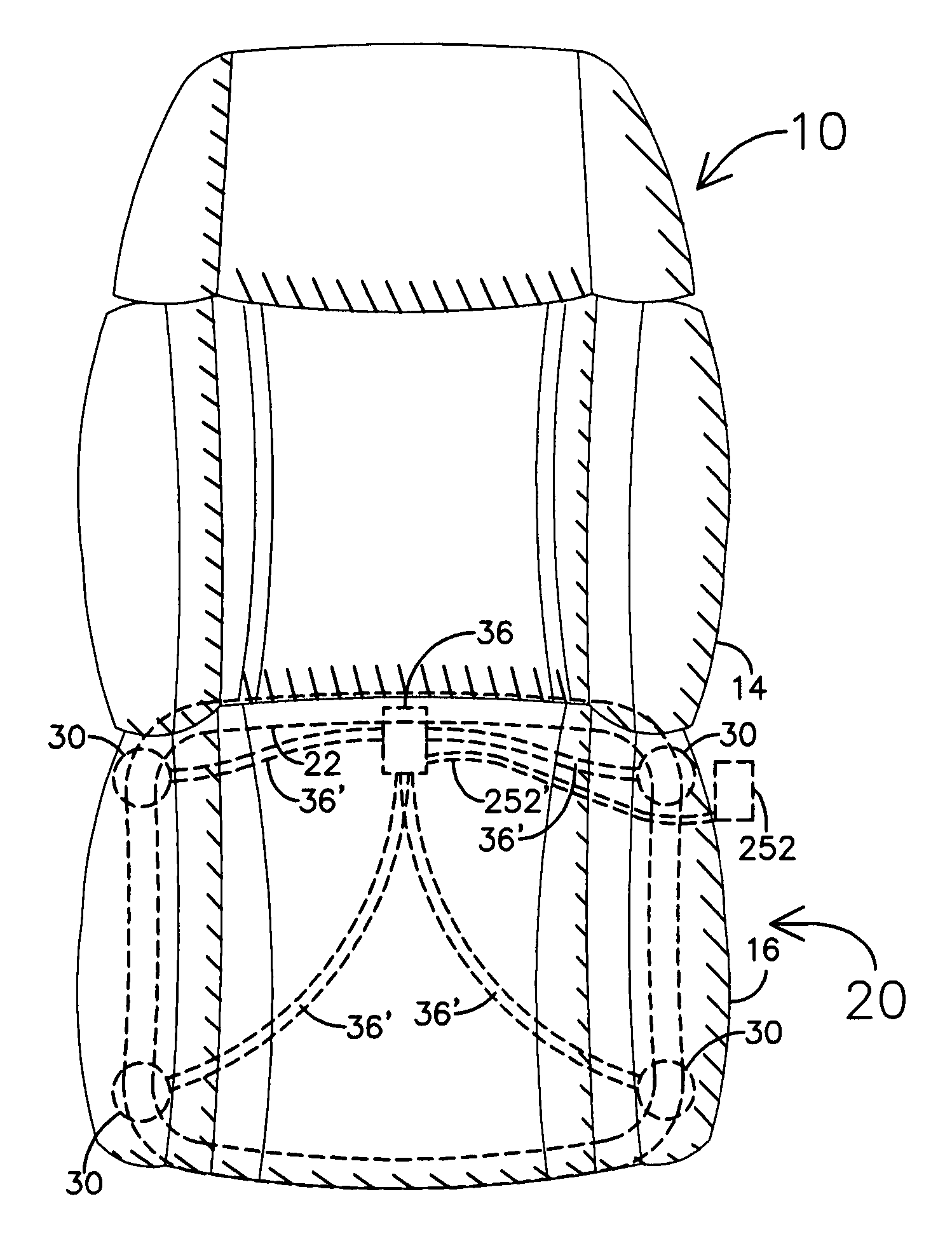

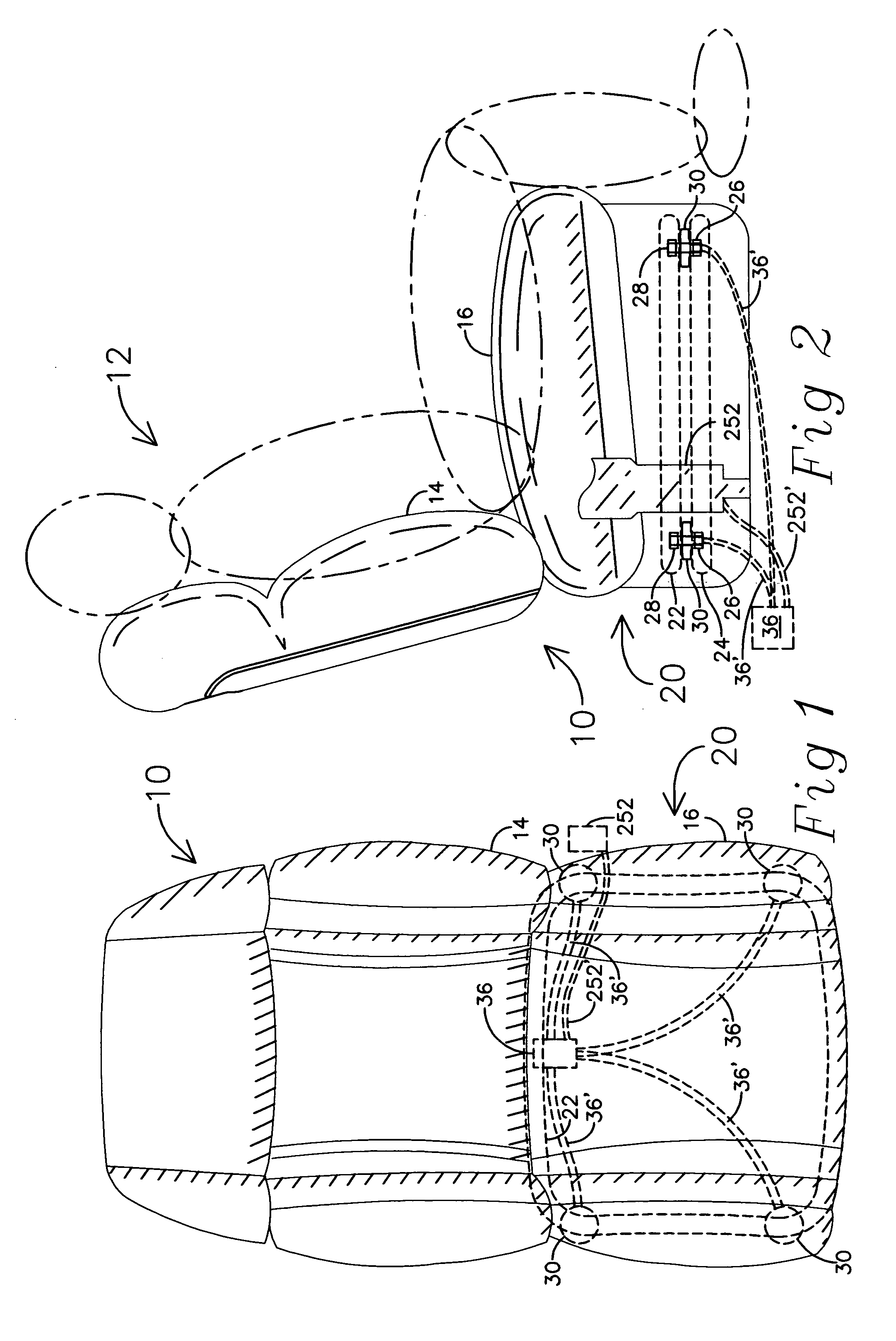

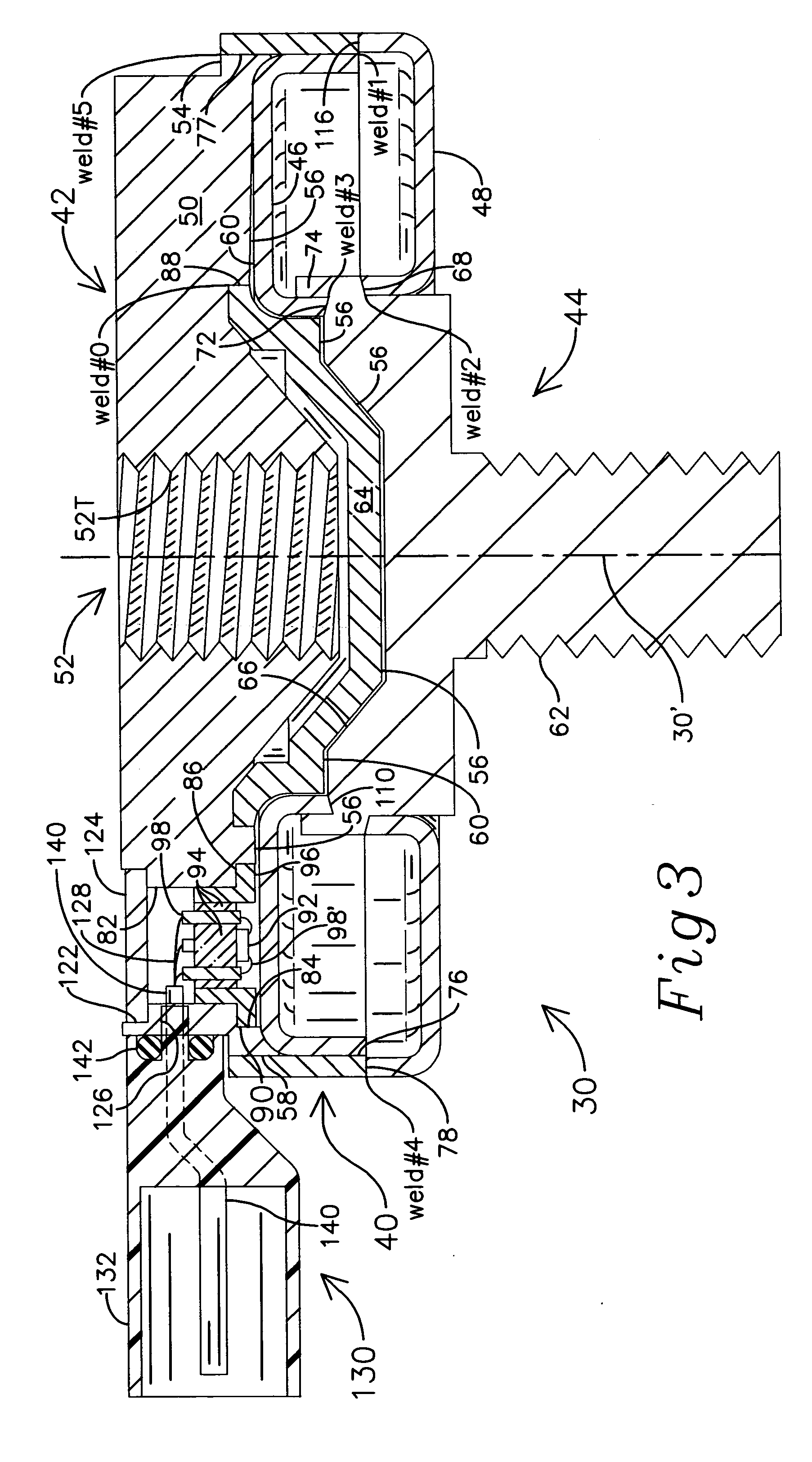

[0054] Proceeding first with reference to FIGS. 1 through 3, vehicle seat 10 is equipped with an occupant weight sensing system 20 for weighing the seat occupant. In FIGS. 1 and 2 the occupant weight sensing components are illustrated with hidden lines. Occupant weight sensing system 20 comprises four load cells 30 connected to a processing unit 36 that adds the outputs of the four load cells 30 and generates an electric signal indicating the weight applied to the seat. Occupant weight sensing system 20 may also comprise a seat belt tension sensor 252. The seat 10 receives weight from the seat occupant through cushion 16 and seat back 14. The weight is transferred to an upper member 22 of the seat frame. The upper frame member 22 applies downward force to the load cells 30 located between the upper seat frame member 22 and a lower seat frame member 24. Alternately, the load cells 30 may be located between the seat and the vehicle floor (not illustrated). The load cells respond to do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com