Method and device for temporarily storing linear body

a technology of linear body and storage device, which is applied in the direction of transportation and packaging, manufacturing tools, instruments, etc., can solve the problems of increasing the length of the temporary storage device in the longitudinal direction, affecting the installation space of existing equipment, and affecting the installation of existing equipment, etc., and achieves the effect of simple configuration and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

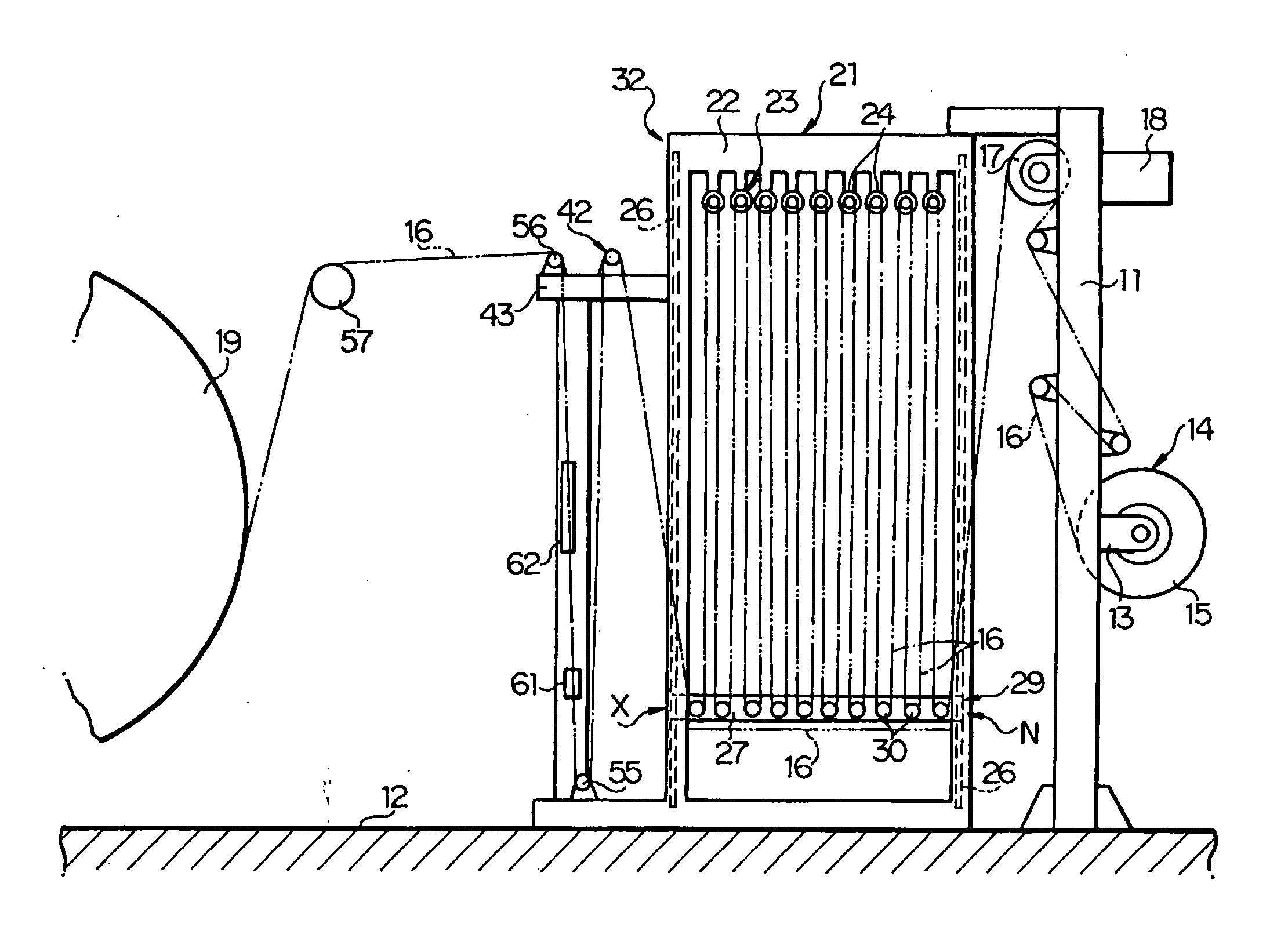

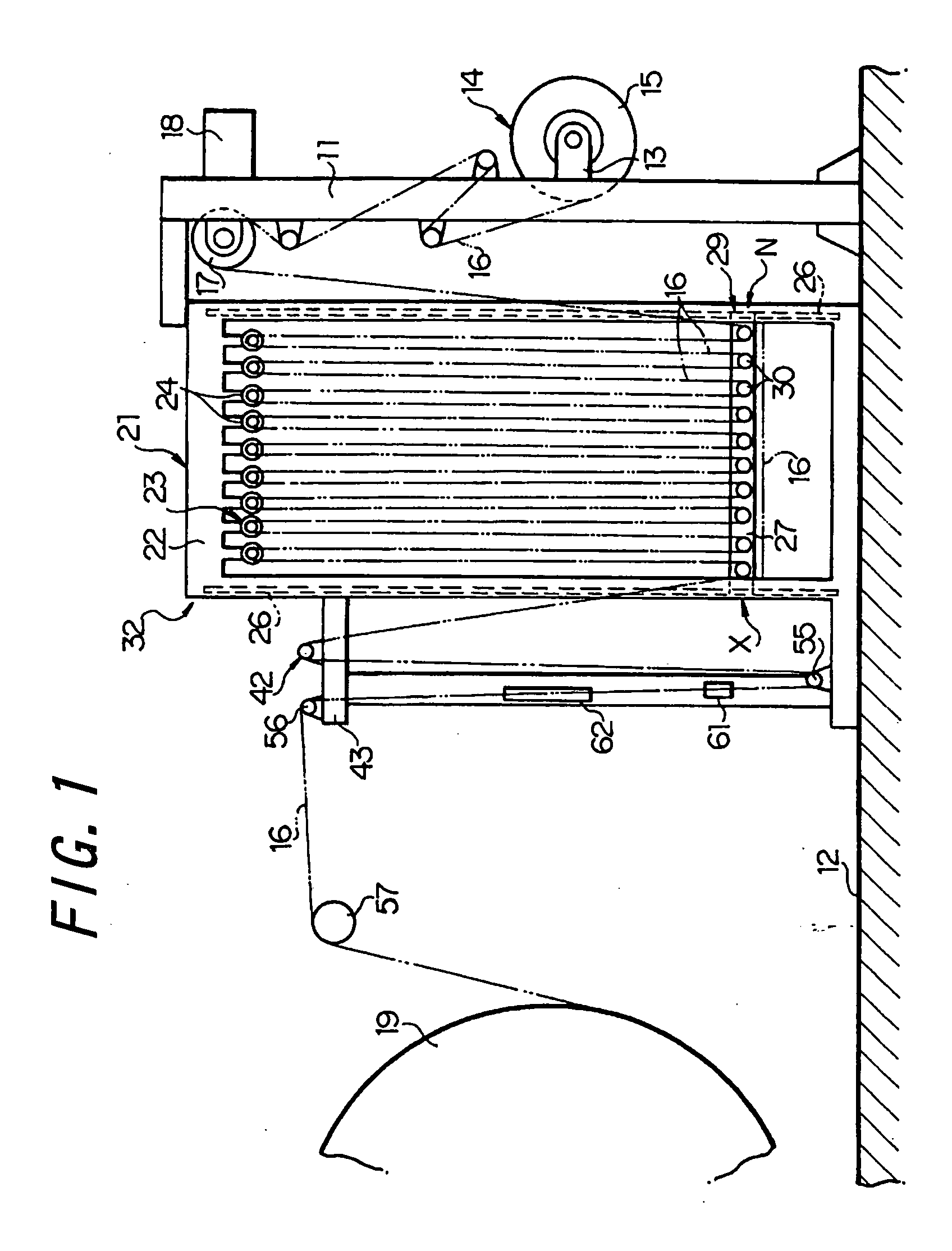

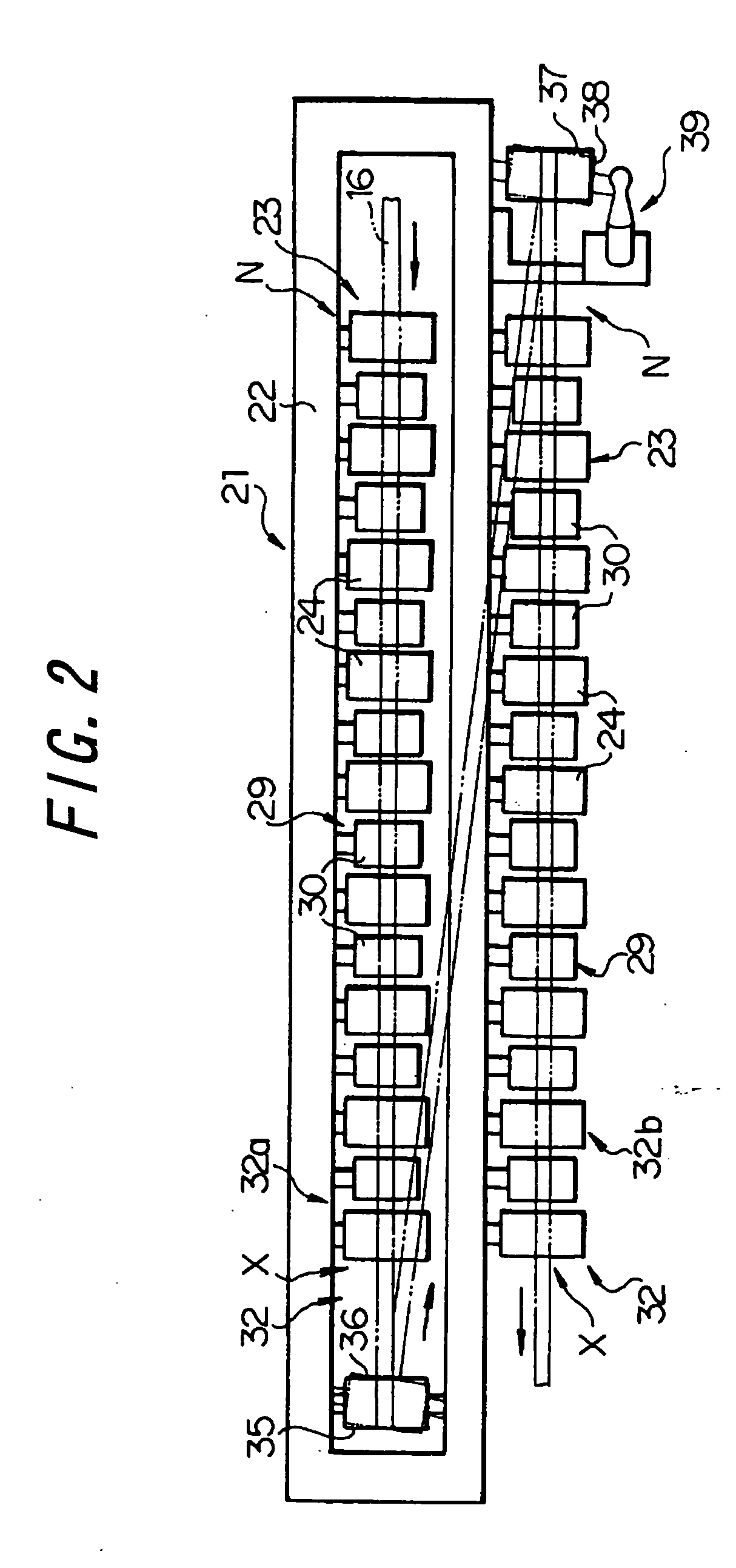

[0021] An embodiment according to the present invention will now be described hereinafter with reference to the accompanying drawings. In FIGS. 1, 2 and 3, reference numeral 11 denotes a support frame which is set on a floor face 12 and extends in a substantially vertical direction, a winding roll 14 is rotatably supported at a central portion of this support frame 11 in the vertical direction through a bearing 13, and this winding roll 14 comprises a cylindrical reel 15 and a linear body 16 wound around the reel 15 multiple times. Reference numeral 17 designates a wind-off roller which is supported at an upper end portion of the support frame 11, and the linear body 16 drawn from the winding roll 14 is wound around this wind-off roller 17. Further, upon receiving a driving force from a motor 18 fixed to the support frame 11, this wind-off roller 17 rotates and takes the linear body 16, and then sequentially winds off the linear body 16 while allowing traveling from the winding roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com