Patents

Literature

37results about "Record carrier with reserve loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

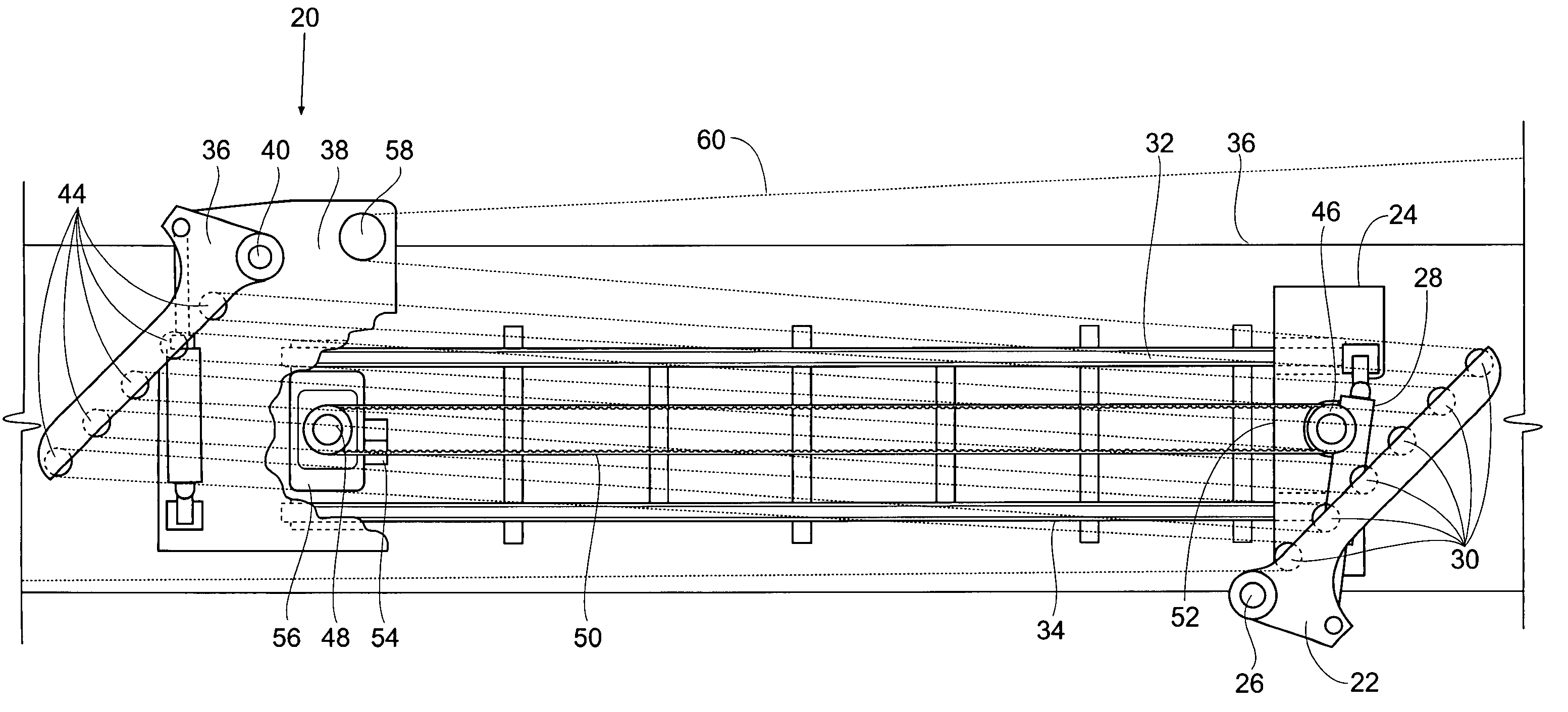

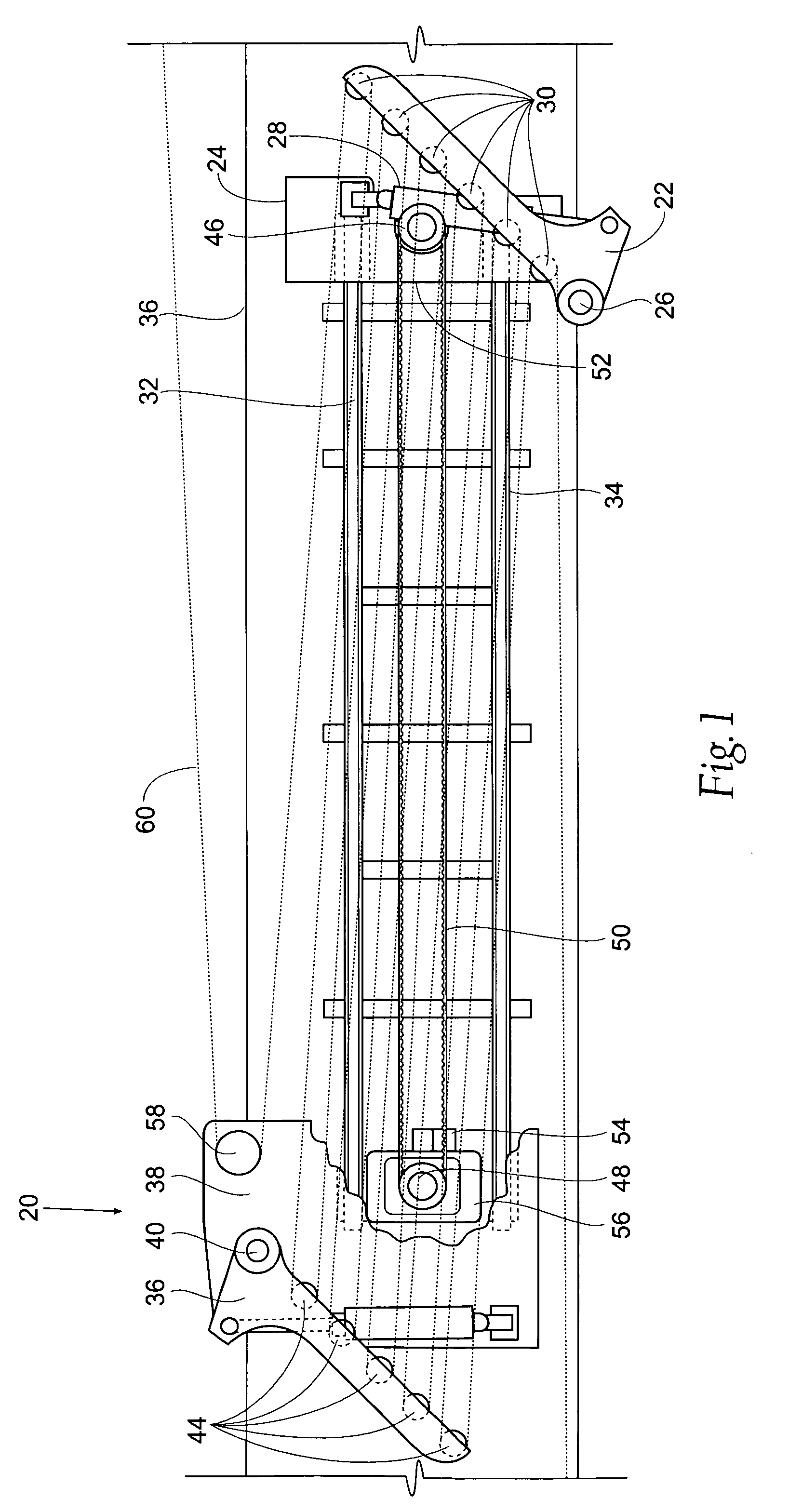

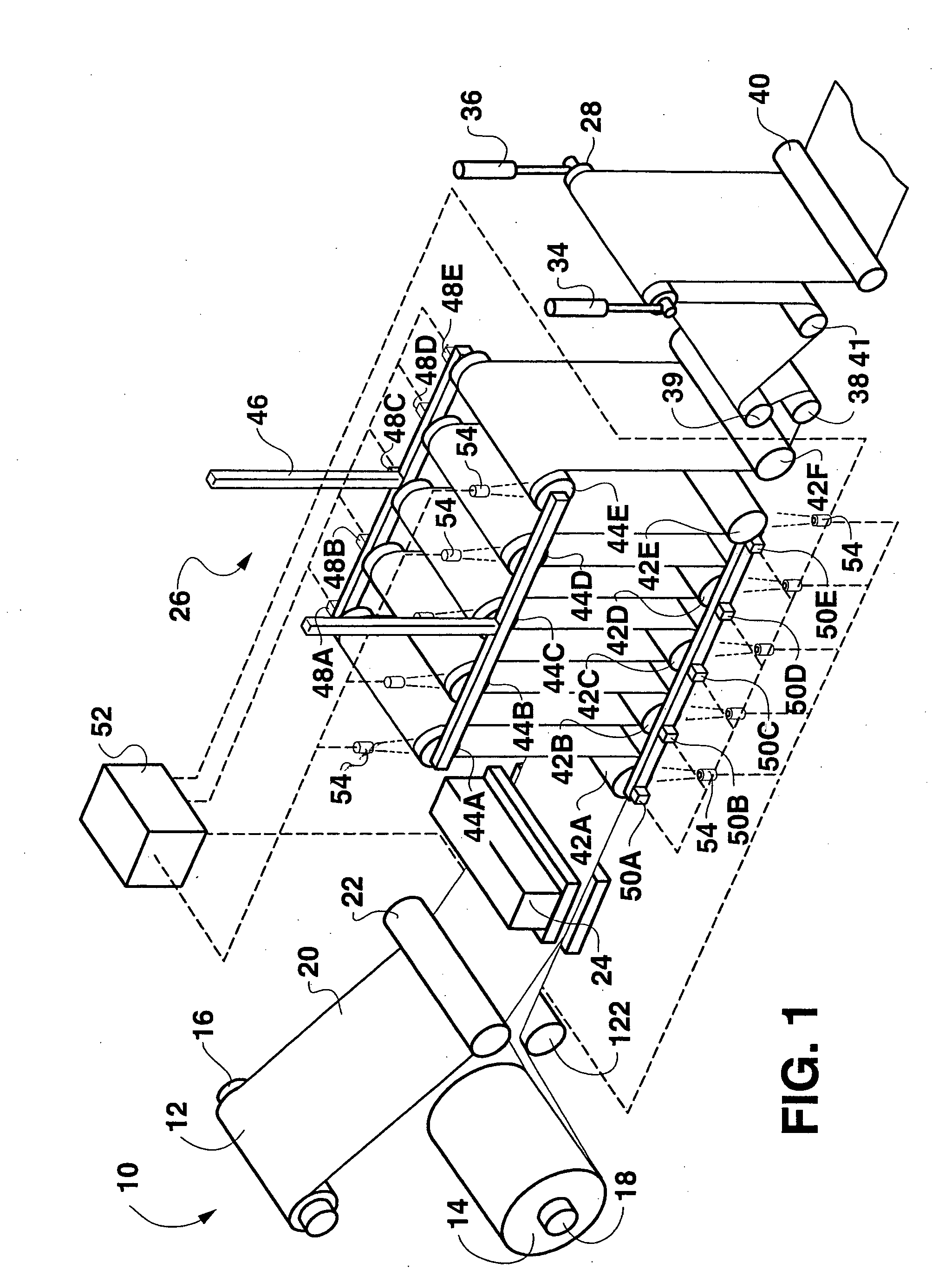

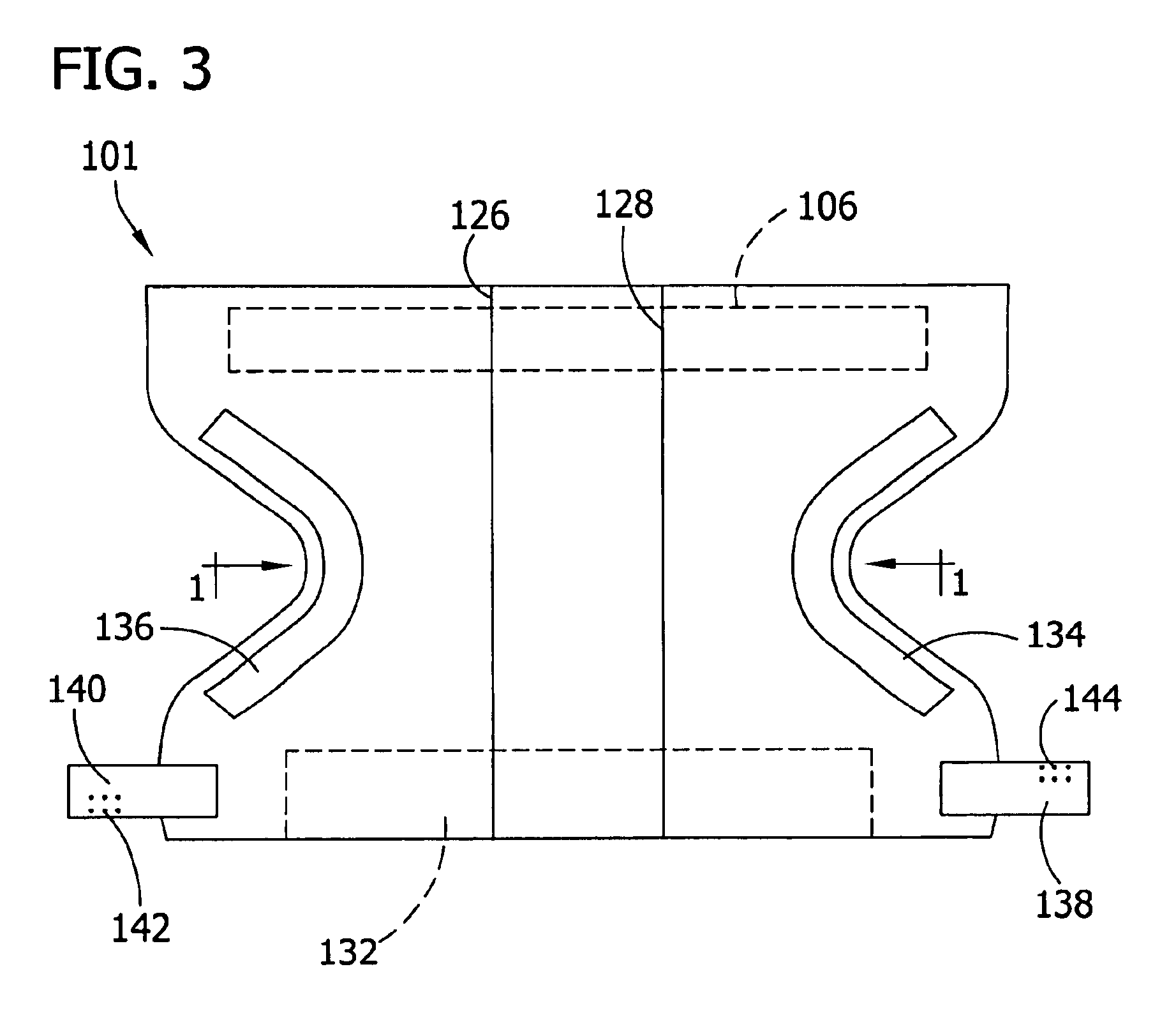

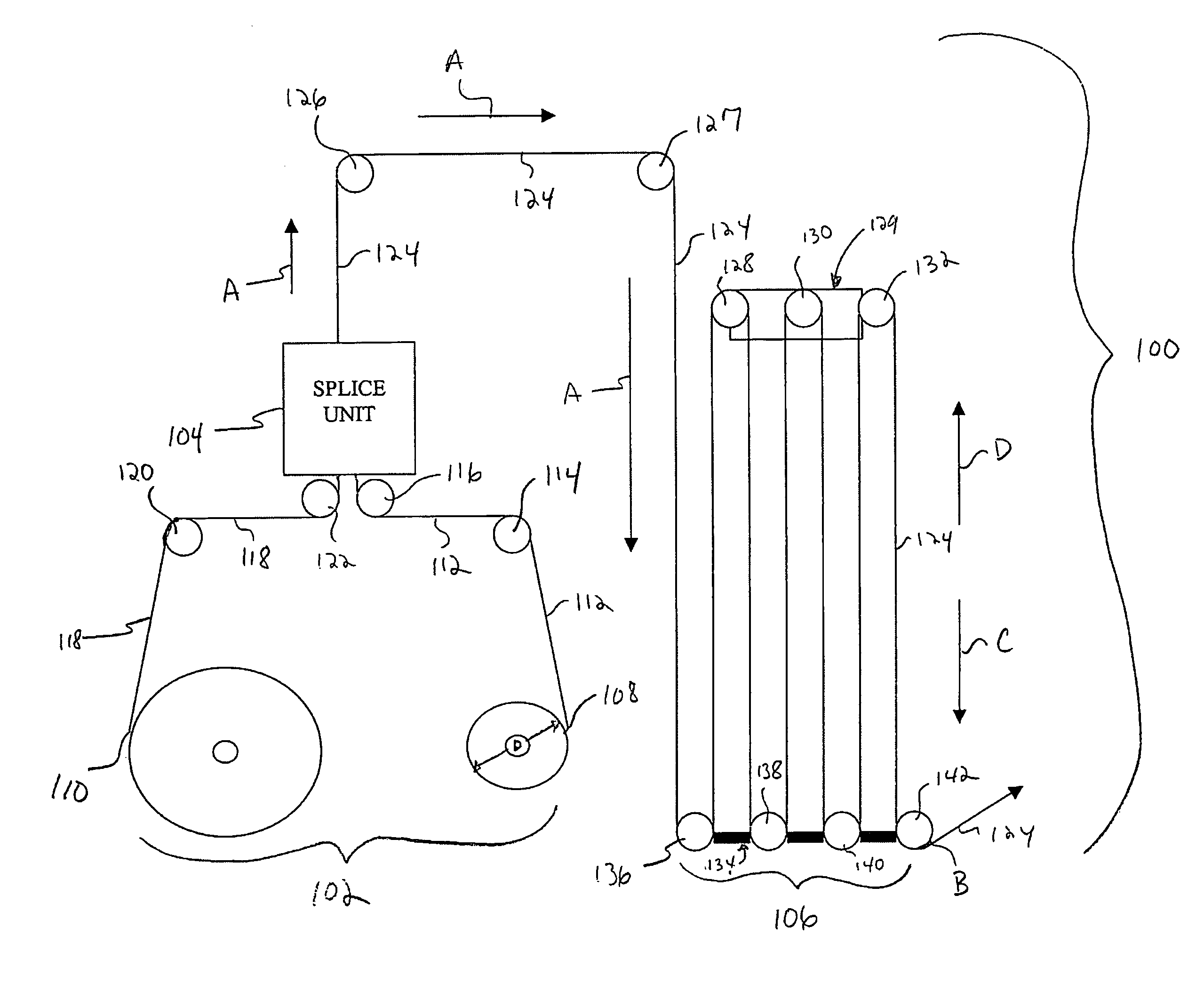

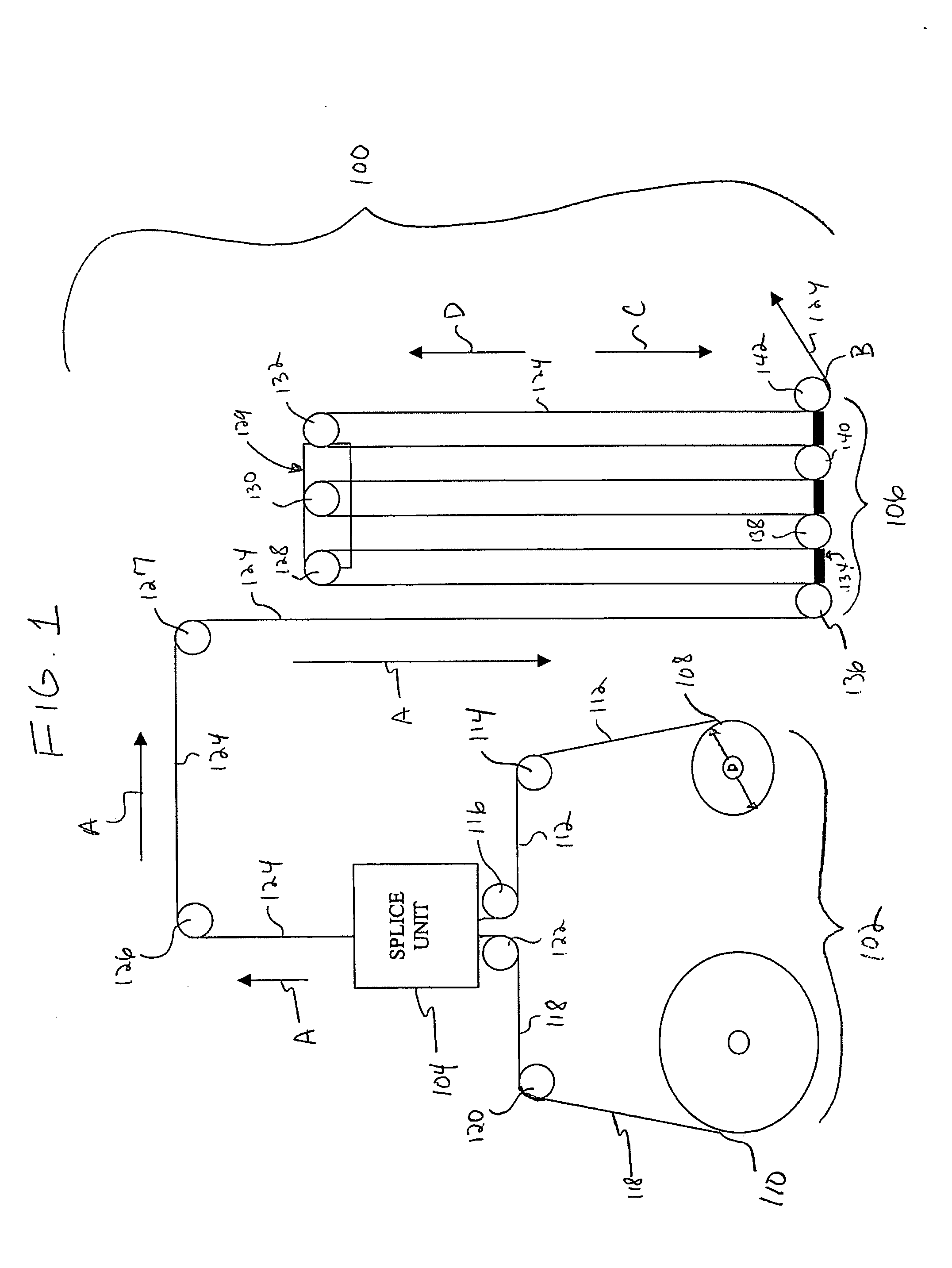

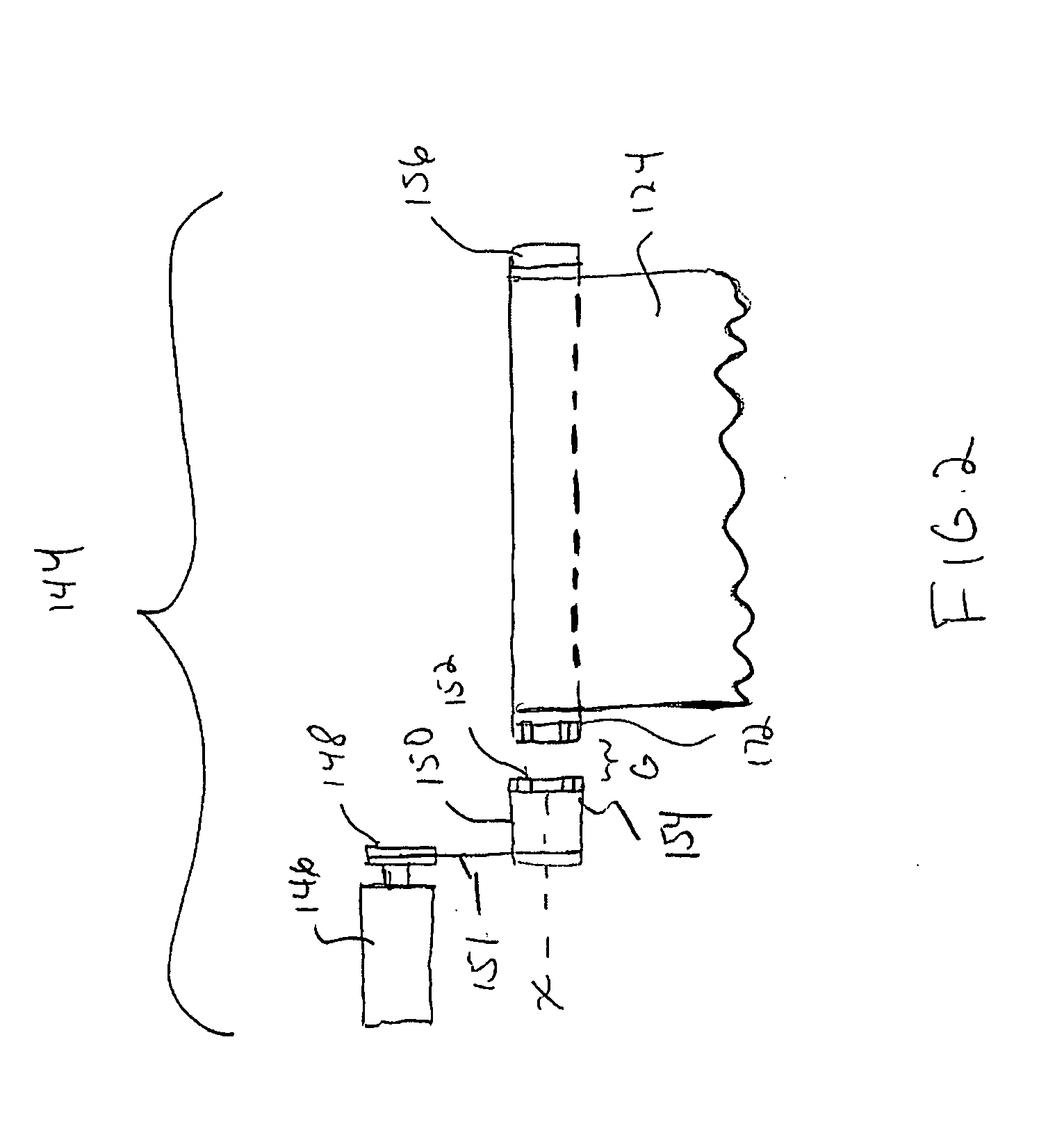

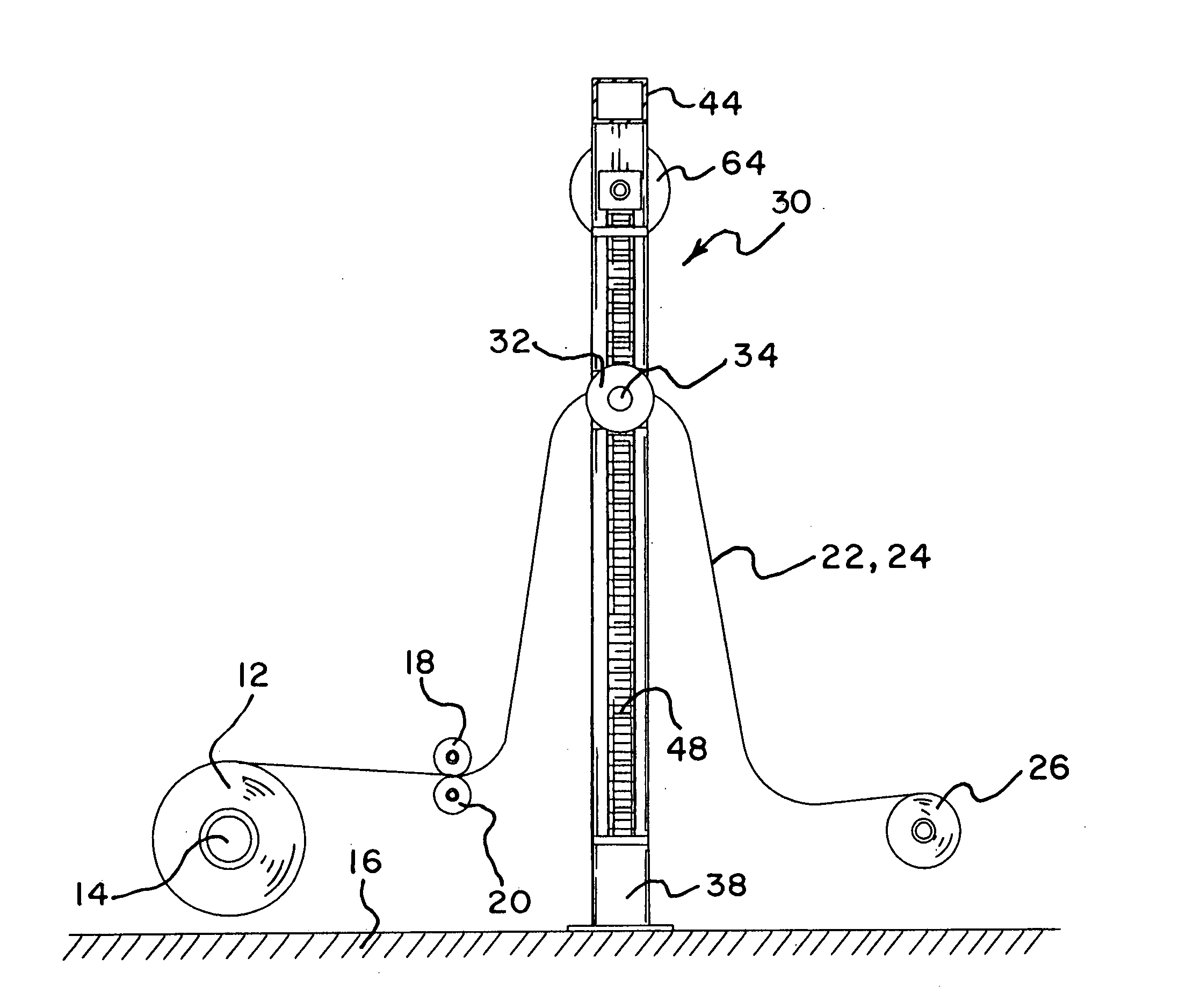

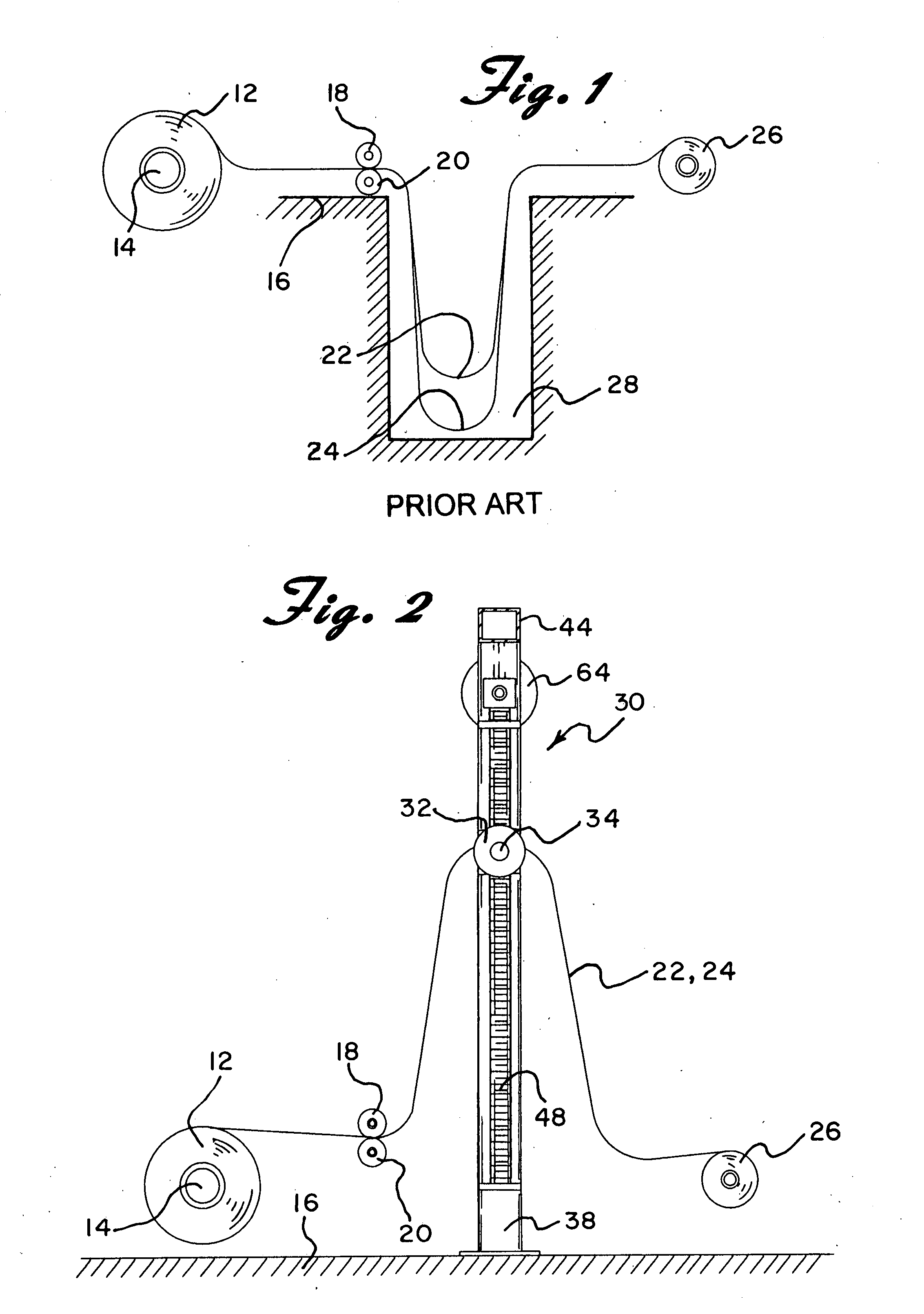

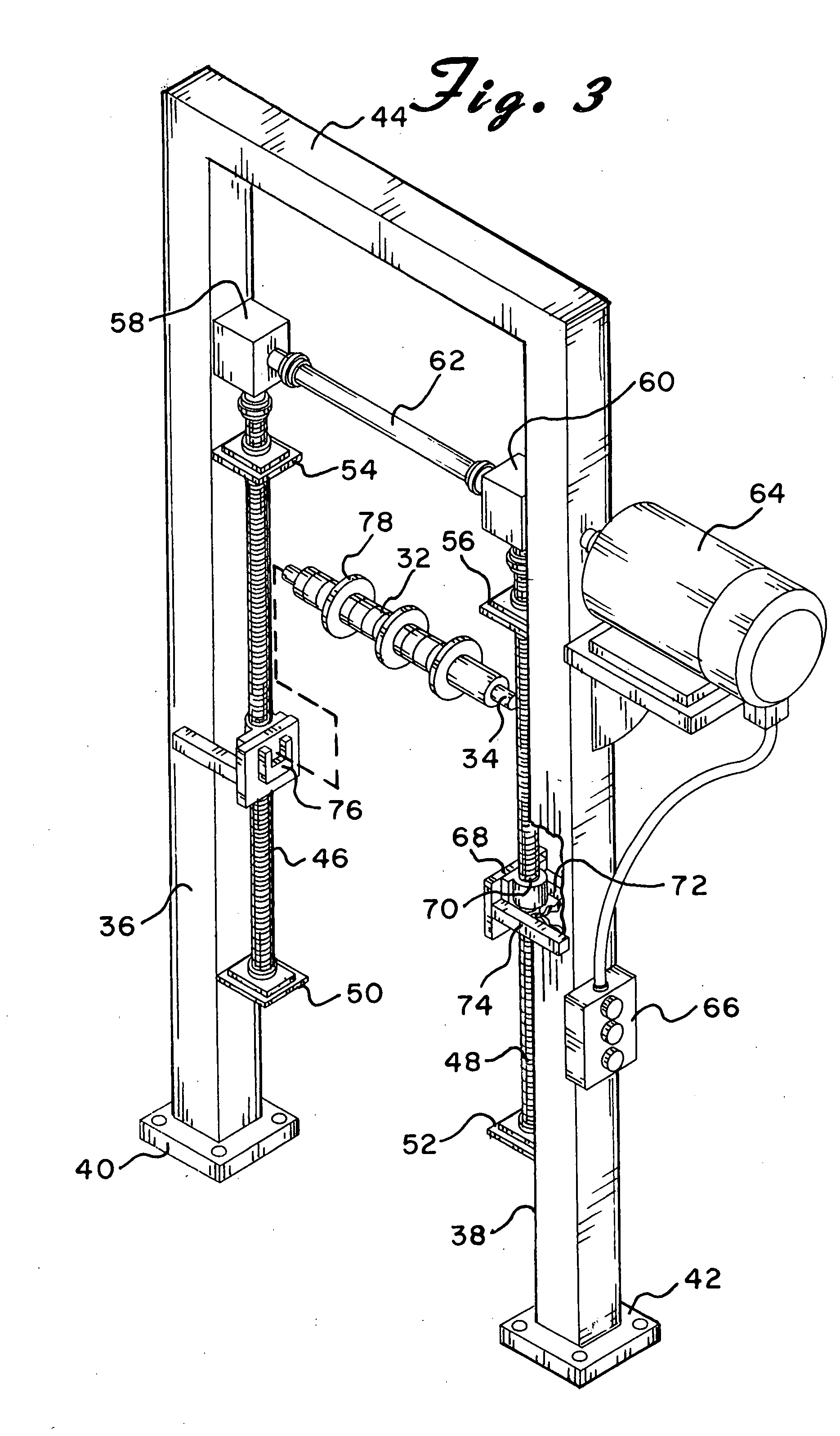

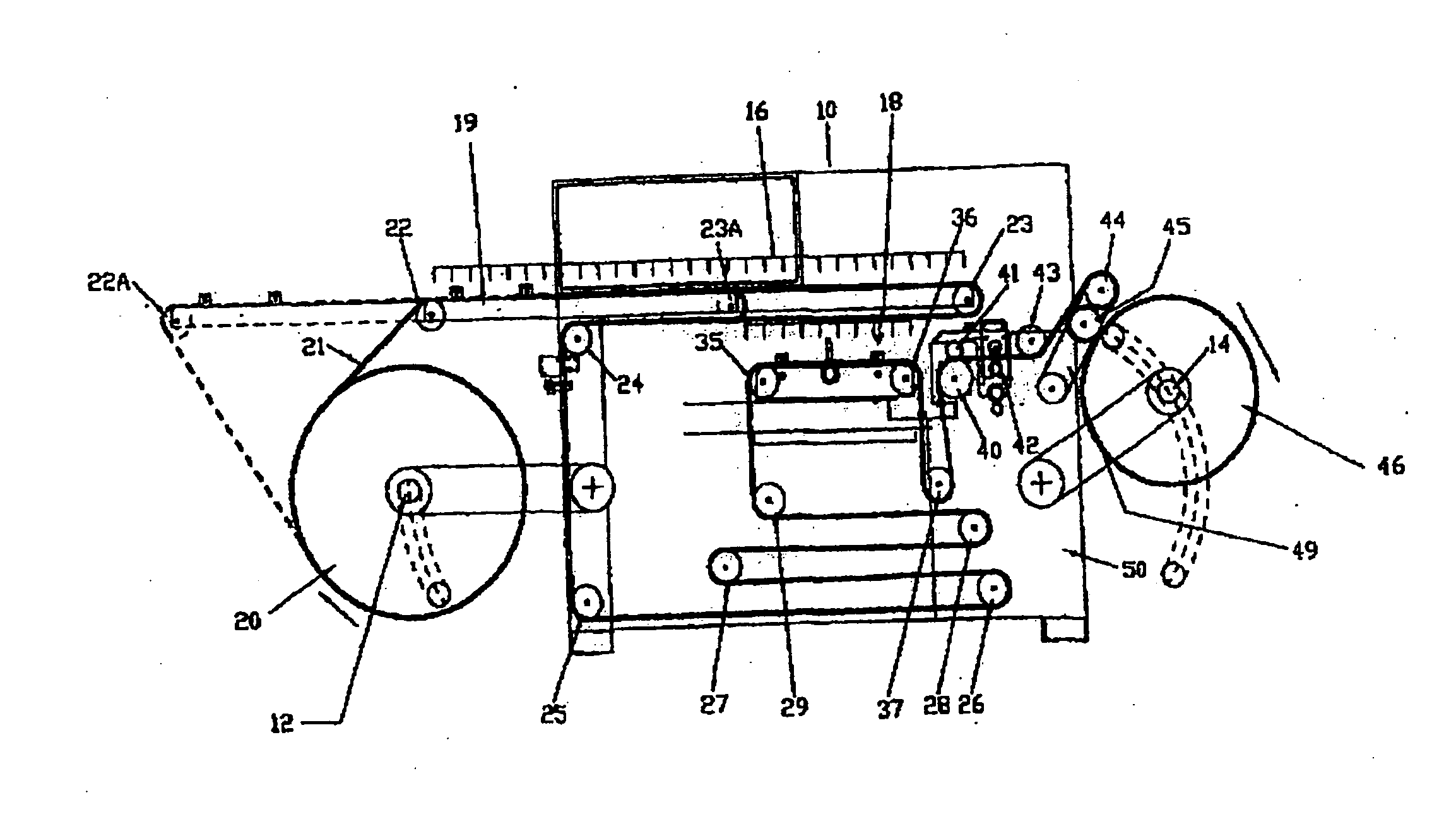

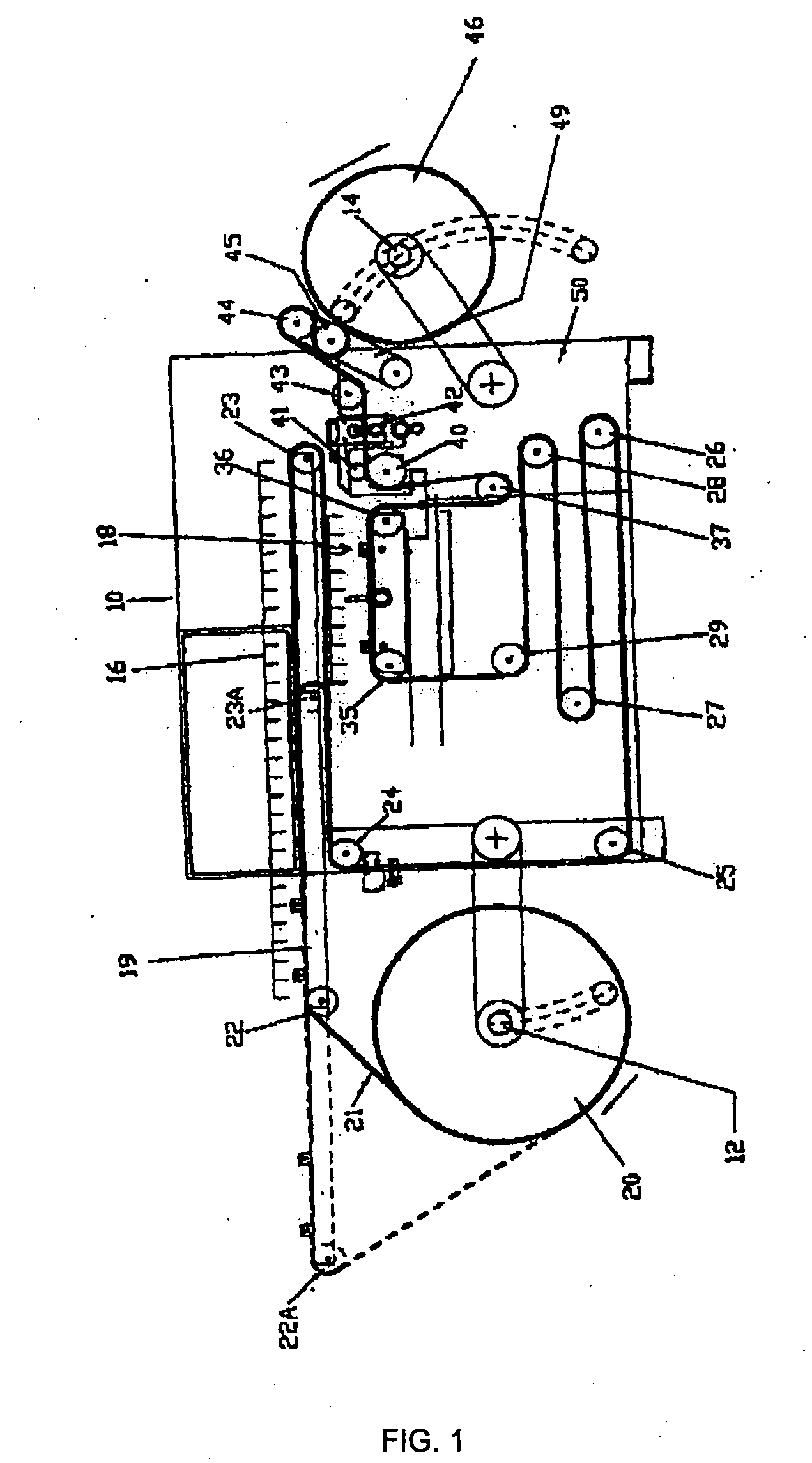

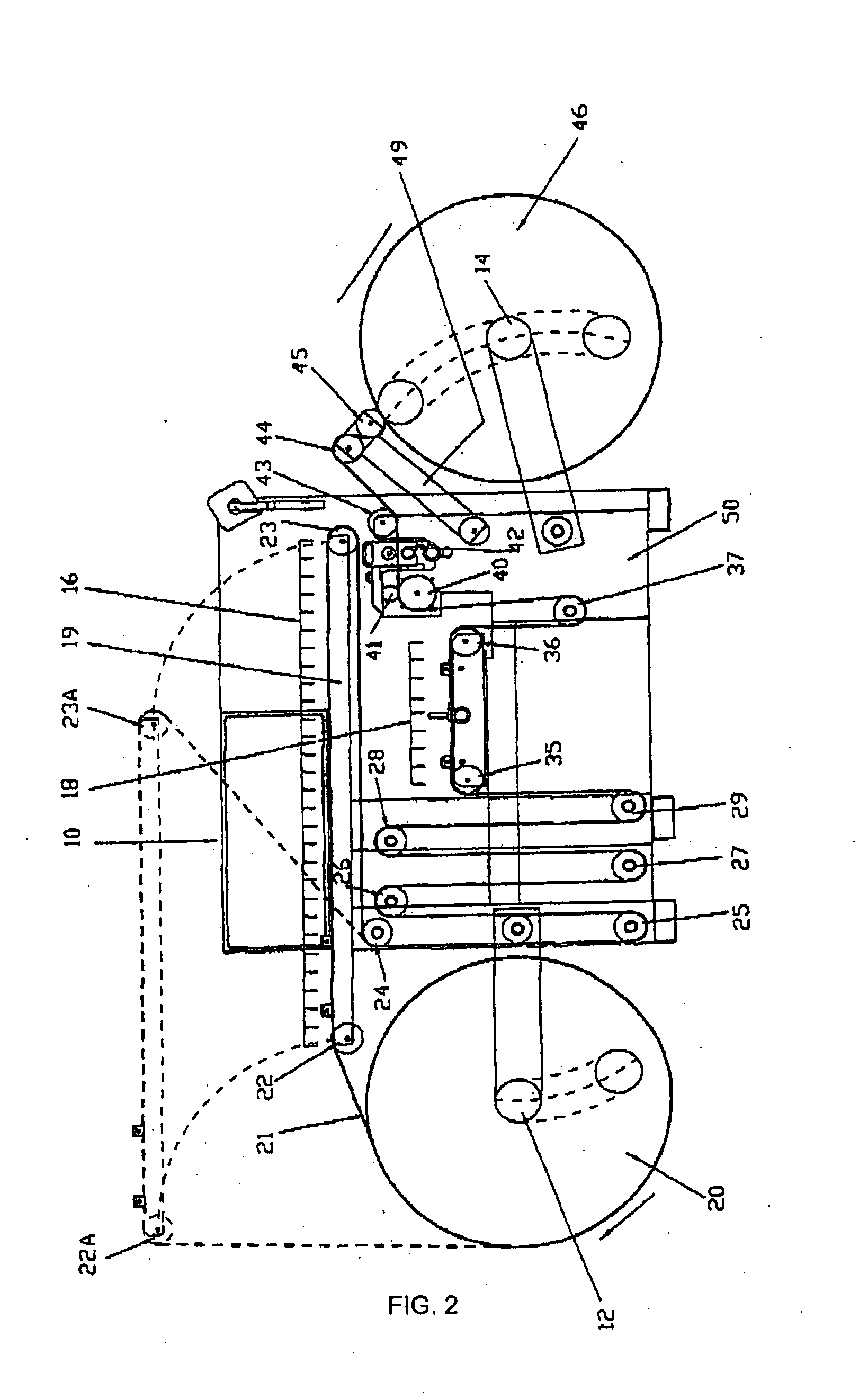

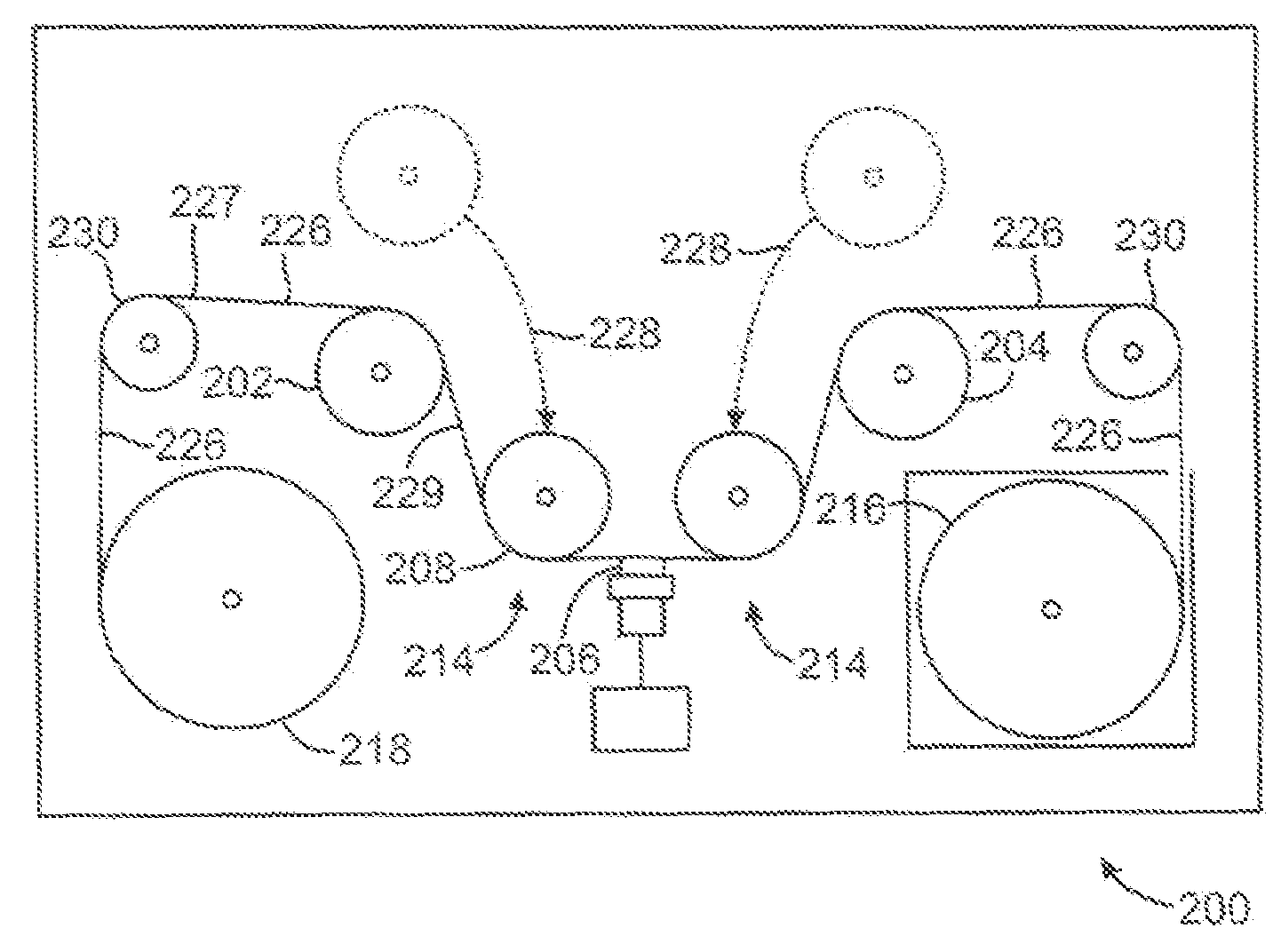

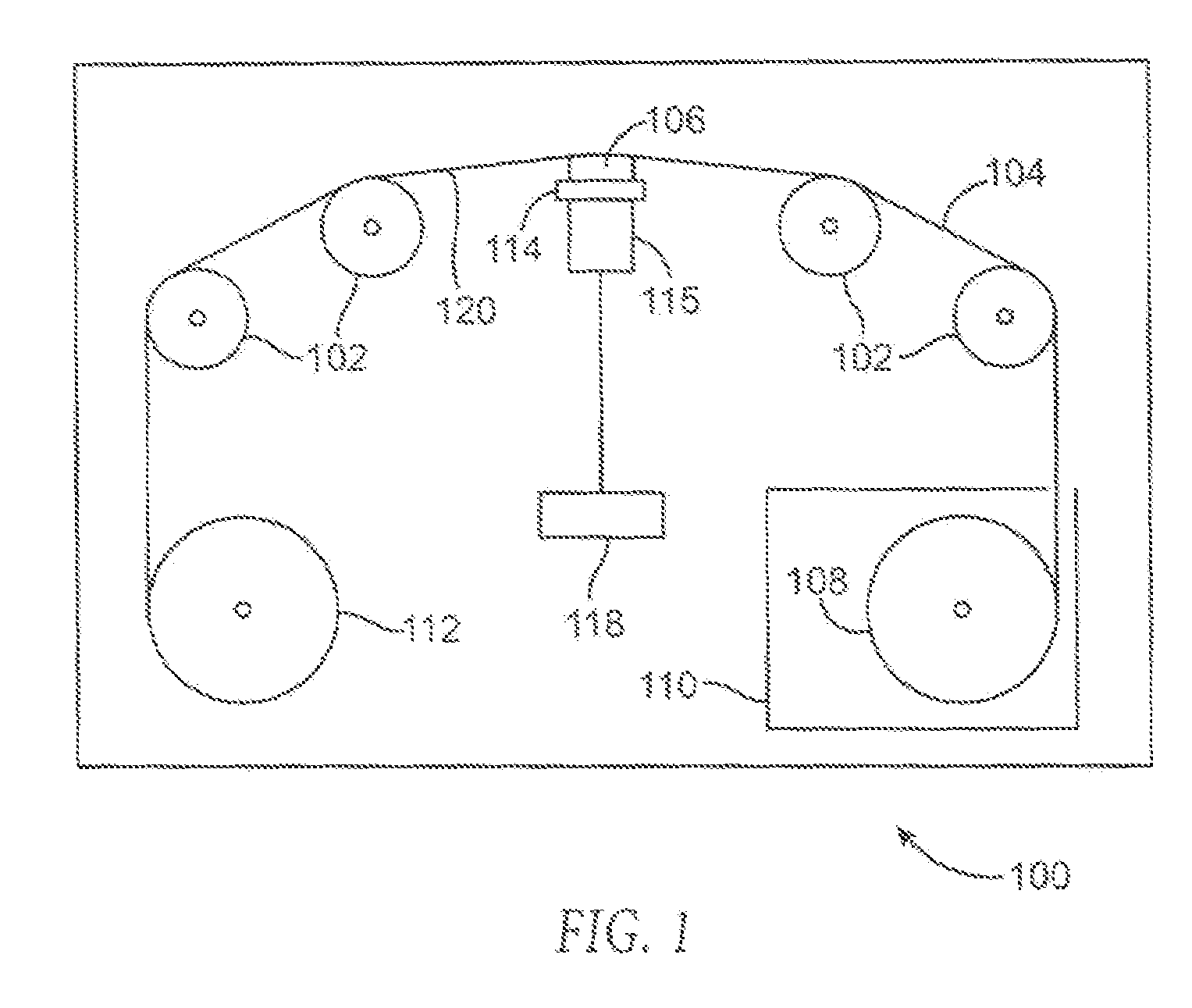

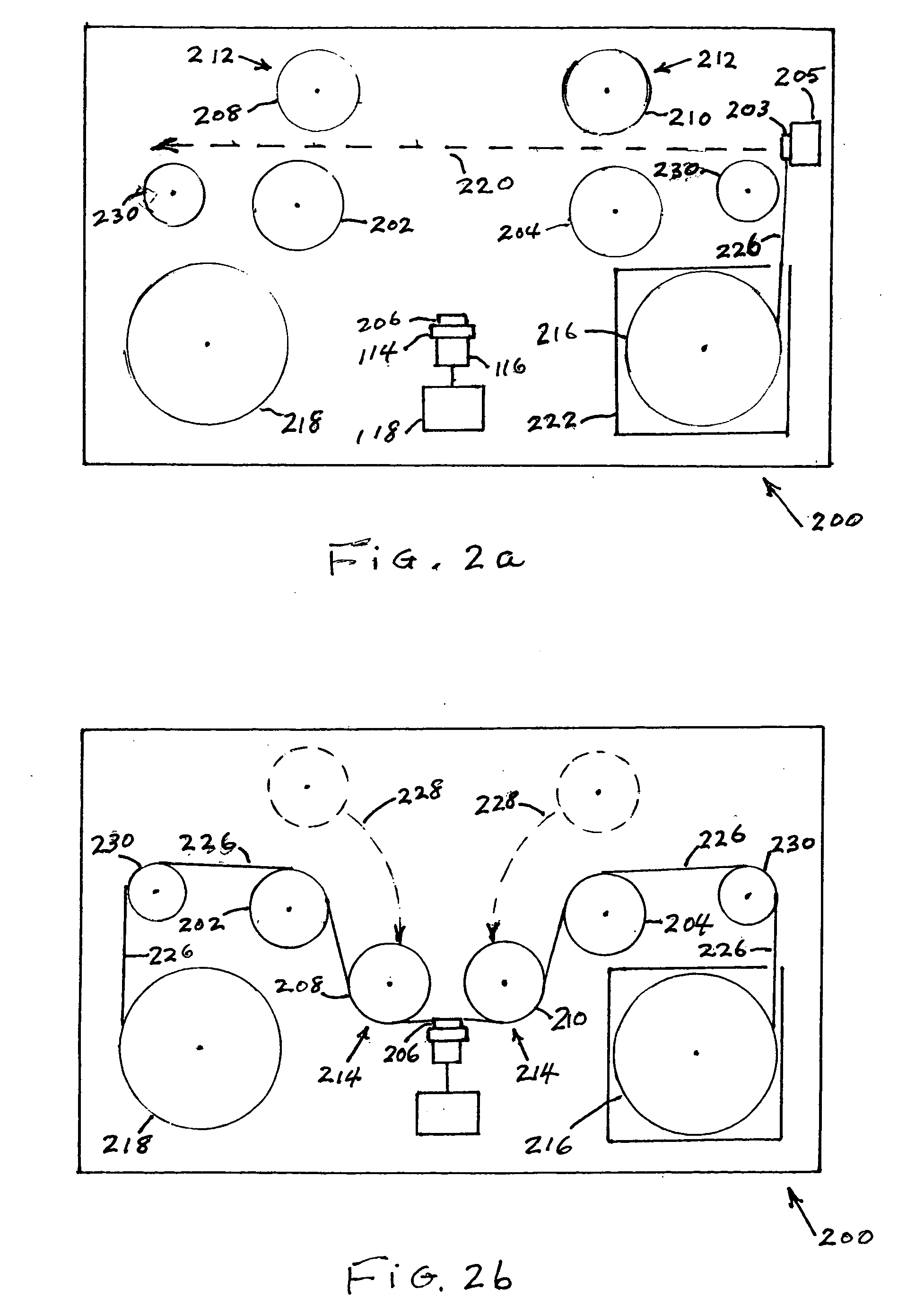

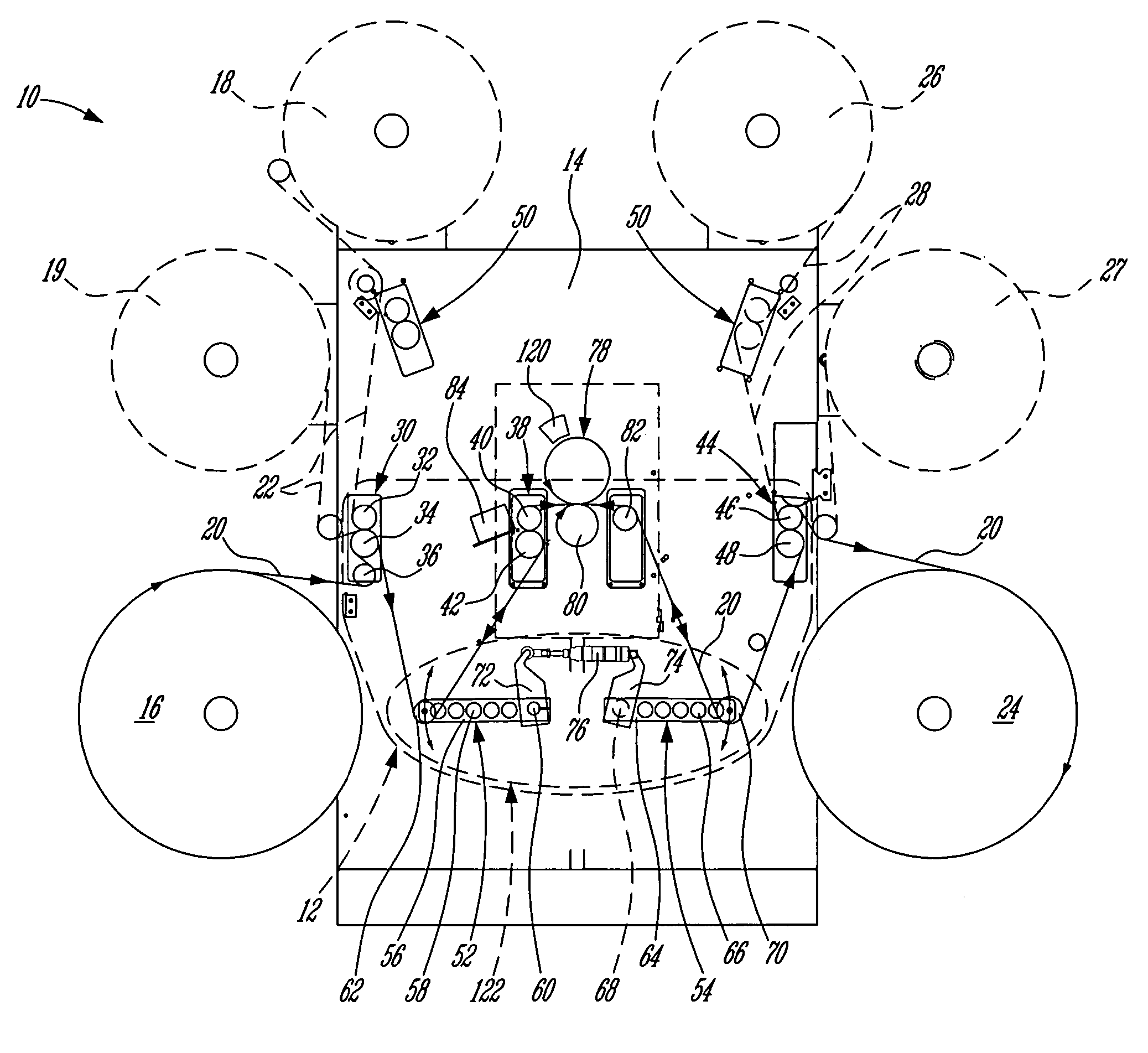

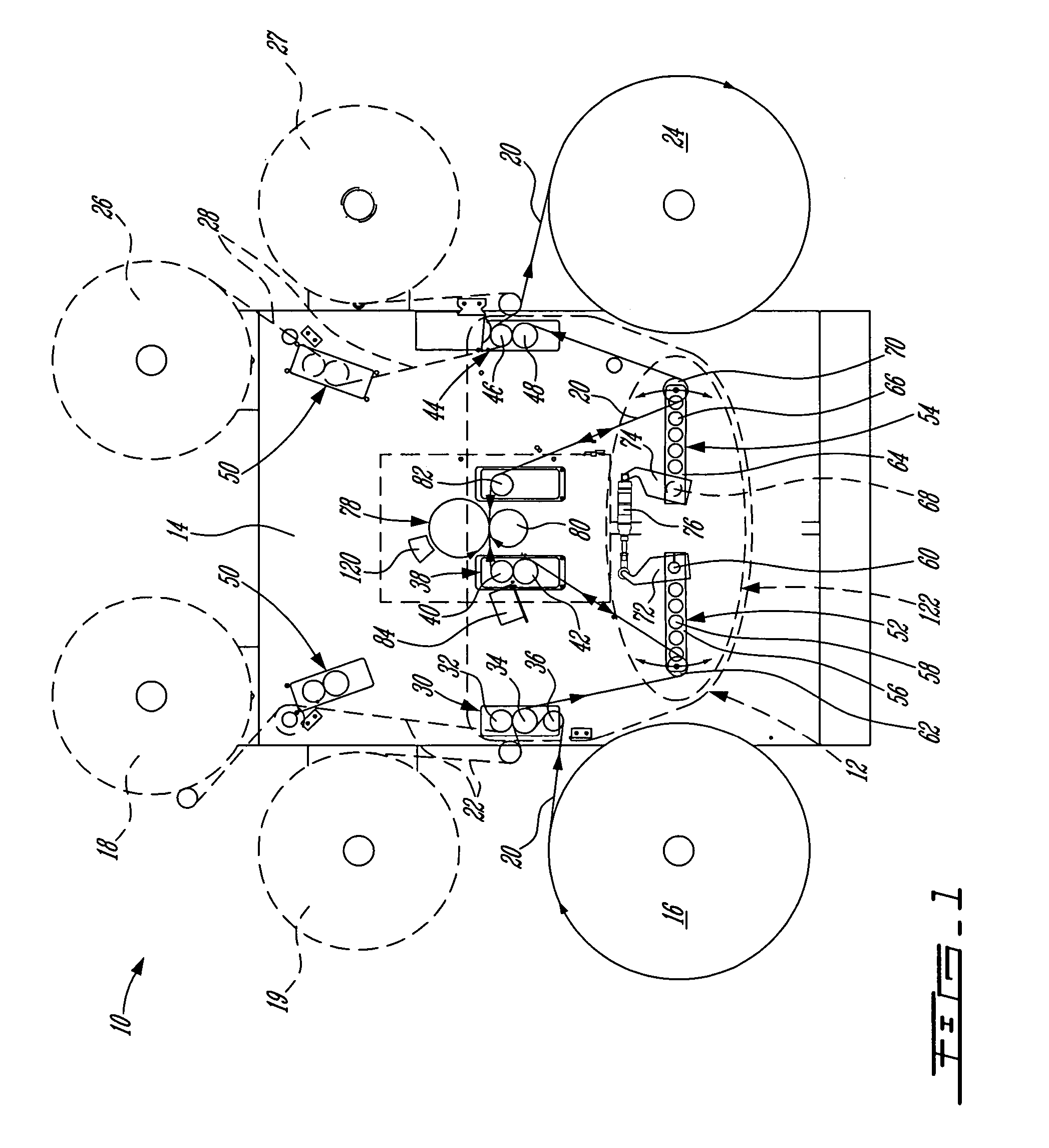

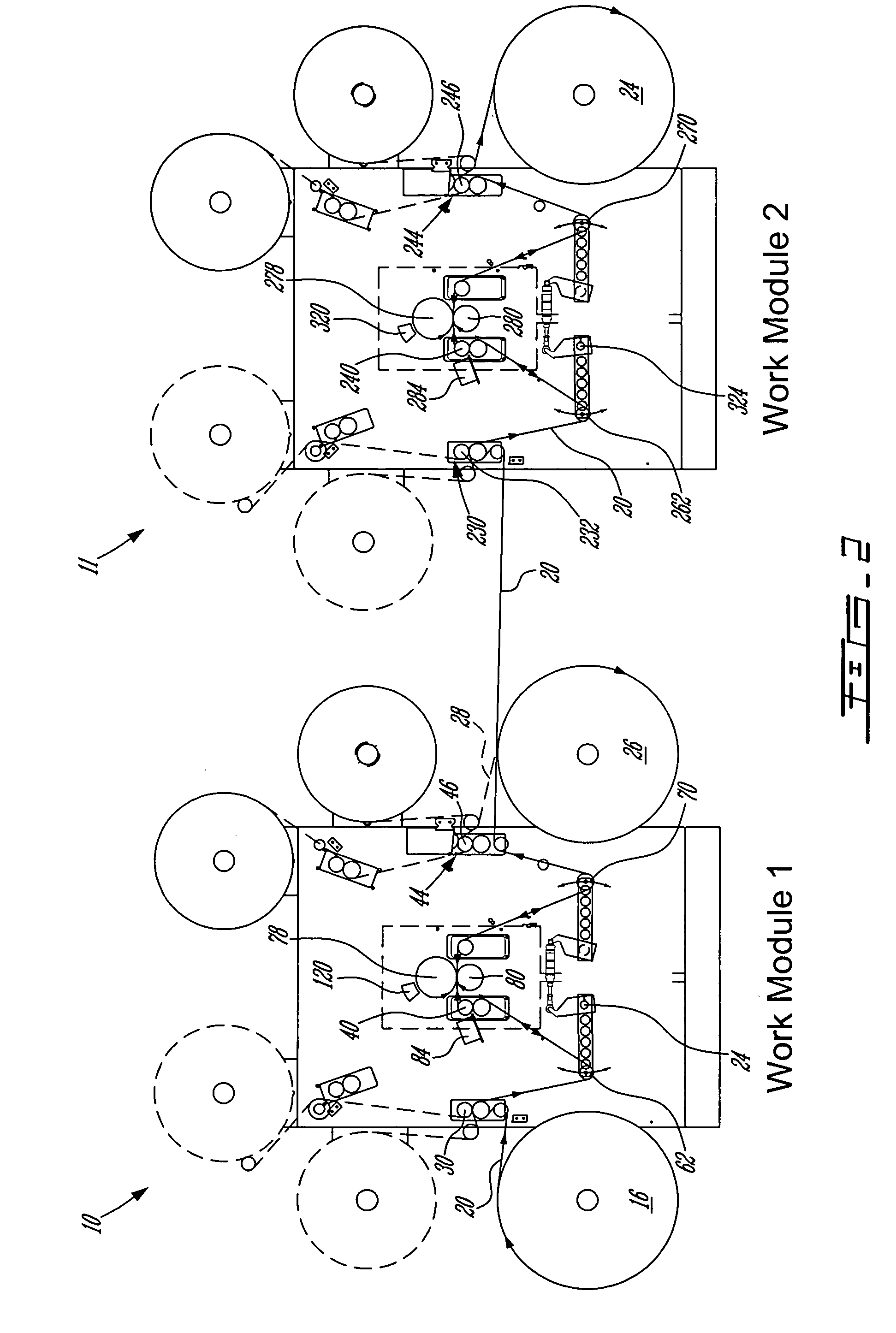

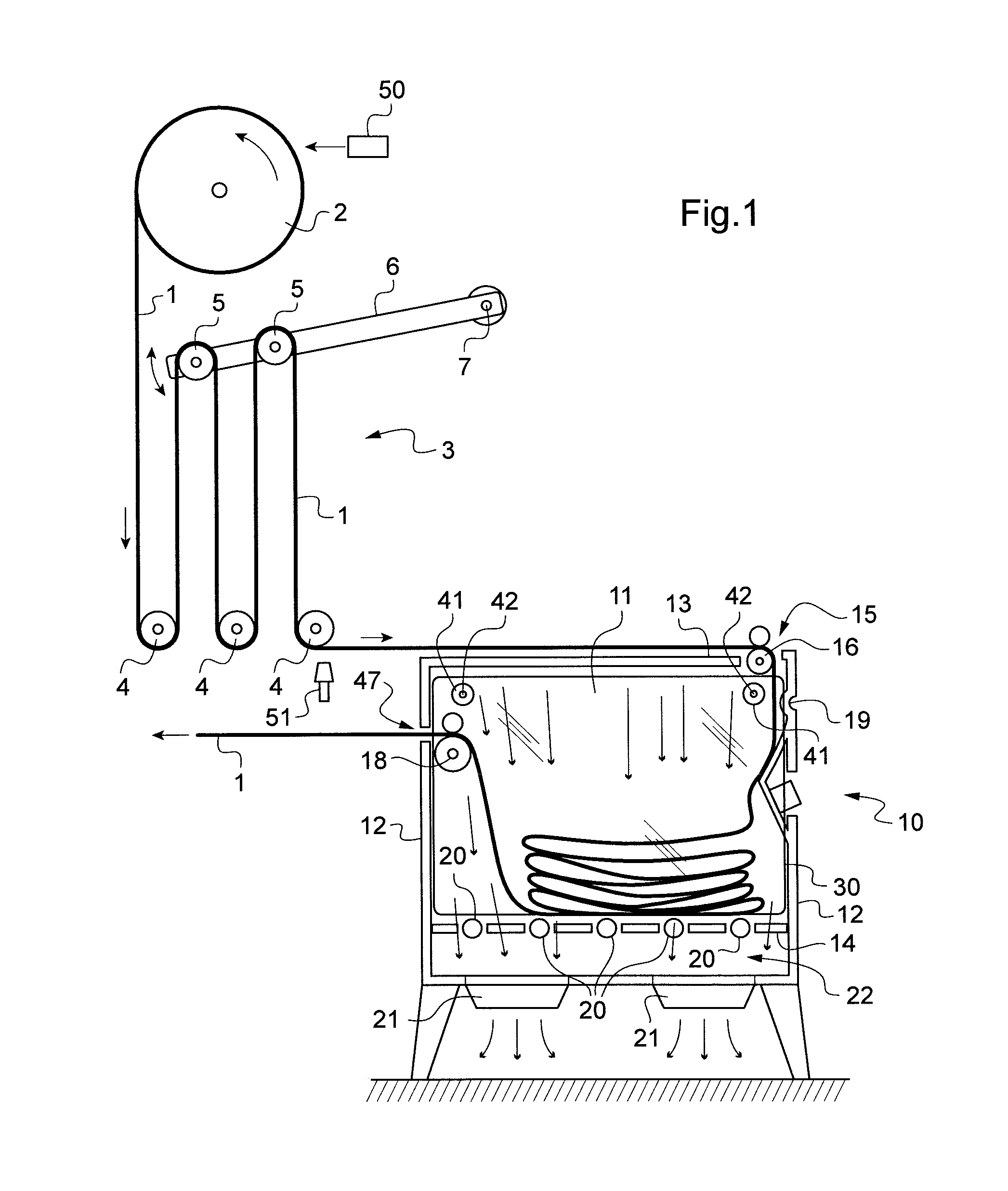

Apparatus and method of increasing web storage in a dancer

InactiveUS20050230449A1Eliminate disadvantagesA large amountRecord information storageRecord carrier with reserve loopWeb storageEngineering

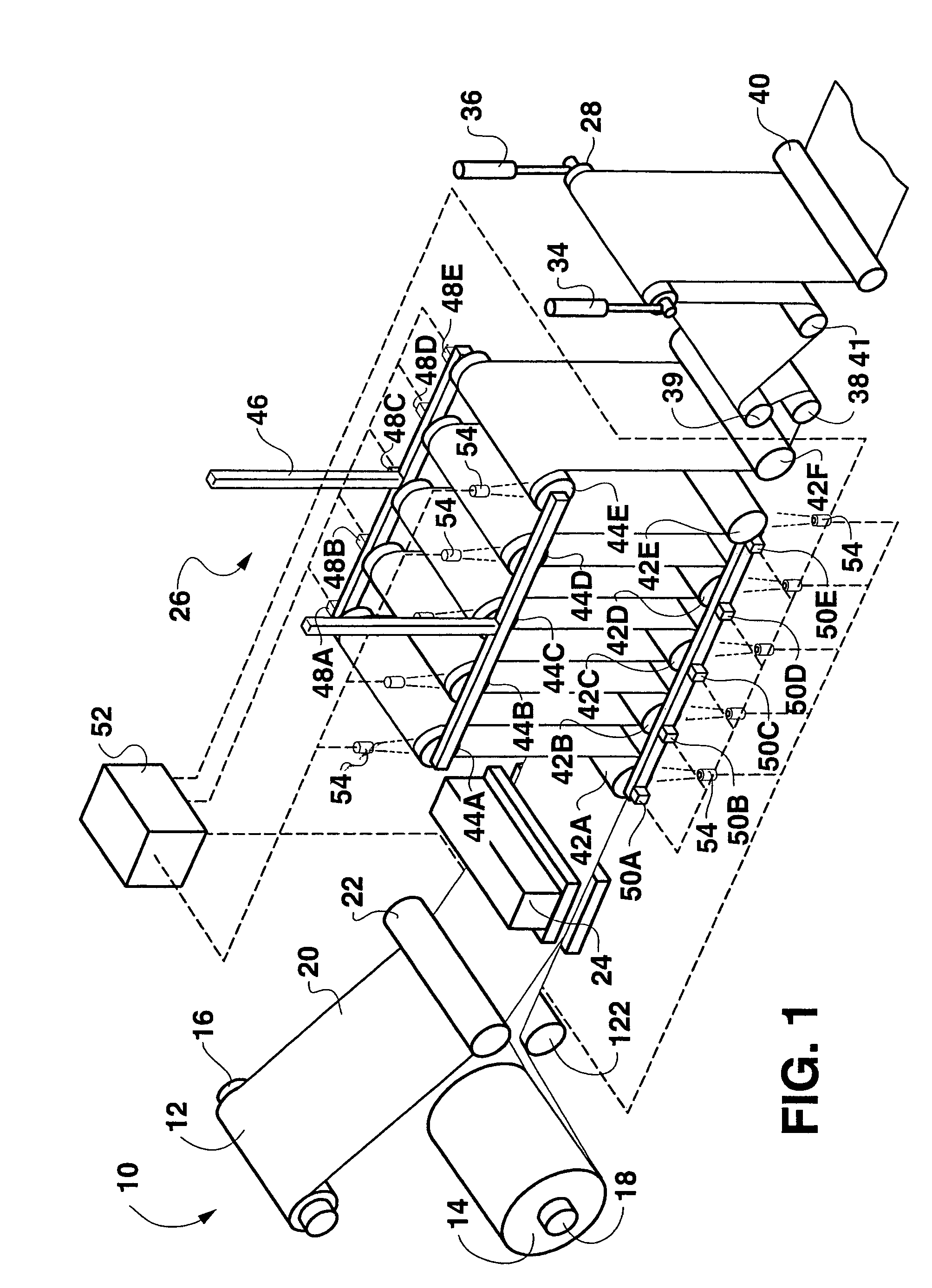

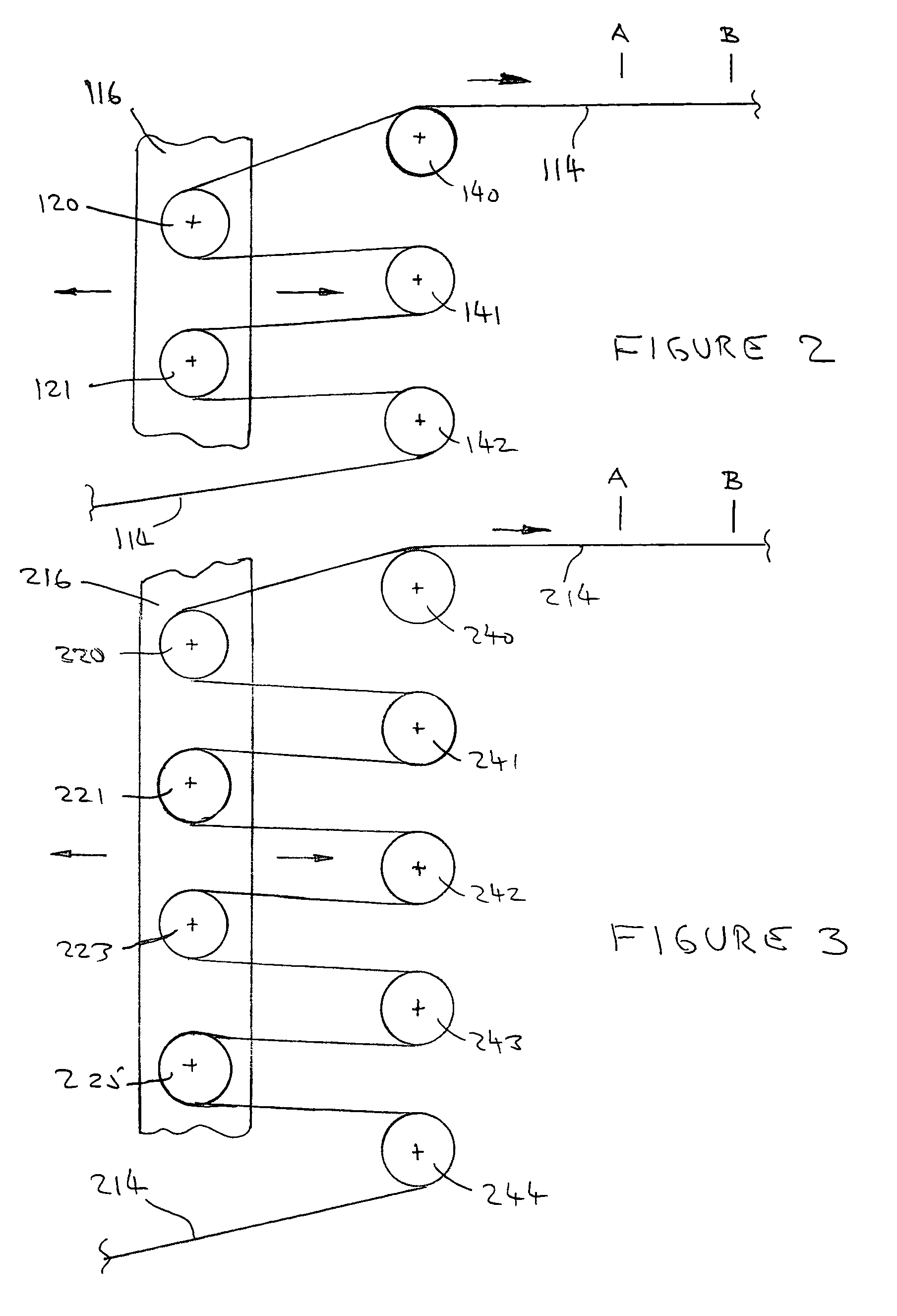

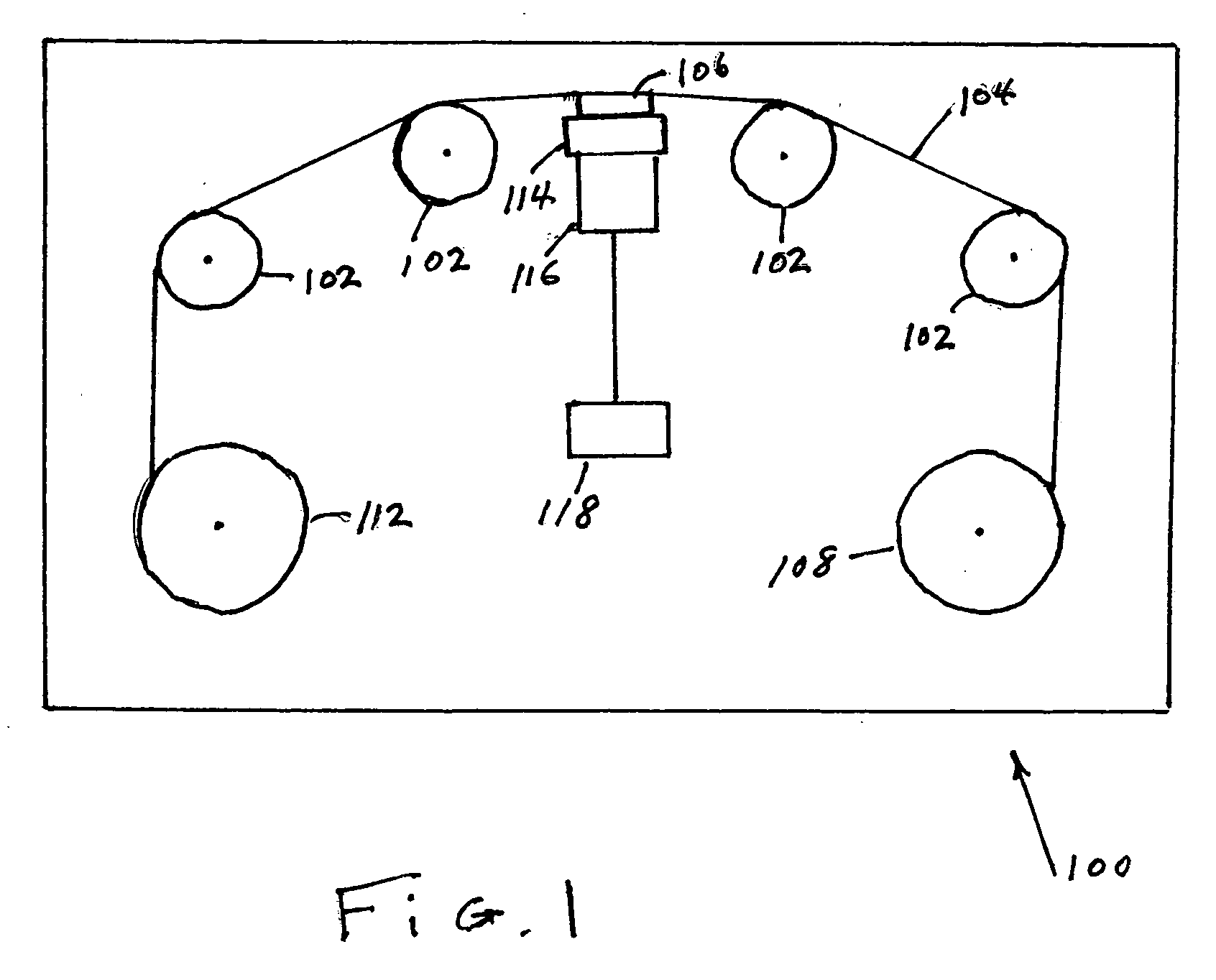

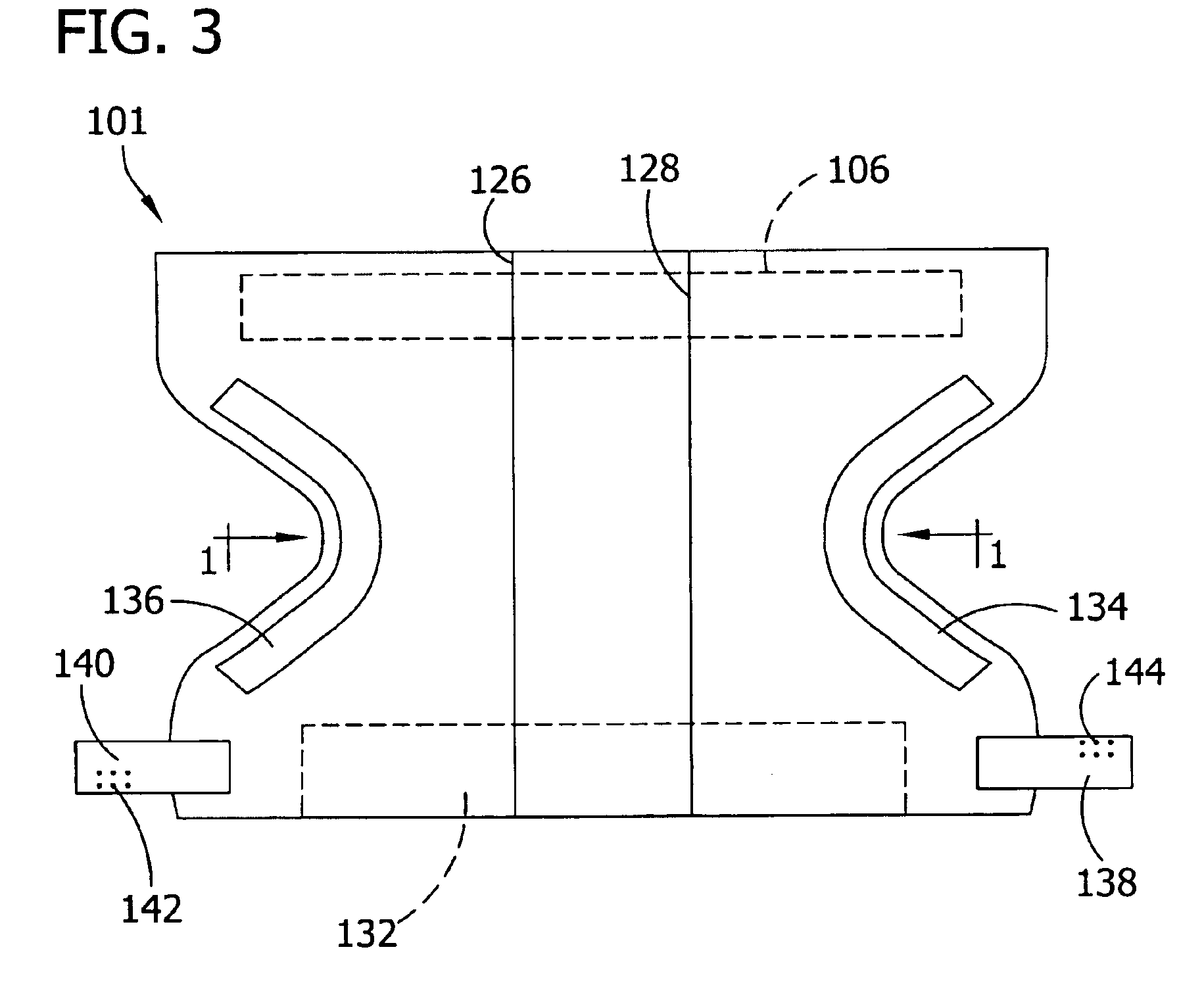

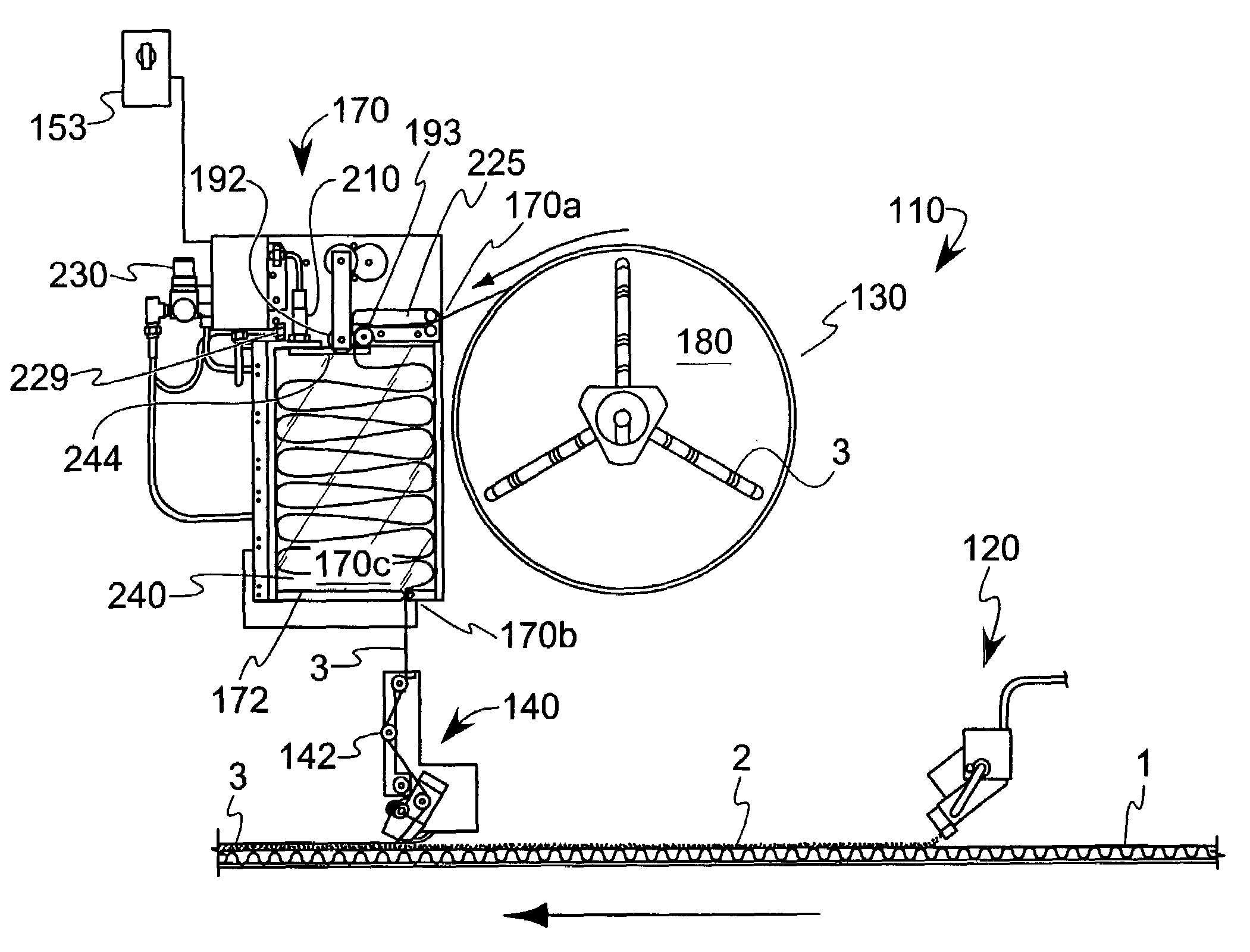

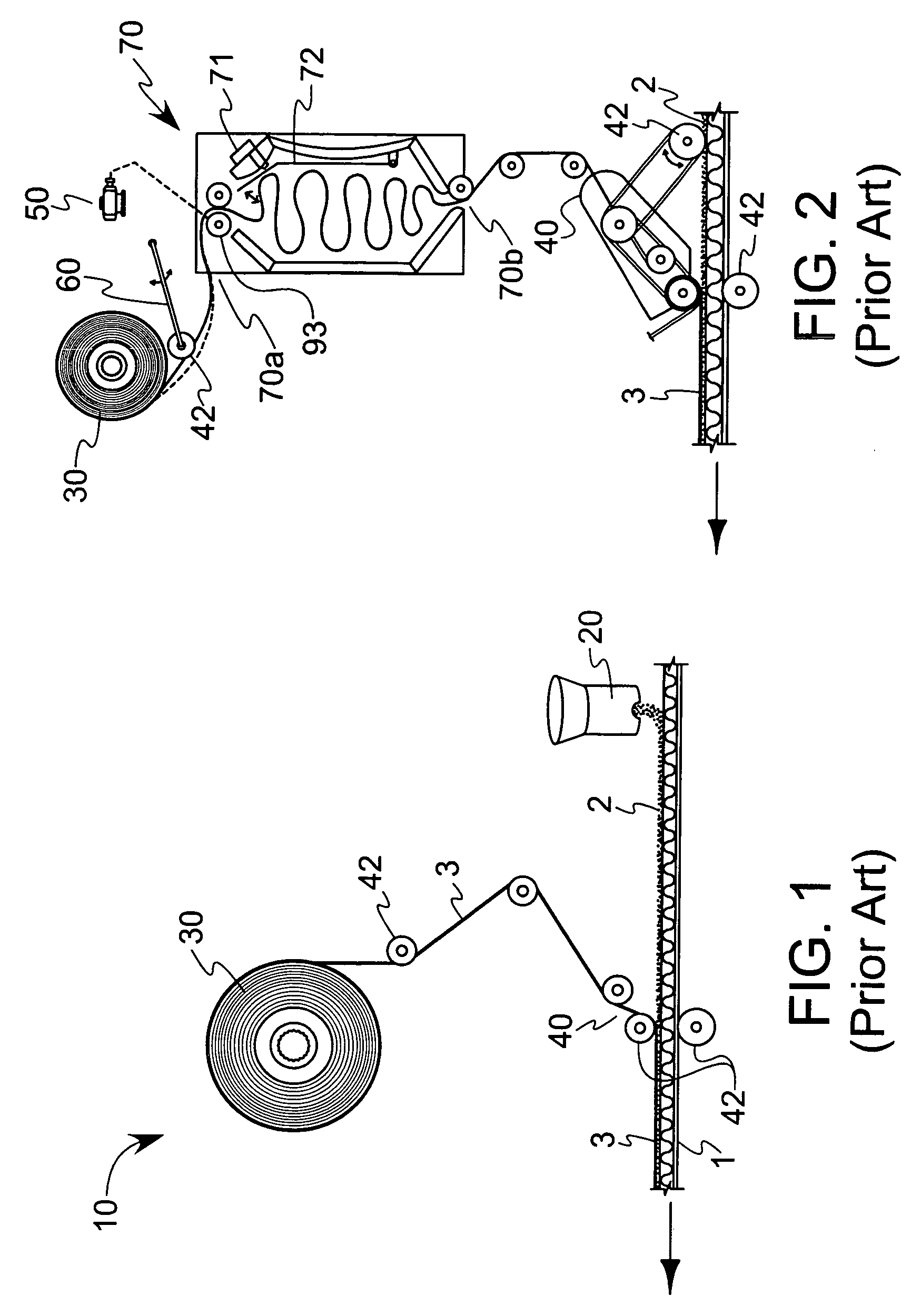

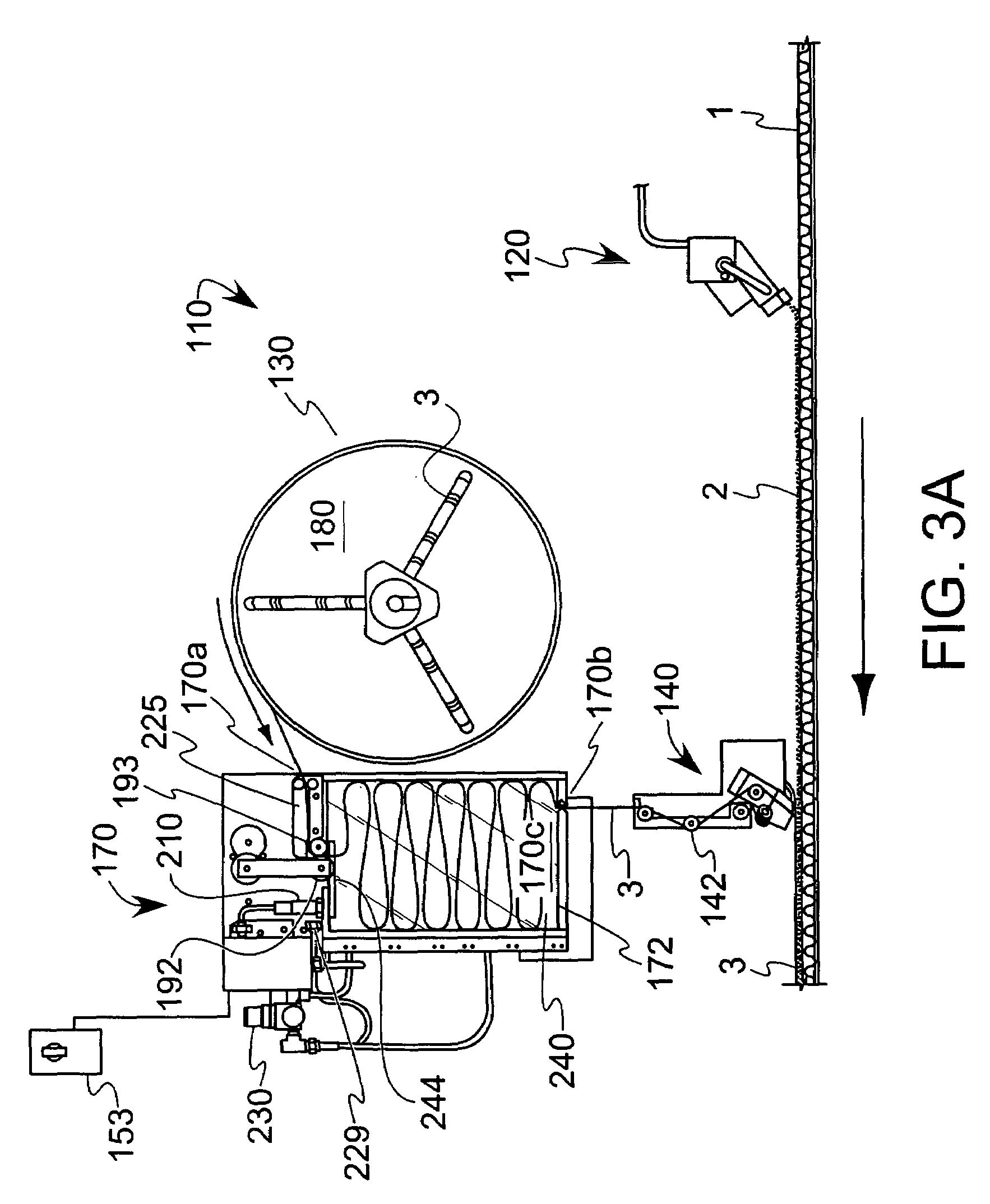

An improved web accumulator with two arms where at least one arm is a swinging dancer arm and at least one arm is attached to a sliding carriage. Each arm has a set of rollers attached. A web is threaded alternately between the two sets of rollers. The arms are mechanically connected to move simultaneously towards or away from each other. The arms are initially position at their maximum separation to accumulate a maximum length of web. When web infeed is interrupted while web outfeed or draw persists, the arms are first rotated in towards each other to pay out the stored length of web. As the demand persists and the dancer arm is rotated beyond some predefined position, the sliding carriage begins to slide to a least storage position. As web infeed returns to normal operational speeds, the dancer arm and the sliding carriage are returned to their original position to again accumulate a maximum amount of web.

Owner:CURT G JOA

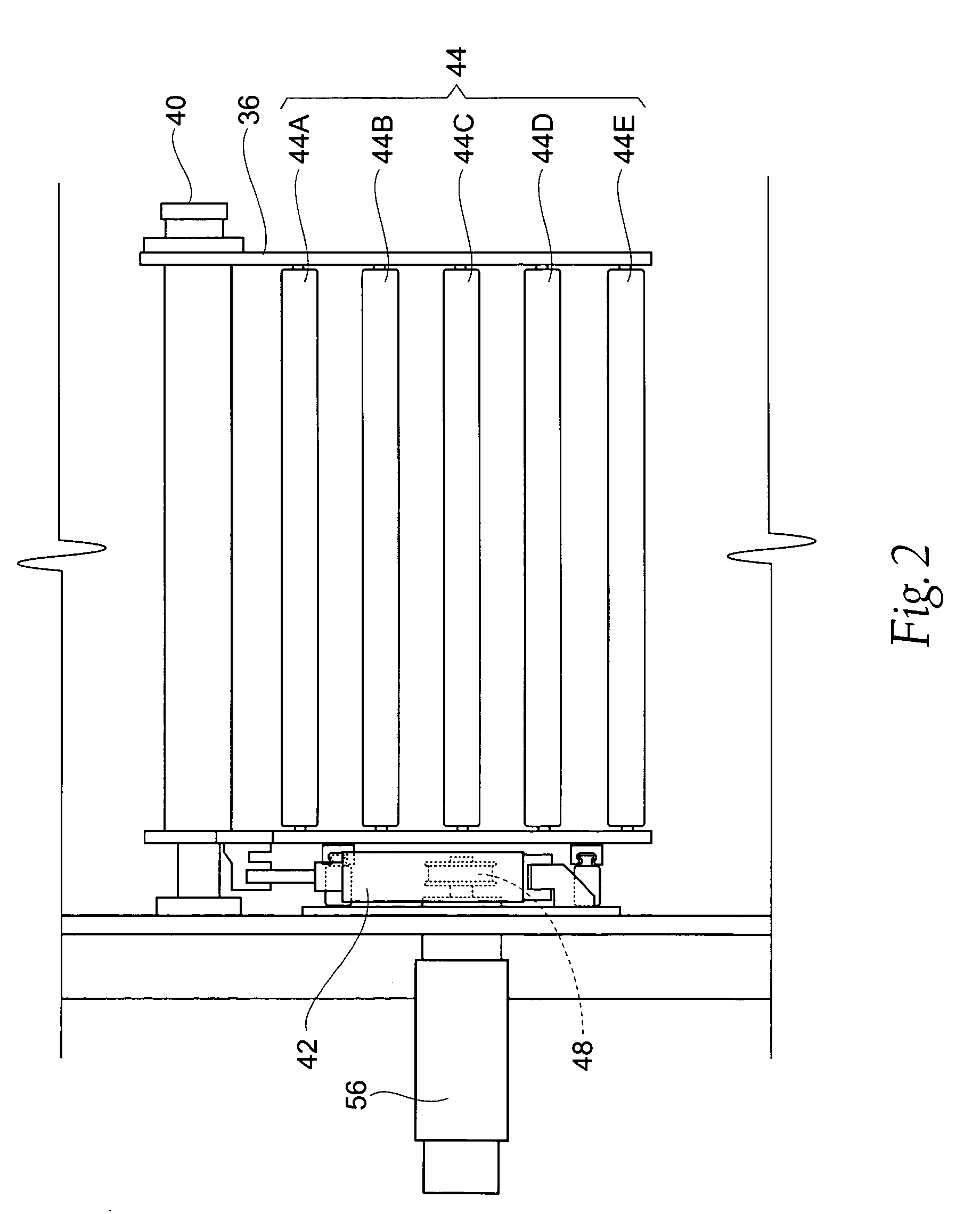

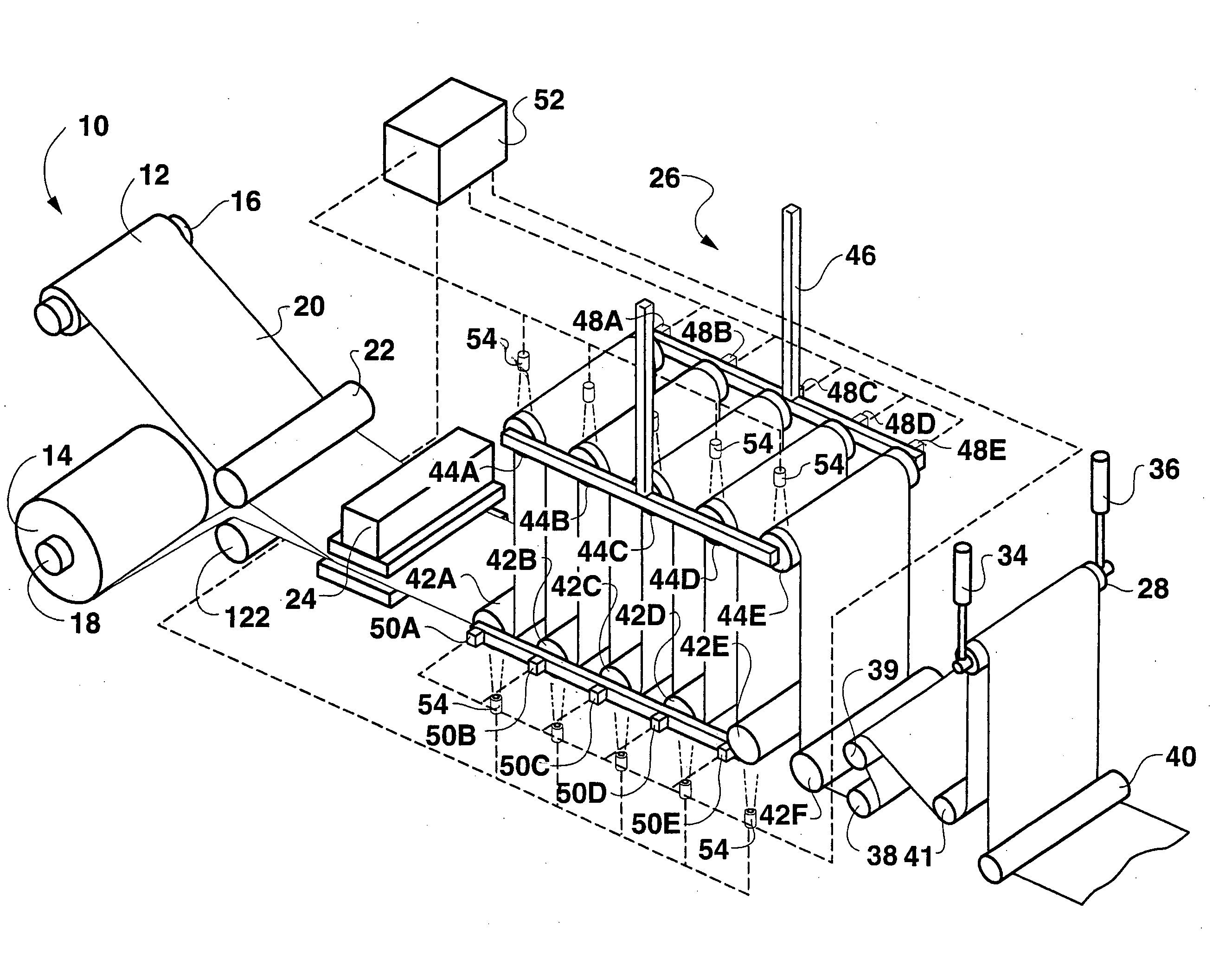

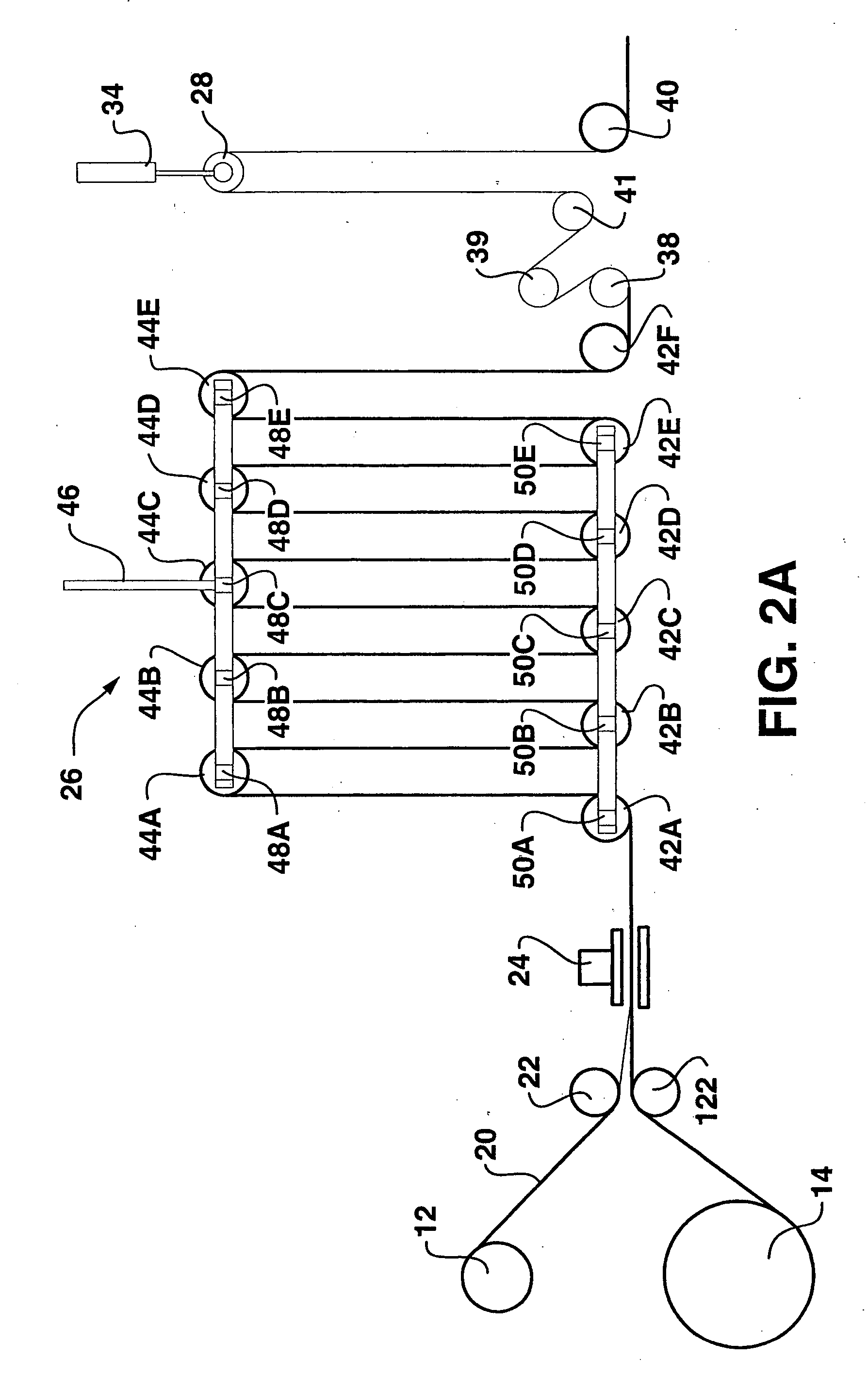

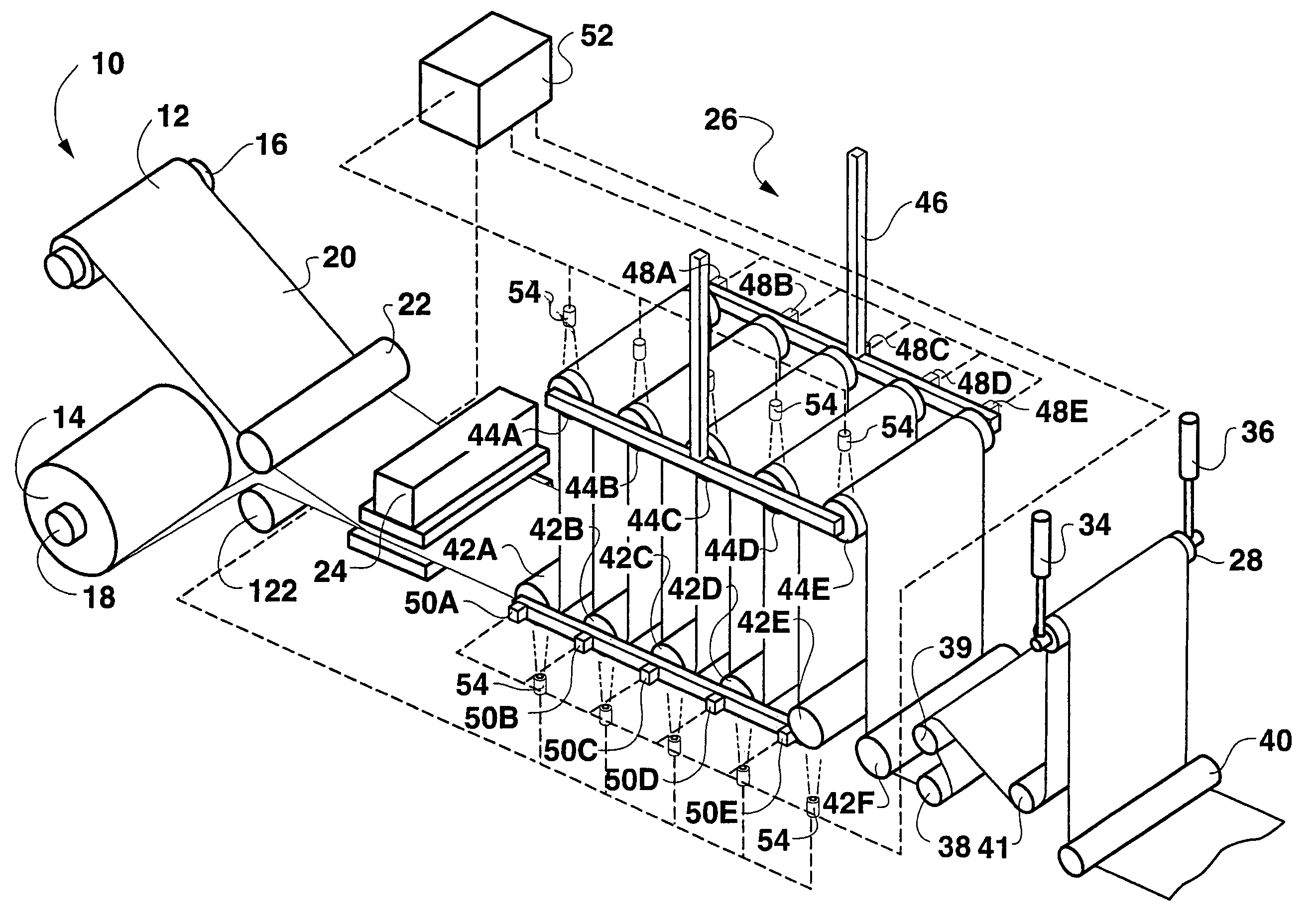

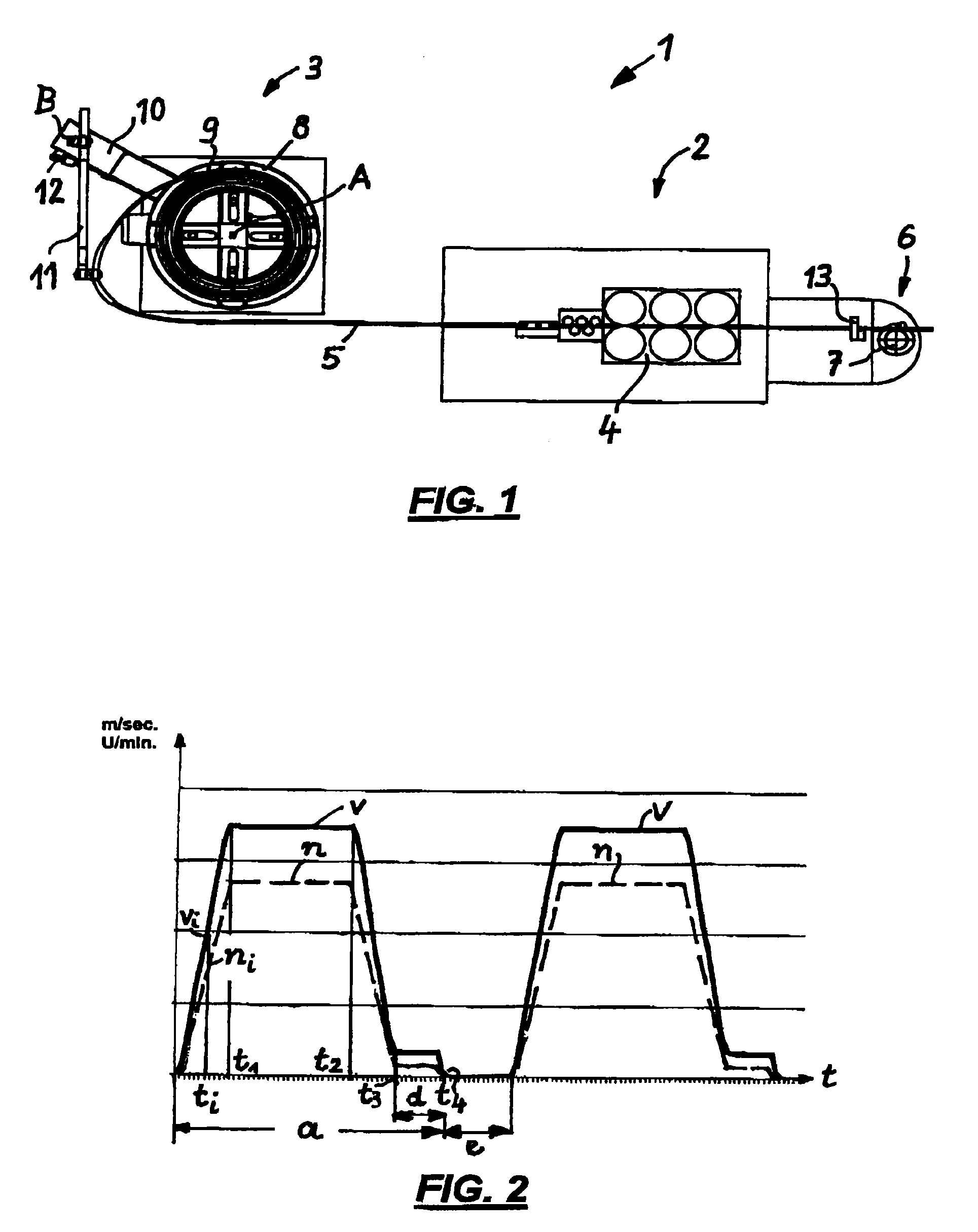

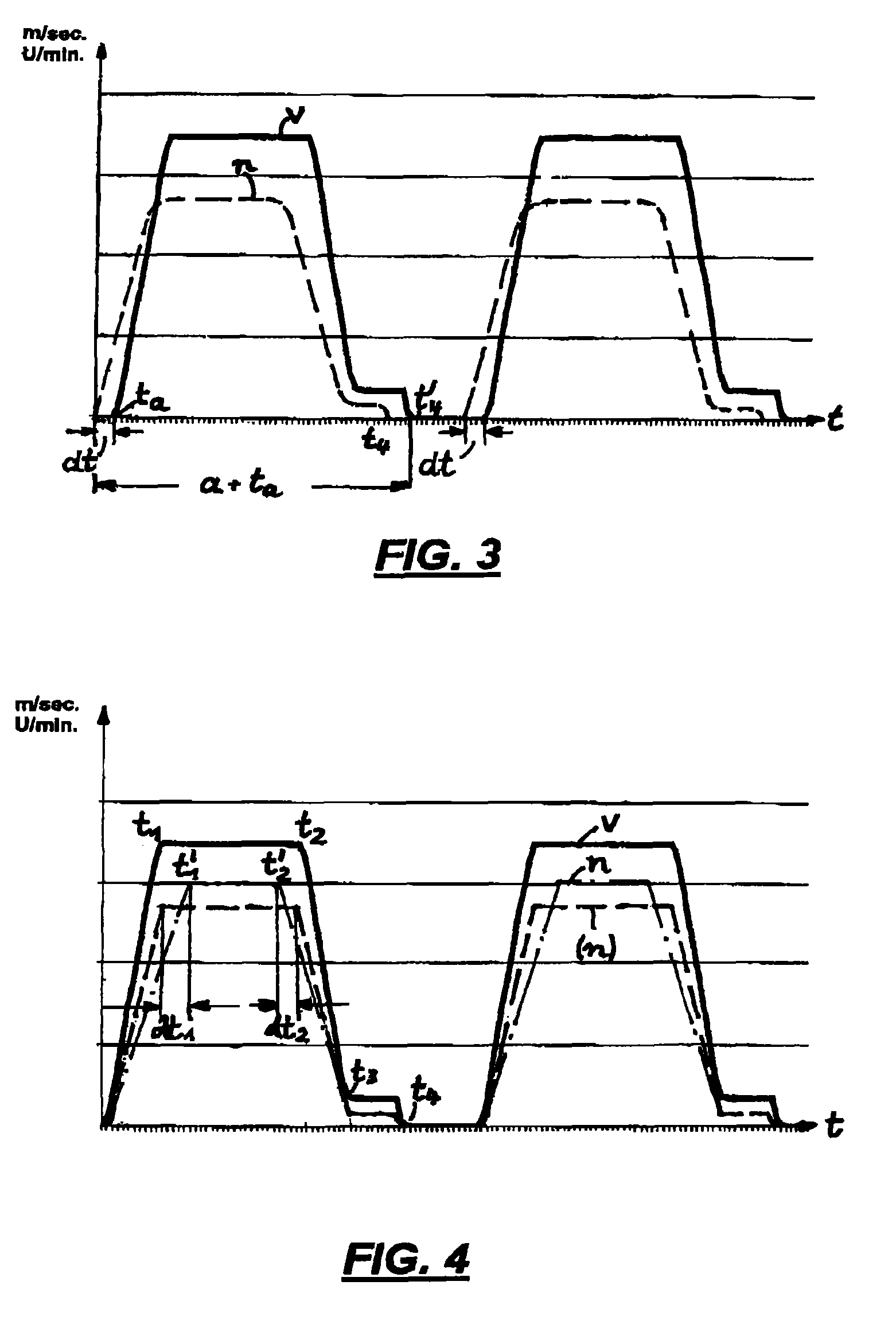

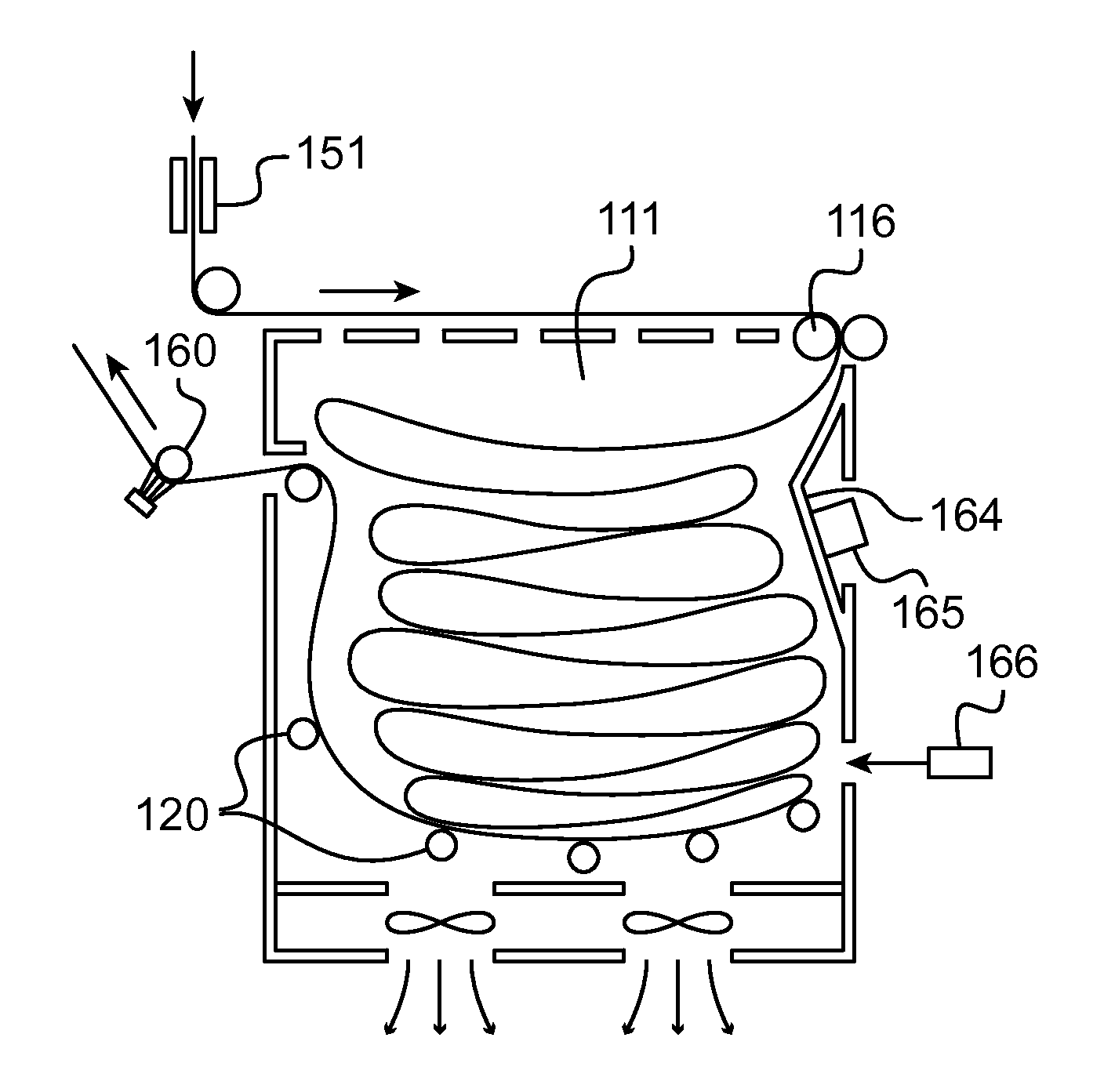

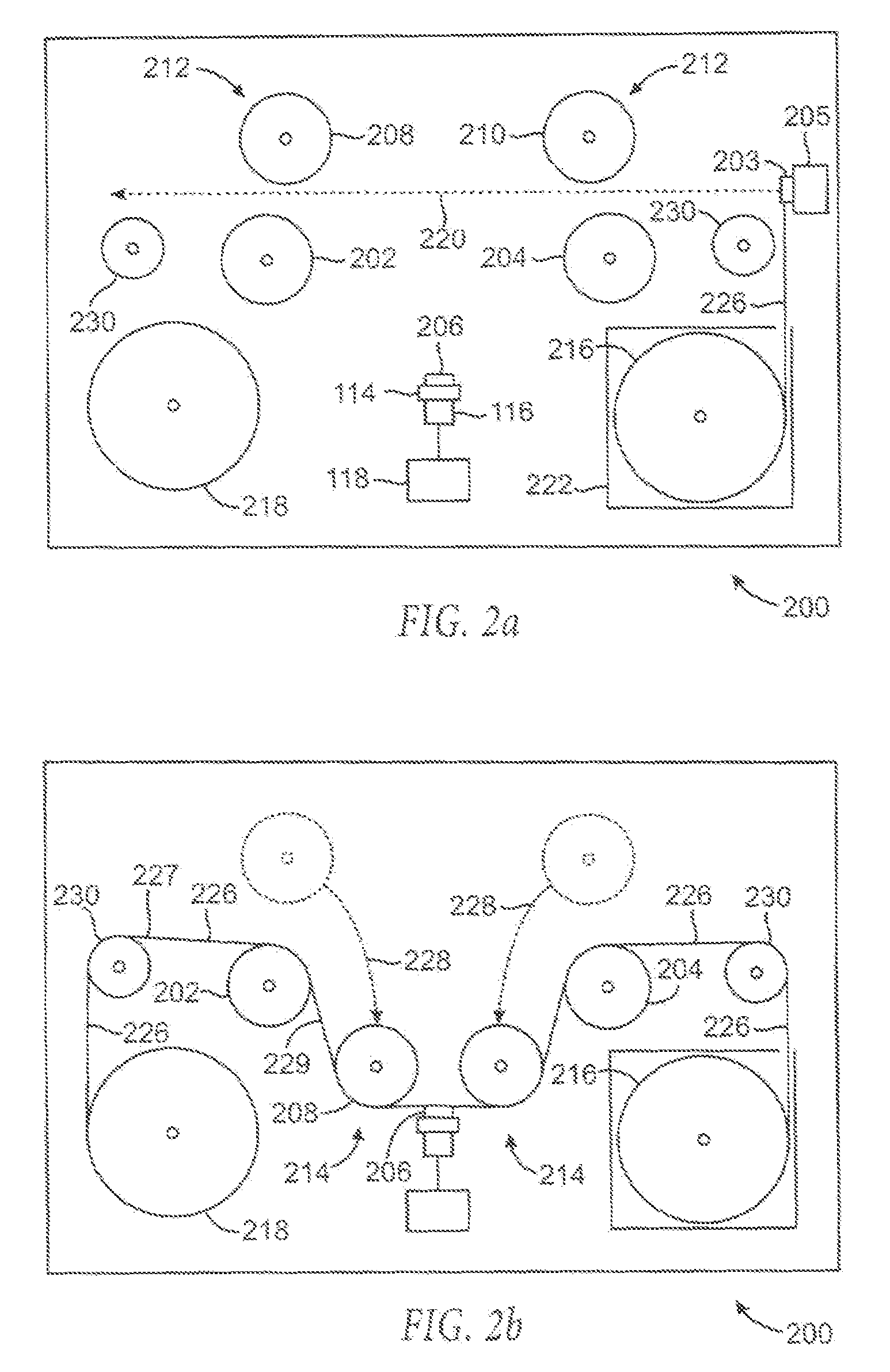

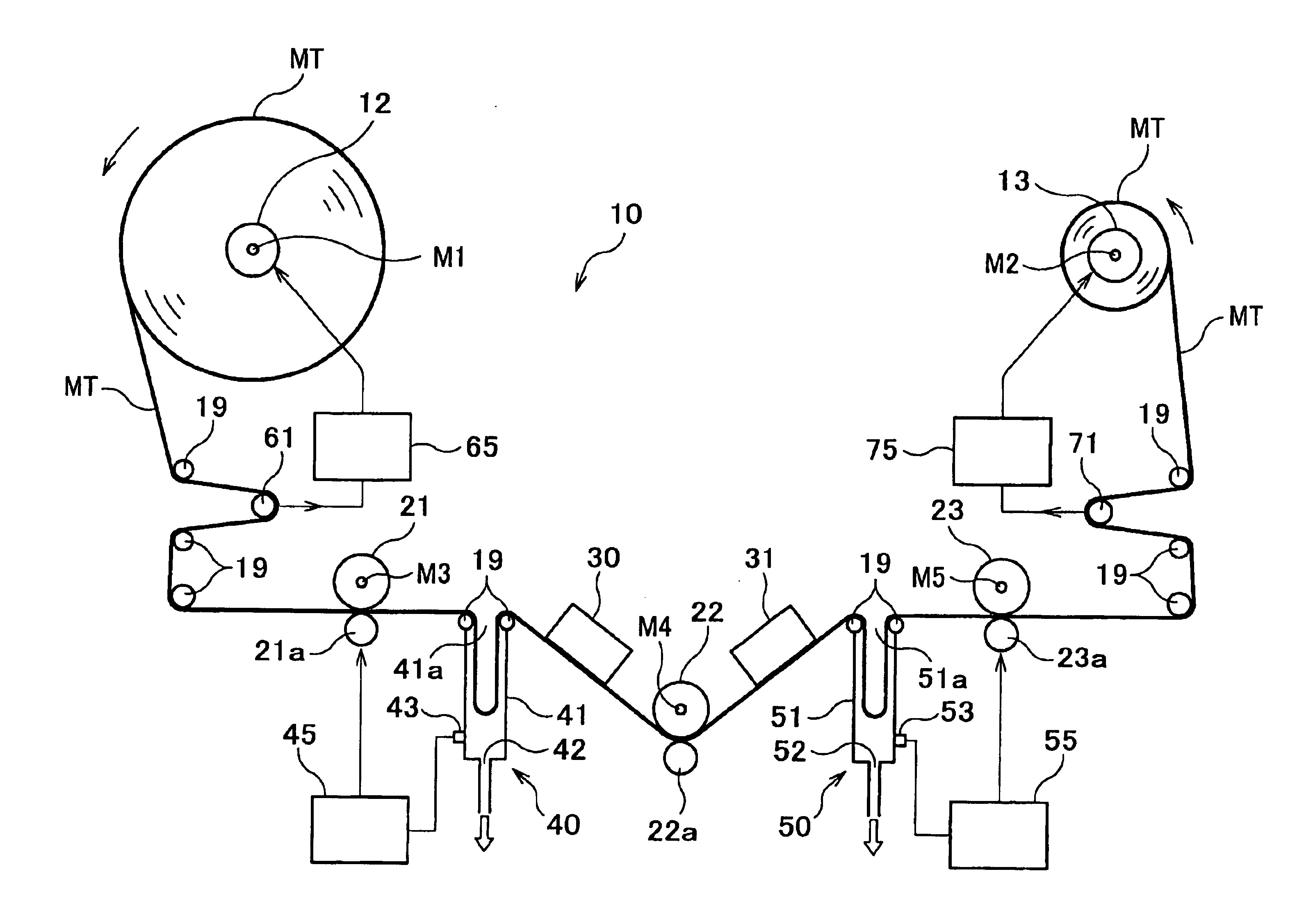

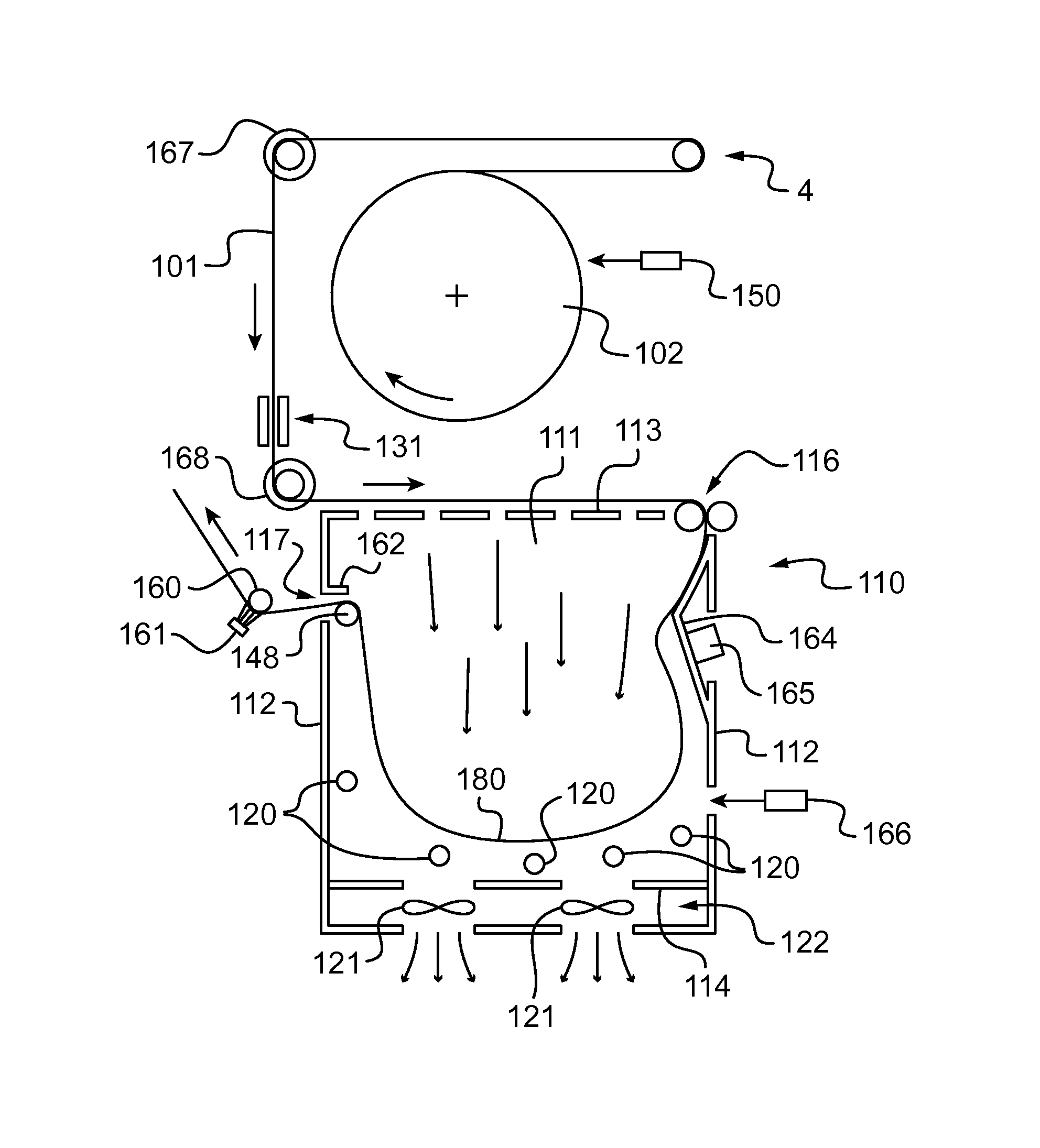

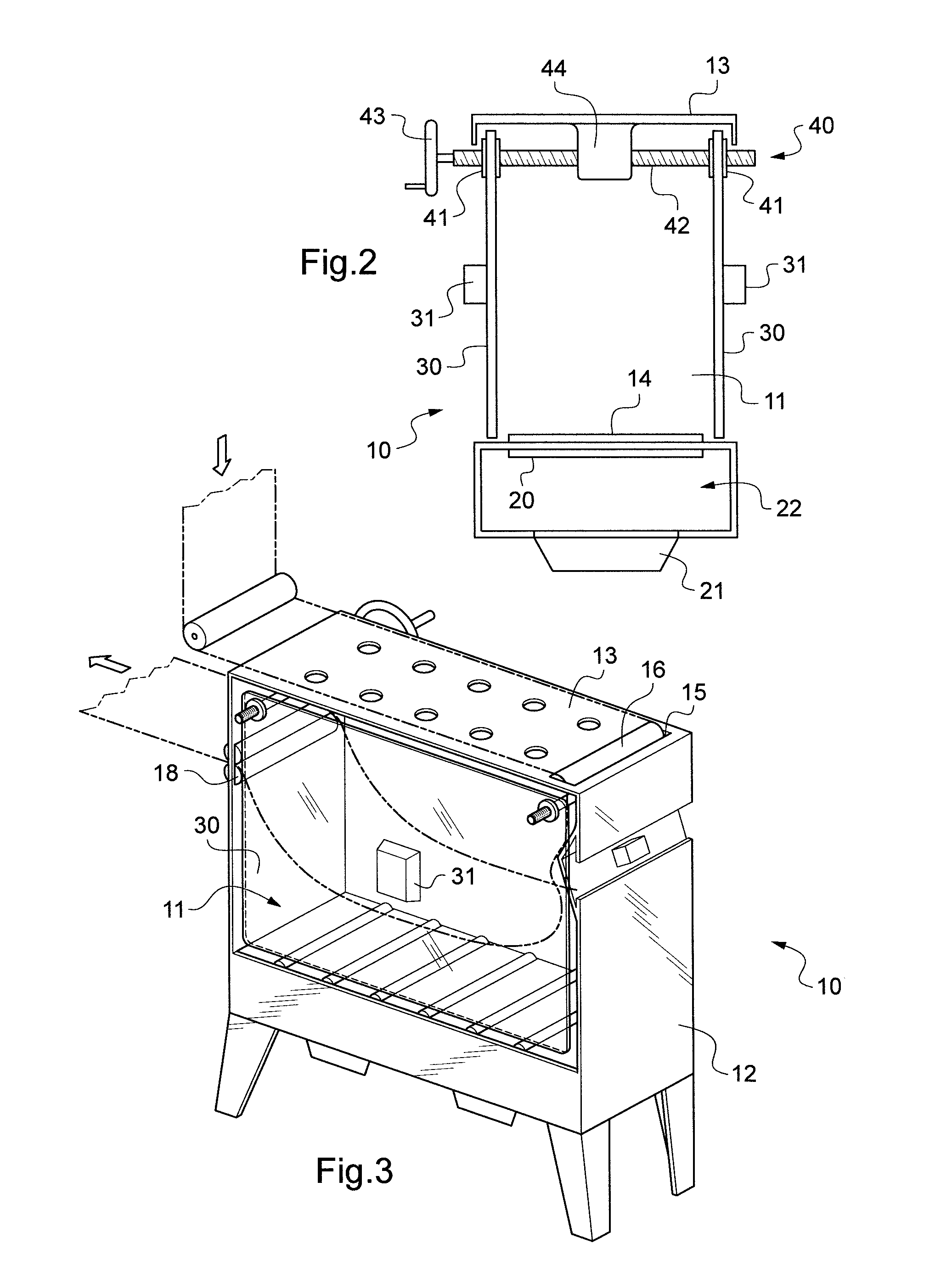

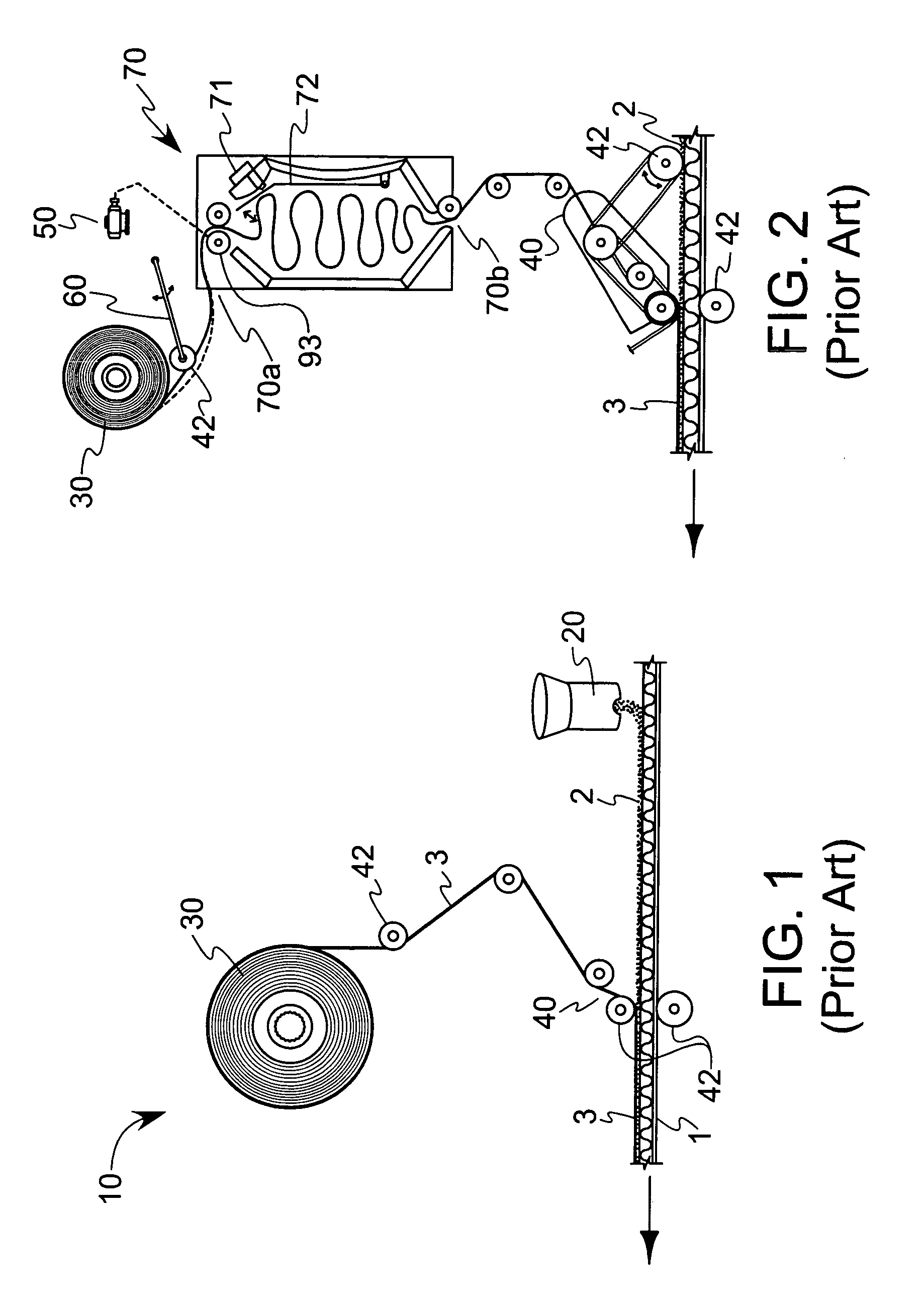

System and process for controlling the deceleration and acceleration rates of a sheet material in forming absorbent articles

ActiveUS20050139713A1Reduce tensionReduce probabilityFilament handlingRecord information storageEngineeringAcceleration rate

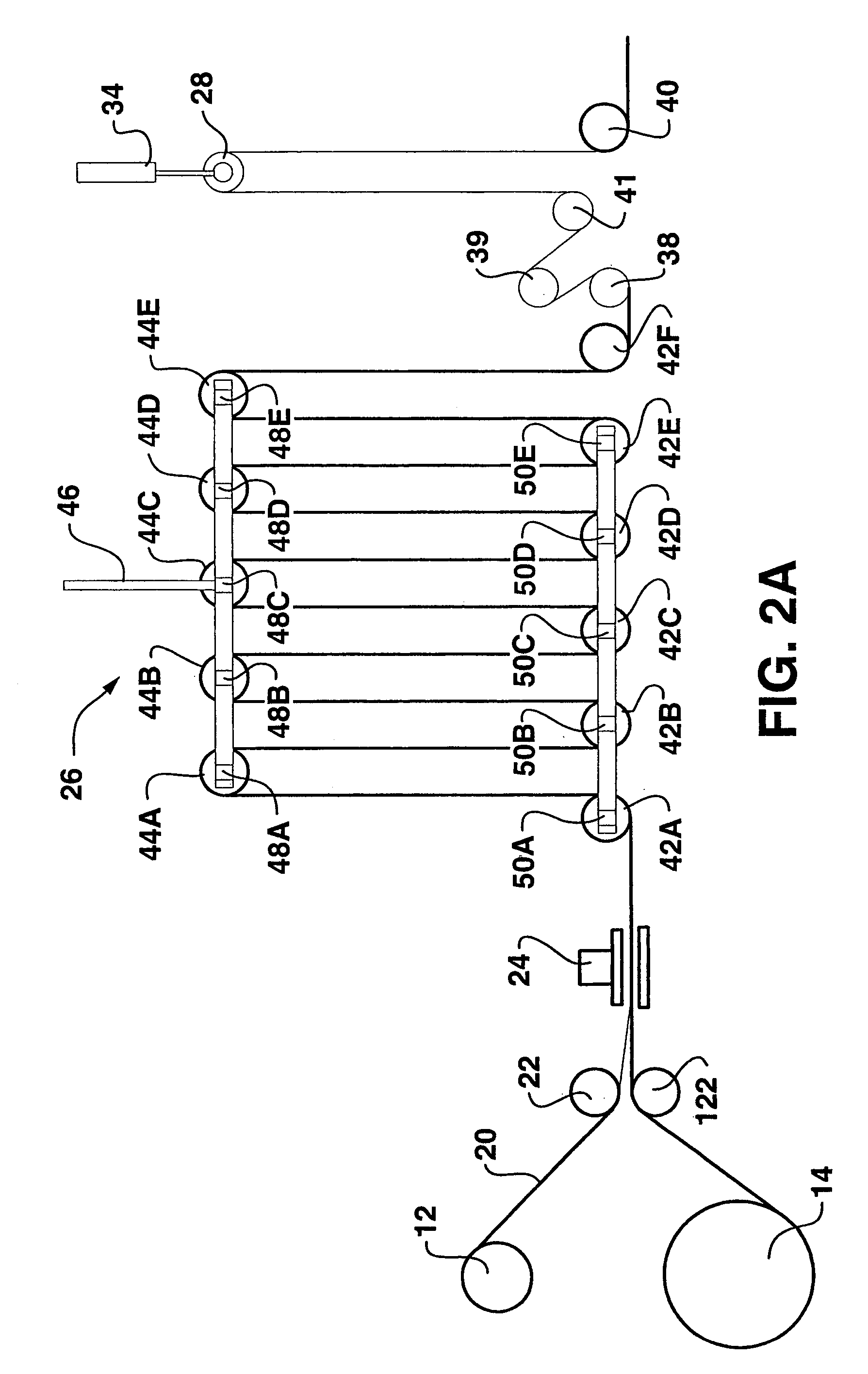

A system and process for unwinding materials in forming absorbent articles is described. The system includes an unwind device in association with a festoon. The festoon is for accumulating a determined length of material. The amount of material contained in the festoon is increased or decreased depending upon the rate at which a roll of material is unwound in relation to the rate at which the first material is fed into a downstream process. In order to minimize the capacity of the festoon and in order to minimize tension swings in the festoon, the festoon includes a plurality of drive devices associated with selected guide rolls contained in the festoon. The drive devices can accelerate and / or decelerate the guide rolls in response to rate increases or decreases occurring at the unwind device in relation to the downstream process speed. In one embodiment, each of the guide rolls is controlled independently of the remaining guide rolls in the festoon.

Owner:KIMBERLY-CLARK WORLDWIDE INC

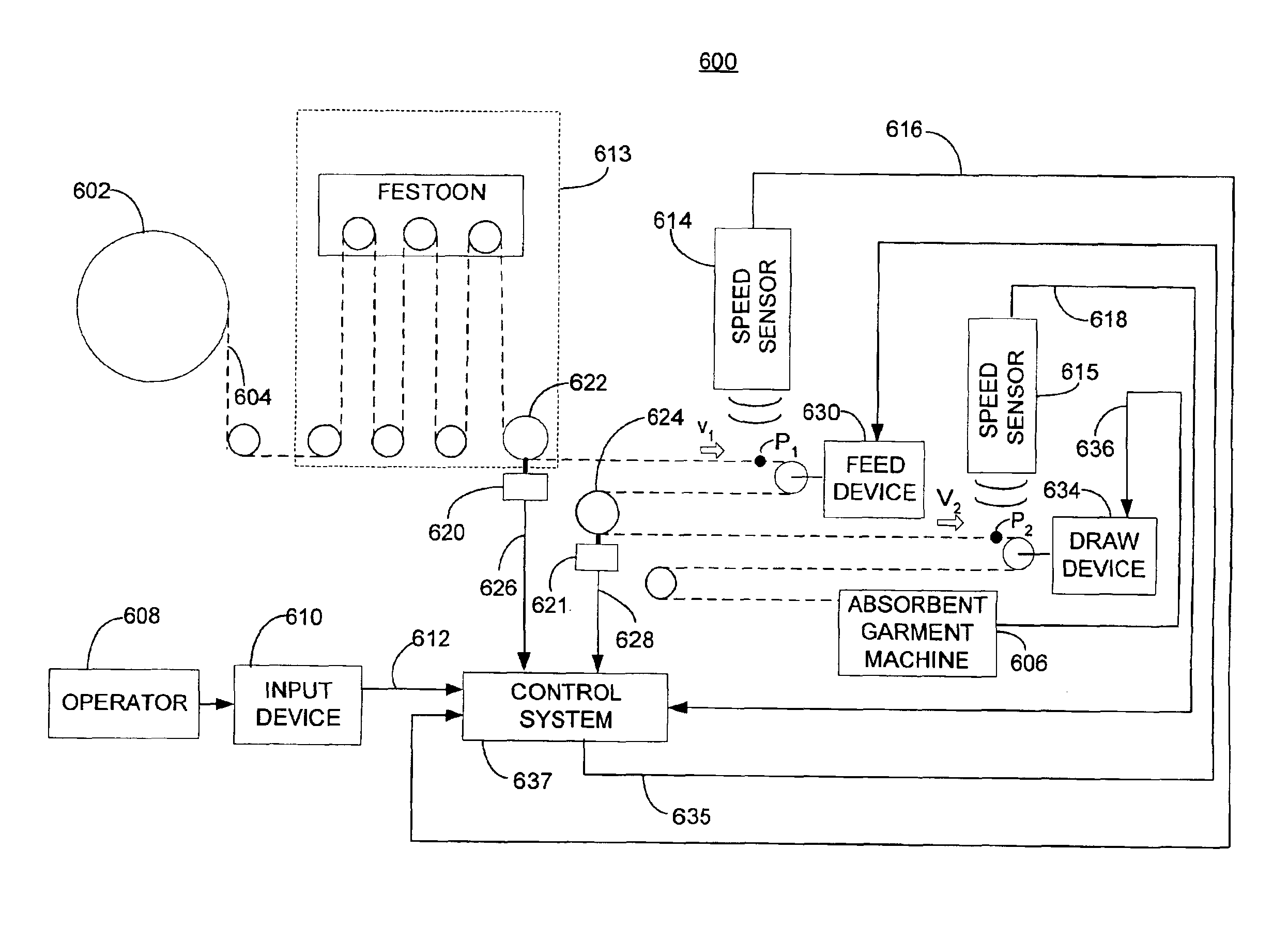

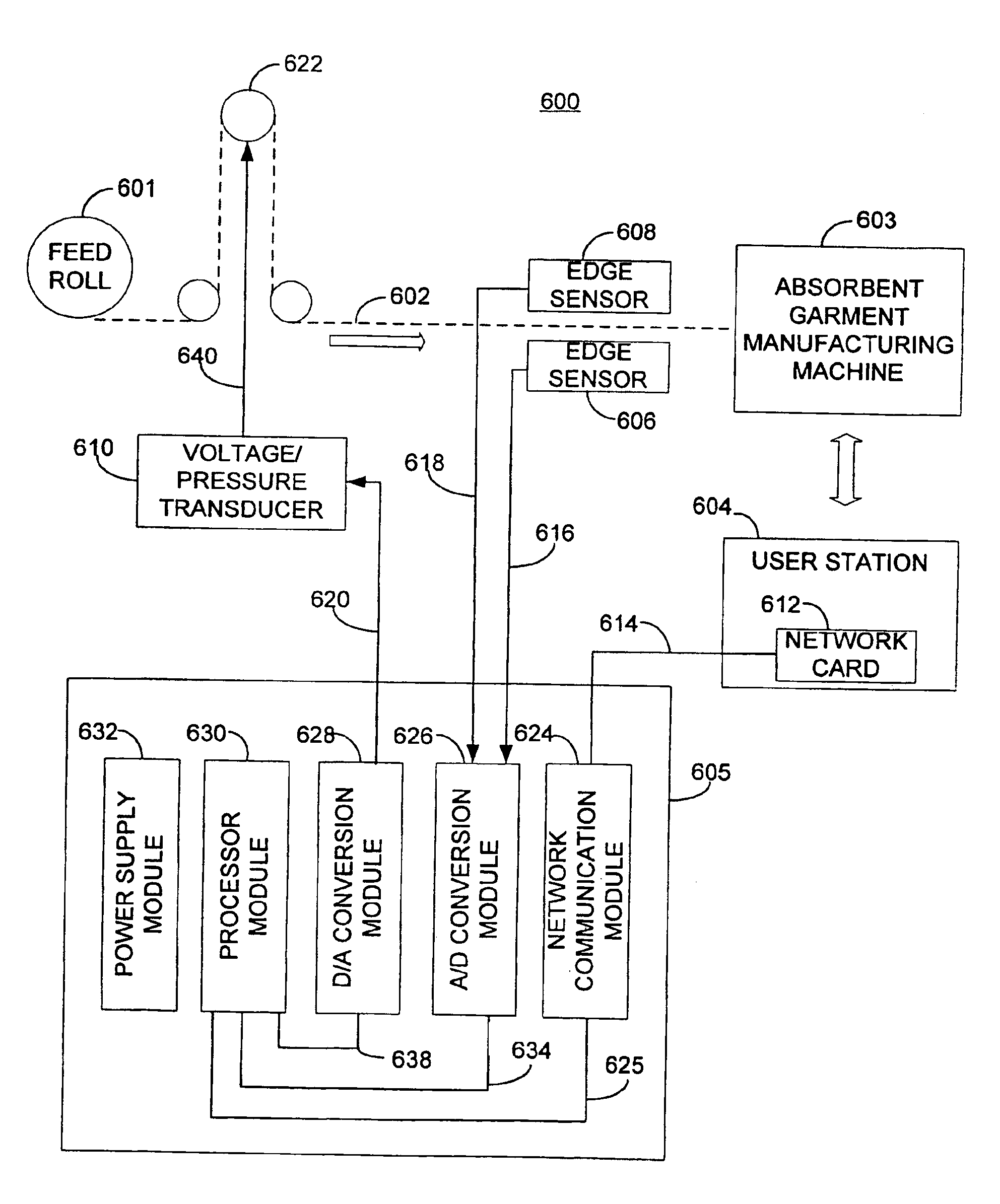

System and method for controlling the strain of web material

InactiveUS6851593B2Automatic control devicesPrecision positioning equipmentControl signalControl system

A system and method for controlling the strain of a web material supplied to a machine by adjusting a tension force applied to the web material. An operator defines a target web strain via an input device. A speed sensor senses the speed of the web material supplied to the machine at a first position and a second position and generates a speed signal representative of the difference. A tension sensor senses a tension force applied to the web prior to the first position and after the first position and generates a tension signal representative of the difference. A control system calculates web strain as a function of the tension signal and speed signal, and compares the calculated strain with the target web strain and generates a speed control signal as a function of the comparison. The feed device is responsive to the speed control signal for adjusting a speed differential of the web to adjust tension force applied to the web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Apparatus for taking up slack of wire harness

Owner:YAZAKI CORP

Magnetic roller

InactiveUS20050061846A1High strengthDynamo-electric brakes/clutchesRecord information storageCouplingEngineering

A magnetic roller system configured for use within a web handling system, the system including a drive hub, and a roller that is magnetically coupled to the drive hub. The roller is configured to support a web of material. An adjustable gap is defined between the drive hub and the roller. The strength of the magnetic coupling increases as the adjustable gap decreases.

Owner:MARTIN AUTOMATIC

System and process for controlling the deceleration and acceleration rates of a sheet material in forming absorbent articles

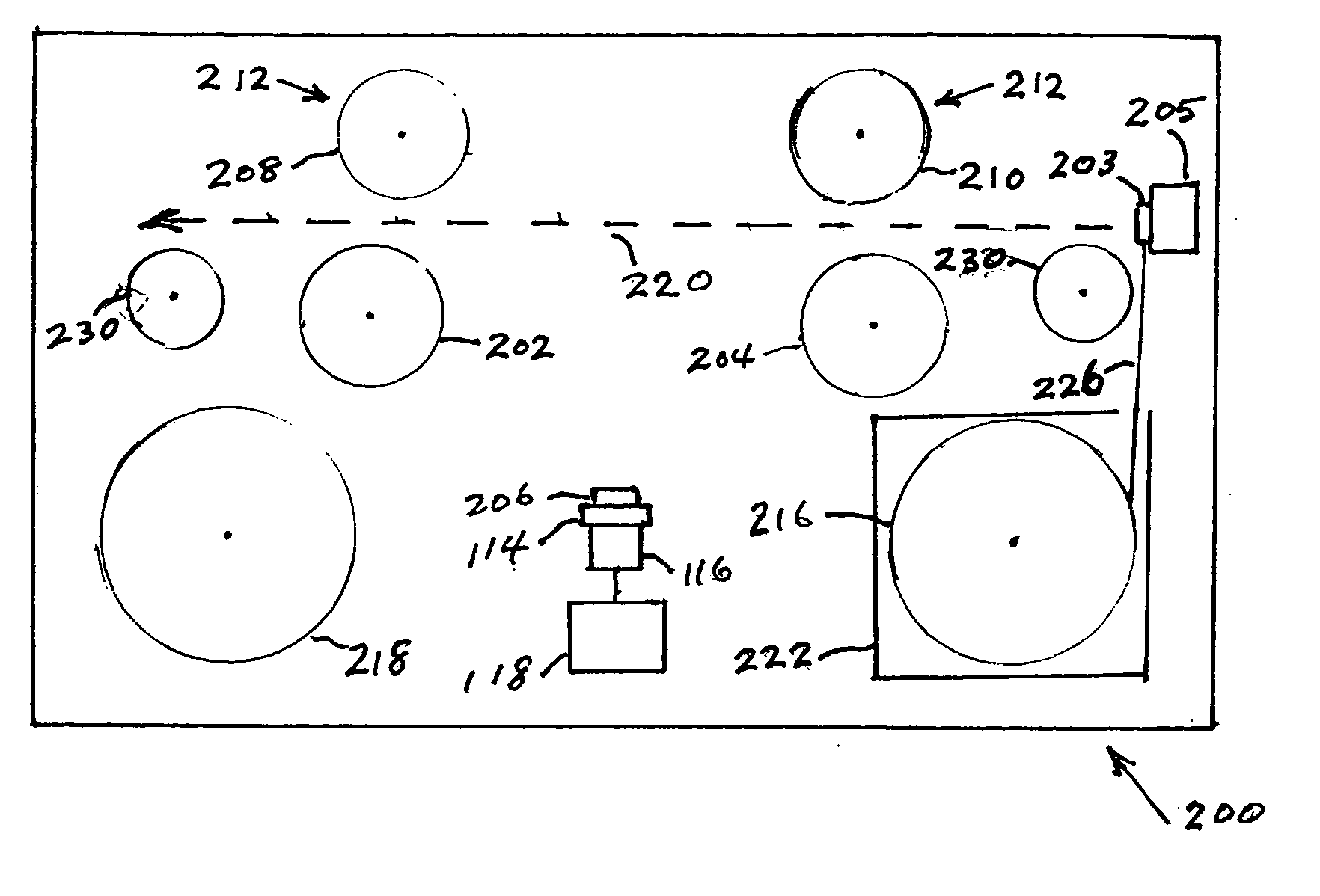

ActiveUS7458540B2Rapid decelerationIncrease in sizeFilament handlingRecord information storageEngineeringAcceleration rate

A system and process for unwinding materials in forming absorbent articles is described. The system includes an unwind device in association with a festoon. The festoon is for accumulating a determined length of material. The amount of material contained in the festoon is increased or decreased depending upon the rate at which a roll of material is unwound in relation to the rate at which the first material is fed into a downstream process. In order to minimize the capacity of the festoon and in order to minimize tension swings in the festoon, the festoon includes a plurality of drive devices associated with selected guide rolls contained in the festoon. The drive devices can accelerate and / or decelerate the guide rolls in response to rate increases or decreases occurring at the unwind device in relation to the downstream process speed. In one embodiment, each of the guide rolls is controlled independently of the remaining guide rolls in the festoon.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Web tensioning device with plural control inputs

InactiveUS7438251B2Easily respondsMinimum delayAutomatic control devicesPrecision positioning equipmentServomotorAcceleration Unit

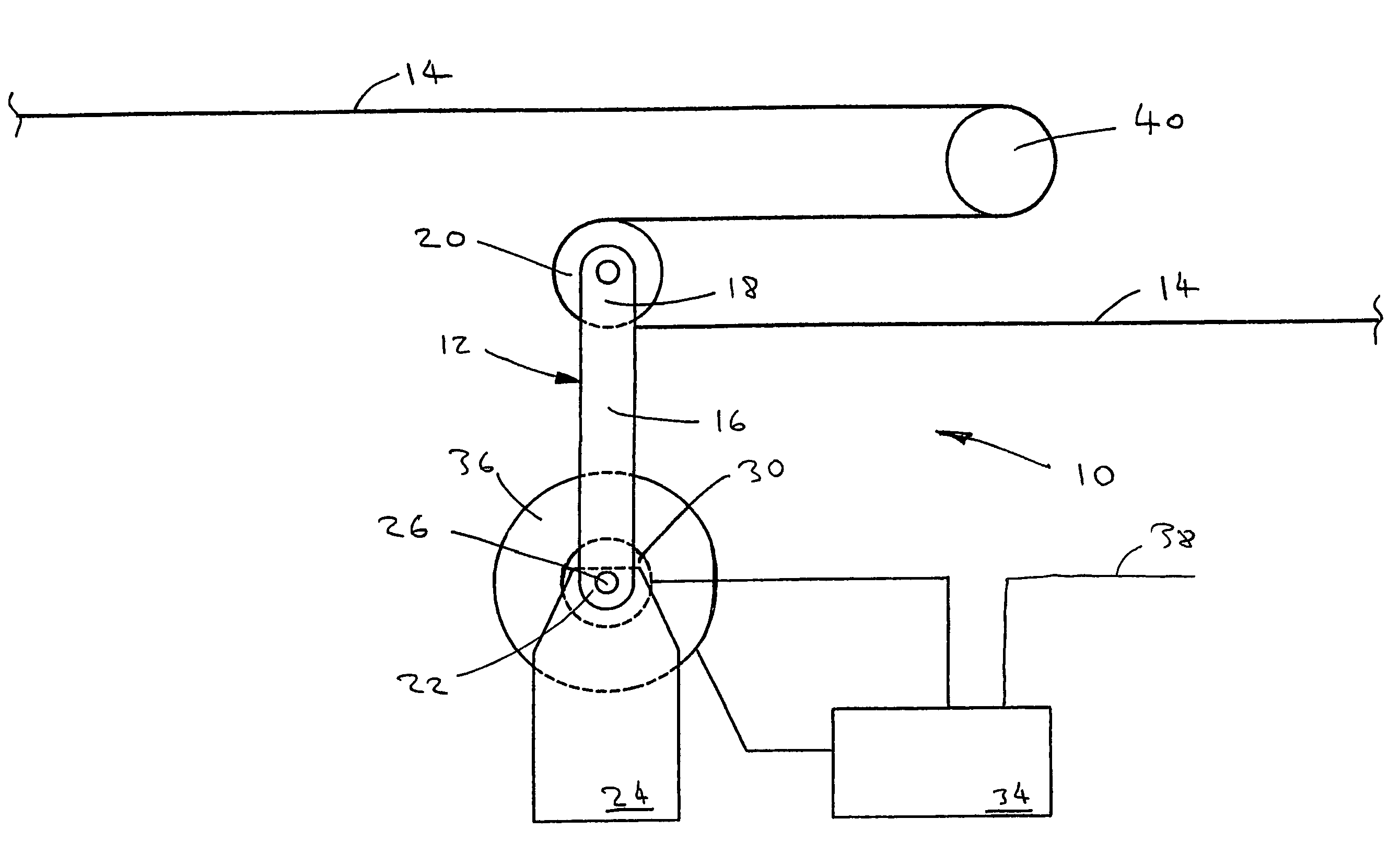

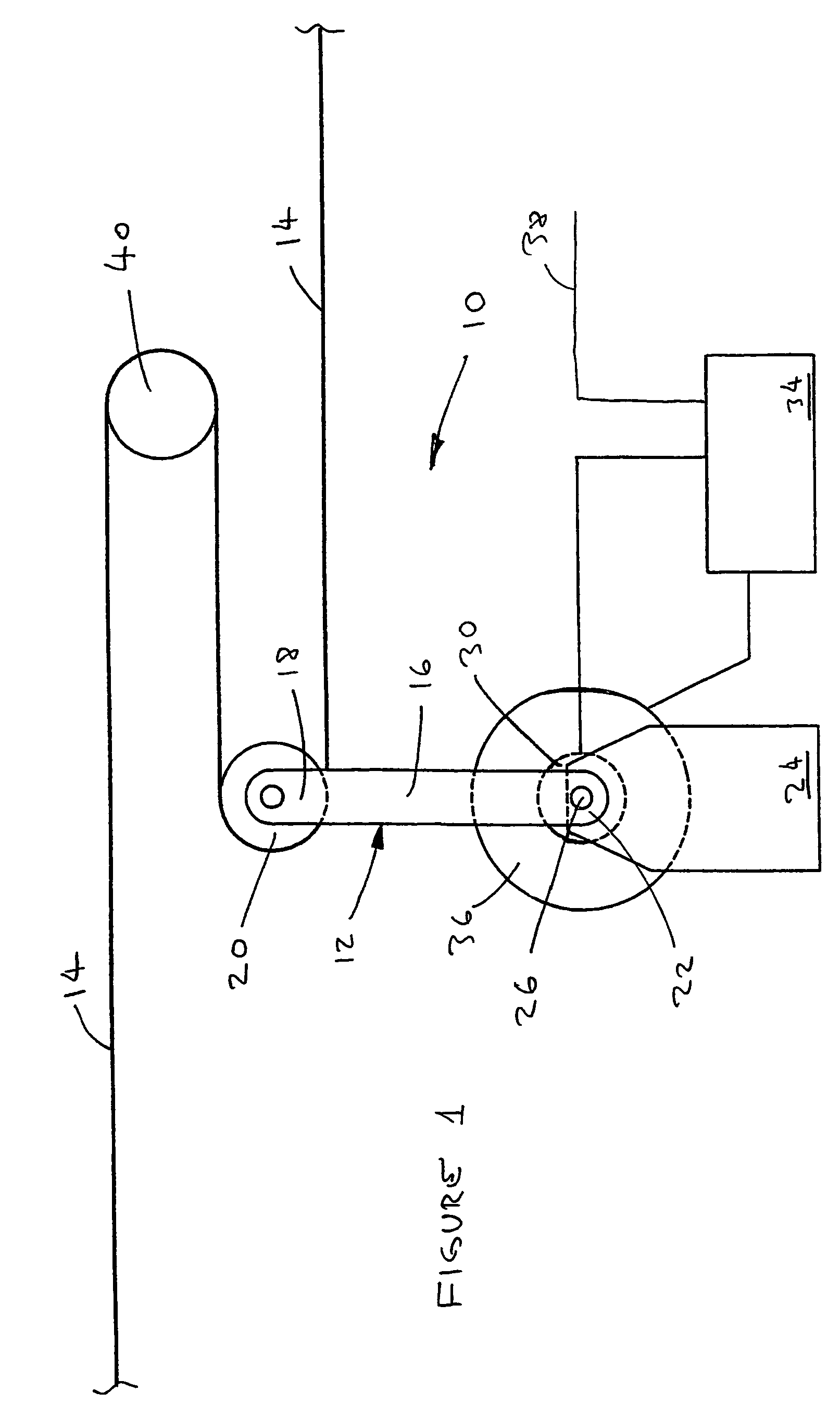

A web tensioning device utilizes a dancer arm which can be positioned by a controlled servo motor. In a preferred embodiment, the controller for the servo motor receives an input signal based on the acceleration (positive or negative) of the dancer arm and implements a torque component necessary to maintain predetermined web tension, for example, an applied torque component that changes the position of the dancer arm. The controller may also receive additional input signals indicative of the acceleration of the web itself.

Owner:C G BRETTING MFG

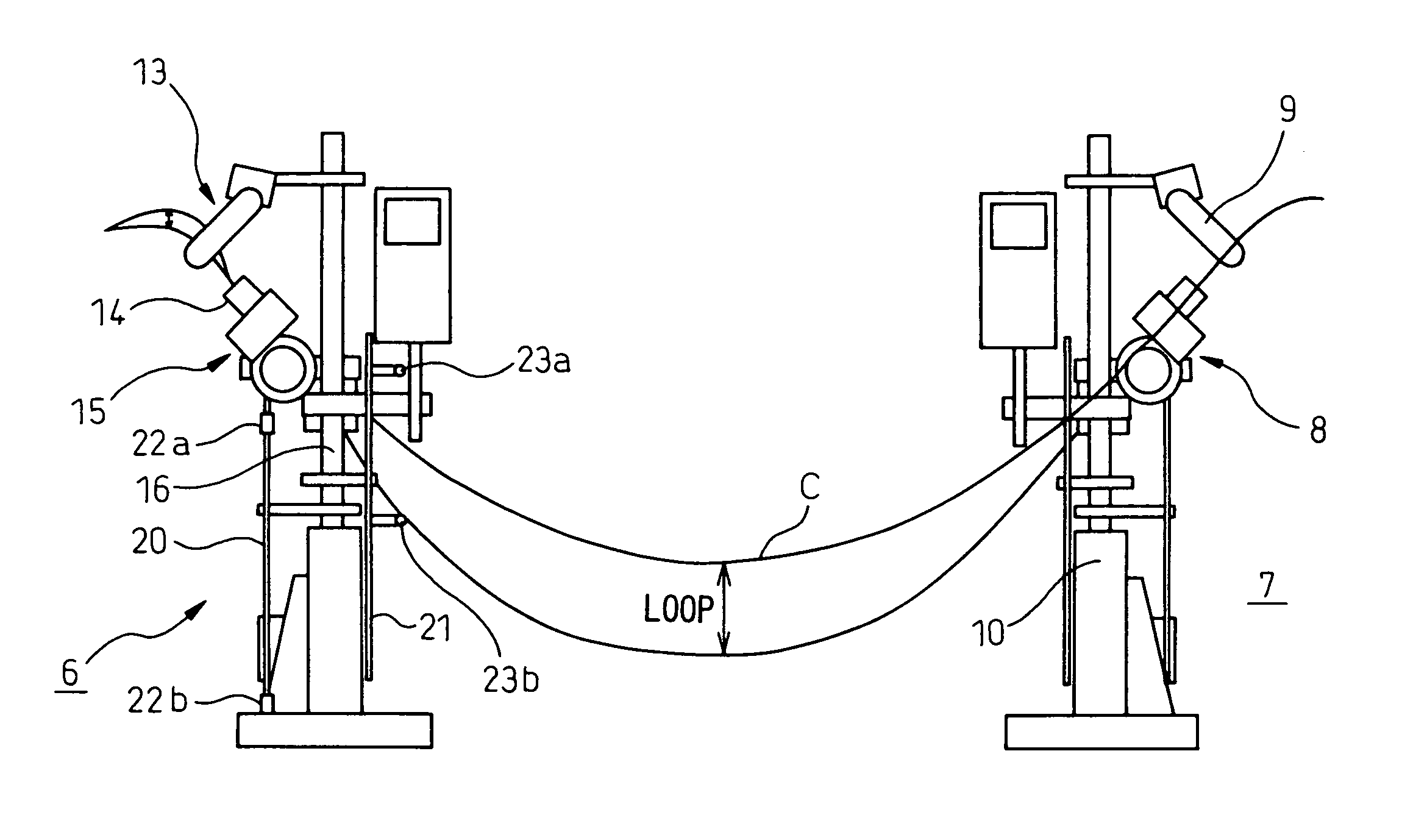

Device for controlling the drive of a reel

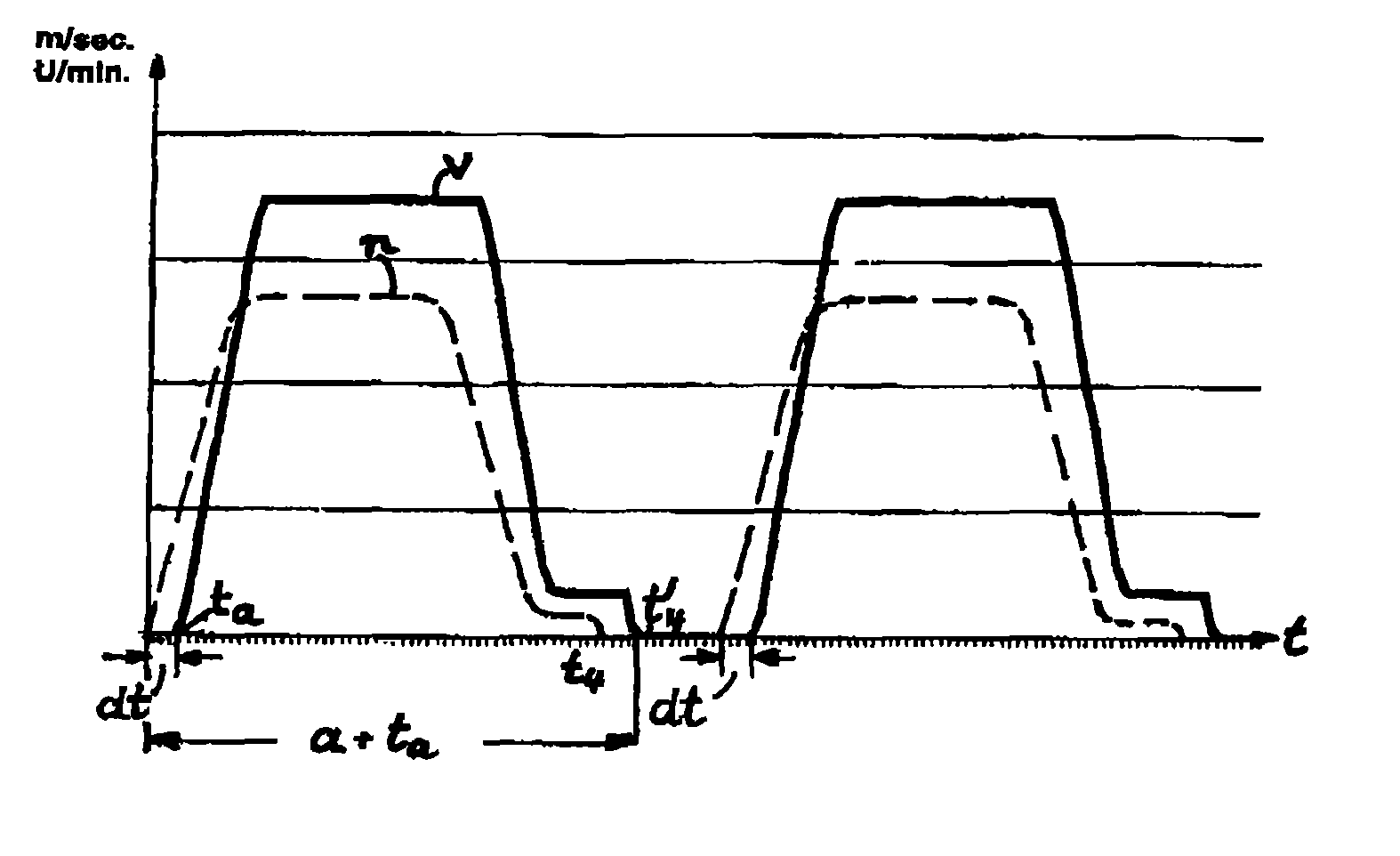

ActiveUS8382024B2Variable speedEasy to controlFilament handlingRecord information storageWire tensionTime profile

With a device for controlling the drive of a reel, with a wire supply in the form of a coil of said wire supply, from which the wire, through interposition of a tensioning device, which is spring-pretensioned in one deflection direction and effective up to a maximum deflection, for approximated stabilization of the wire tension of a feed installation of the wire infeed of a downstream positioned wire processing machine, the velocity curve of the feed rate of the wire infeed in accordance with a preset velocity-time profile is controlled by a control unit of the wire processing machine, and whereby the curve of the rotation speed of the reel in accordance with a preset rotation speed-time profile is controlled by the drive control of the reel, whereby the drive control of the reel sets the rotation speed-time profile of the reel, with regard to the velocity-time profile of the feed rate, forward by a preset time interval.

Owner:WAFIOS AKTIENGES

Regulating the web tension of a continuous material

InactiveUS20070119894A1Improve product qualityIncrease productionAutomatic control devicesPrecision positioning equipmentControl theorySupport point

Owner:BOSCH REXROTH AG

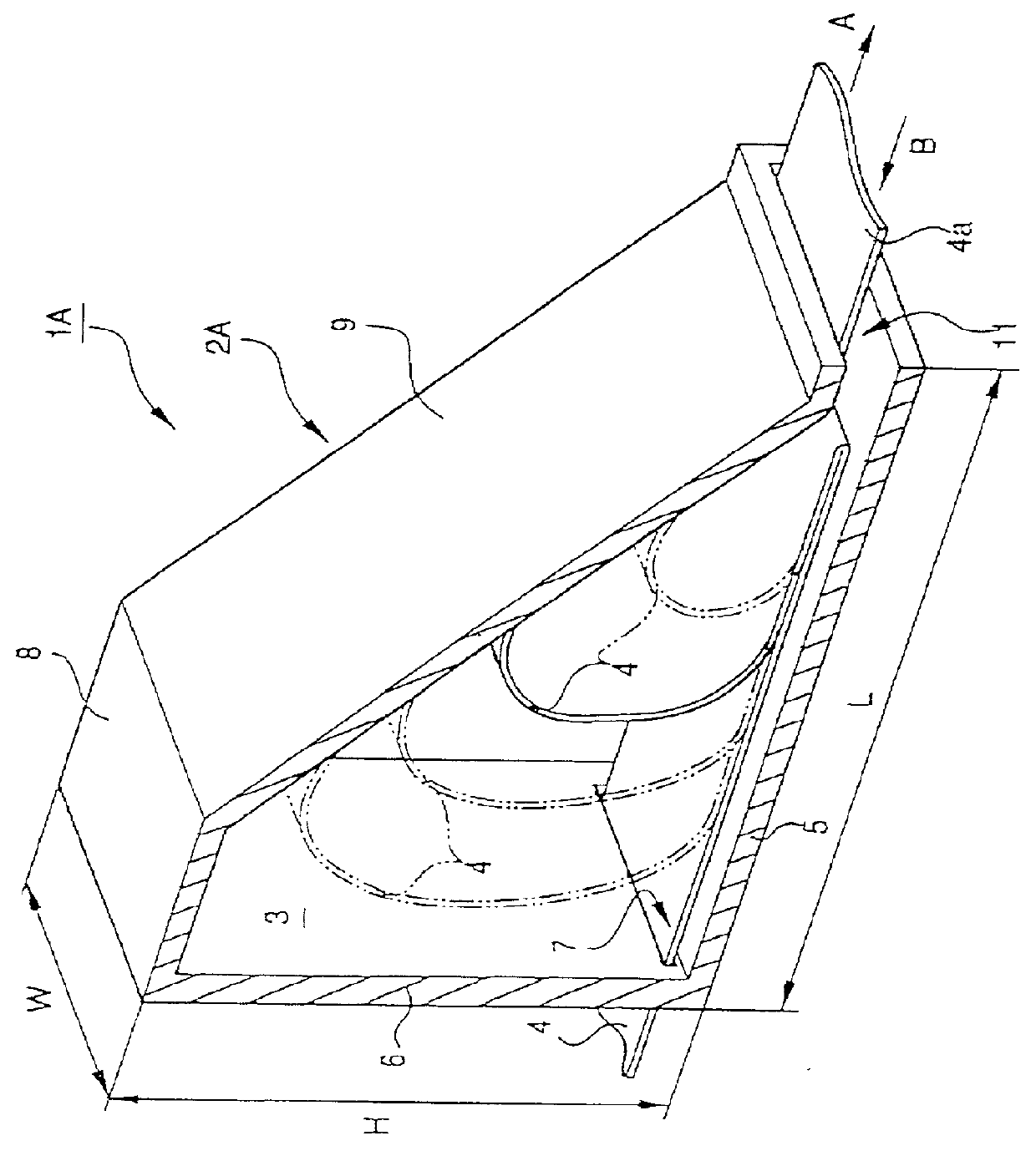

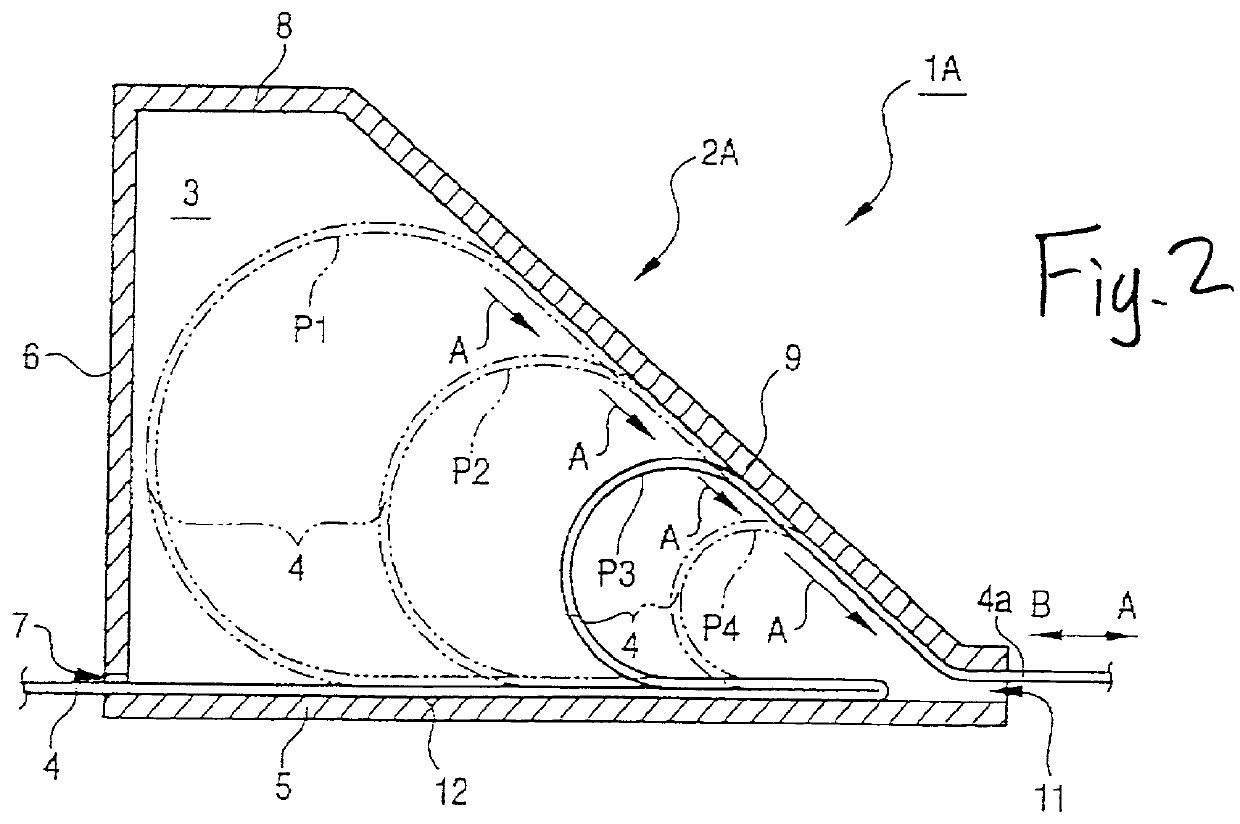

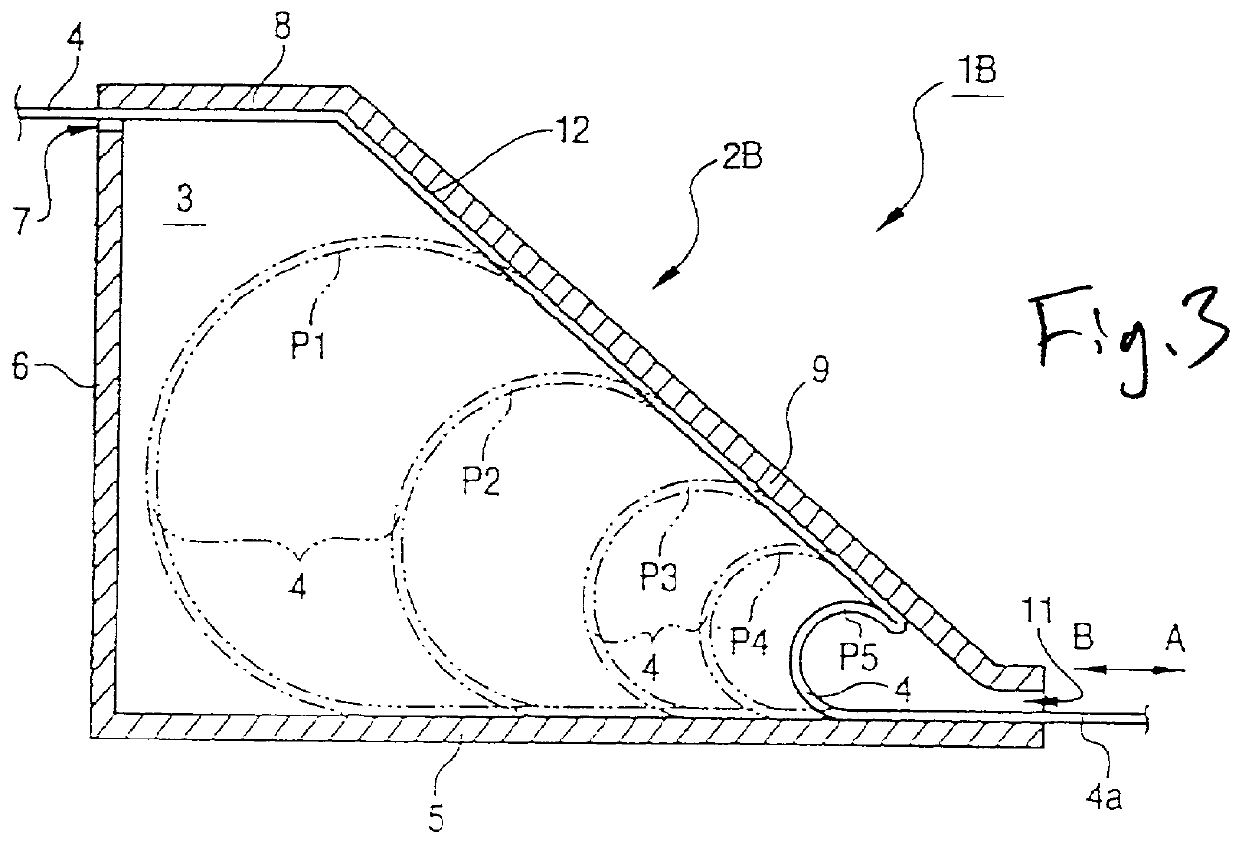

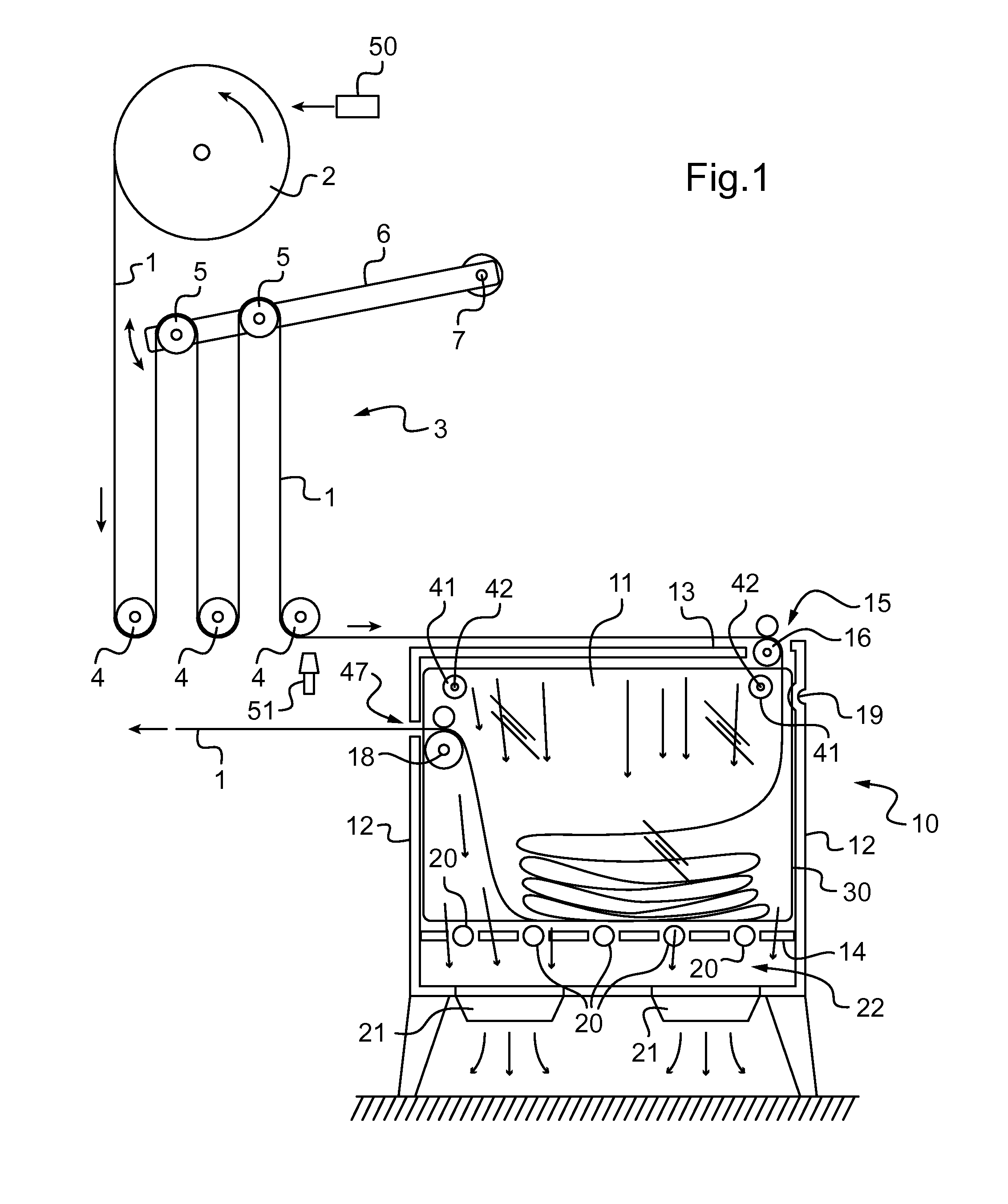

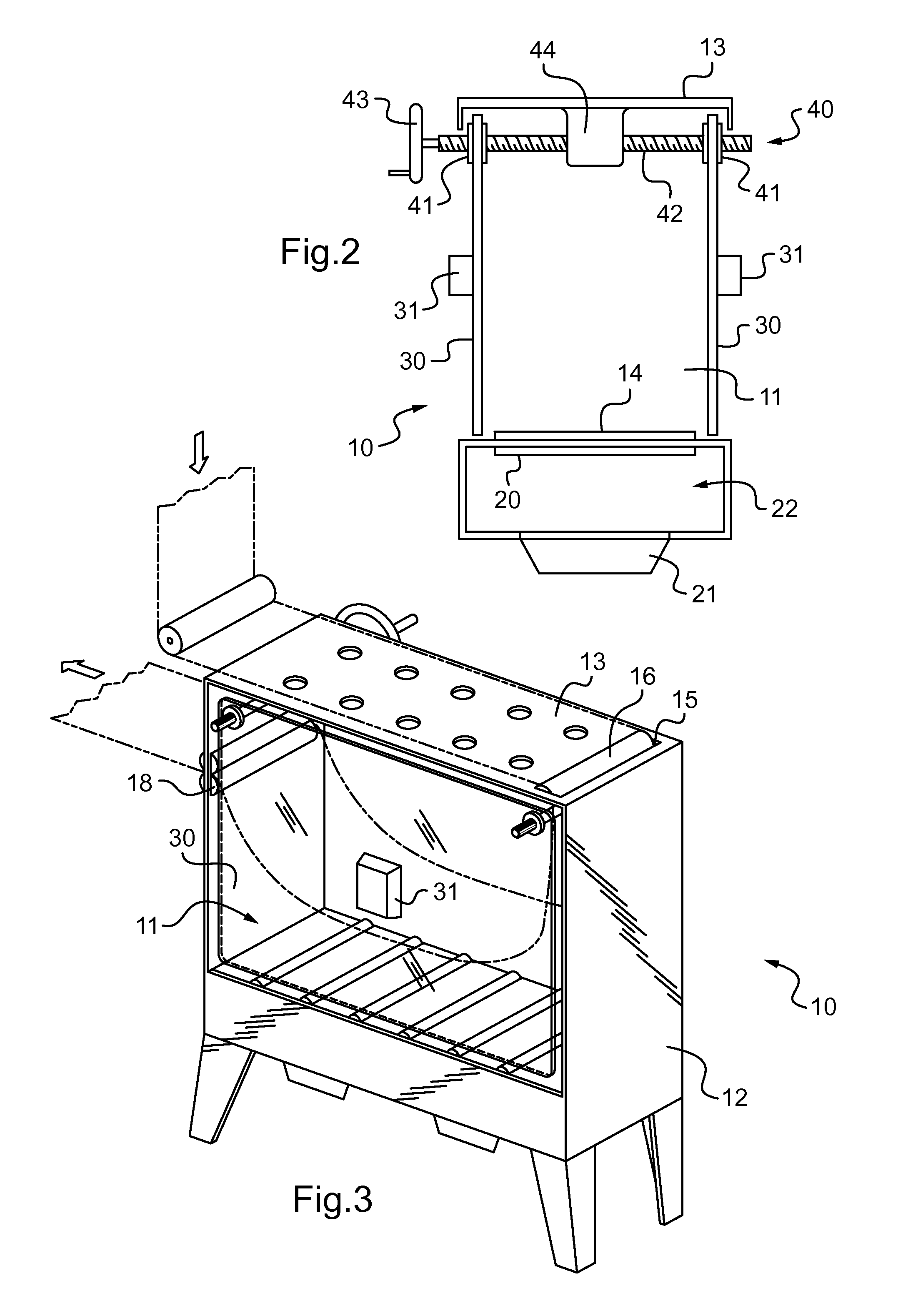

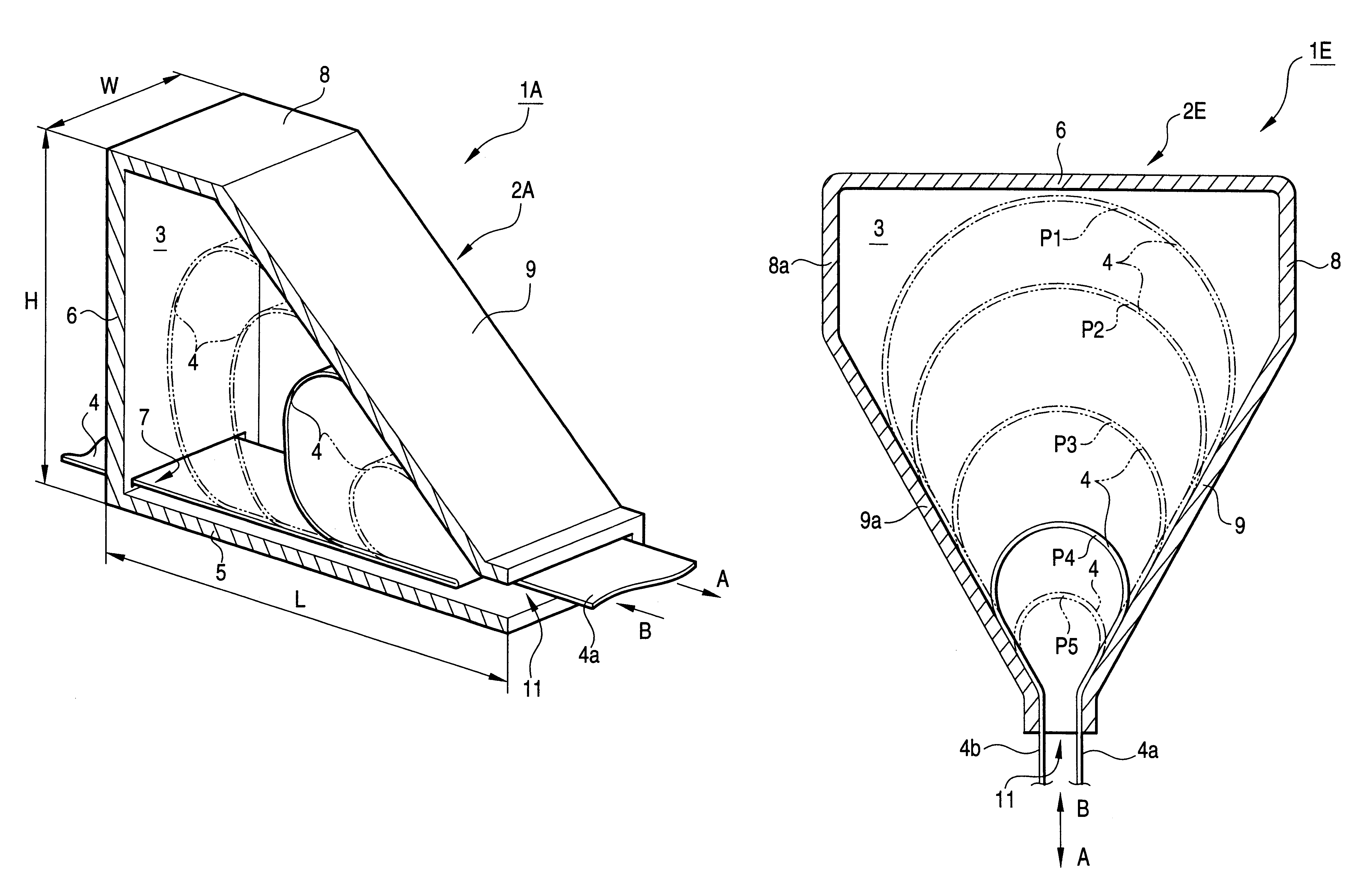

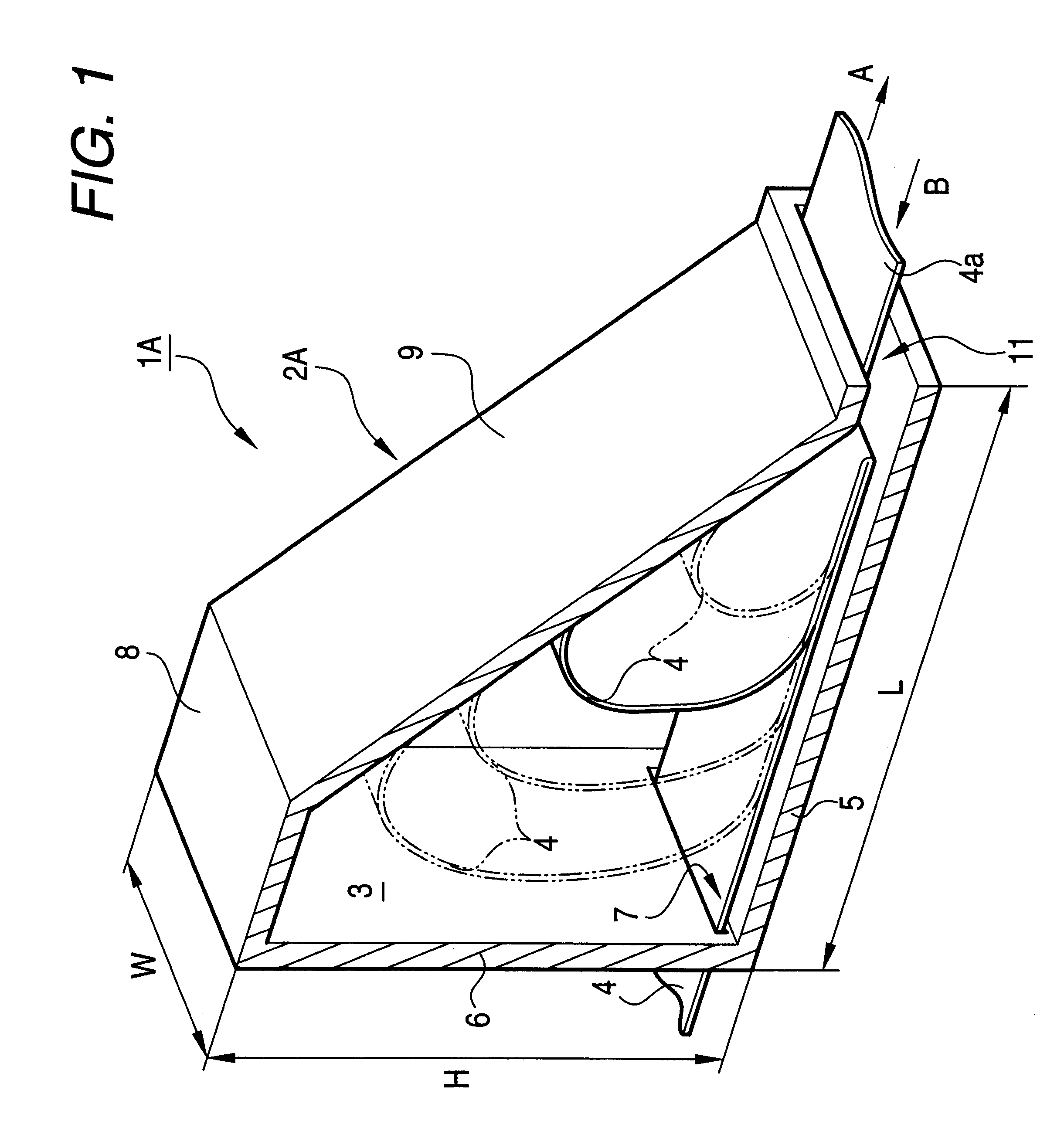

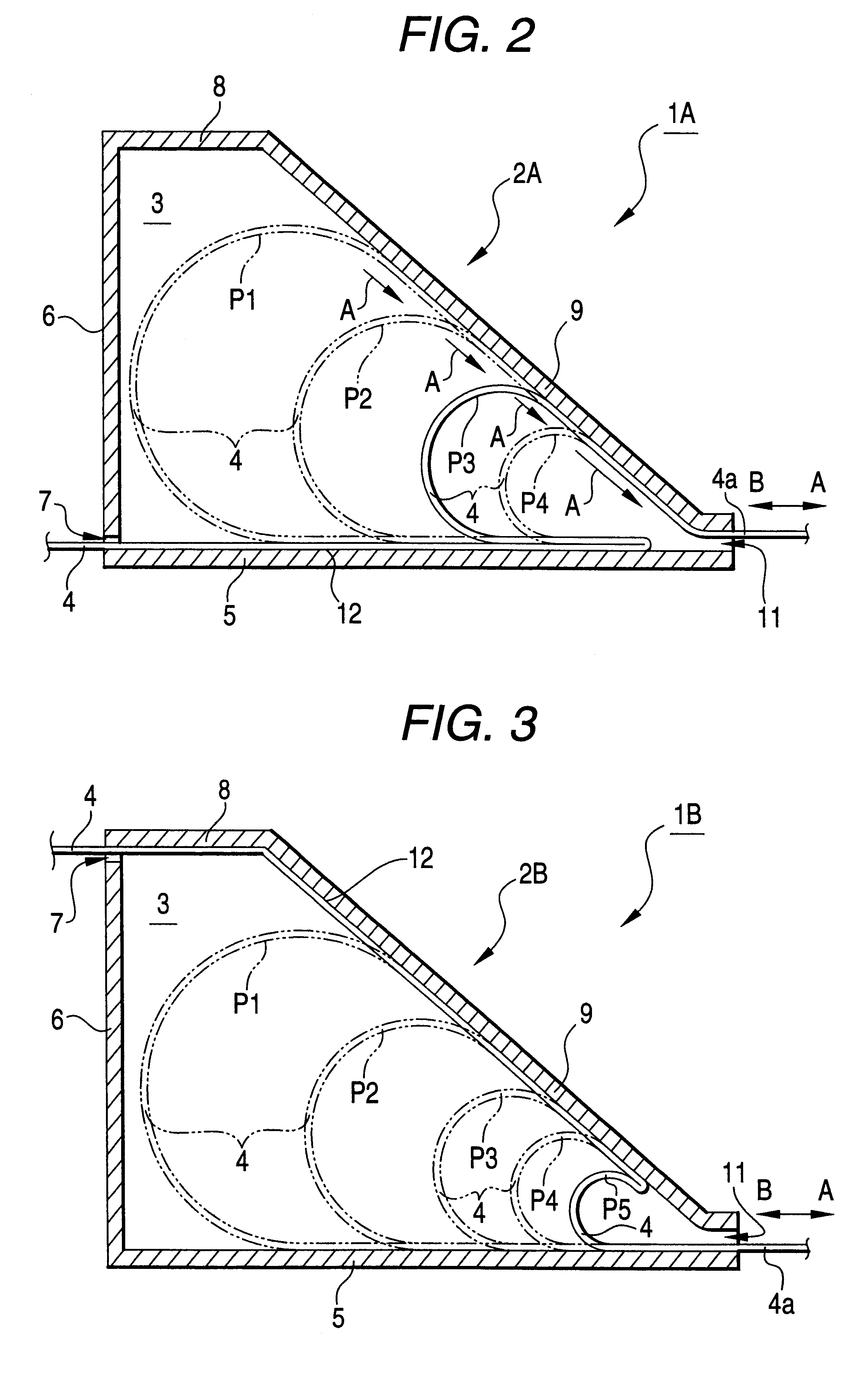

Device for accumulating flat material in flexible strip form

InactiveUS20120228353A1Solve the greater riskReduce riskFunction indicatorsRecord information storageEngineeringMechanical engineering

Owner:SLEEVER INT

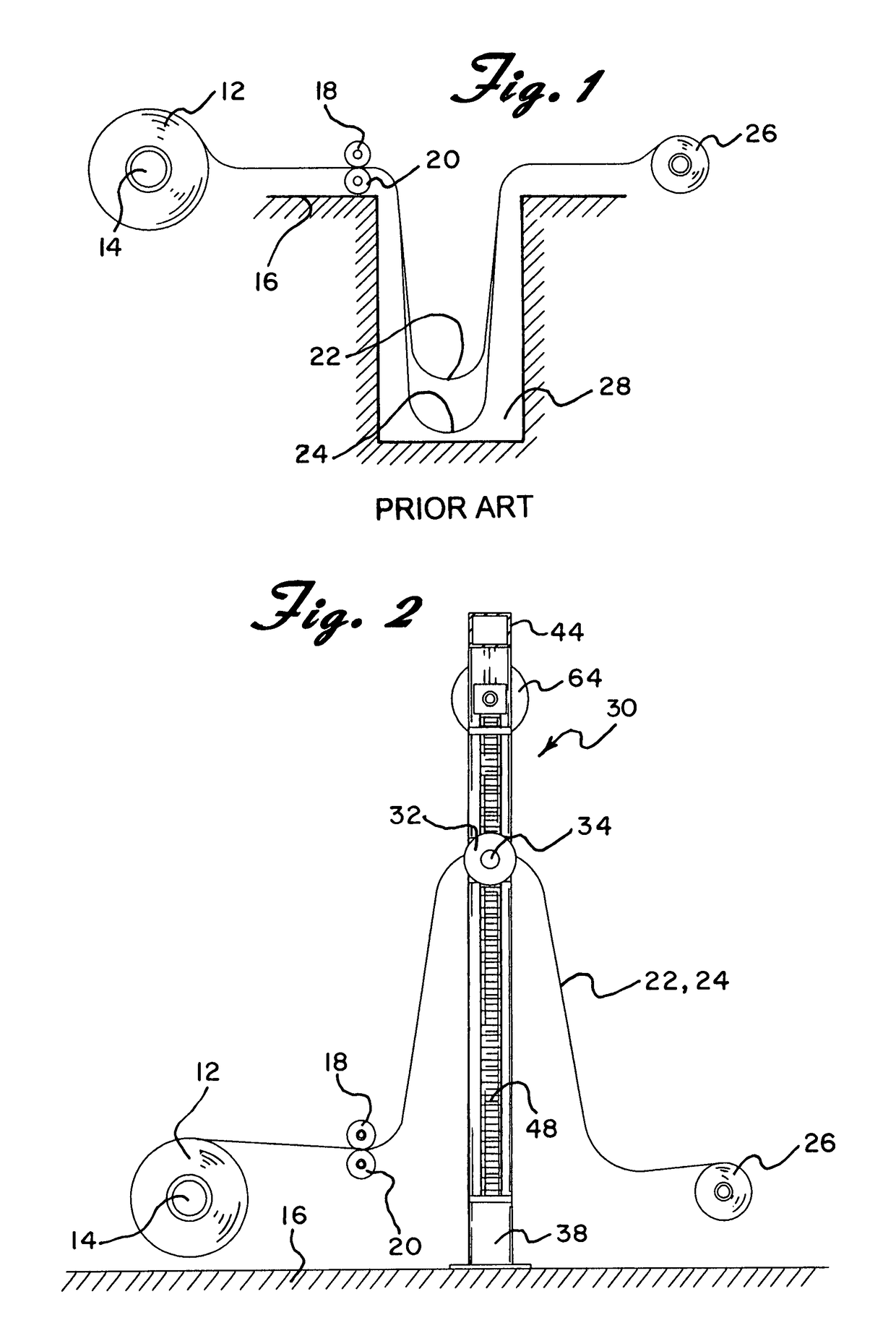

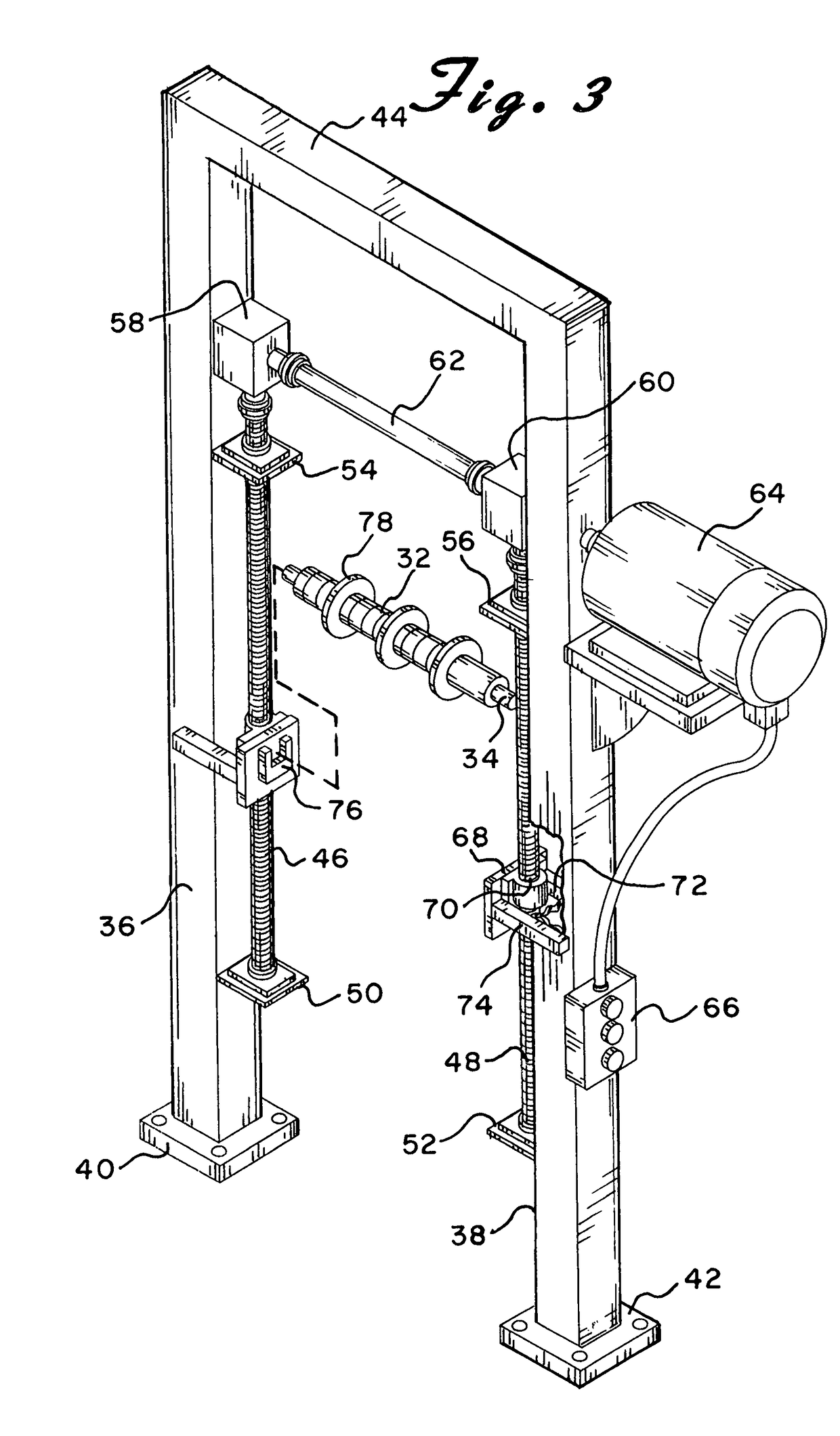

Adjustable vertical accumulator for slitting operation

InactiveUS20090108120A1Overcome deficienciesEliminate needRecord information storageMaterial accumulating devicesHorizontal axisEngineering

A vertical accumulator for use in a sheet metal unwinding, slitting and rewinding operation accumulates the slack created in the plurality of strips cut from an initial wide coil so that the proper tension can be maintained on the individual strips being rewound. The accumulator includes an elongated mandrel mounted for rotation about a horizontal axis parallel to the axis of the original sheet metal coil and is arranged such that all of the plurality of cut strips pass over the top of the mandrel. The mandrel is located above the height of the coil and above the height of the slitter and the rewound individual strips. A plurality of disks mounted on the mandrel separate the cut strips from each other. Upwardly extending threaded rotatable rods located on either side of the sheet metal strips carry holders that releasably support the mandrel. Rotation of the rods causes the holders to move up or down to thereby adjust the height of the mandrel.

Owner:PAPANIA JAMES F

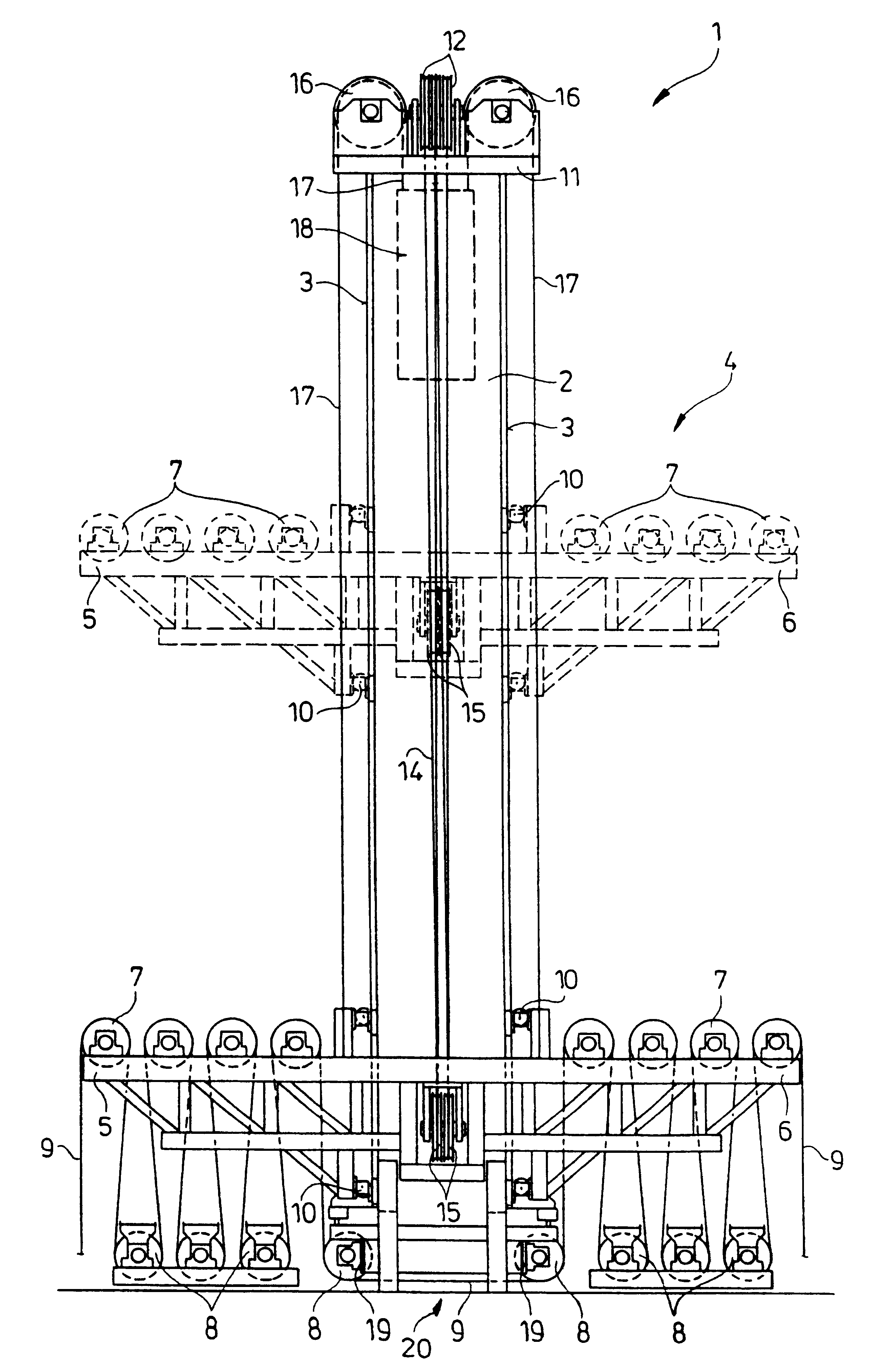

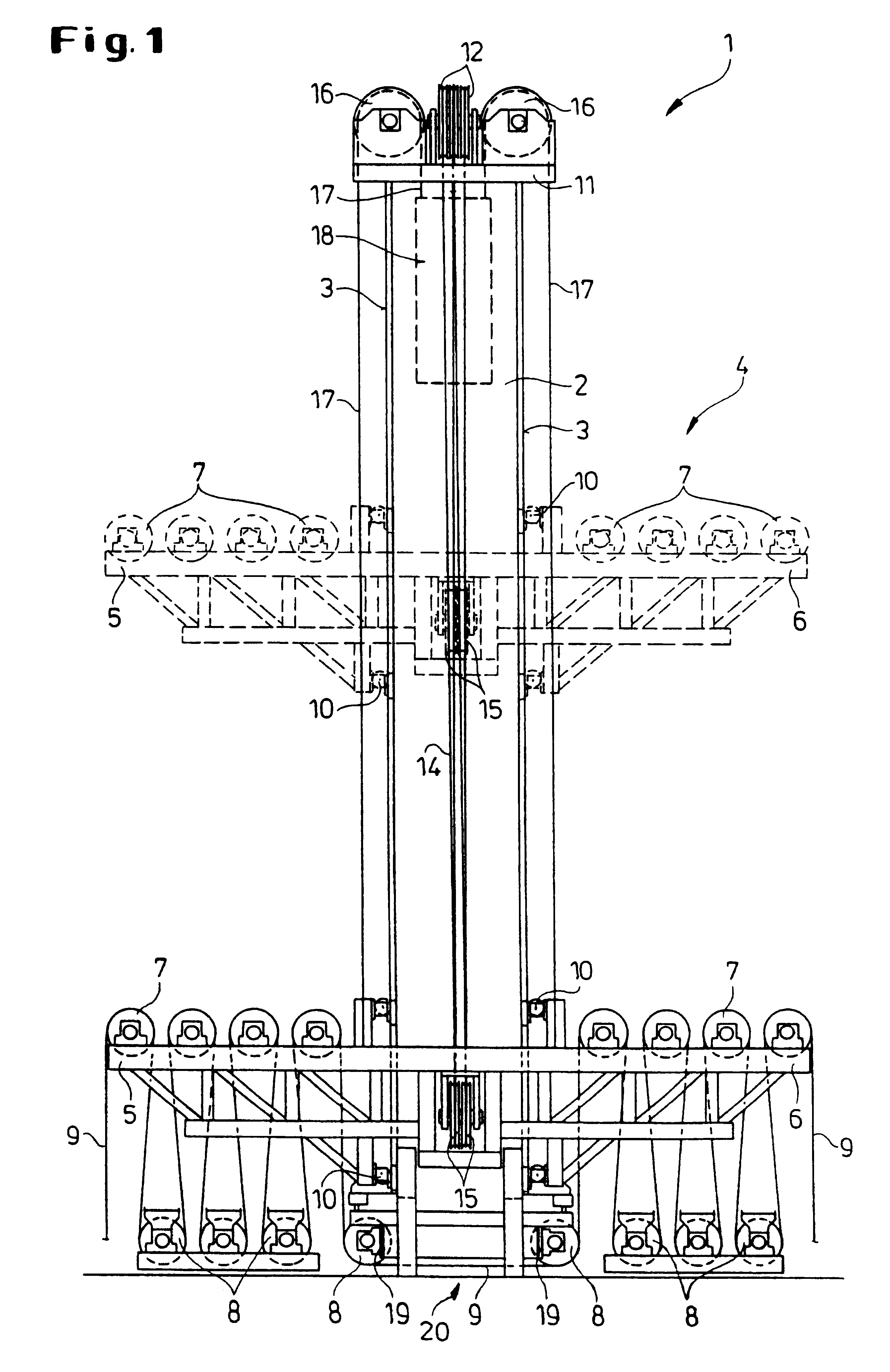

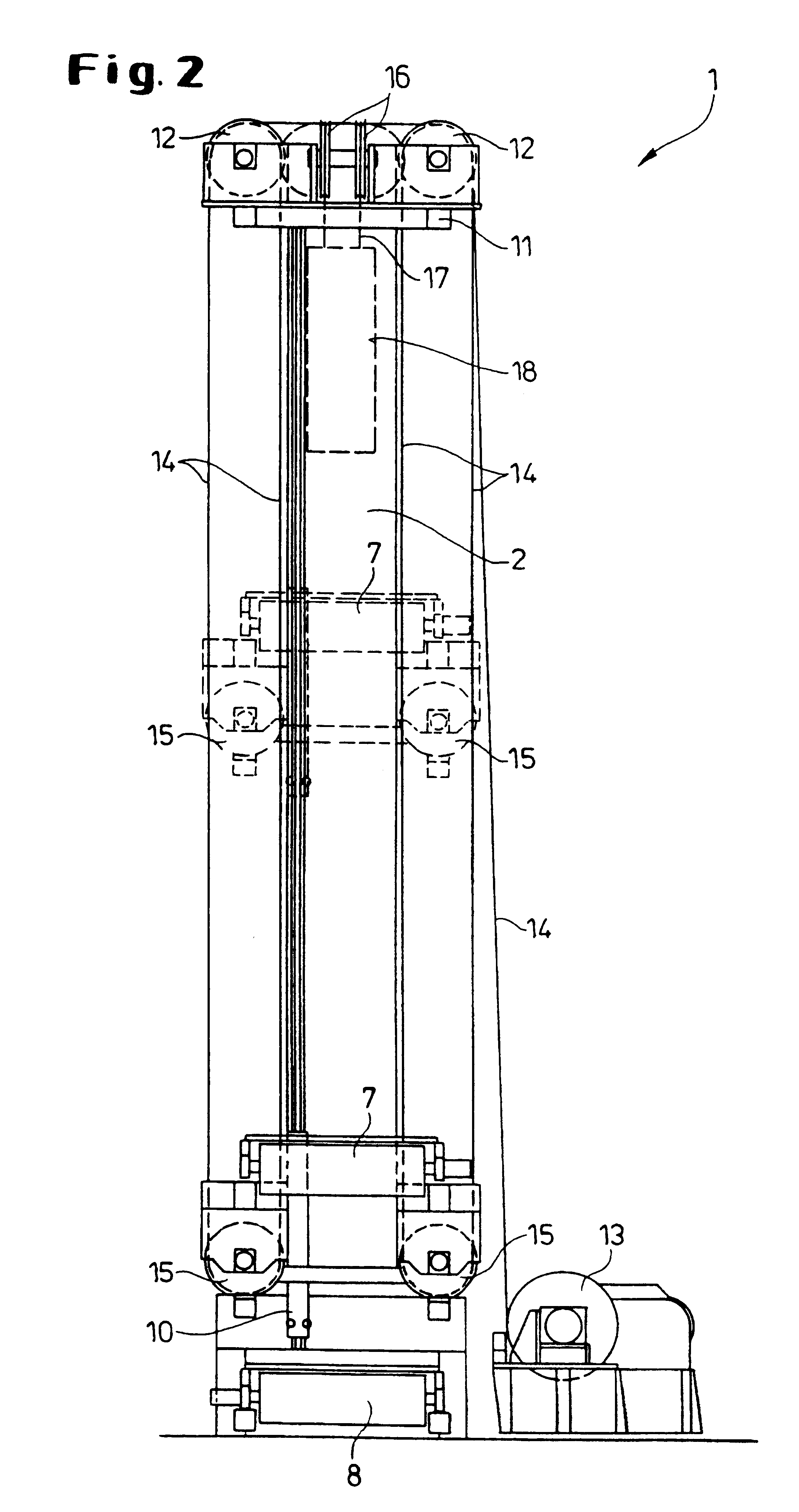

Vertical belt storage system

A vertical strip storage system has a support structure and a storage car connected to the support structure by cables in the fashion of a pulley block so as to be lifted and lowered relative to the support structure. The storage car is provided with a counterweight and with deflection pulleys which deflect and guide an incoming and / or outgoing strip in cooperation with stationary deflection pulleys on the ground. The support structure is a free-standing column without lateral supports and the storage car is a salient vehicle running on the outer surface of the column, wherein the column has an interior and the counterweight is guided in the interior of the column.

Owner:SMS SCHLOEMANN SIEMAG AG

Web inspection and repair machine with retractable inspection zone

InactiveUS20070187020A1Mechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

A web processing machine permitting inspection and repair of a roll of web material includes an inspection zone vertically juxtaposed to a splicing zone. The inspection zone is structured to be removed from the juxtaposed position to a retracted position in which the splicing zone is exposed to permit an operator to perform a modification of the web without having to substantially move physically from the position in which the operator was located to perform inspection while the machine is running.

Owner:PRITTIE FAMILY TRUST 1989

Adjustable vertical accumulator for slitting operation

InactiveUS7905443B2Overcome deficienciesEliminate needRecord information storageMaterial accumulating devicesMetal stripsHorizontal axis

A vertical accumulator for use in a sheet metal unwinding, slitting and rewinding operation accumulates the slack created in the plurality of strips cut from an initial wide coil so that the proper tension can be maintained on the individual strips being rewound. The accumulator includes an elongated mandrel mounted for rotation about a horizontal axis parallel to the axis of the original sheet metal coil and is arranged such that all of the plurality of cut strips pass over the top of the mandrel. The mandrel is located above the height of the coil and above the height of the slitter and the rewound individual strips. A plurality of disks mounted on the mandrel separate the cut strips from each other. Upwardly extending threaded rotatable rods located on either side of the sheet metal strips carry holders that releasably support the mandrel. Rotation of the rods causes the holders to move up or down to thereby adjust the height of the mandrel.

Owner:PAPANIA JAMES F

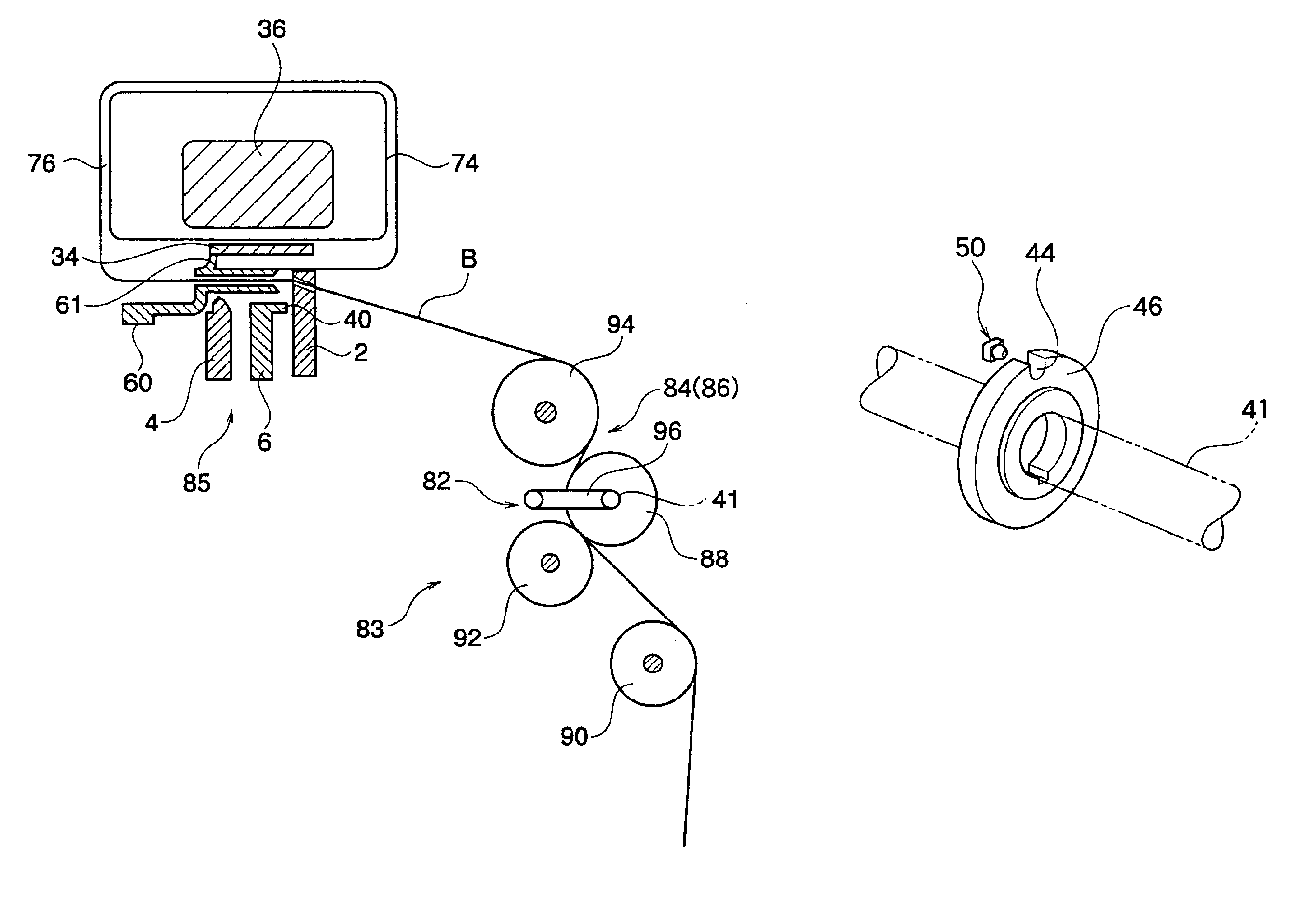

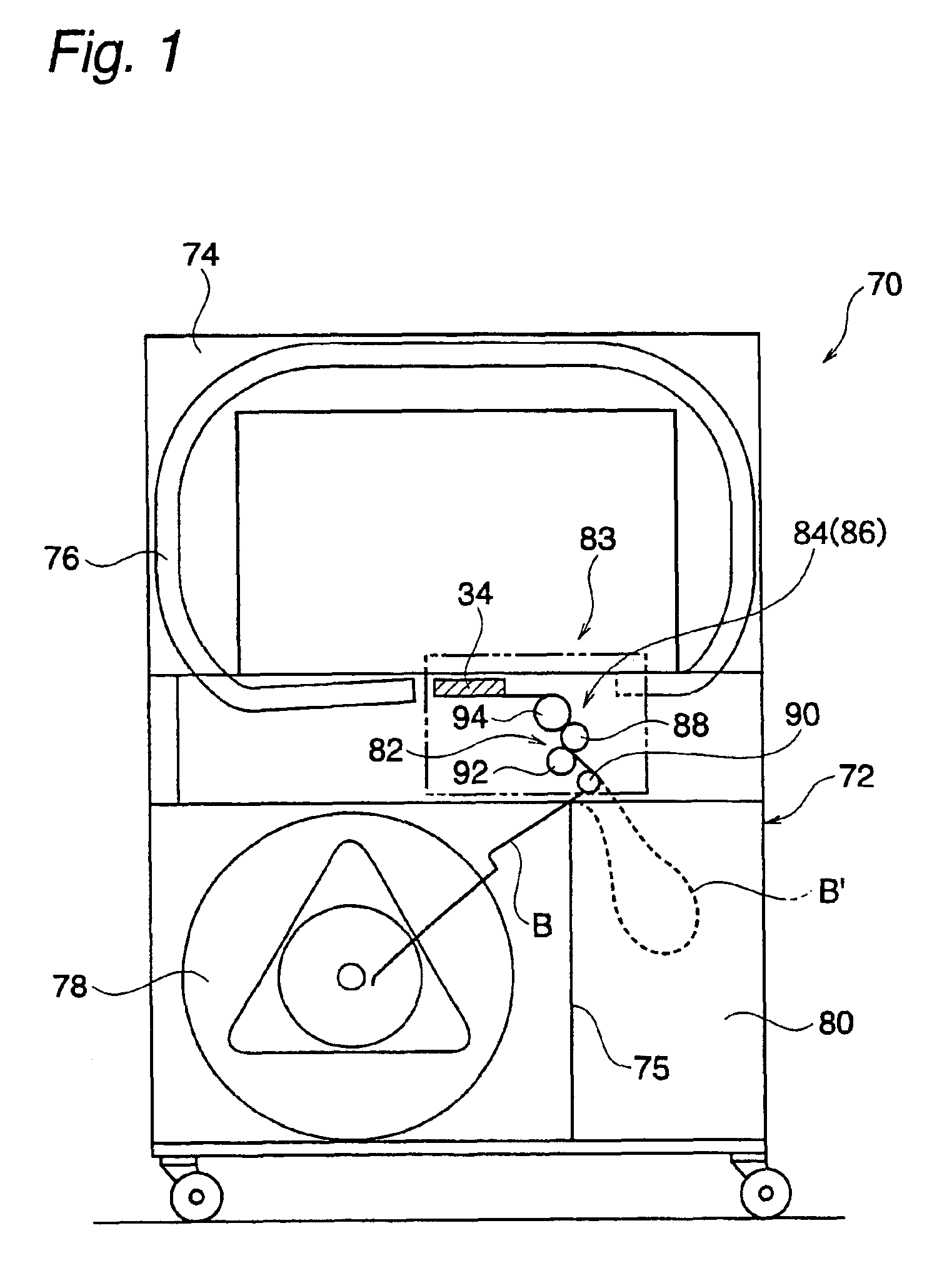

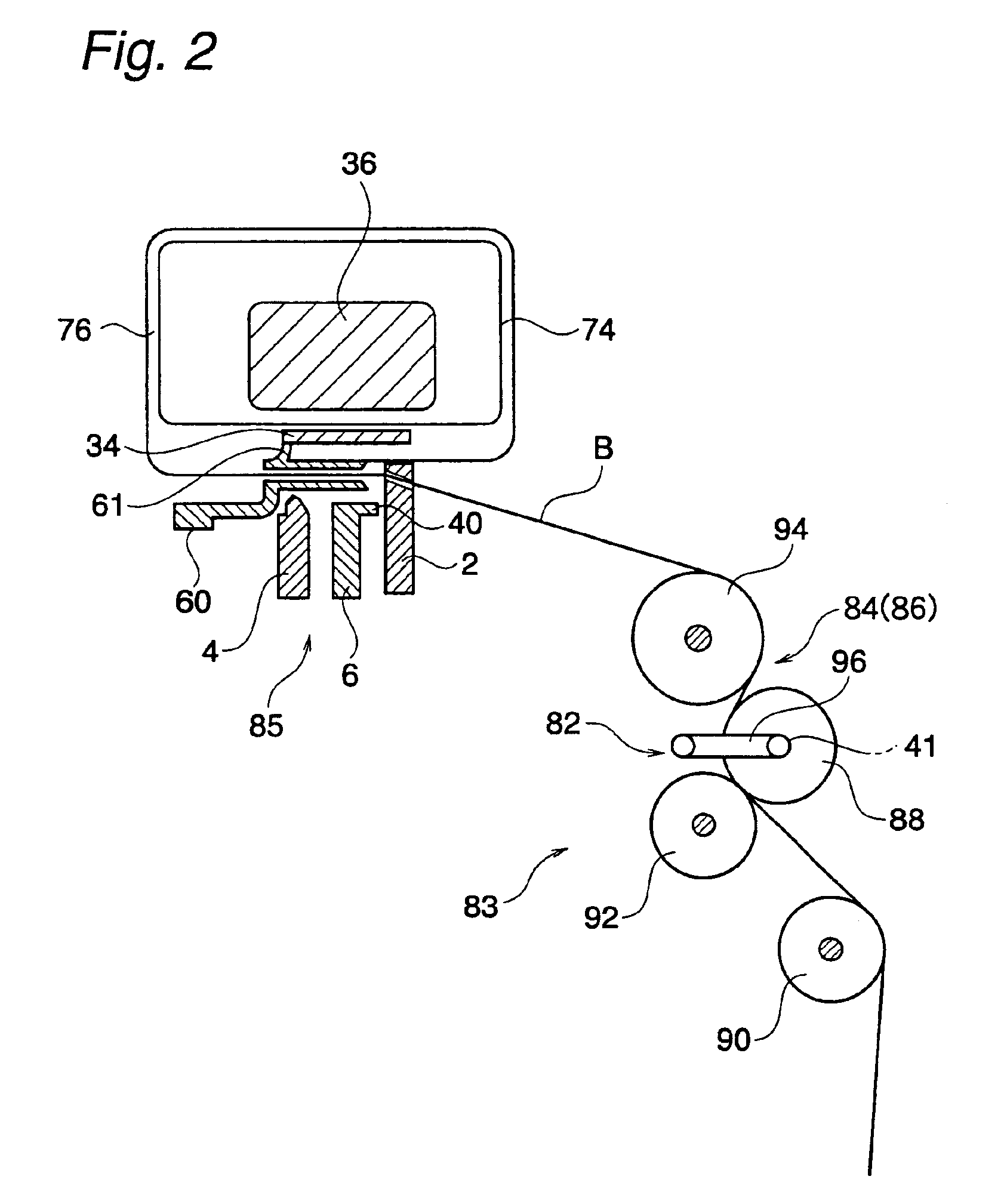

Banding packing machine

InactiveUS6928787B2Easy to detectInexpensively detecting endWrapping material feeding apparatusRecord information storageEngineeringConstant speed

A banding packing machine capable of inexpensively detecting the end of a band reel, thereby contributing to a reduction in cost. In a banding packing machine having a back pool box in a packing machine body and serving to feed an unused band (B) stored in the back pool box and a band from a band reel, the rotating speed of a touch roller is detected when a required amount of band is being pulled out of the band reel wherein the band is not left in the band reel if the rotating speed is not changed but the rotation is carried out at an almost constant speed, and the tip portion of the band does not arrive at the predetermined position of a band guide arch. Then, the driving operation of a normal rotating roller is stopped based on the decision signal.

Owner:STRAPACK SHIMOJIMA CO LTD

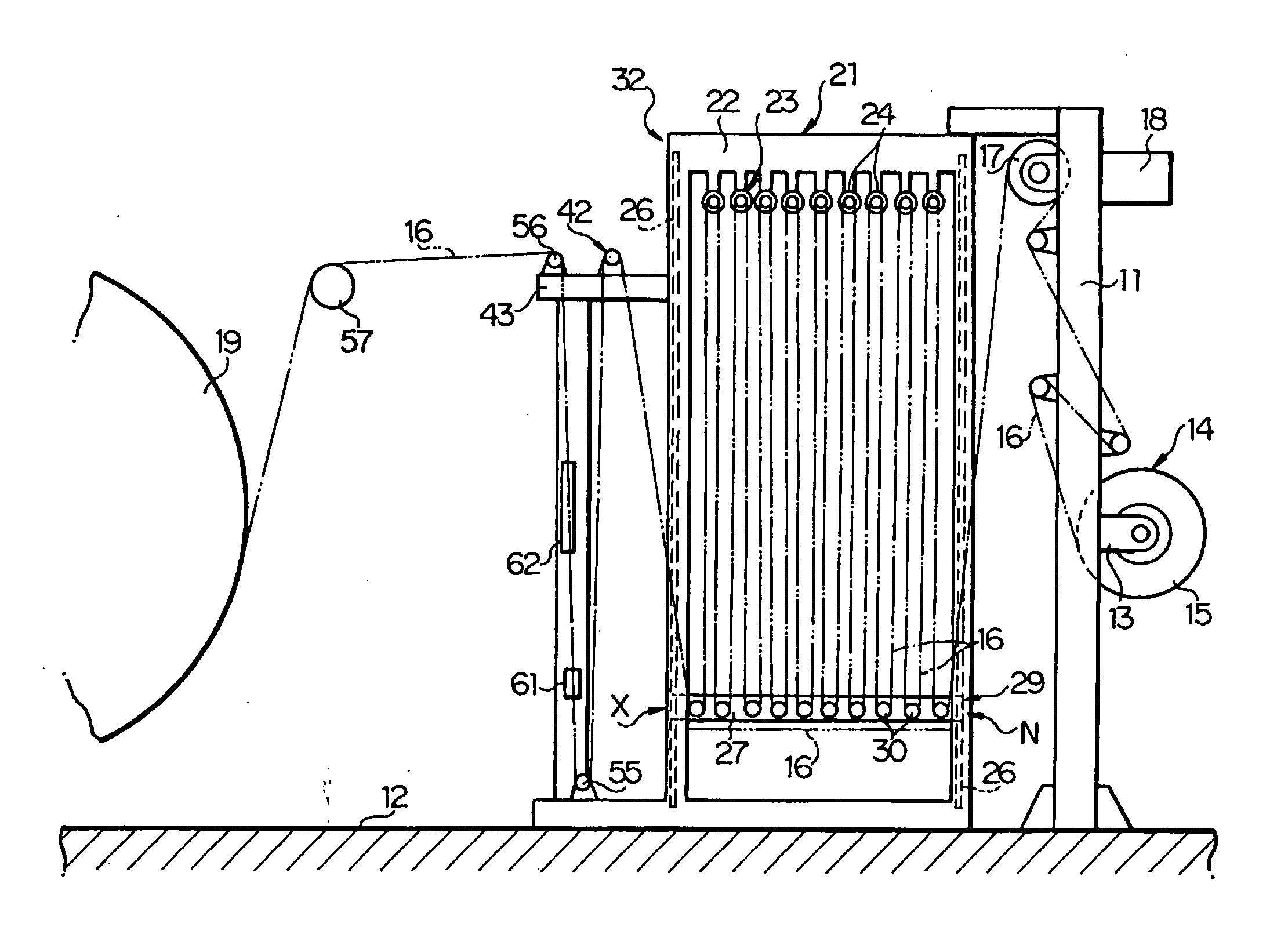

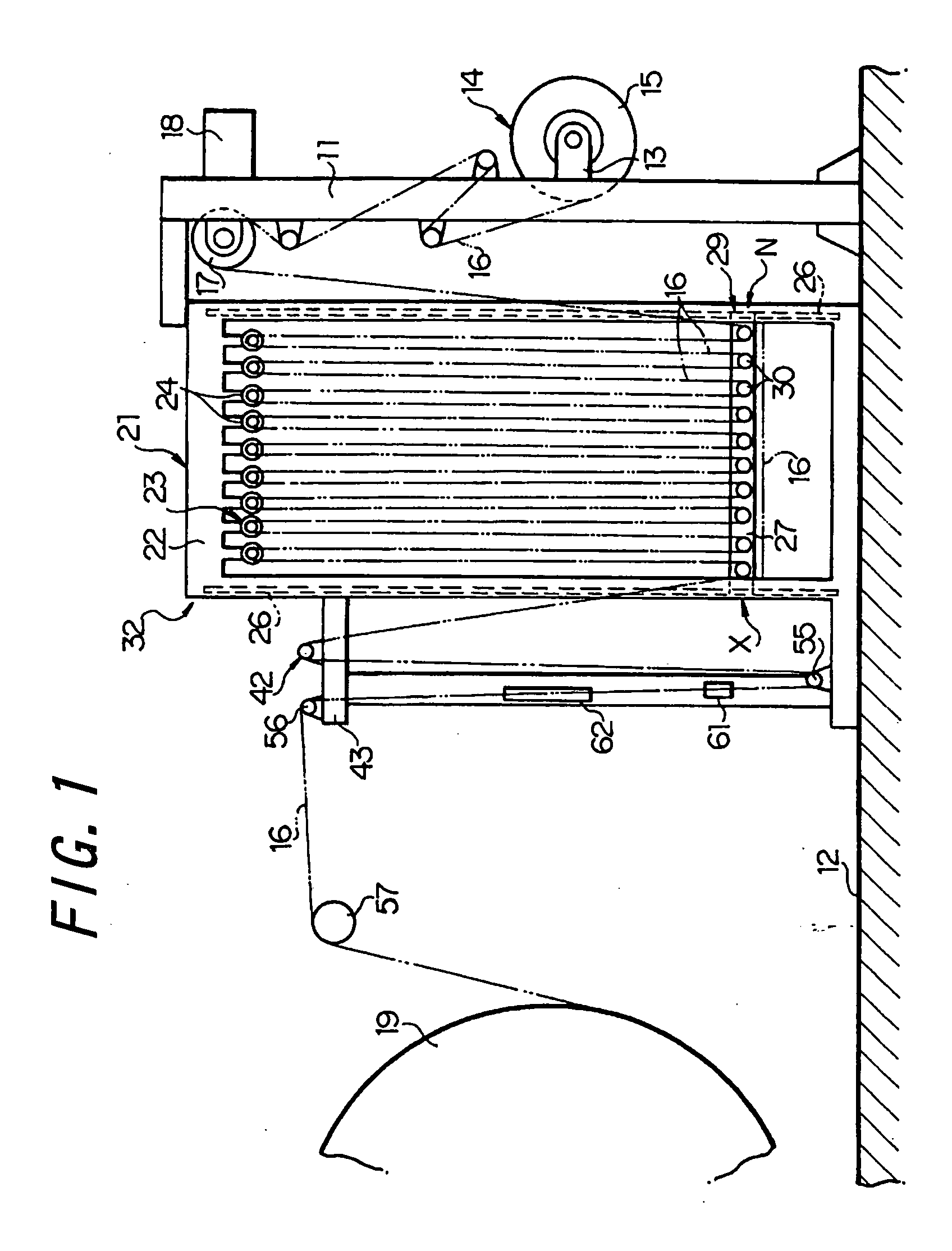

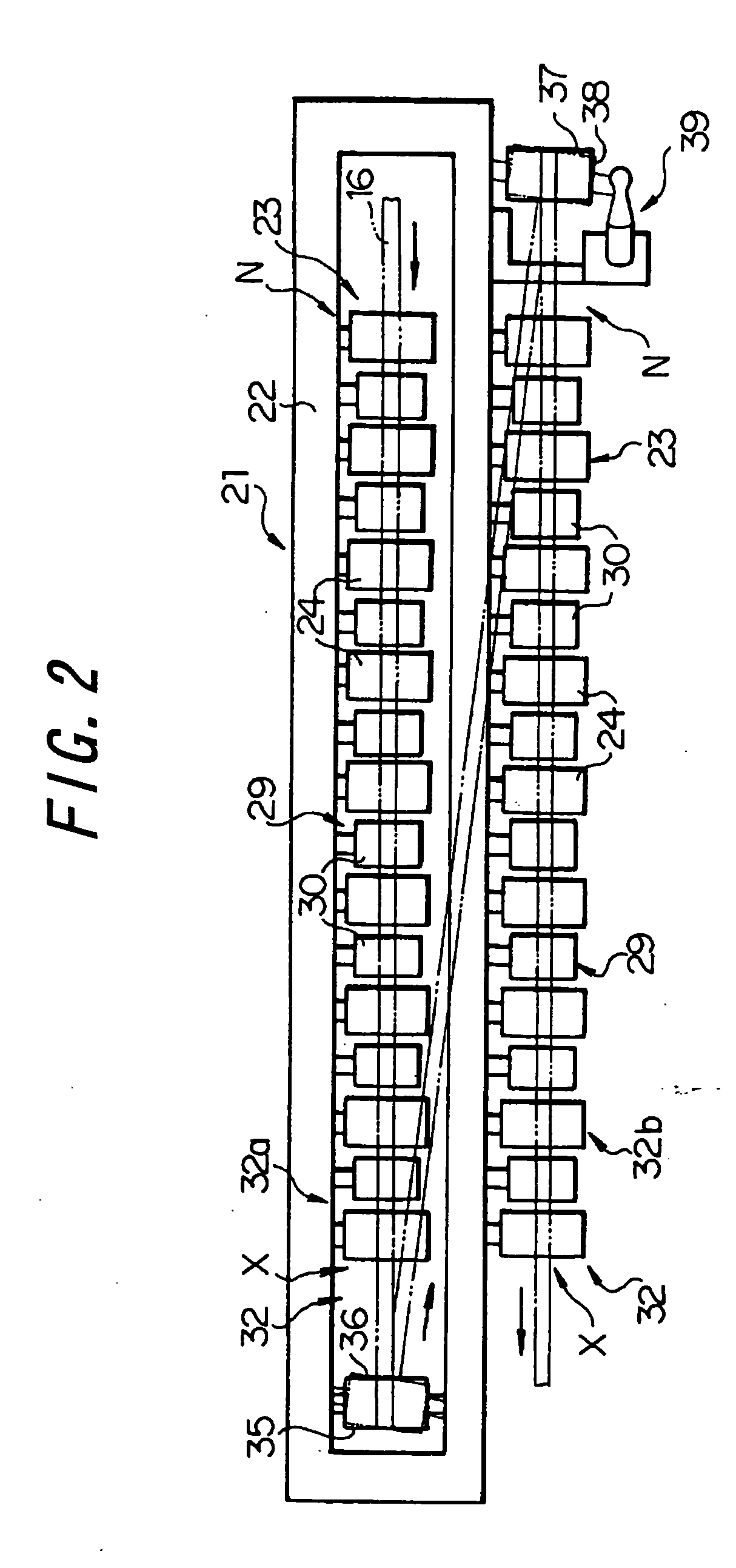

Method and device for temporarily storing linear body

InactiveUS20060113348A1Reduce manufacturing costSimple configurationAutomatic control devicesPrecision positioning equipmentEngineering

A temporary storage device (21) includes a plurality of temporarily storing means (32), two in the disclosed embodiment, arranged parallel with each other in a lateral direction, wherein a linear body (16) is led from the outlet (X) of the temporarily storing means (32a) to the inlet (N) of the temporarily storing means (32b) by a guide means (39) so that, when the length of the temporarily stored linear body (16) is the same as a conventional one, the longitudinal length of the temporarily storing device (21) can be formed rather shorter than that of a conventional device and more specifically, the longitudinal length of the temporarily storing device (21) can be shortened approximately to a length obtained by dividing the longitudinal length of the conventional device by the number (i.e., two in this case) of the temporarily storage means (32). The temporarily storing device (21) can be thus generally made compact and easily installed also in an existing equipment.

Owner:BRIDGESTONE CORP

Tape system with an isolated load/unload tape path

InactiveUS7195189B2Reduce contaminationAvoid damagePicture changing apparatusProjector film strip handlingMagnetic tapeRecording system

A tape recording system is provided having an improved load / unload path, the system comprising a first pair of guides and a second pair of guides movable from an unloaded position to a loaded position. In the unloaded position, a gap between the first pair of guides and the second pair of guides provides a path for loading a tape from a supply reel to a take-up reel without contacting any of the first pair of guides, the second pair of guides and the head assembly to prevent contamination and damage of these components. The tape loader path is isolated from the head by the first pair of guides providing protection of the head from possible contact damage by the loader mechanism and tape leader.

Owner:INT BUSINESS MASCH CORP

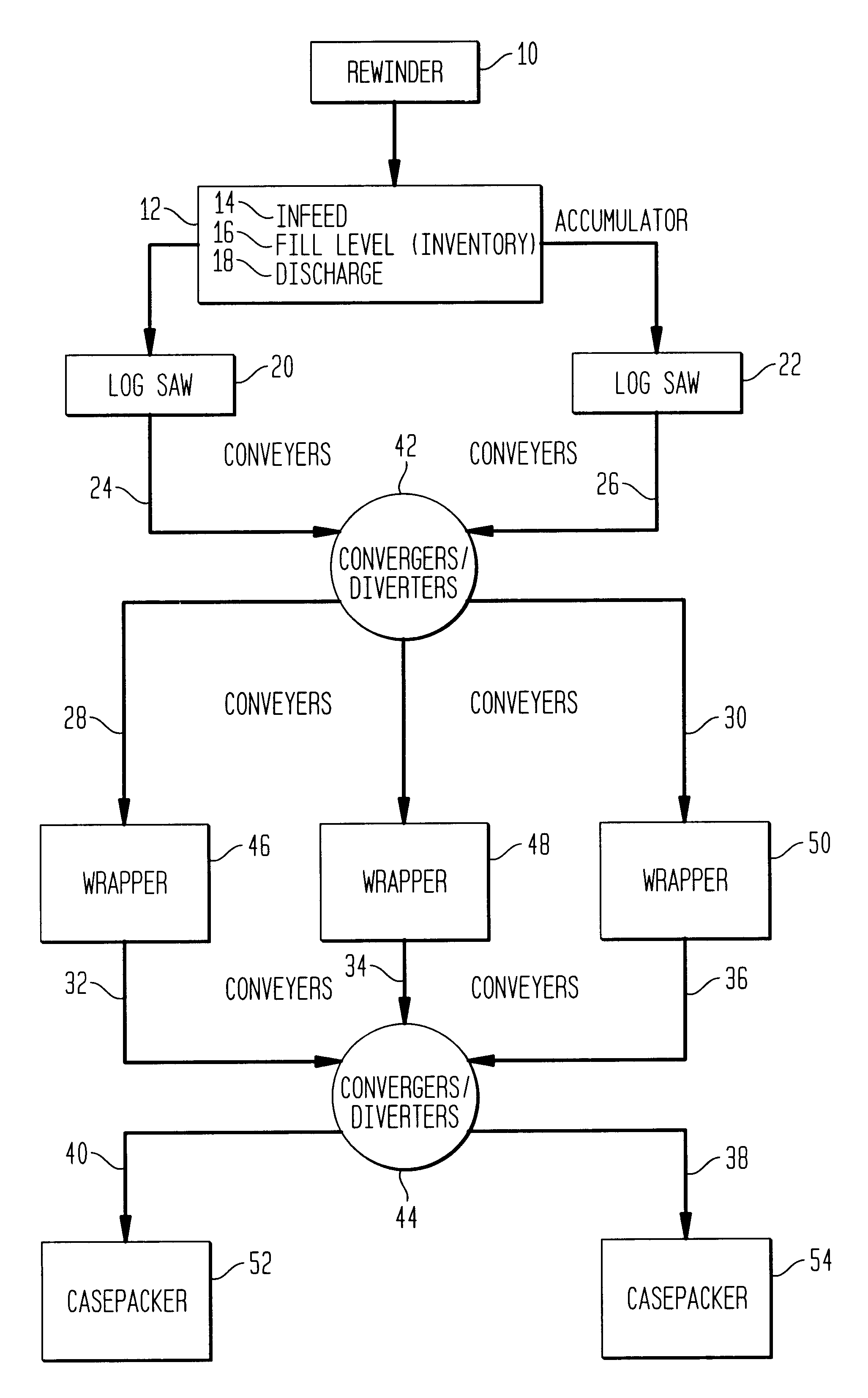

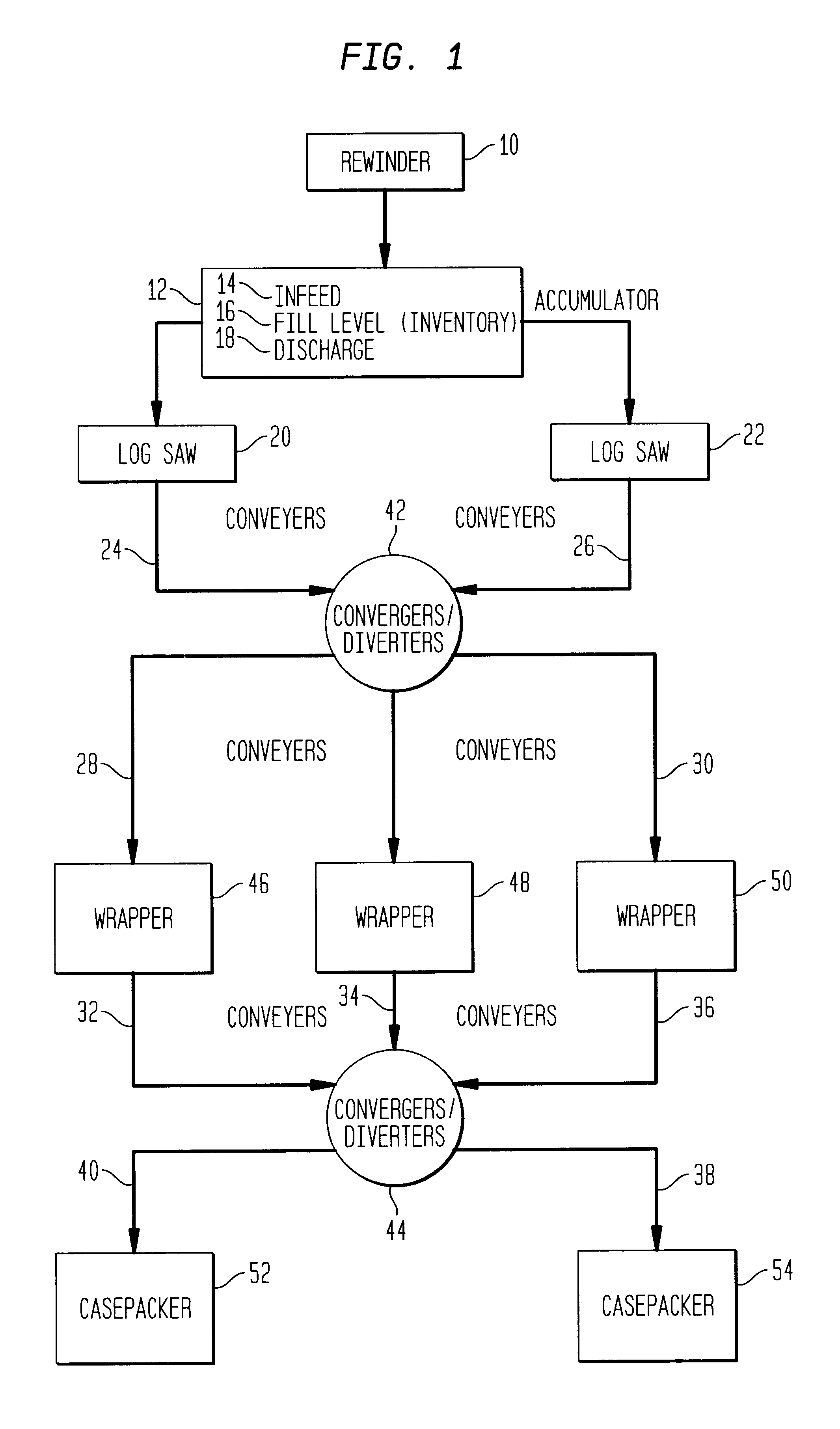

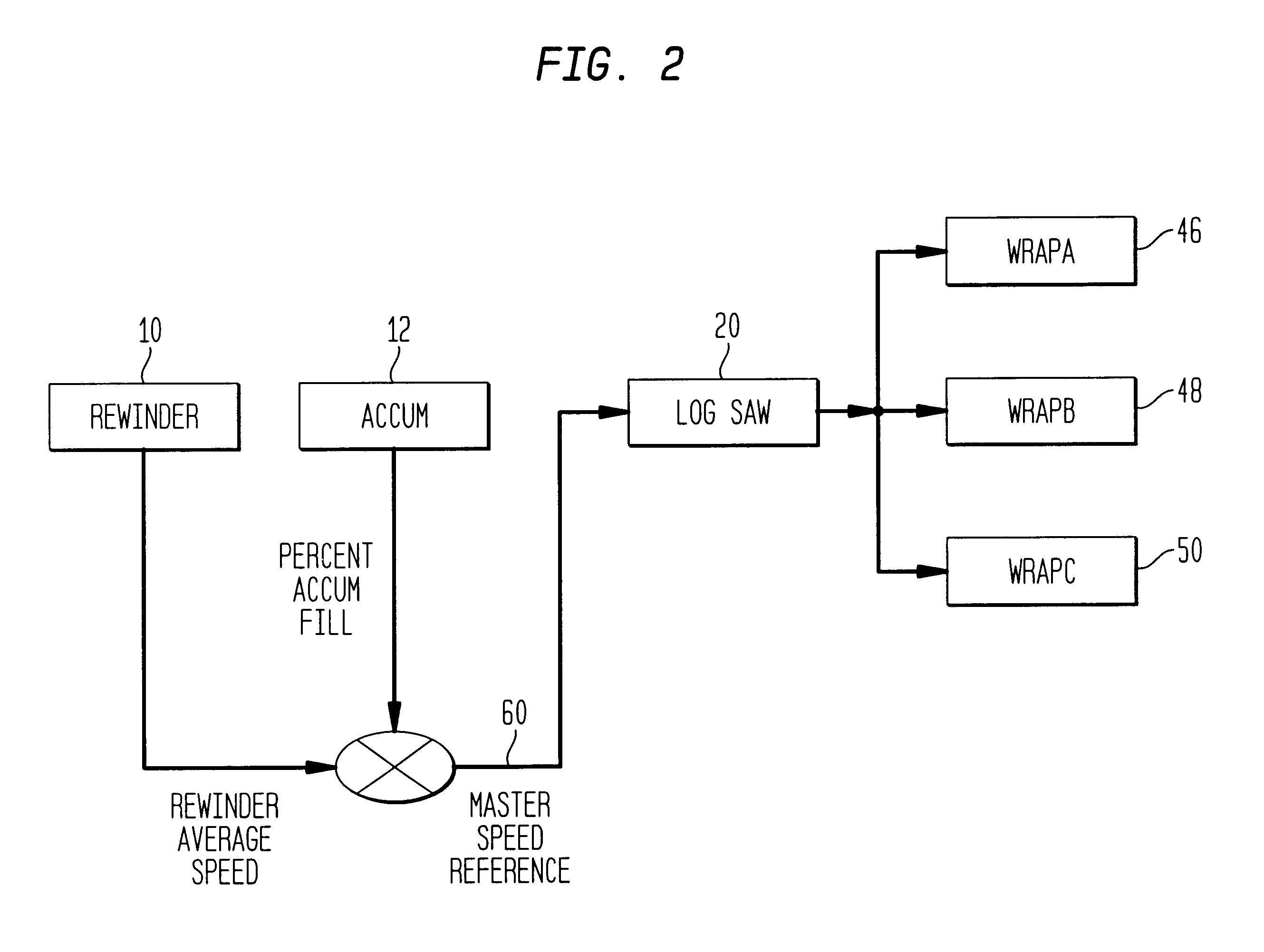

Method and apparatus for controlling converting rewinder lines

InactiveUS6738684B2Improve efficiencyMinimizing undesirable starts/stopsFunction indicatorsRecord information storageControl theory

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

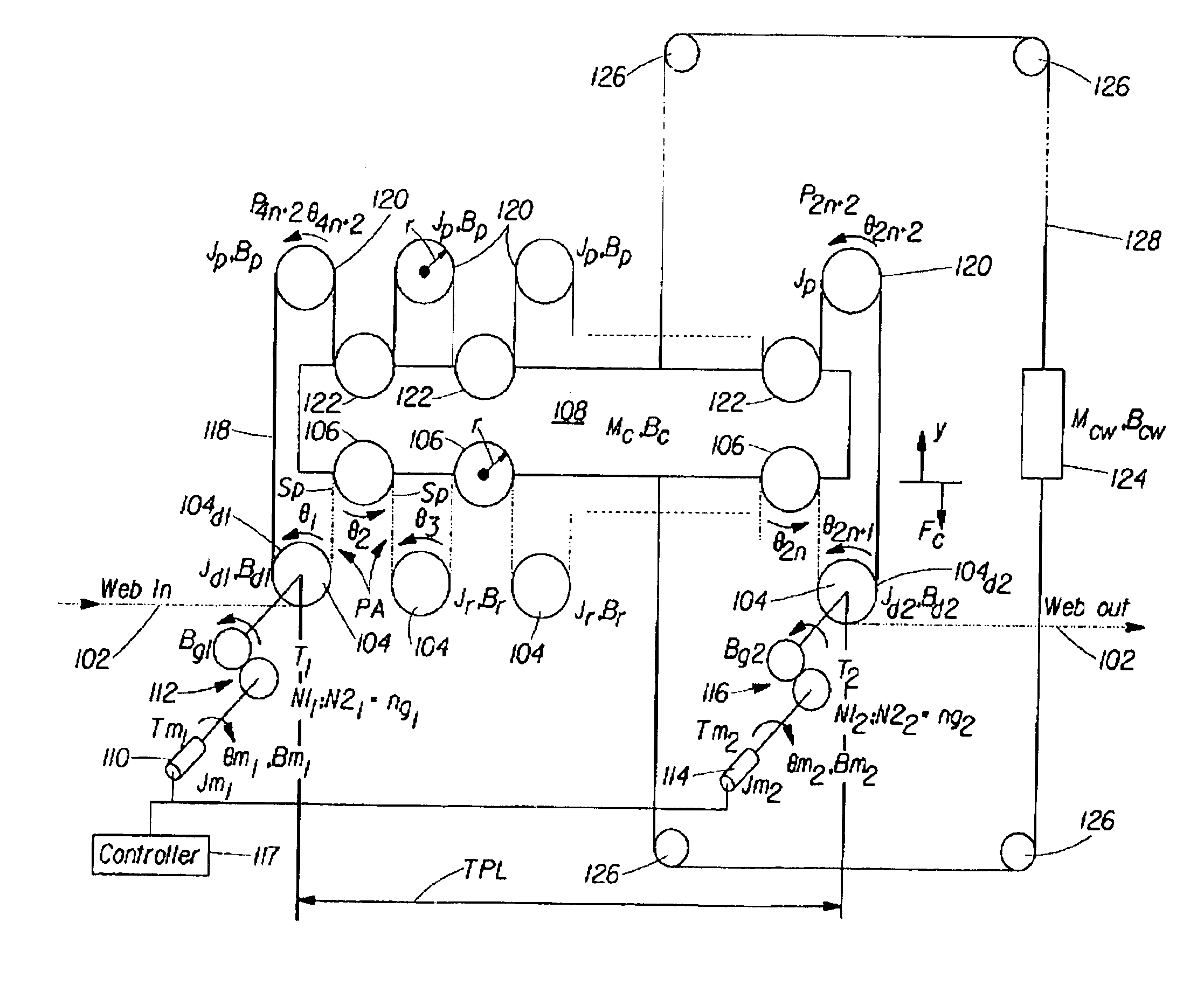

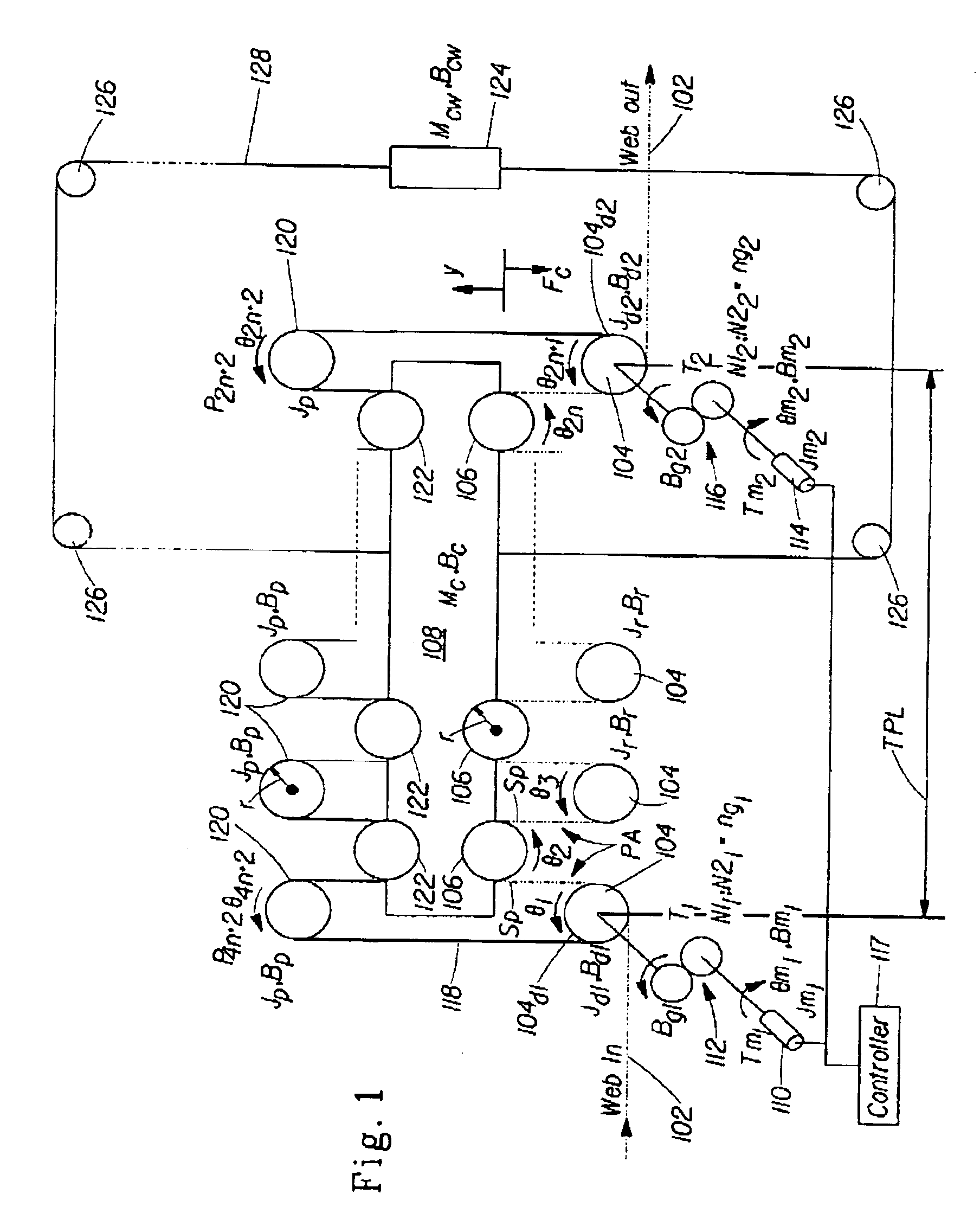

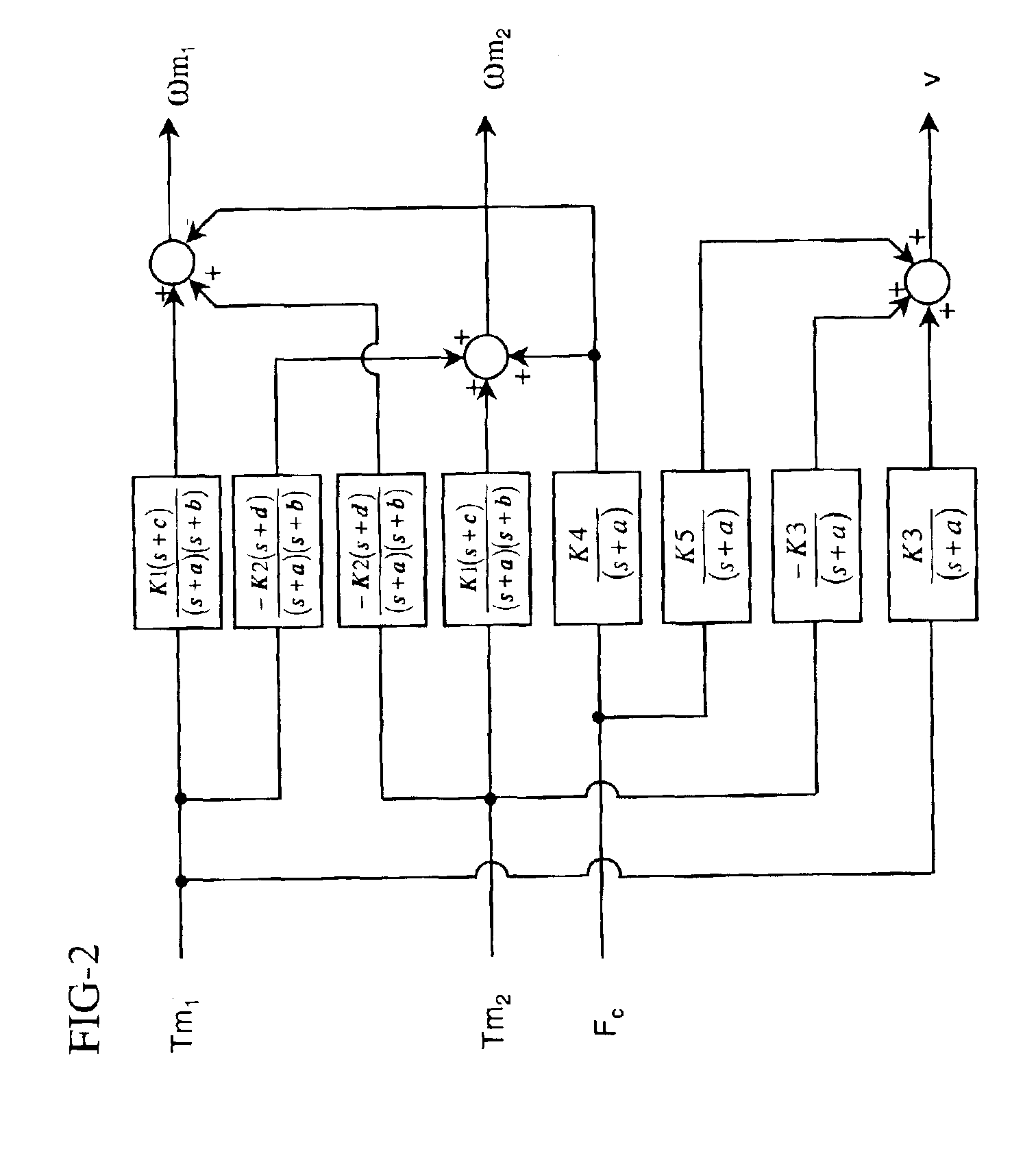

Web accumulator having limited torque disturbance

A control arrangement decoupled two driven inputs for driven belt web accumulators using gear trains, gear trains with torque feed-forward control or gear trains with toque feed-forward control and velocity feedback control.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus for taking up slack of wire harness

Owner:YAZAKI CORP

Servo writer

ActiveUS6914741B2Avoid mistakesErrors due to the distortion of the servo signals can be preventedDriving/moving recording headsAlignment for track following on tapesMagnetic tapeEngineering

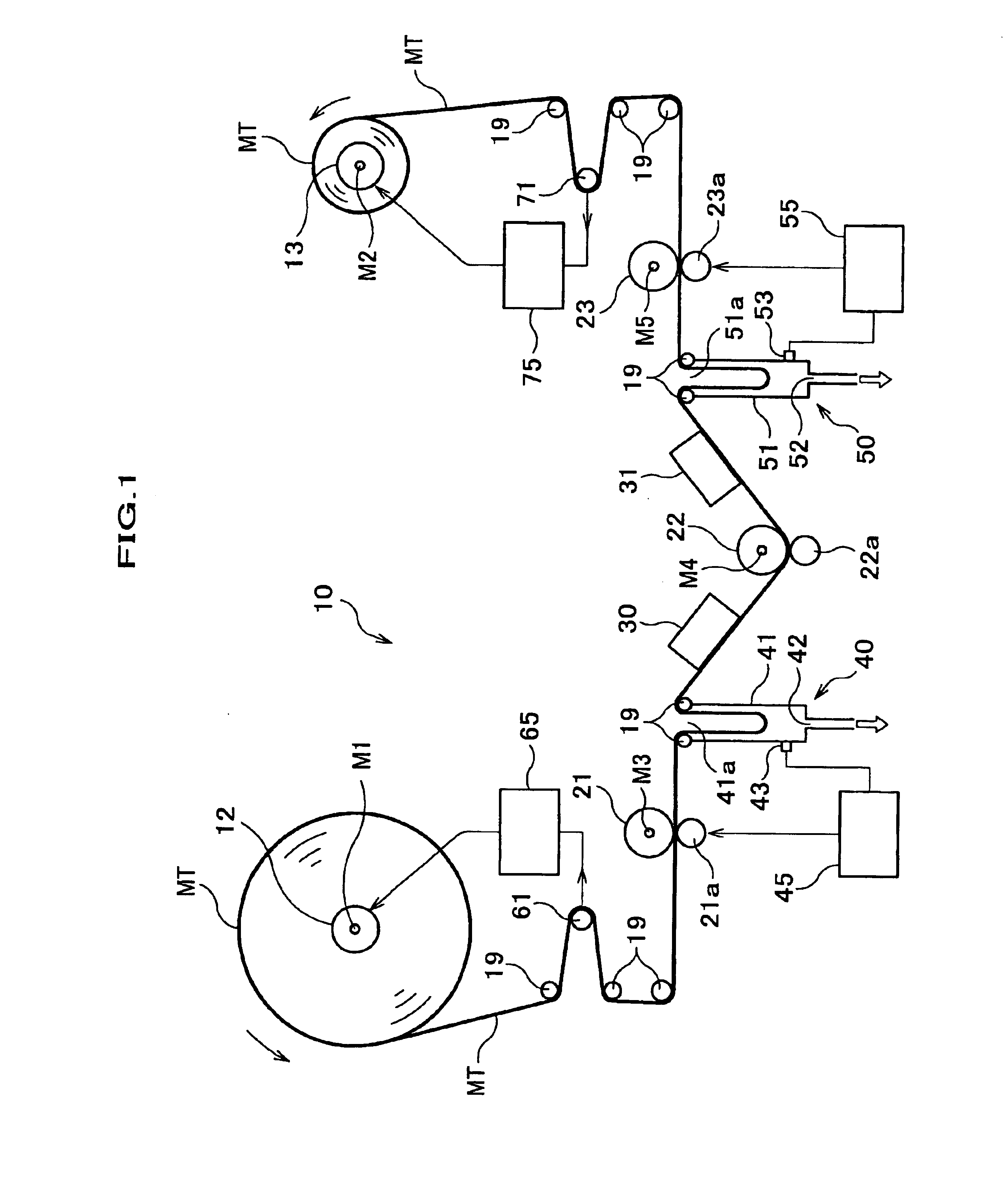

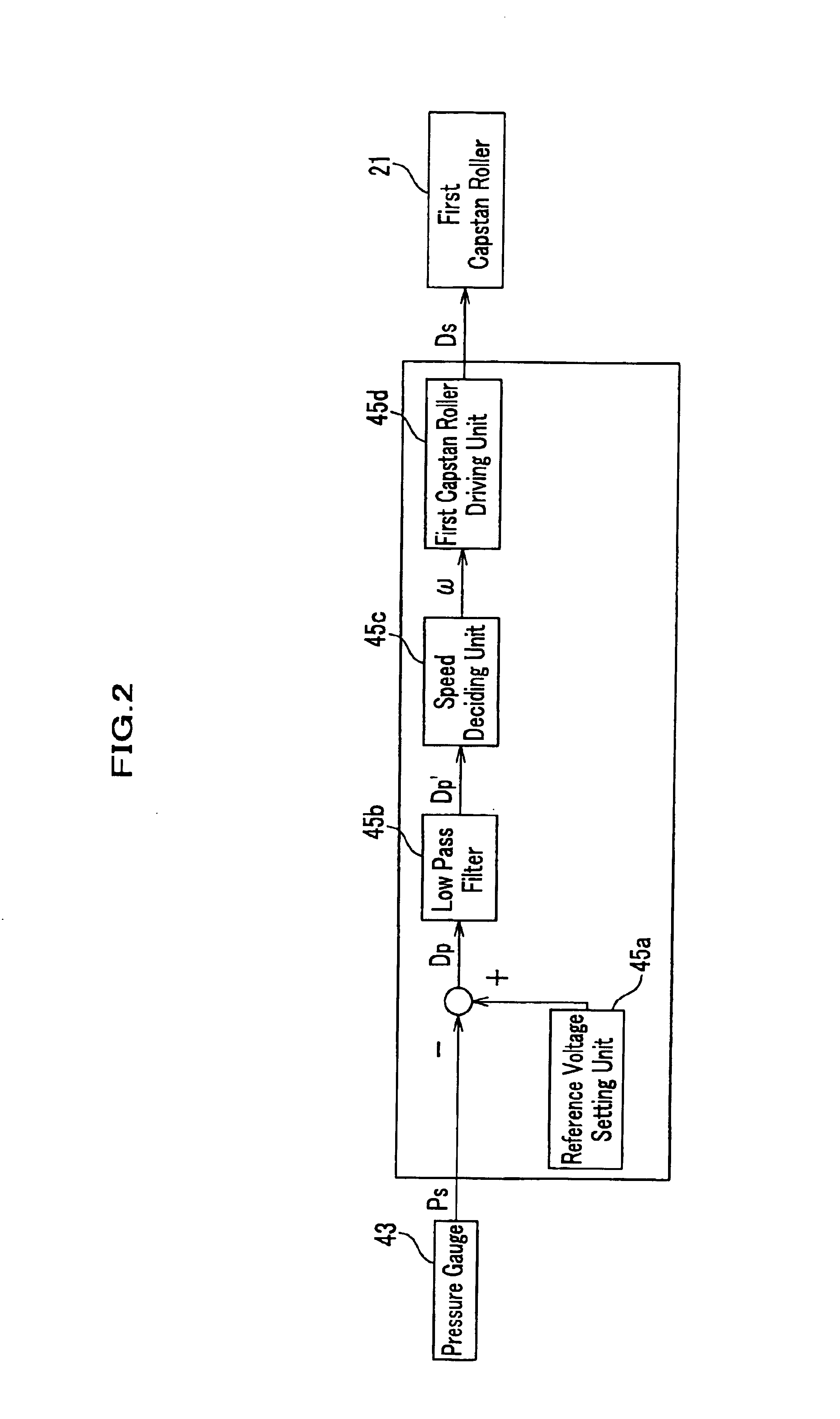

A servo writer which writes a servo mend on a tape by the write head is characterized by being equipped with a pay-off side motor paying off the tape from tie payoff reel by rotating the pay-off reel; a winding side motor winding the tape on the winding reel by rotating the winding reel; a first capstan roller and second capstan roller which are provided at an upstream side and down stream side of the write head, respectively, and by rotating the capstan rollers, run the tape in a state pinched between respective pinch rollers and the capstan rollers; a first tension detector which is provided between the first capstan roller and second capstan roller and detects running tape tension; and a capstan roller controlling unit controlling a rotation speed of the first capstan roller and second capstan roller so that tension detected by the tension detector becomes constant.

Owner:FUJIFILM HLDG CORP +1

Tape system with an isolated load/unload tape path

InactiveUS20060175452A1Reduce contaminationAvoid damagePicture changing apparatusProjector film strip handlingMagnetic tapeEngineering

A tape recording system is provided having an improved load / unload path, the system comprising a first pair of guides and a second pair of guides movable from an unloaded position to a loaded position. In the unloaded position, a gap between the first pair of guides and the second pair of guides provides a path for loading a tape from a supply reel to a take-up reel without contacting any of the first pair of guides, the second pair of guides and the head assembly to prevent contamination and damage of these components. The tape loader path is isolated from the head by the first pair of guides providing protection of the head from possible contact damage by the loader mechanism and tape leader.

Owner:IBM CORP

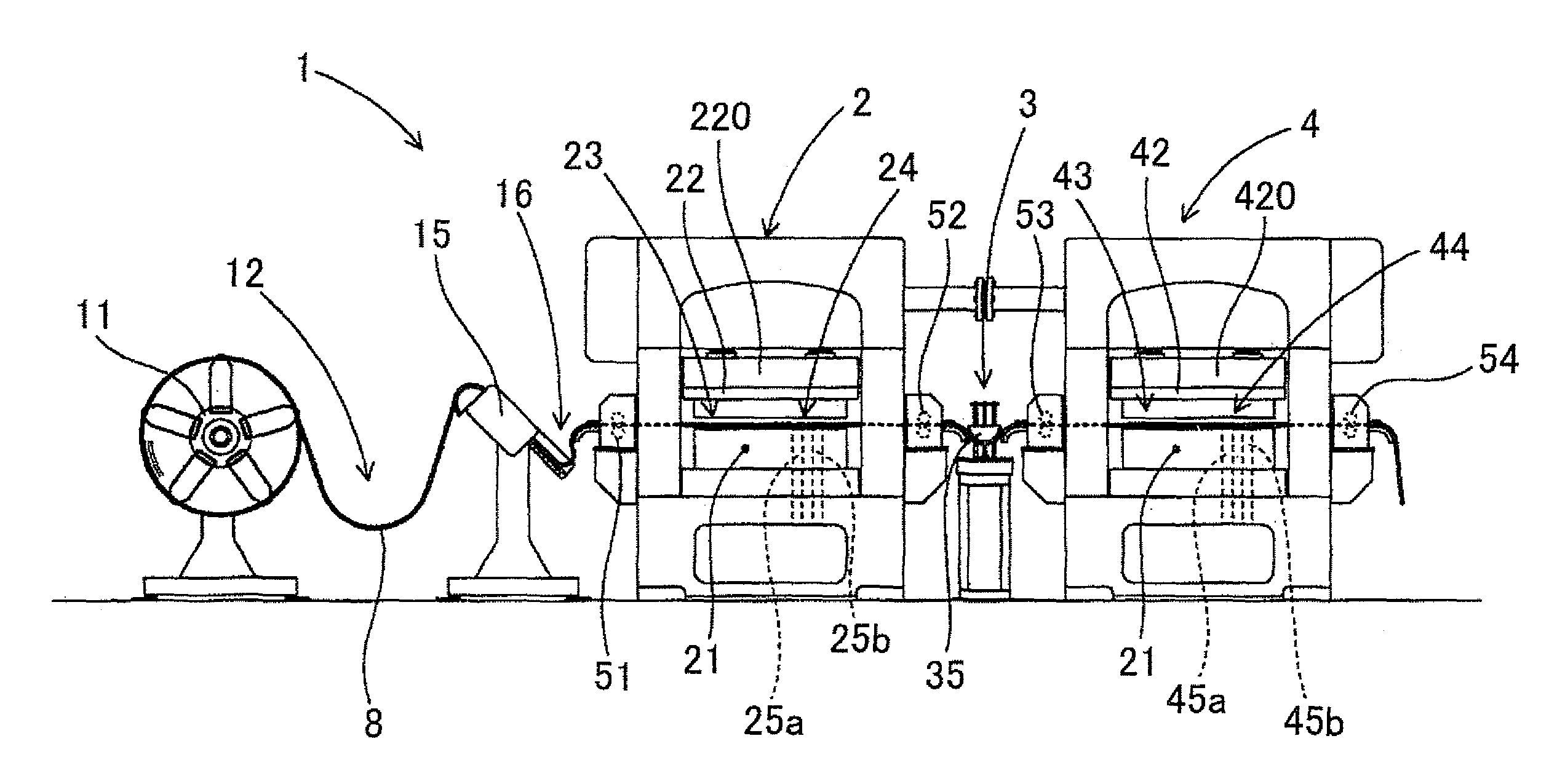

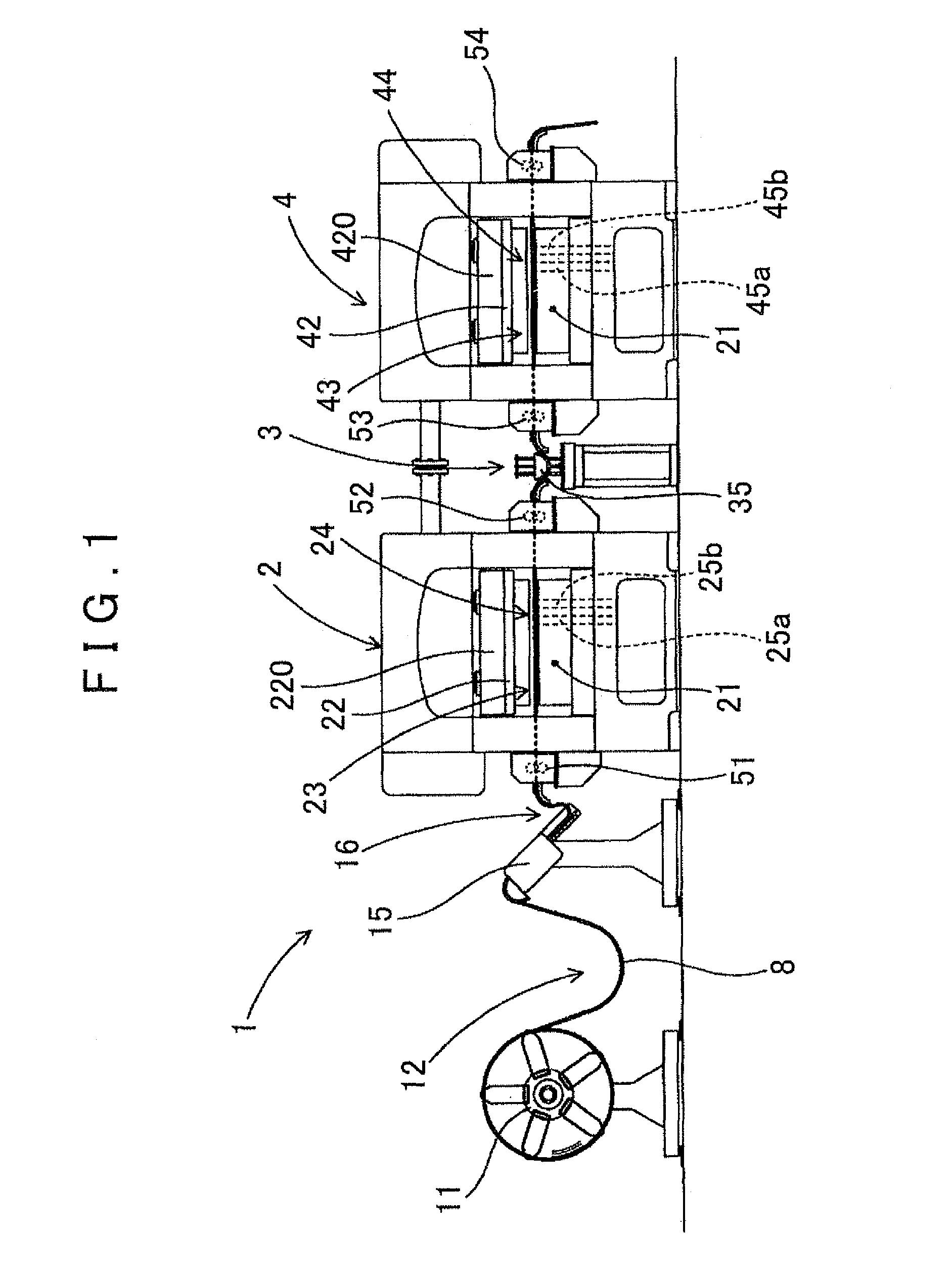

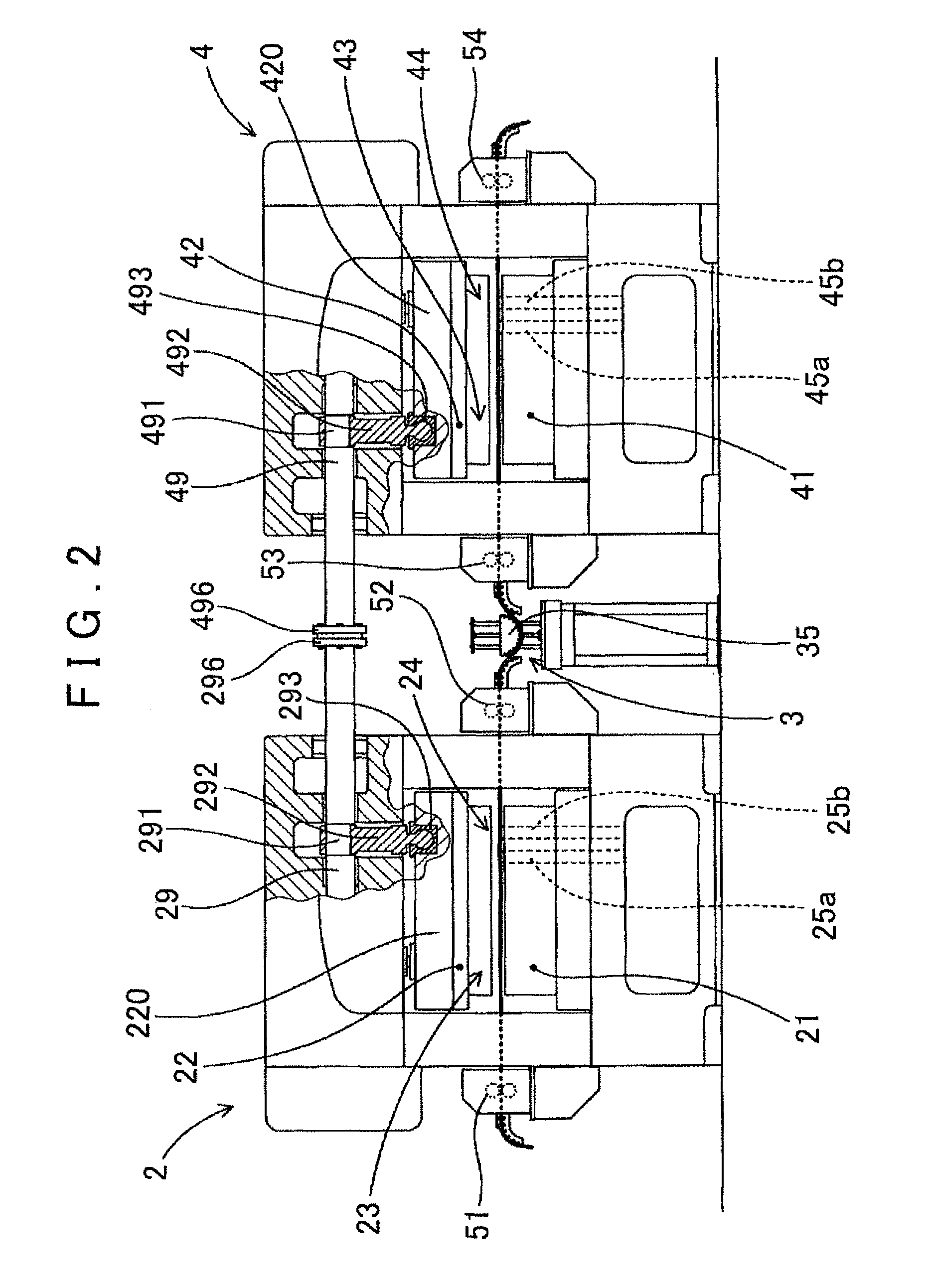

Laminated core punching apparatus

ActiveUS8720039B2Fast punching speedIncrease in sizeProjector film strip handlingFilament handlingSheet steelPunch press

Owner:NORITSU KIKAI SEISAKUSHO

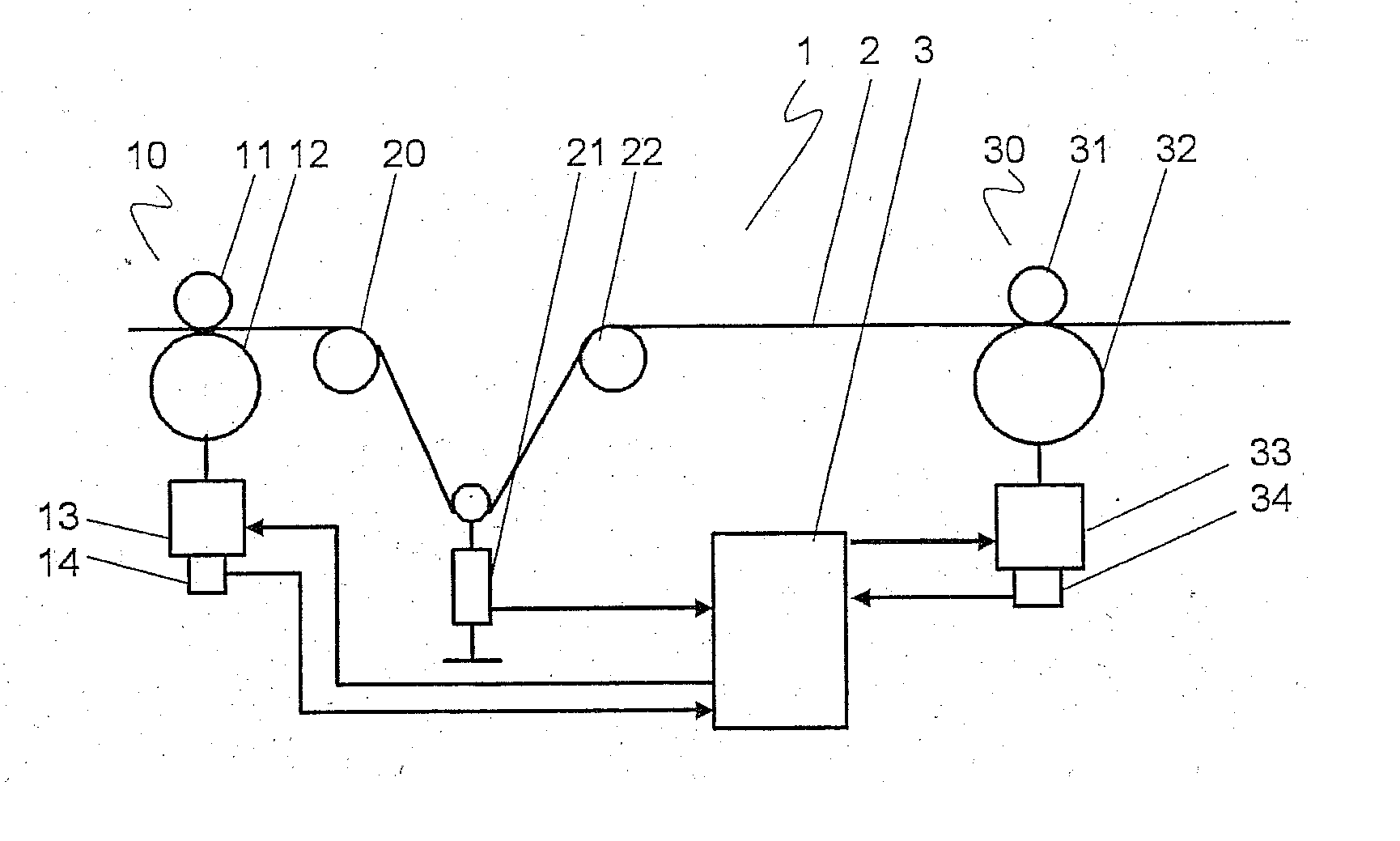

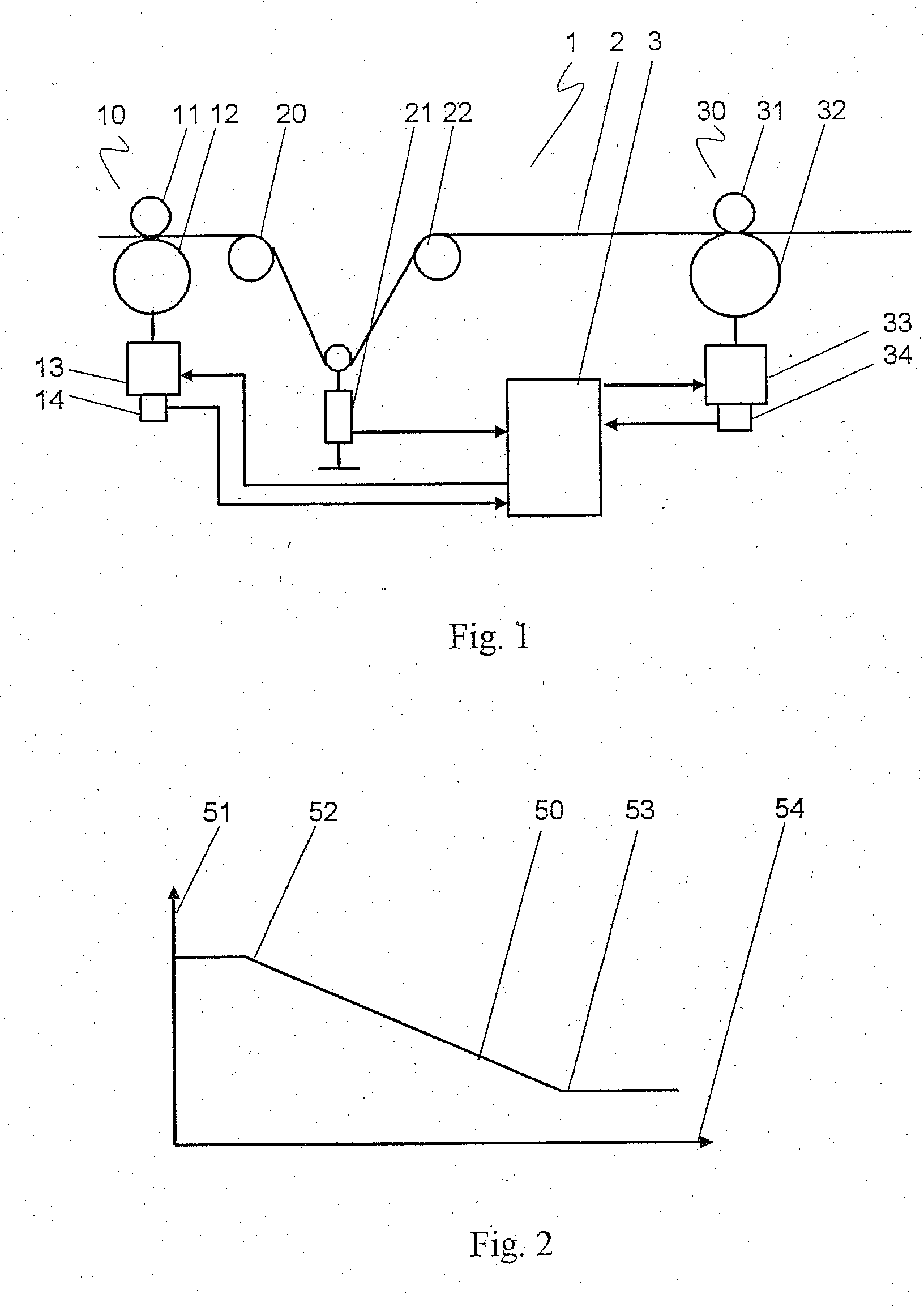

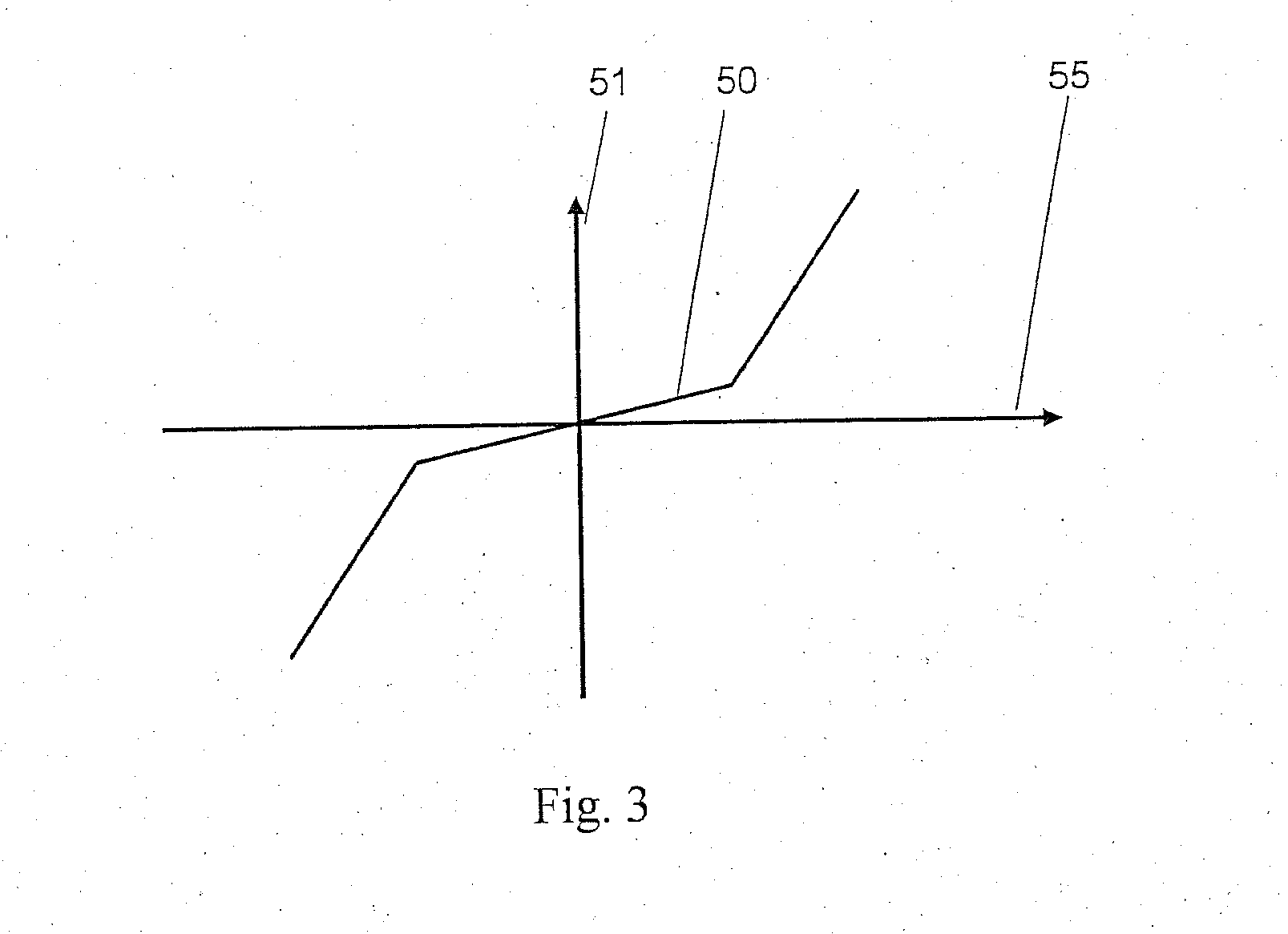

Tension-controlled web processing machine and method

InactiveUS7926688B2Speed up the processSimple systemAutomatic control devicesPrecision positioning equipmentEngineeringTension control

A web processing assembly including first, second and third fixed spaced apart pairs of nip rollers moving the web respectively at a first, second and third speeds, the first and third speeds being constant and similar, the second speed being variable with a mean speed similar to the first and third speeds, a first idler roller engaging the web between the first and second pair of rollers and a second idler roller engaging the web between the second and third pair of rollers, each idler roller maintaining the web in constant tension by moving along a restrained path perpendicular to its axis to compensate for a difference between the variable second speed and the respective one of the constant first and third speeds. A method for processing a web and system for conveying a web are also disclosed.

Owner:DURST PHOTOTECHN

Device for accumulating flat material in flexible strip form

InactiveUS9120637B2Solve the greater riskReduce riskFunction indicatorsRecord information storageBand shapeEngineering

Owner:SLEEVER INT

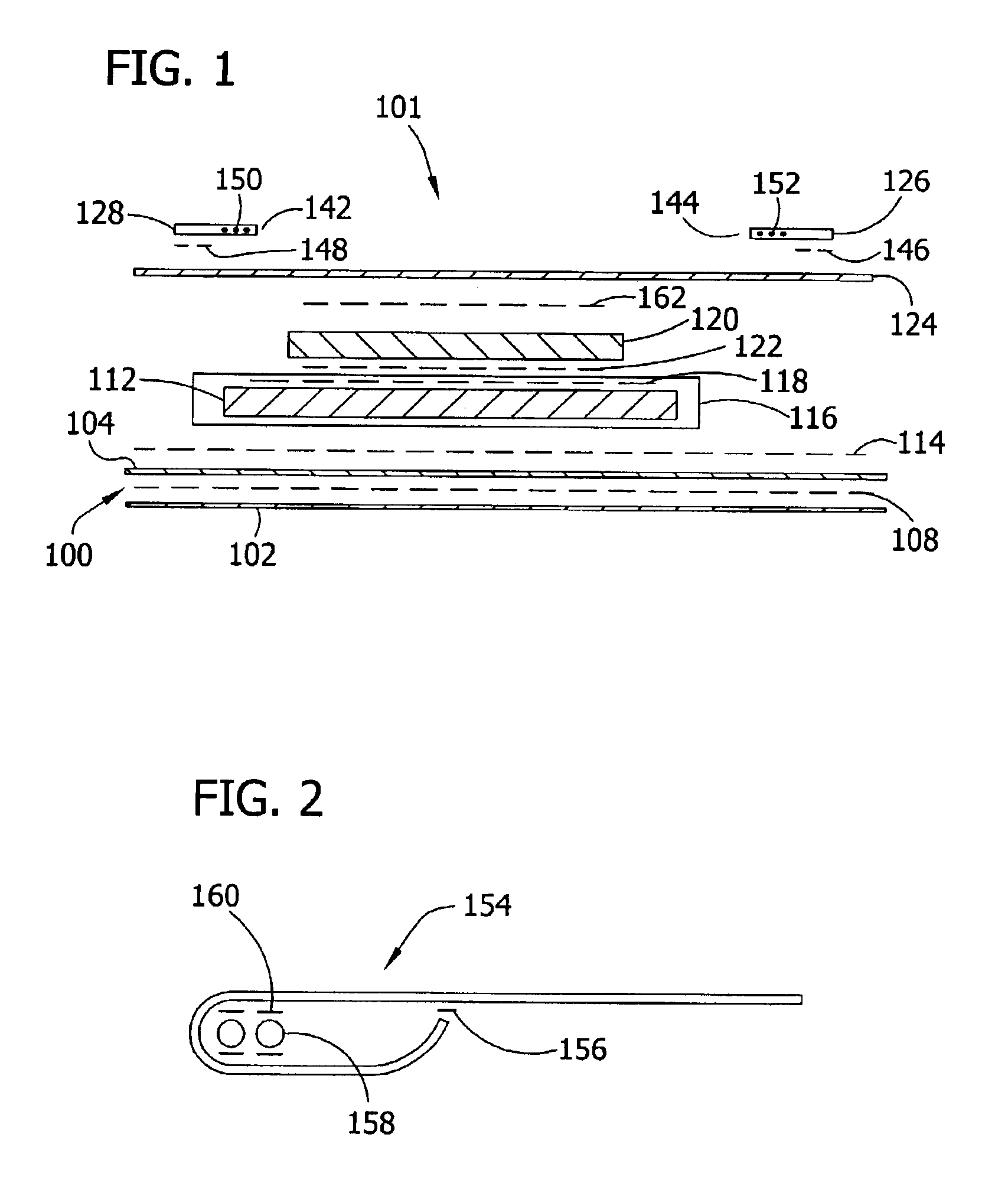

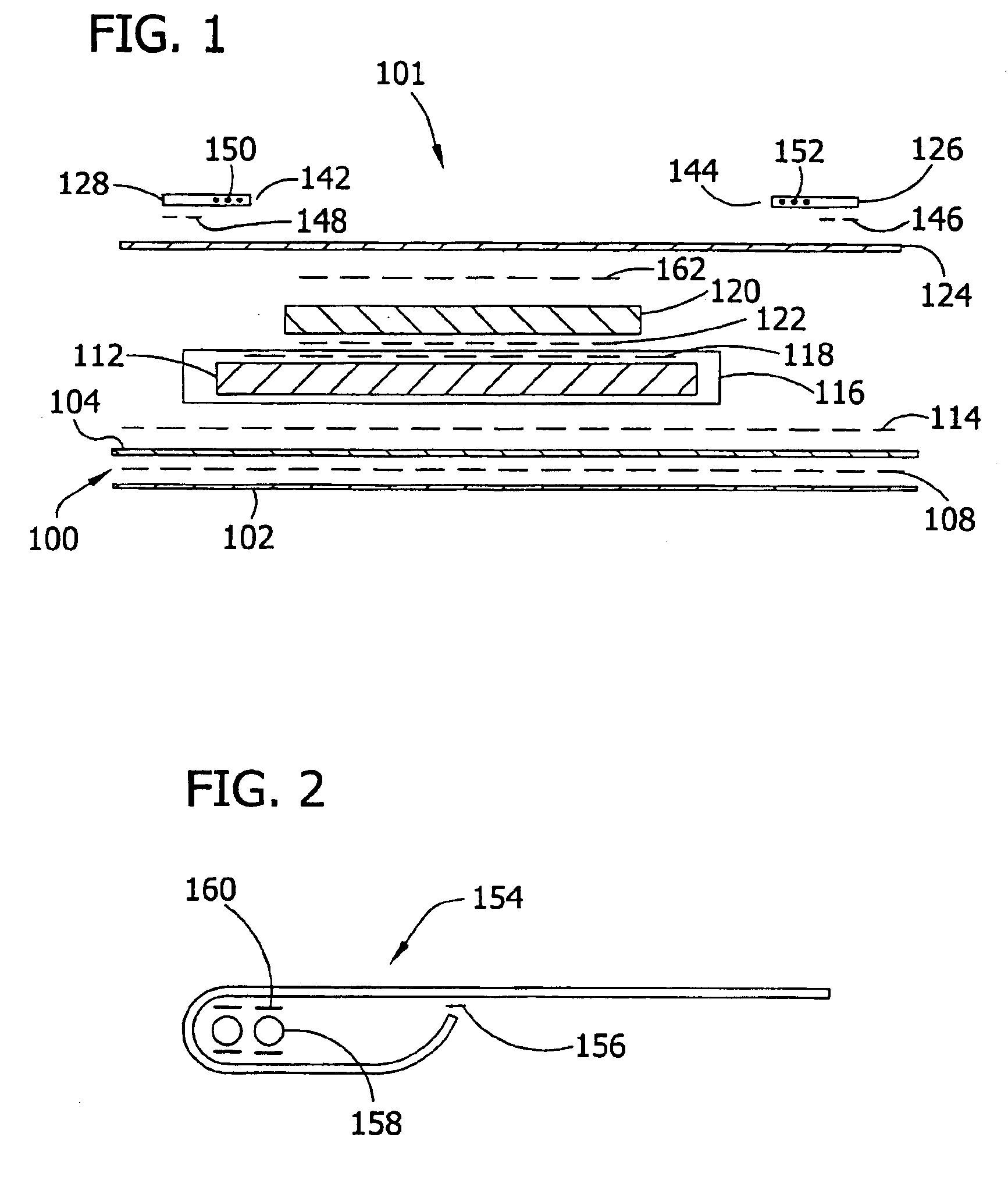

System and method for controlling the width of web material

ActiveUS7014083B2Increasing web tensionDecrease in web tensionAutomatic control devicesPrecision positioning equipmentControl circuitMaterial supply

A system and method for controlling the width of a web material supplied to a machine by adjusting the tension of the web material. An operator defines a target web width via an input device. The input device generates a reference signal representative of the target web width. A sensing device senses the width of the web material supplied to the machine and generate feedback signal representative of the sensed width. A control circuit compares the feedback and reference signals and generates a tensioning signal as a function of the comparison. A tensioning device is responsive to tensioning signal for adjusting web tension.

Owner:KIMBERLY-CLARK WORLDWIDE INC

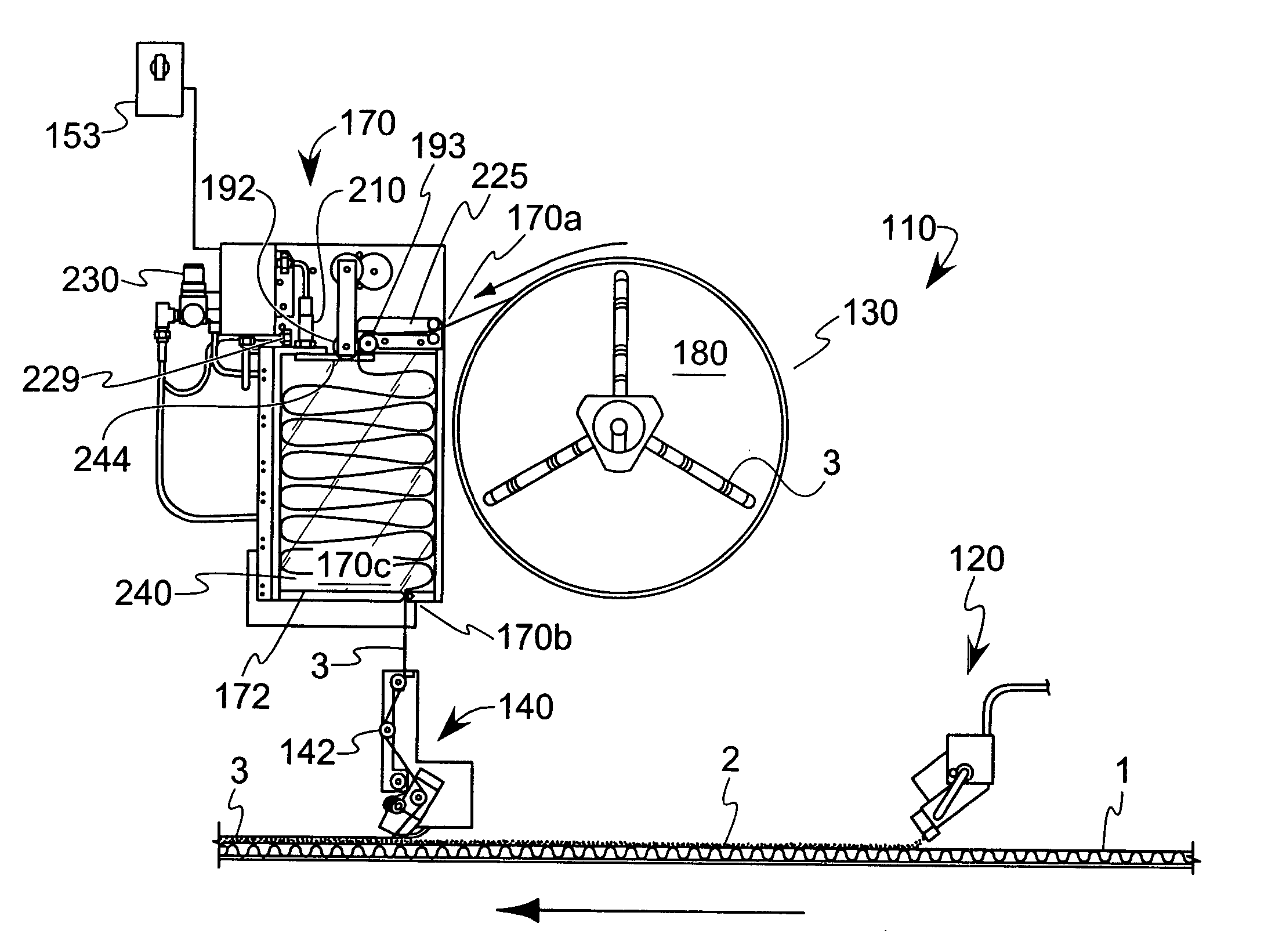

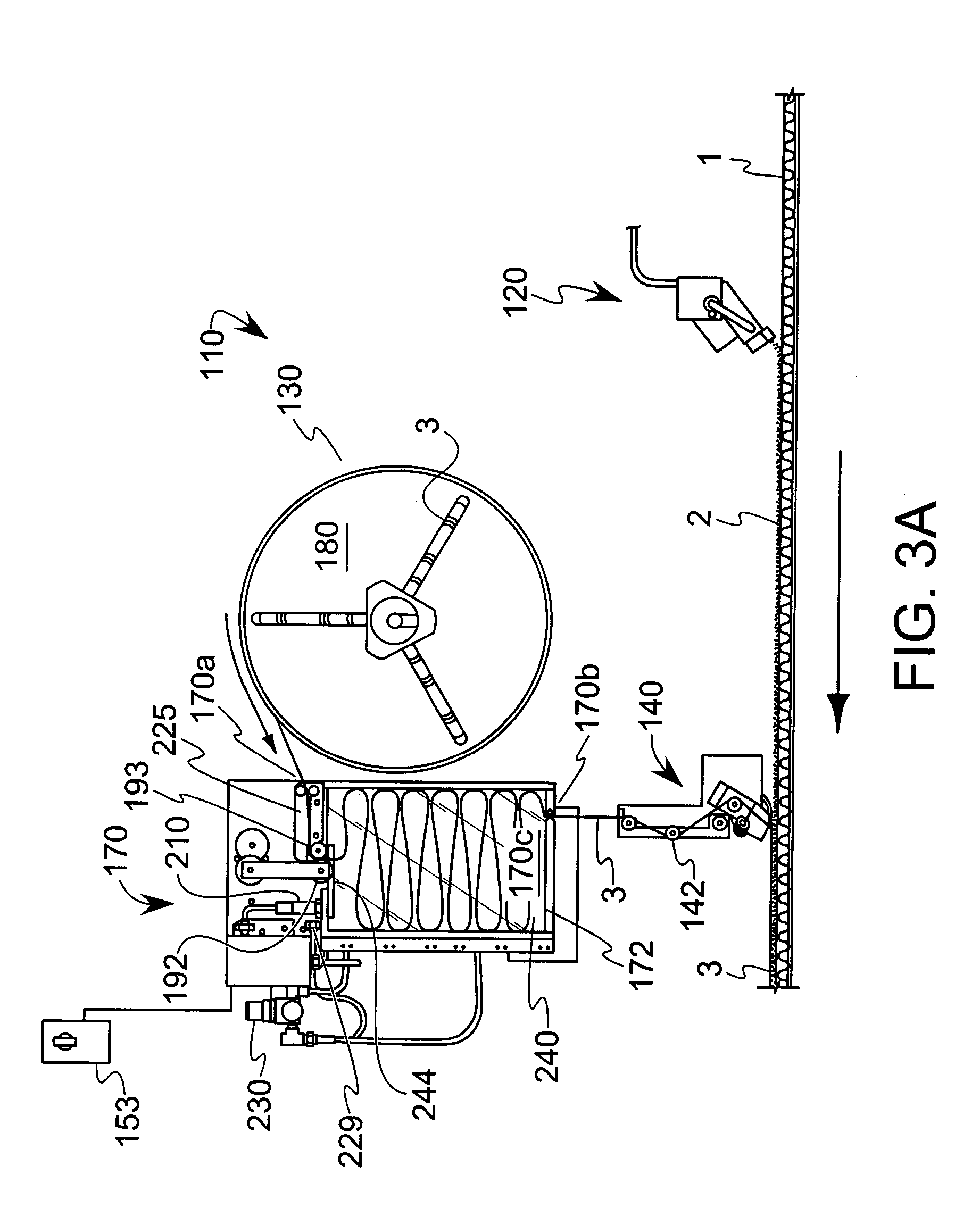

Release liner staging unit and system incorporating same

ActiveUS7441578B2Avoid distortionFacilitate cleaning and threadingLamination ancillary operationsControlling laminationSaturated LevelTime delays

Owner:VALCO CINCINNATI

Release liner staging unit and system incorporating same

ActiveUS20050252597A1Avoid distortionFacilitate cleaning and threadingLamination ancillary operationsControlling laminationSaturated LevelTime delays

A release liner staging unit for depositing a release liner onto an adhesive layer. The unit includes an accumulator that creates a buffer between an amount of release liner supplied and an amount needed for covering a layer of adhesive. The tendency of release liner placed within the accumulator to settle allows additional release liner to be introduced, thereby producing a slightly saturated level of release liner in the accumulator. Time delays can be accounted for to reduce the number of times a drive mechanism needs to operate, thereby reducing wear on such componentry. The unit may also form part of a larger release liner application device and adhesive application system.

Owner:VALCO CINCINNATI

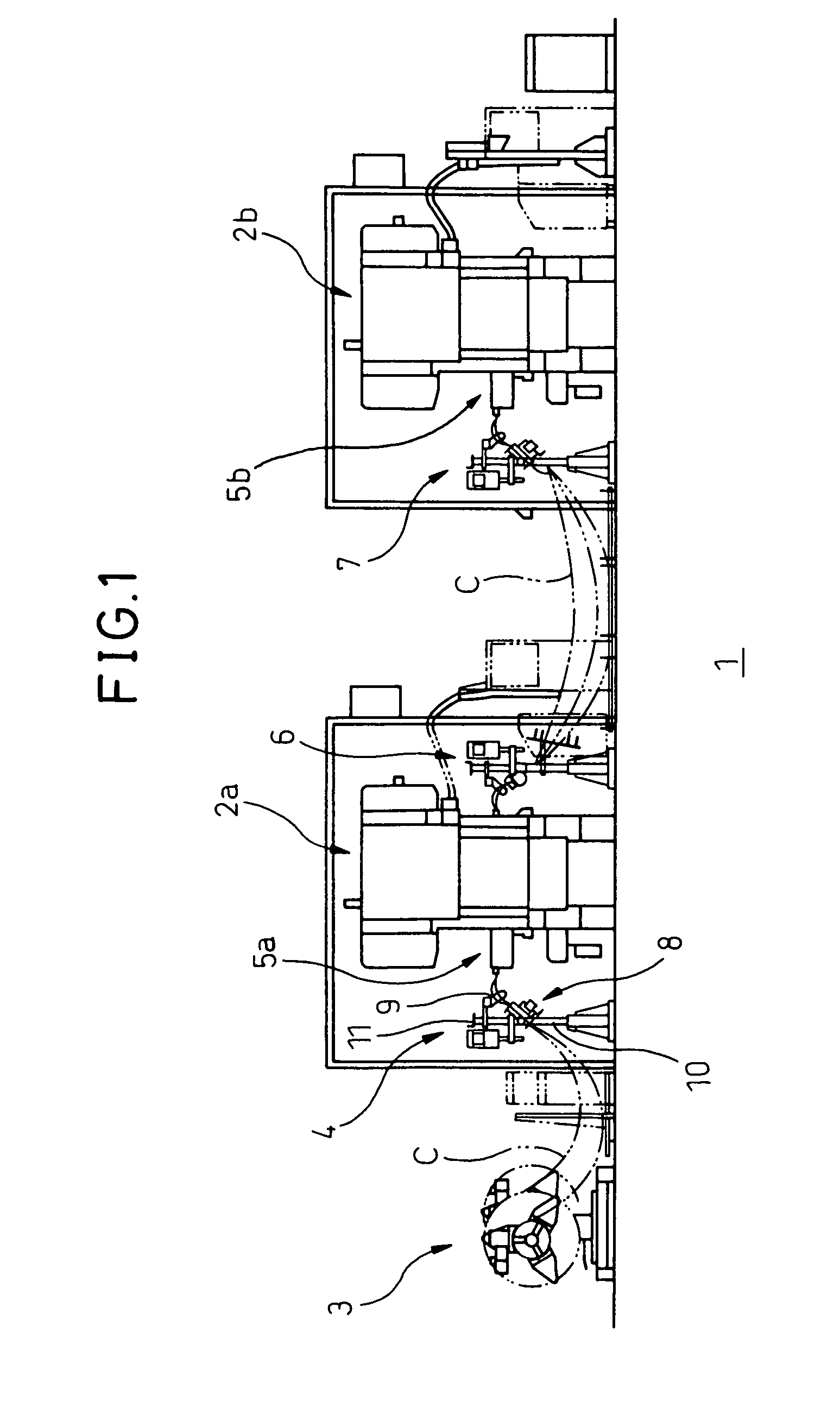

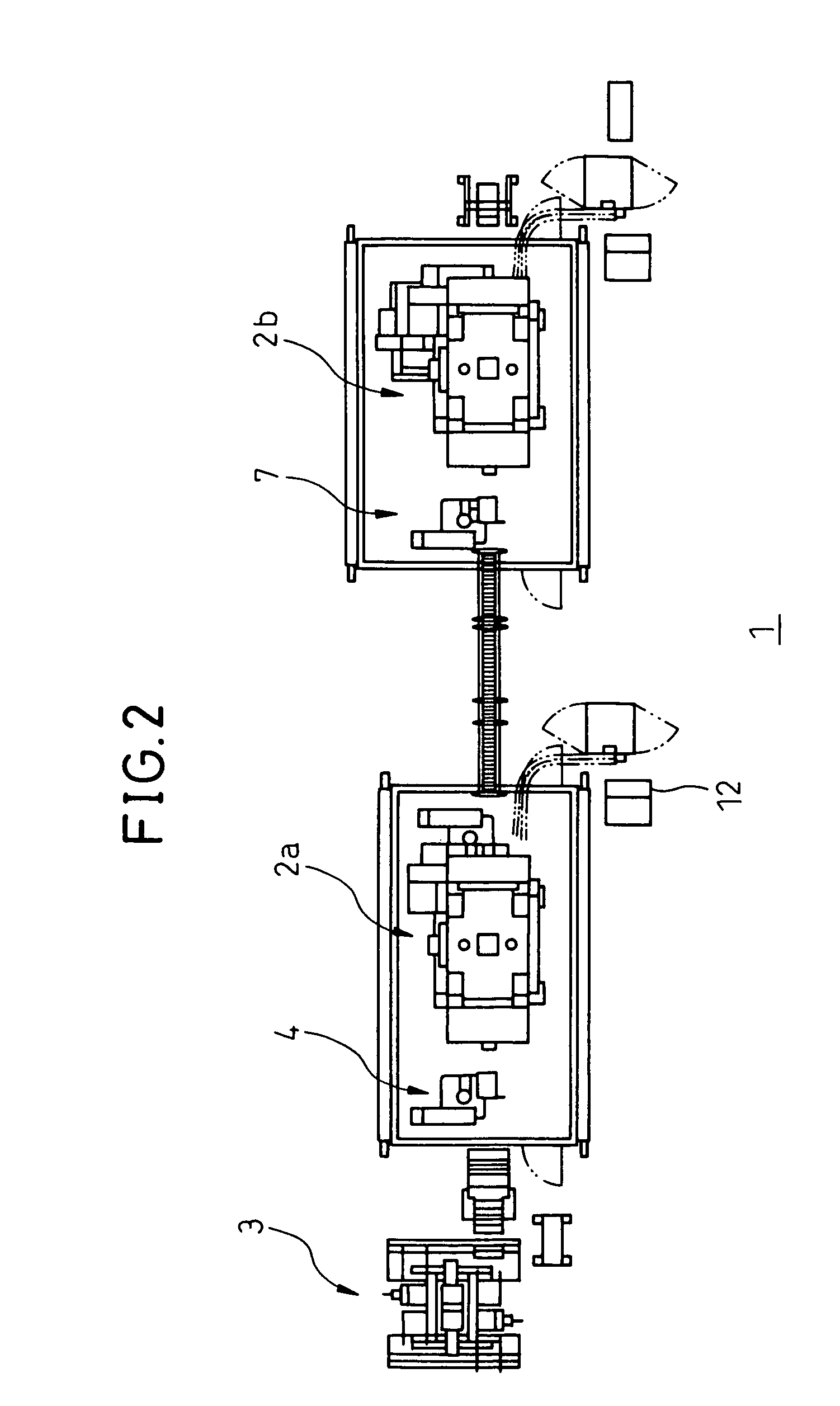

Plastic working method and plastic working system

ActiveUS8047033B2Reduce impactImprove productivityMetal-working feeding devicesForging hammersEngineeringContinuous feeding

Owner:DENSO CORP +1

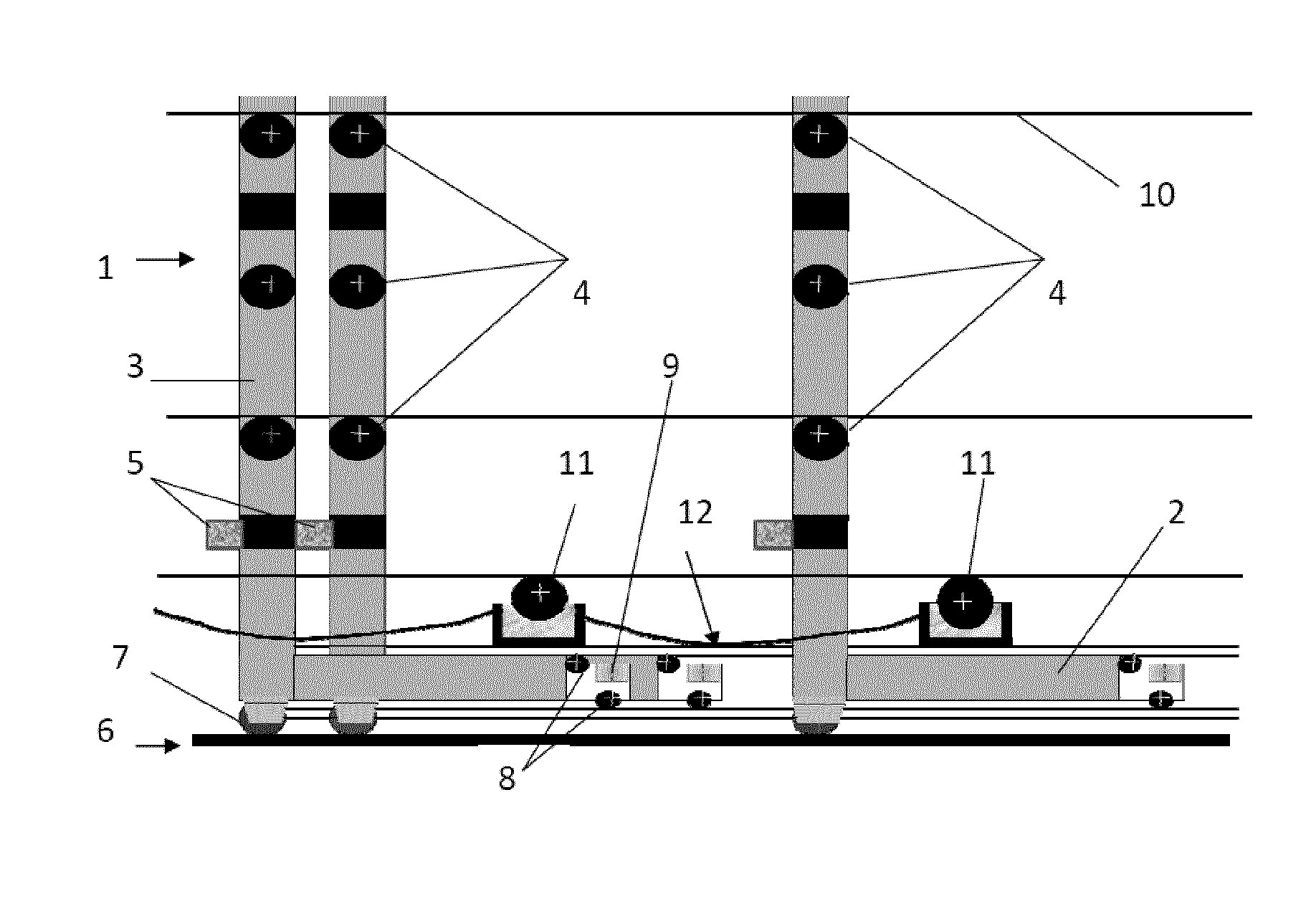

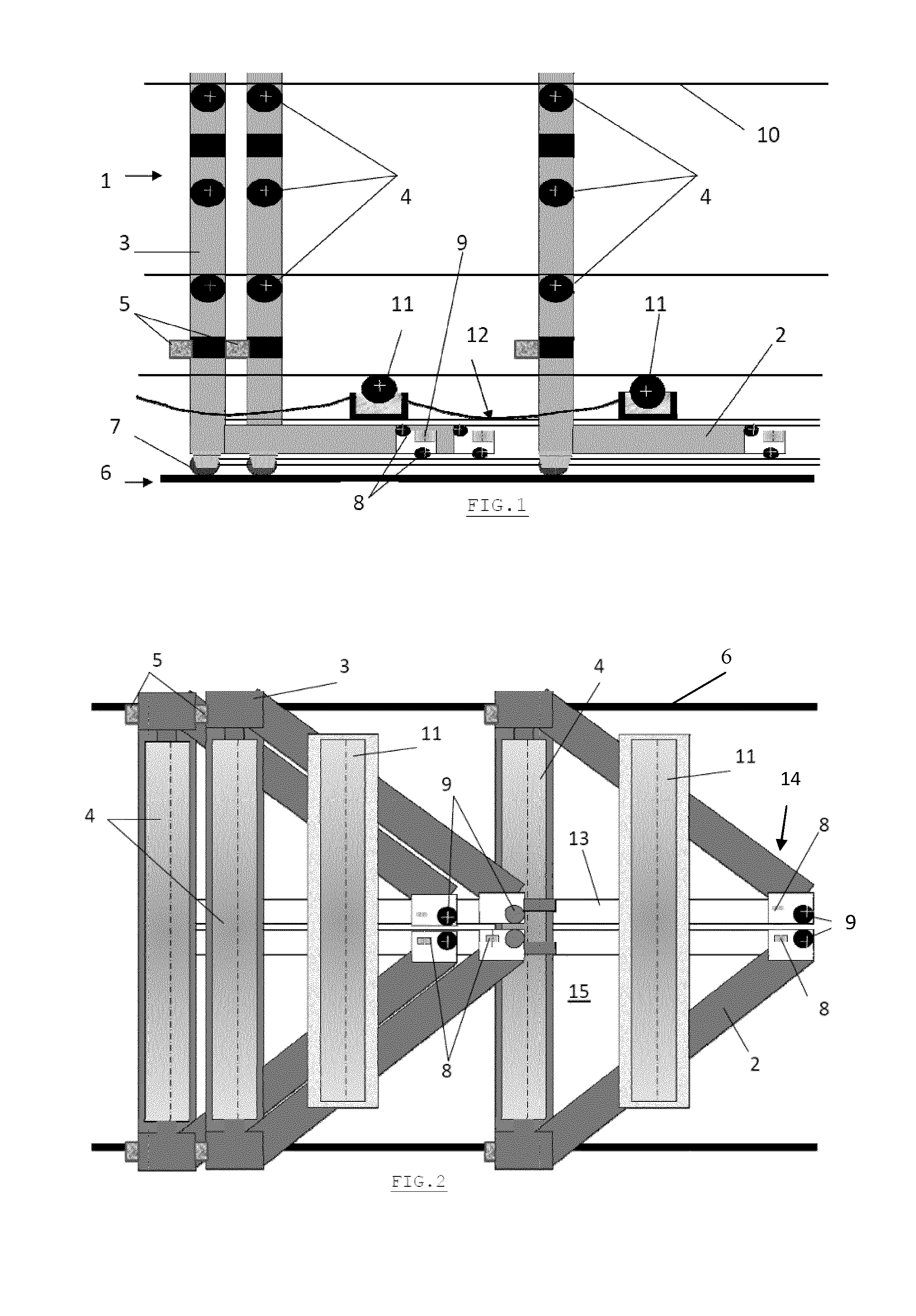

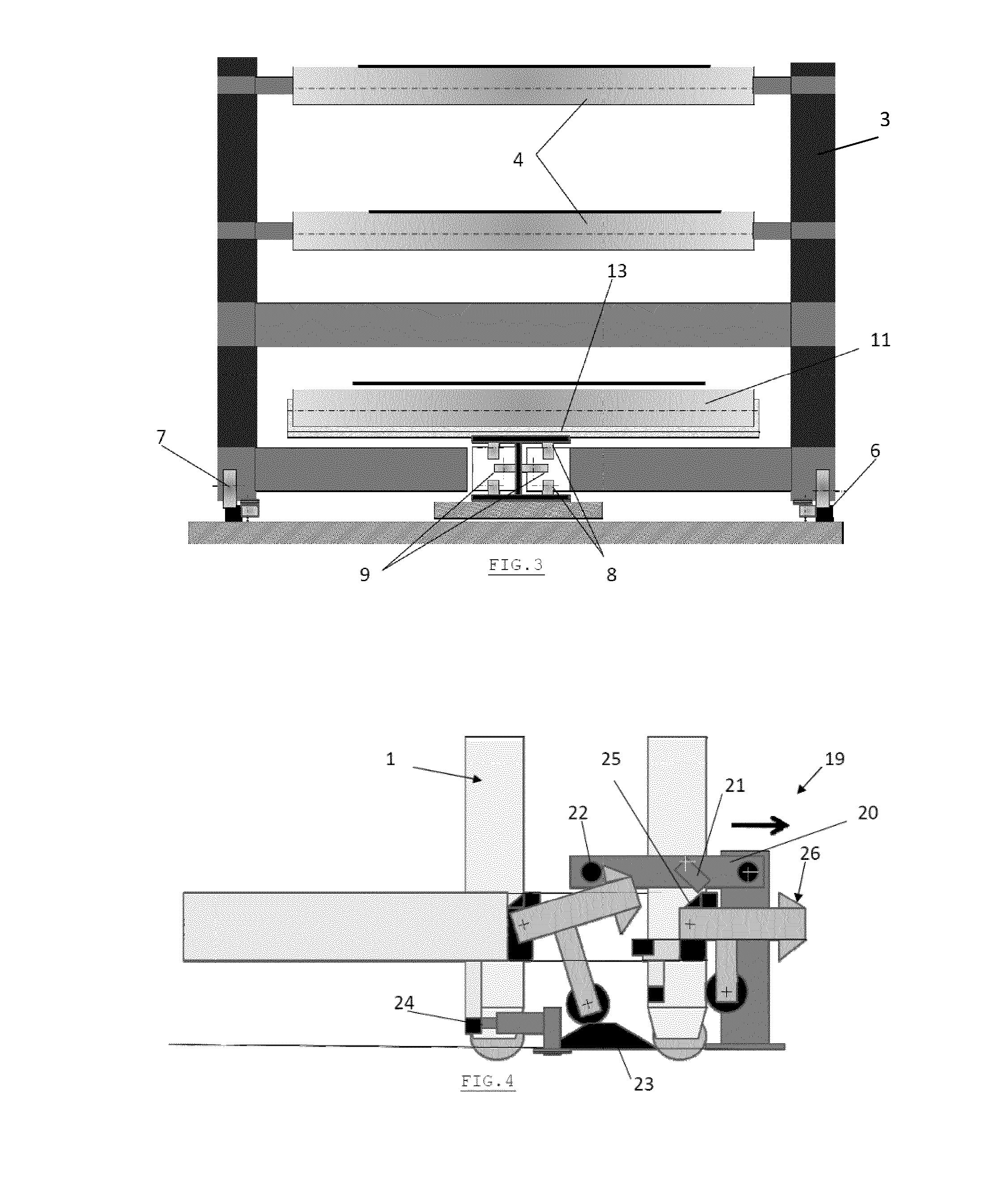

Horizontal Strip Accumulator with Telescoping of Strip Support Roll Carriages and Passive Location Systems Thereof

InactiveUS20130306698A1Record information storageMaterial accumulating devicesProduction lineCarriage

The present invention relates to a horizontal strip accumulator in a continuous processing strip line, comprising a looping carriage riding on a pair of external rails (6) and a plurality of adjacent strip supporting roll carriages (1) riding on the same external rails (6) to support the strip (10) between the looping carriage and a strip feeding location, wherein the strip supporting carriages (1) have a horizontal triangular lower part (2) and a vertical framework (3), the triangular lower part (2) having an open transverse base (15) opposite to an apex (14), to allow the telescoping of the strip supporting carriages (1) in the internal triangular space between the open base (15) and the two other triangular sides rejoining at the opposite apex (14).

Owner:COCKERILL MAINTENANCE & INGIE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com