Sealing arrangement for sealing a gap between two components which can rotate in relation to each other about a common rotational axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

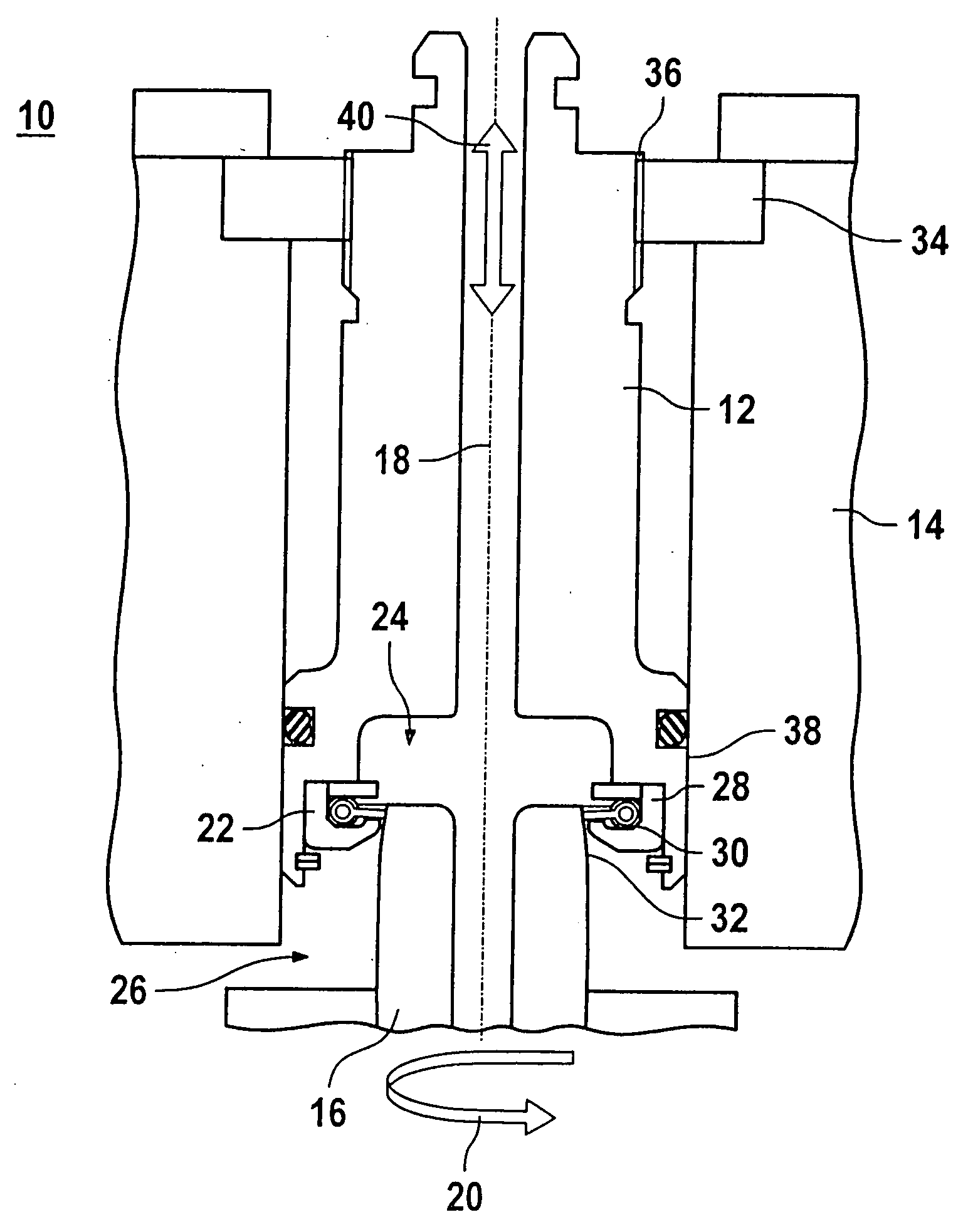

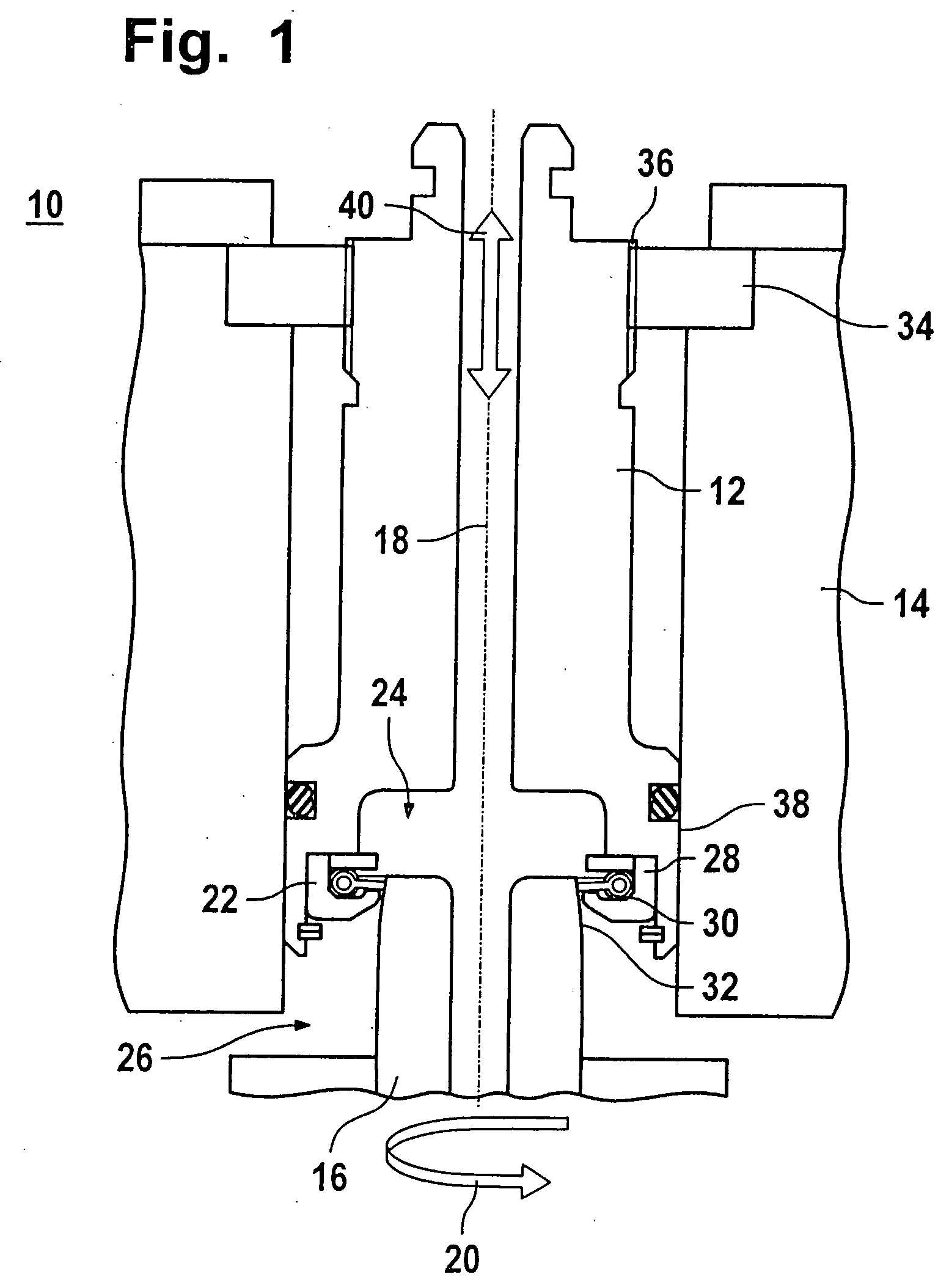

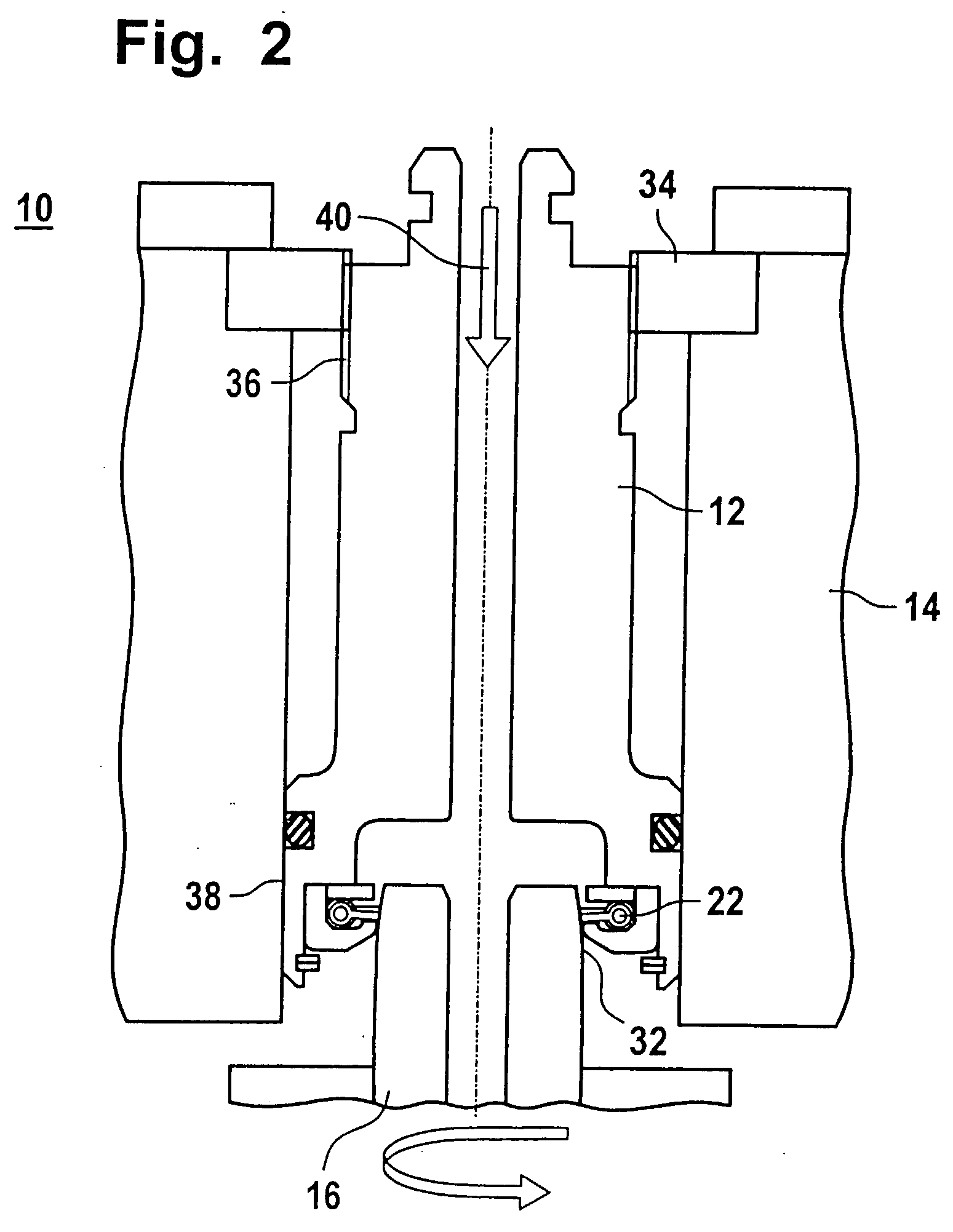

[0018] A sealing arrangement, which is denoted overall by reference numeral 10 in FIG. 1, for sealing a gap between two components which can move rotationally with respect to one another in a turbomachine (not shown in more detail), such as for example a steam turbine or a gas turbine, comprises a first component 12, which is surrounded by a casing 14, and a second component 16. The two components 12, 16 have a common axis of rotation 18.

[0019] The second component 16 is mounted such that it can move in rotation with respect to the first component 12 about the axis of rotation 18. The rotational mobility of the second component 16 is indicated by arrow 20.

[0020] A brush seal 22 has been introduced into the annular gap between the components 12, 16, in order, for example, to seal off a region 24 which is at a high pressure with respect to a region 26 which is at a lower pressure.

[0021] The brush seal 22 in this case comprises a brush casing 28 and a plurality of bristles 30 fitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com