Large rotary kiln system and working method thereof

A rotary kiln and large-scale technology, applied in the field of rotary kiln, can solve the problems of low output of a single kiln, difficulty in forming economies of scale, and low proportion of production capacity, and achieve the effect of improving lime quality, significant comprehensive benefits and advantages, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

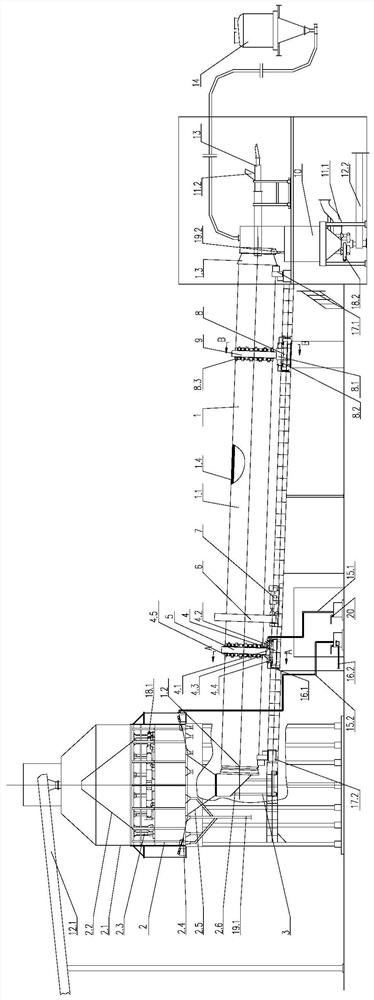

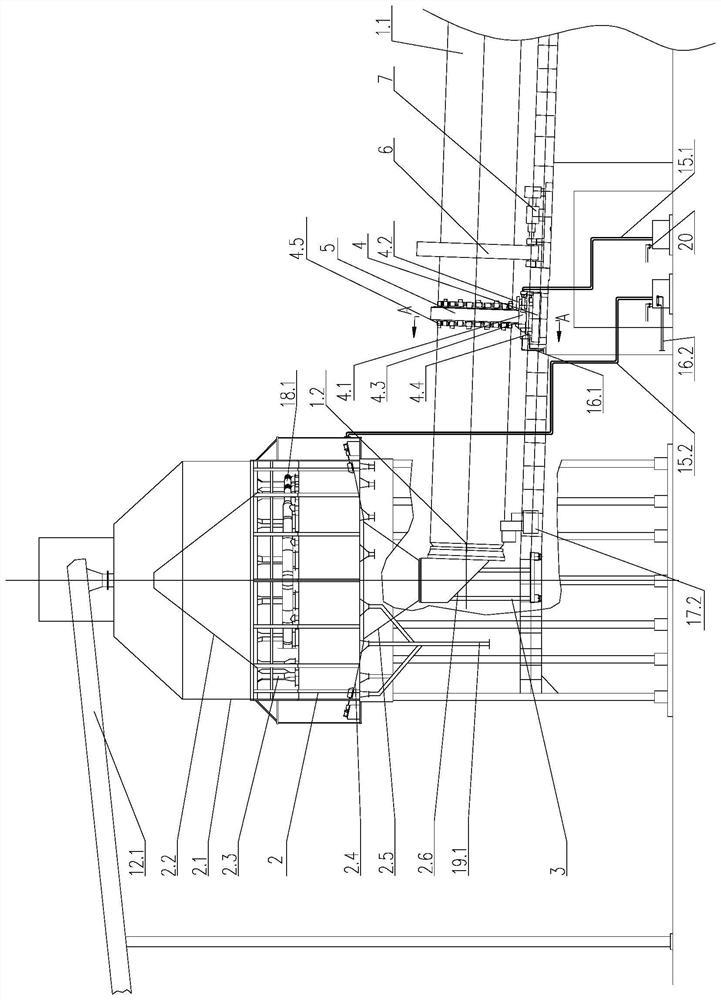

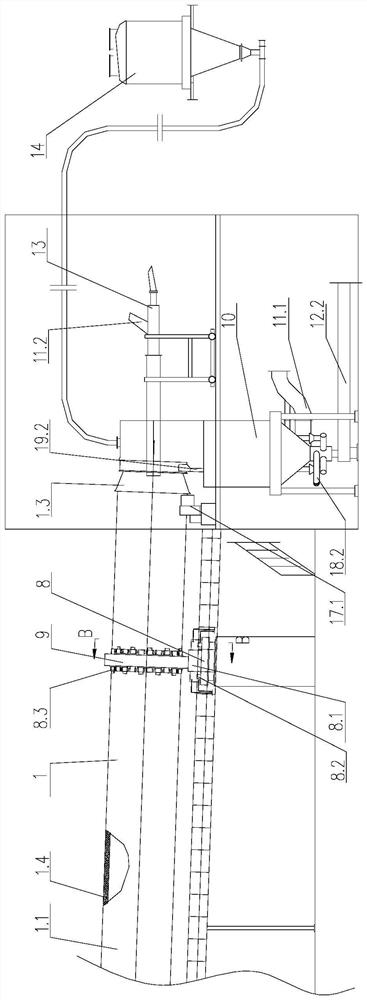

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0034] like figure 1 , Figure 1a , Figure 1b As shown, a large-scale rotary kiln system according to the present invention includes a rotary kiln 1, a preheater system 2, a feeder car 3 and a material cooling system 10; the rotary kiln 1 is provided with two-speed supports, and the kiln body of the rotary kiln 1.1 The inclined setting, the low end is the kiln head end, and the high end is the kiln tail end; the preheater system 2 is set at the kiln tail end, including the material distribution bin 2.1, the preheater body and the pushing system; the bottom of the preheater system 2 The material cooling system 10 is arranged at the head end of the kiln, the top of the material cooling system 10 is connected with the outlet of the rotary kiln, the material outlet is arranged at the bottom, and the middle of the material cooling system 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com