Pet chew device

a chewing device and chewing technology, applied in the field of chewing devices for pets, can solve the problems of chew products that are dangerous for pets, all chew products are subject to breakdown, and pets can be easily injured,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

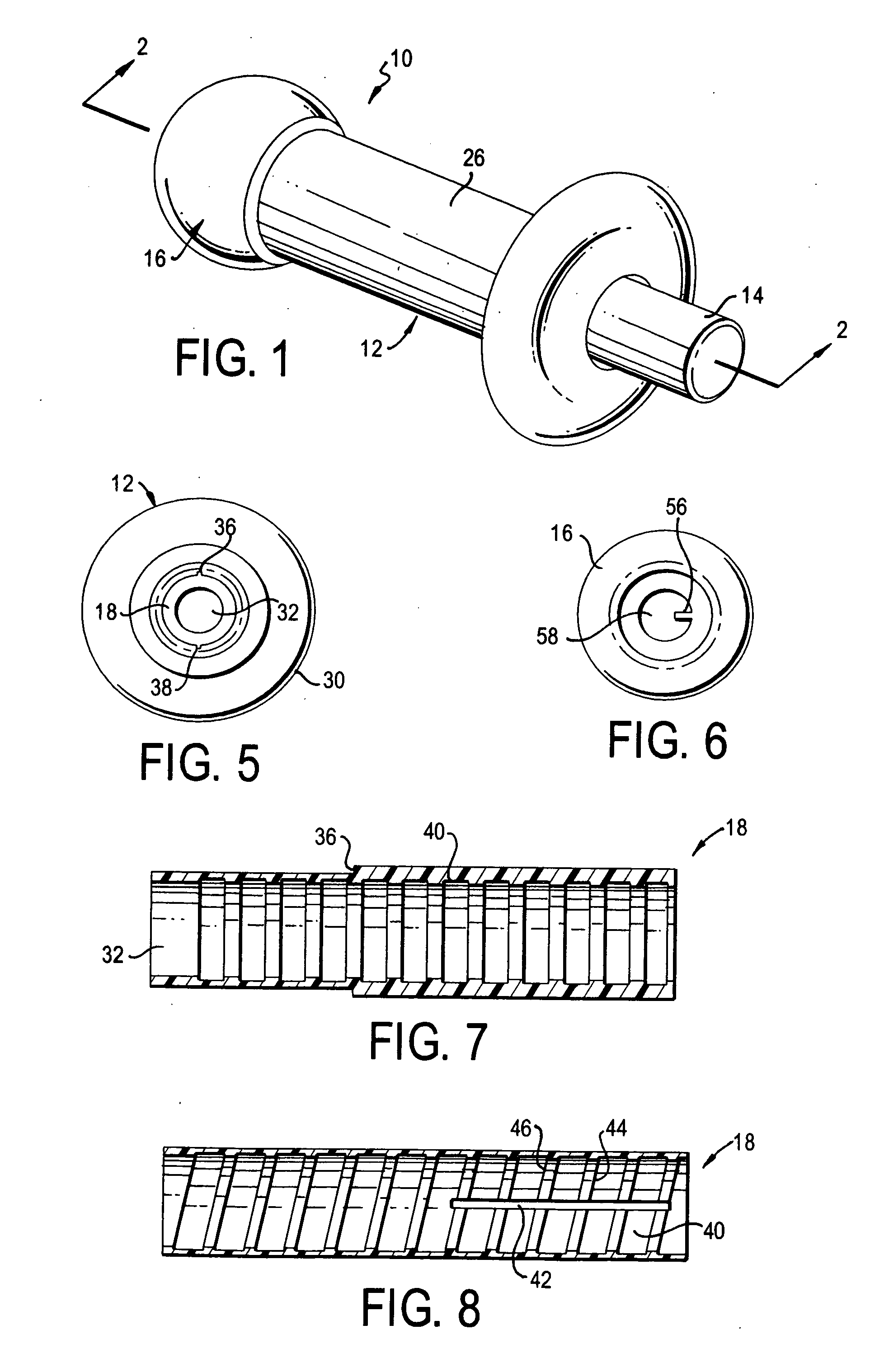

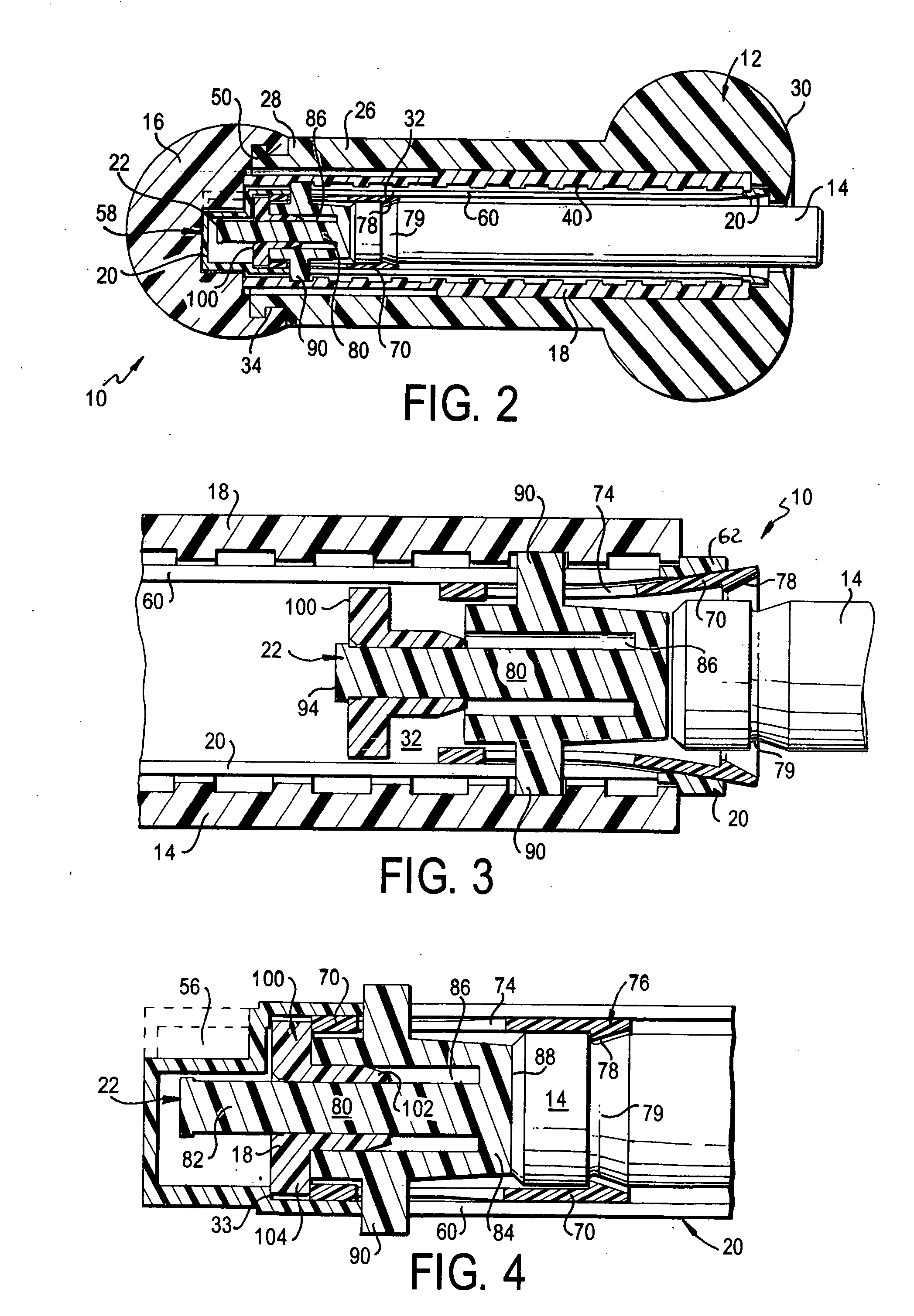

[0047] As seen in FIG. 19, pusher member 80′ of the second embodiment includes a cylindrical body 300 with opposite first and second ends 302 and 304, the first end 302 being open and the second end 304 forming a wall 306 that abuts the food product 14. Slots 308 extend between the first and second ends 302 and 304 of the cylindrical body 300 providing resiliency to the pusher member 80′ and for engaging the ridges 200 of the collet member 70′. Radial lugs 310 extend from the cylindrical body 300 for engaging the threads 40 of the inner bore 32. Lugs 310 can have sloped outer surfaces 312, as seen in FIG. 19, to facilitate loading of the food product 14 in the device 10 by allowing the lugs 310 to skip over the threads 40 more easily. The wide section 202 of the ridge 200 allows the pusher lugs 310 to stay engaged with the threads 40 while the food product 14 is ejected. Once the food product is ejected, the narrow section 204 of the ridge 200 allows the pusher grooves 308 to compre...

first embodiment

[0048] As seen in FIGS. 20 and 21, the pusher assembly 22′ is assembled by inserting the pusher member 80′ into the cylindrical body 72′ of the collet member 70′. Lugs 310 are received in corresponding slots 74′ of the collet member 70′ and ridges 200 are received in slots 308 of the pusher member 80′. Ridges 200 eliminate the need for a separate plug, such as plug 100 of the The pusher assembly 22′ is received in the rotating sleeve 20 with the lugs 310 extending through the longitudinal slots 60 of the rotating sleeve 20.

[0049] In operation, the food product 14 is loaded into the device 10, as seen in FIG. 3. The design of the pusher assembly 22 facilitates rapid loading of the food product 14. Upon initial insertion of the food product 14 into the inner bore 32 of the main body 12, the resilient fingers 76 of the collet member 70 lock onto the groove 79 of the food product 14 via pads 78 with the food product 14 abutting or nearly abutting the end wall 88 of the pusher member 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com