Lithographic apparatus and device manufacturing method

a technology of lithographic apparatus and manufacturing method, which is applied in the direction of instruments, radiation therapy, therapy, etc., can solve the problems of difficult thermal control, inefficiency of beam splitters, and inability to use different polarizations to create different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

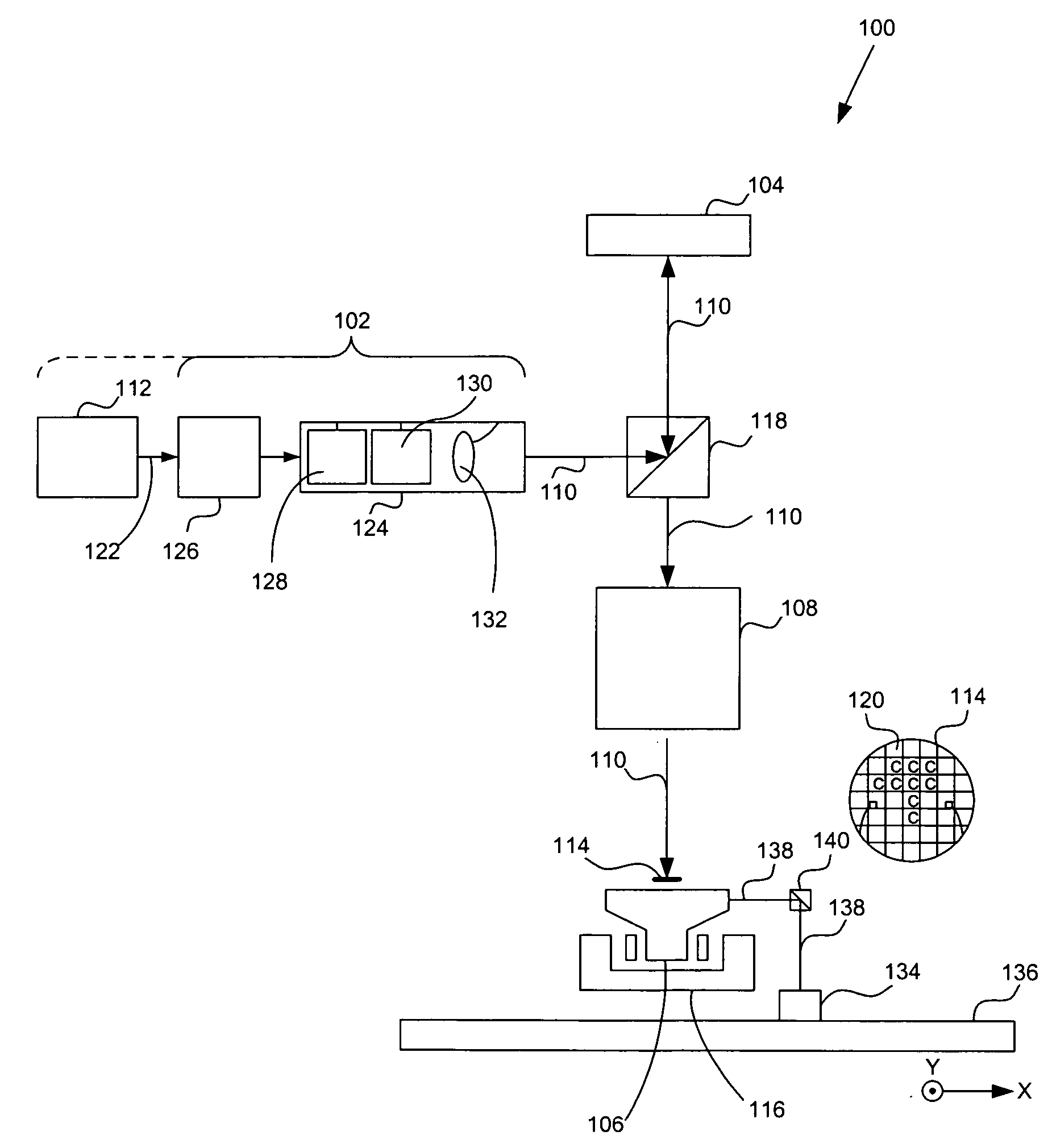

Image

Examples

Embodiment Construction

Overview and Terminology

[0028] Throughout the remainder of this specification the terms “alignment mark” and “alignment marks” will be used to denote one or more individual, indiscrete alignment marks respectively, unless otherwise stated. By “individual” it is meant that each alignment mark is separate and distinct from others of its kind (i.e., from the other alignment marks). By “indiscrete” it is meant that each alignment mark is not divided into parts (e.g., each alignment mark is a single, undivided entity). A variety of such marks can be used in embodiments of the invention, and it will be appreciated that the dots, dashes, and lines referred to in this specification are merely specific examples. Other forms can be used.

[0029] Although specific reference can be made in this text to the use of lithographic apparatus in the manufacture of integrated circuits (ICs), it should be understood that the lithographic apparatus described herein can have other applications, such as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com