Perforated capsule filter

a filter and capsule technology, applied in the field of filters, can solve the problems of poor filtration of smokers, less than preferred, and carbon in smoking articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

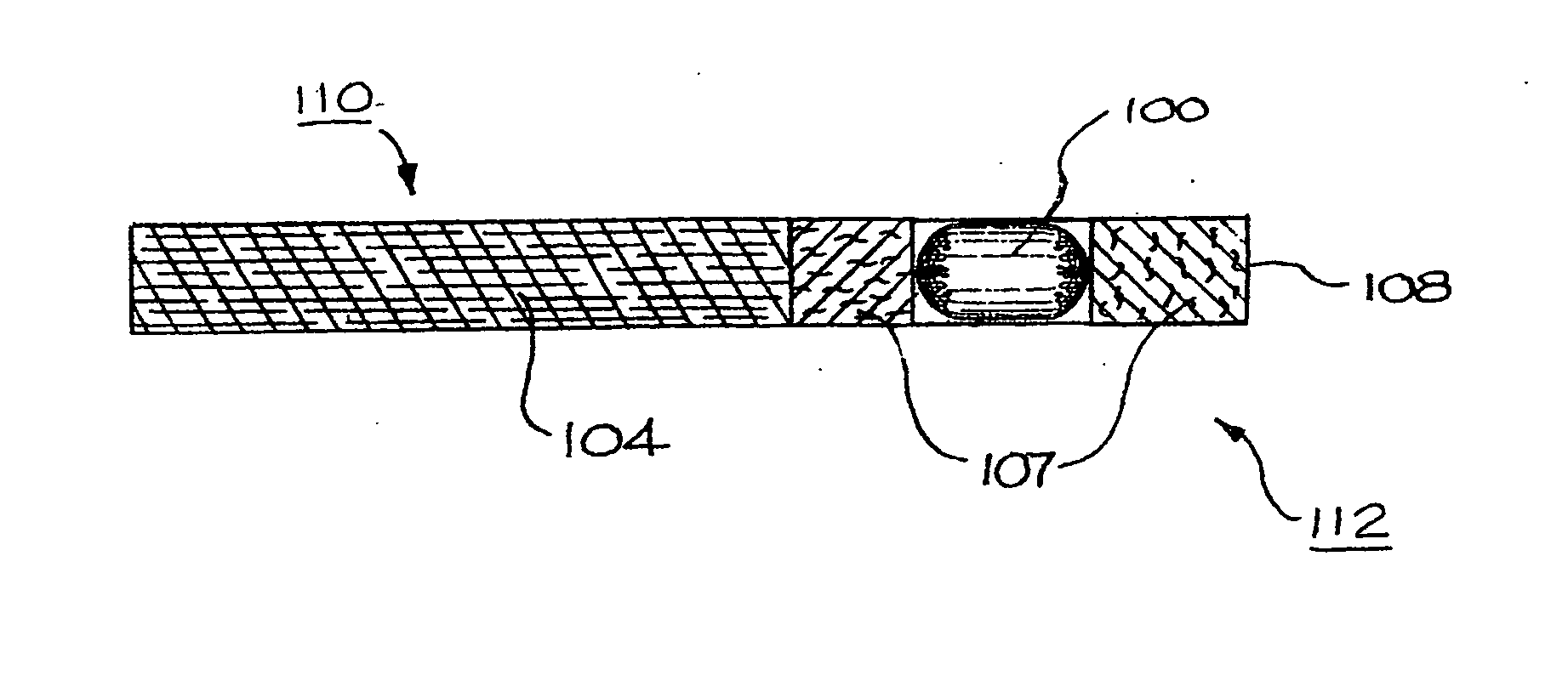

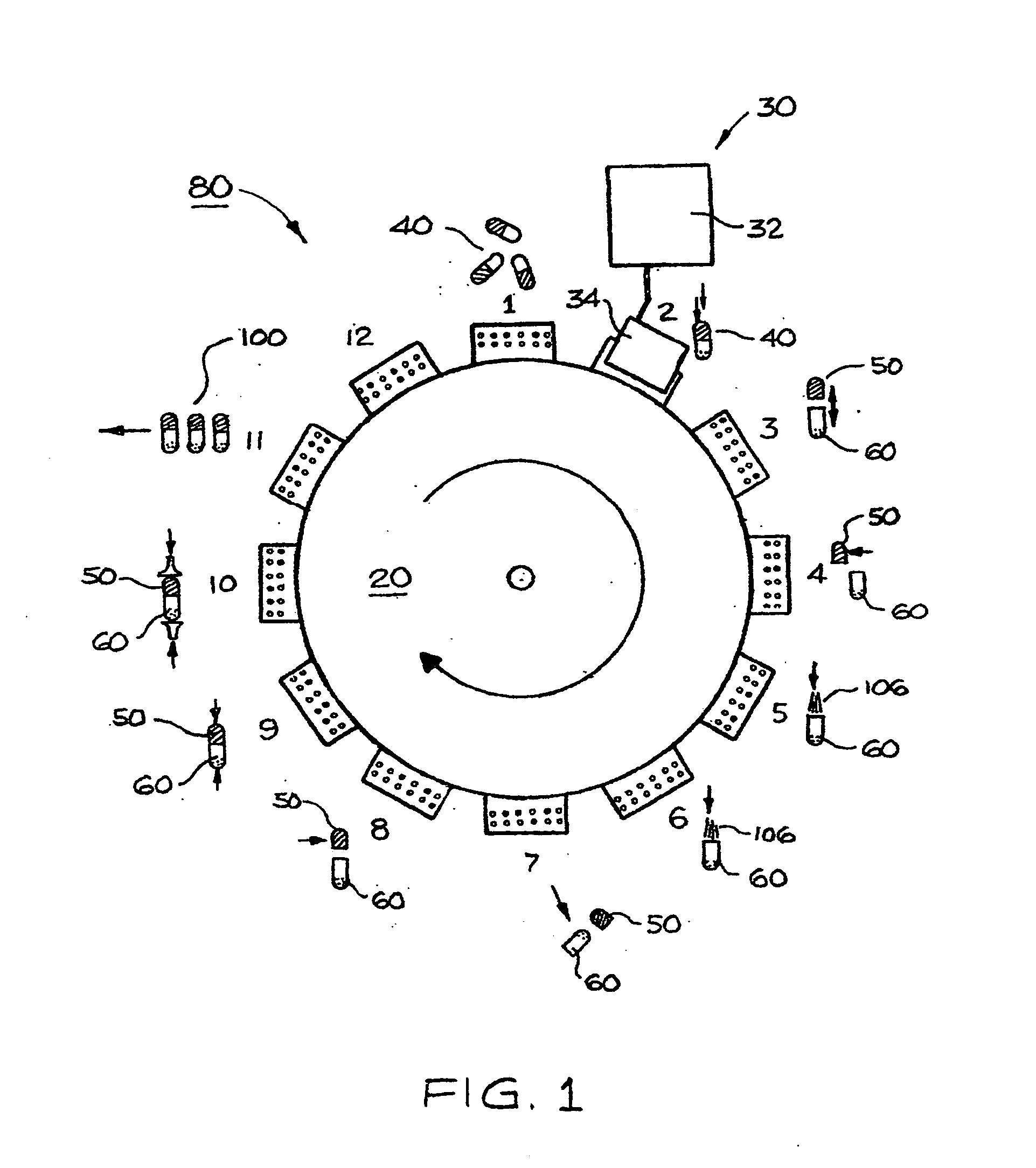

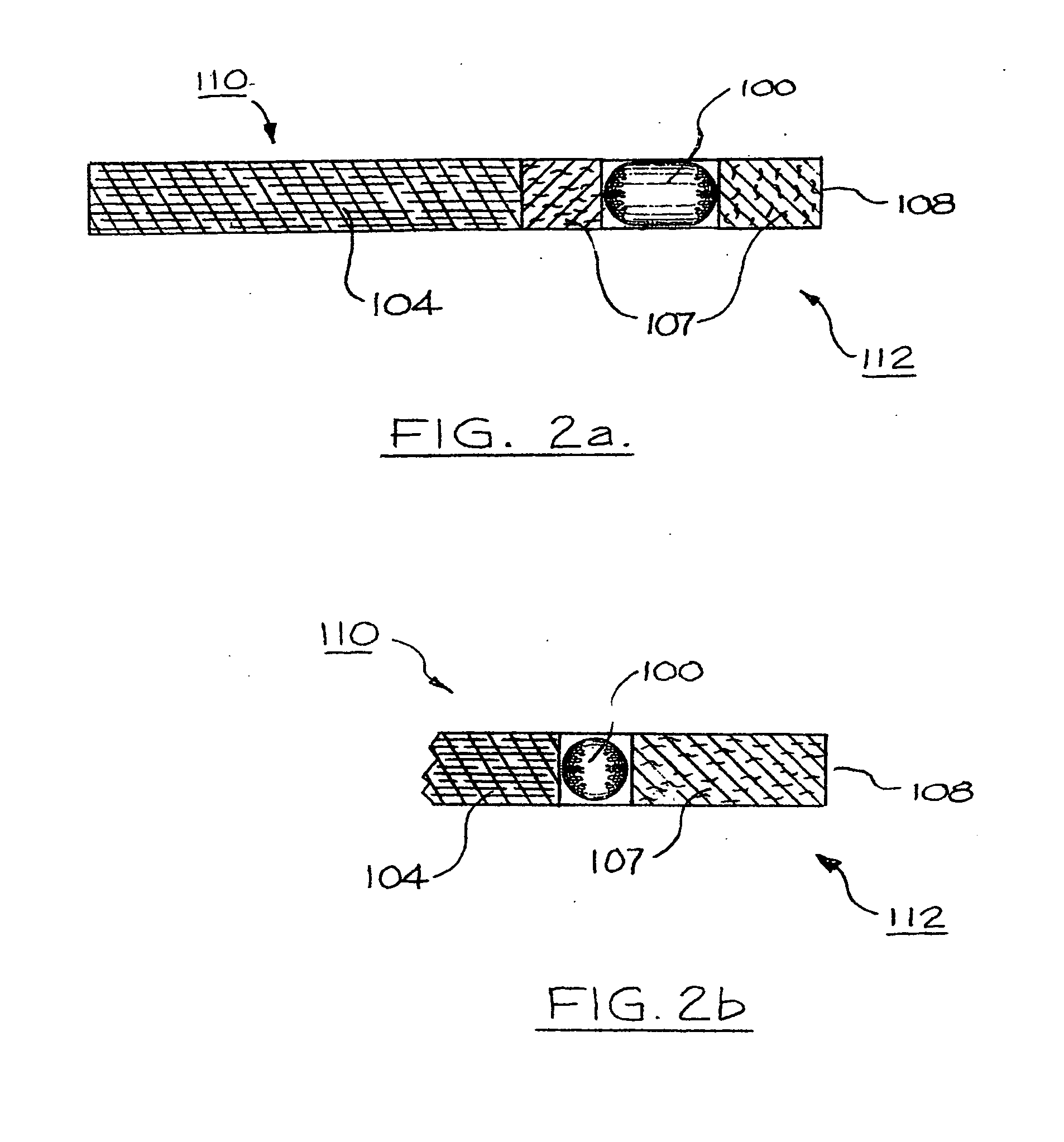

[0025] As illustrated in FIG. 1, one preferred method for forming the capsules of the present invention involves the modification of any standard hard capsule filling and closing machine 80, such as the Bosch GKF 400, GKF 700, GKF 1200, GKF 1500, GKF 2000, GKF 2500, GKF 3000, distributed by Bosch Group of TL Systems Corporation of Minneapolis, Minn. While any filling and closing machine may be used, as shown in FIG. 1, the machine 80 may include a turntable 20 which rotates among a plurality of process stations 1-12. One or more discrete process steps may be performed at each station 1-12. In the embodiment shown in FIG. 1, empty non-perforated capsules 40 are delivered to the turntable 20 at station 1, and the capsules 40 are straightened and aligned for subsequent processing. Next, the capsules 40 are passed to station 2 for perforation of the ends of the capsules 40 by laser 30. Laser 30 may include a control unit 32 and a remote head 34. Laser light is directed from the remote h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com