Prefabricated swimmingpool

a prefabricated and swimming pool technology, applied in the field of prefabricated swimming pools, can solve the problems of slowing down the circulation of water in the area of the floor corners and floor edges, in particular, and insufficient success, and achieve the effect of limited available property area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

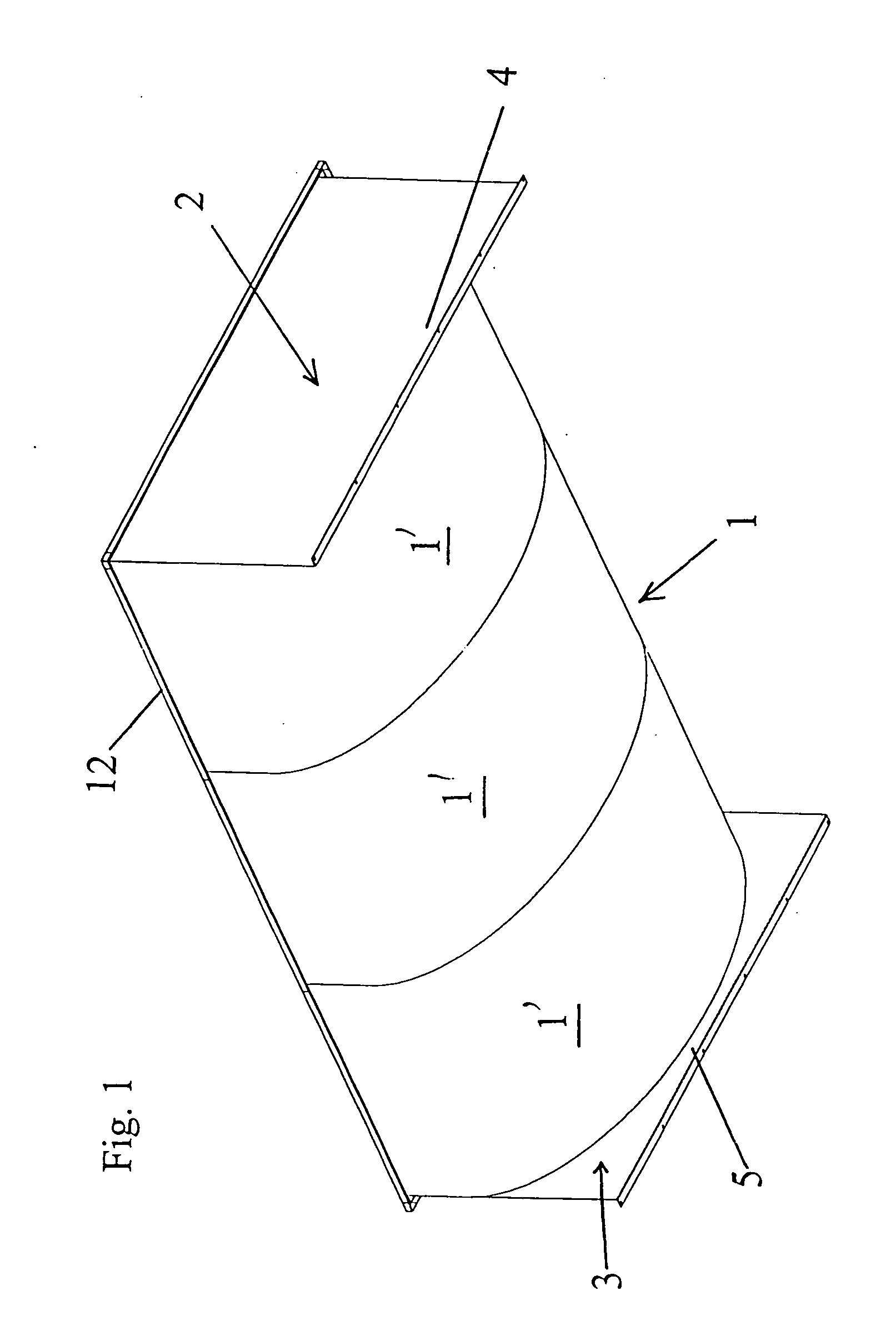

[0016] An optimum embodiment is a pool floor having a cross-section in the shape of a half ellipse and a continuous curvature along its lateral axis. Here both longitudinal edges are broken up with a wide area of sufficient swimming depth in the middle, i.e. the pool depth allows unimpaired breaststroke swimming without having to be afraid that the feet may make contact with the pool floor while swimming.

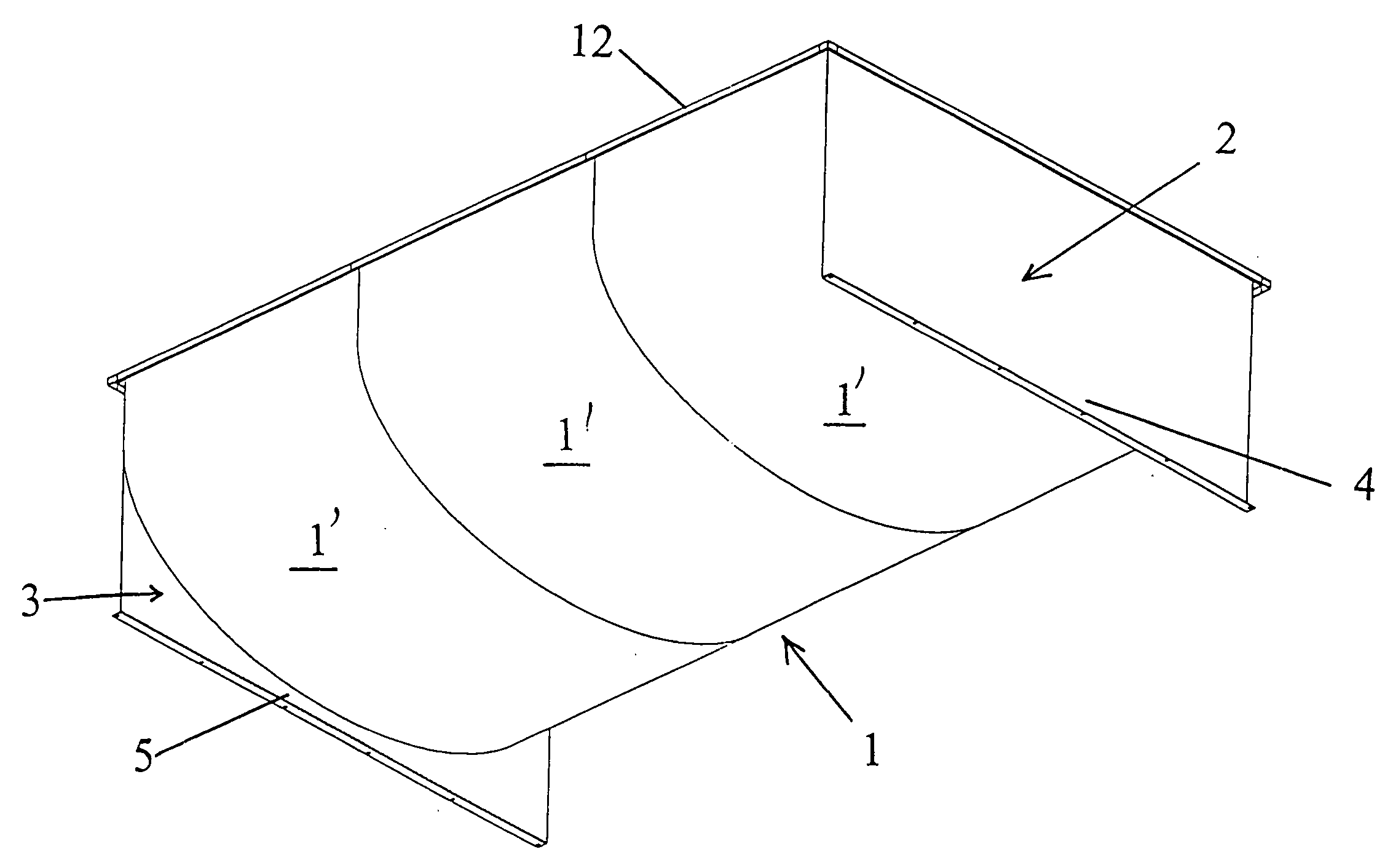

[0017] The embodiment according to FIG. 1 has a pool floor 1, continuously curved along the lateral axis, having a half ellipsoidal cross-section. Depending on the desired pool length, pool floor 1 is made of several segments. The two narrow ends are formed by vertical side walls 2 and 3 having molded-on support ribs 4 and 5 which support the pool against the ground.

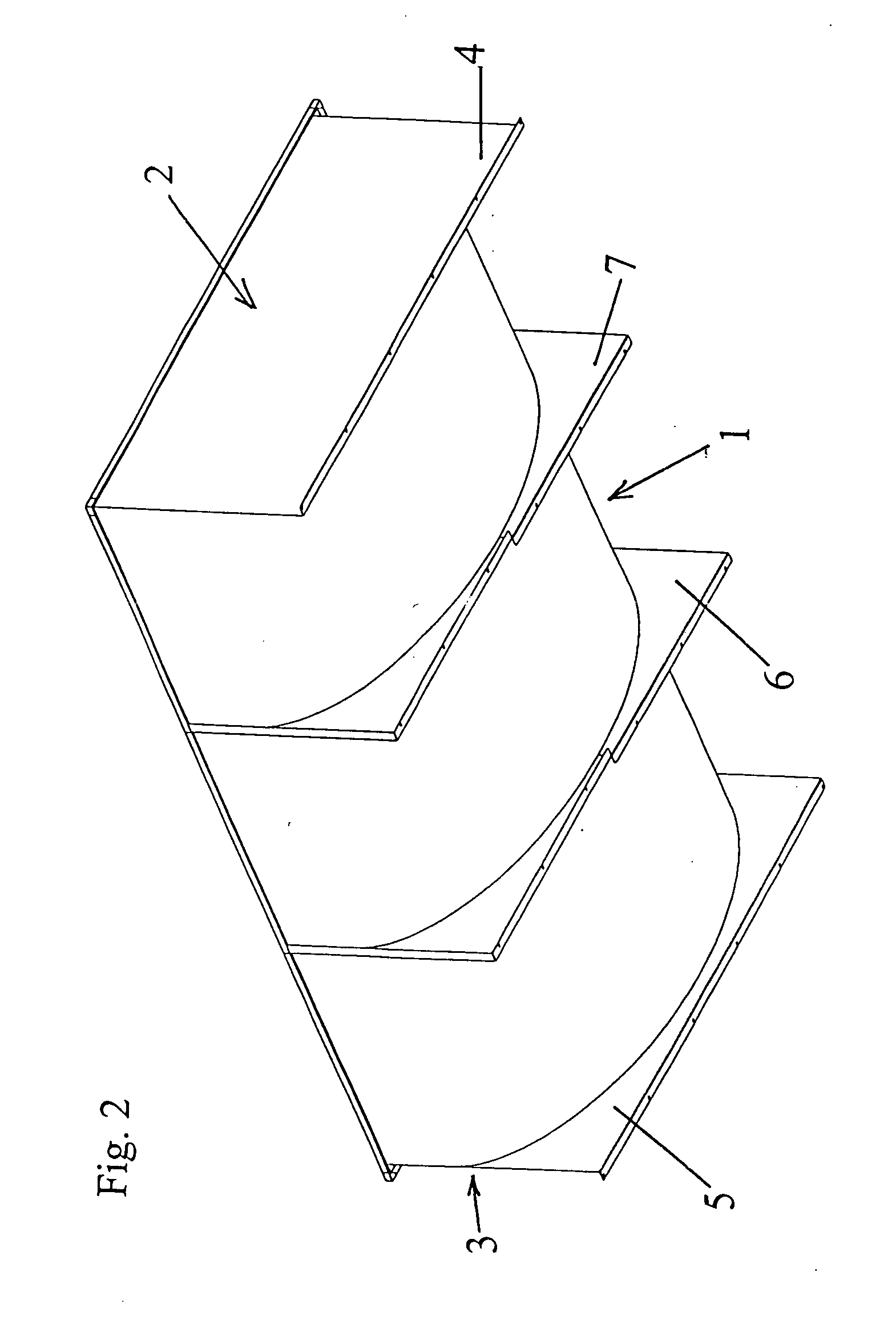

[0018] In the preferred embodiment variant according to FIG. 2, additional support ribs 6, 7 are distributed evenly across the pool floor, increasing the shape stability of the pool during backfilling.

[0019] Of course...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com