Caulk removing device and associated methods of manufacture and use

a technology of caulk and removal device, which is applied in the field of caulk, can solve the problems of not providing the existing lines of caulk in the joint may become visibly deteriorated, and the device and the tool do not provide the same efficient and quick removal of caulk or the like, so as to achieve the effect of effective quick and easy removal of existing caulk or

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

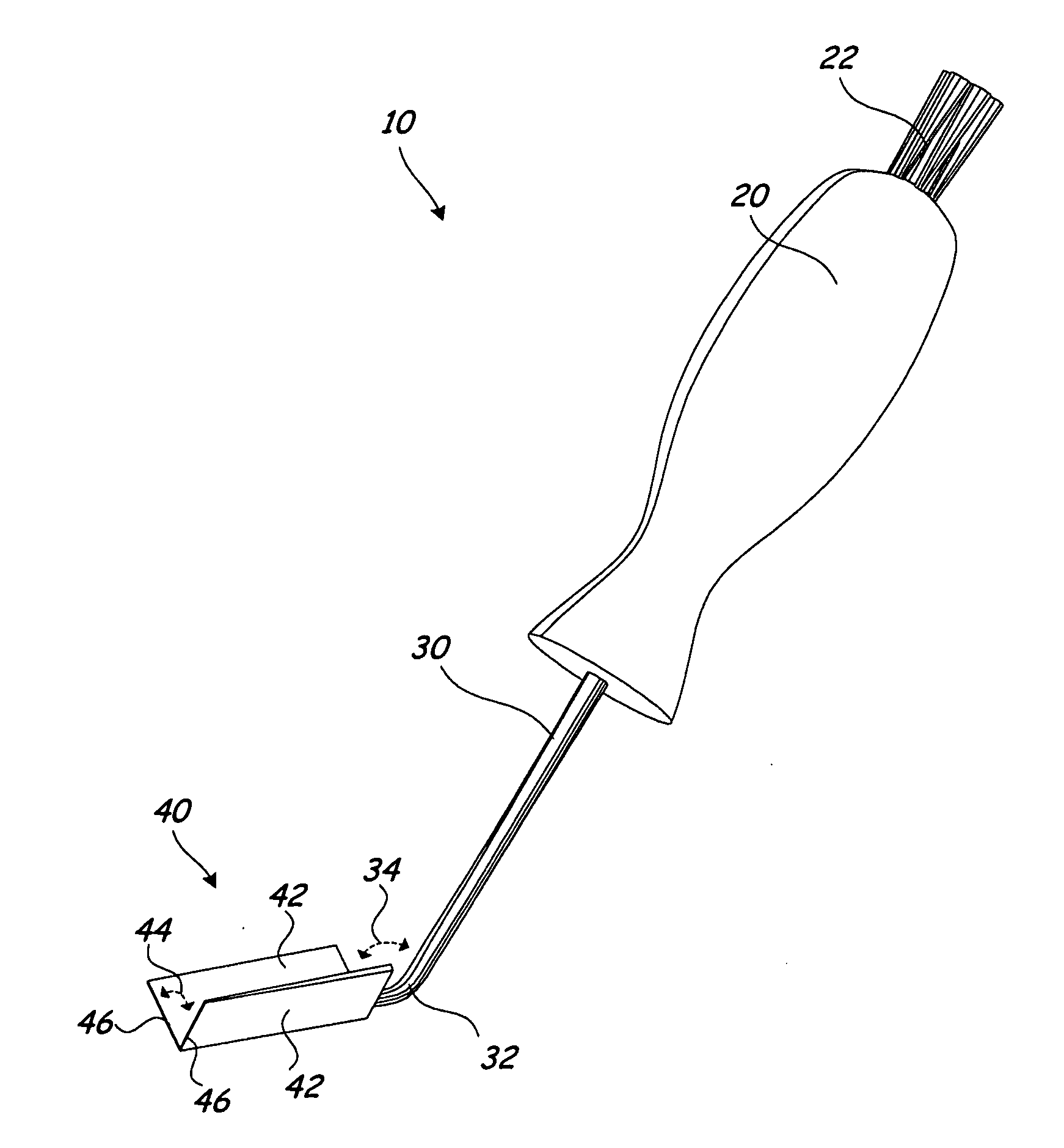

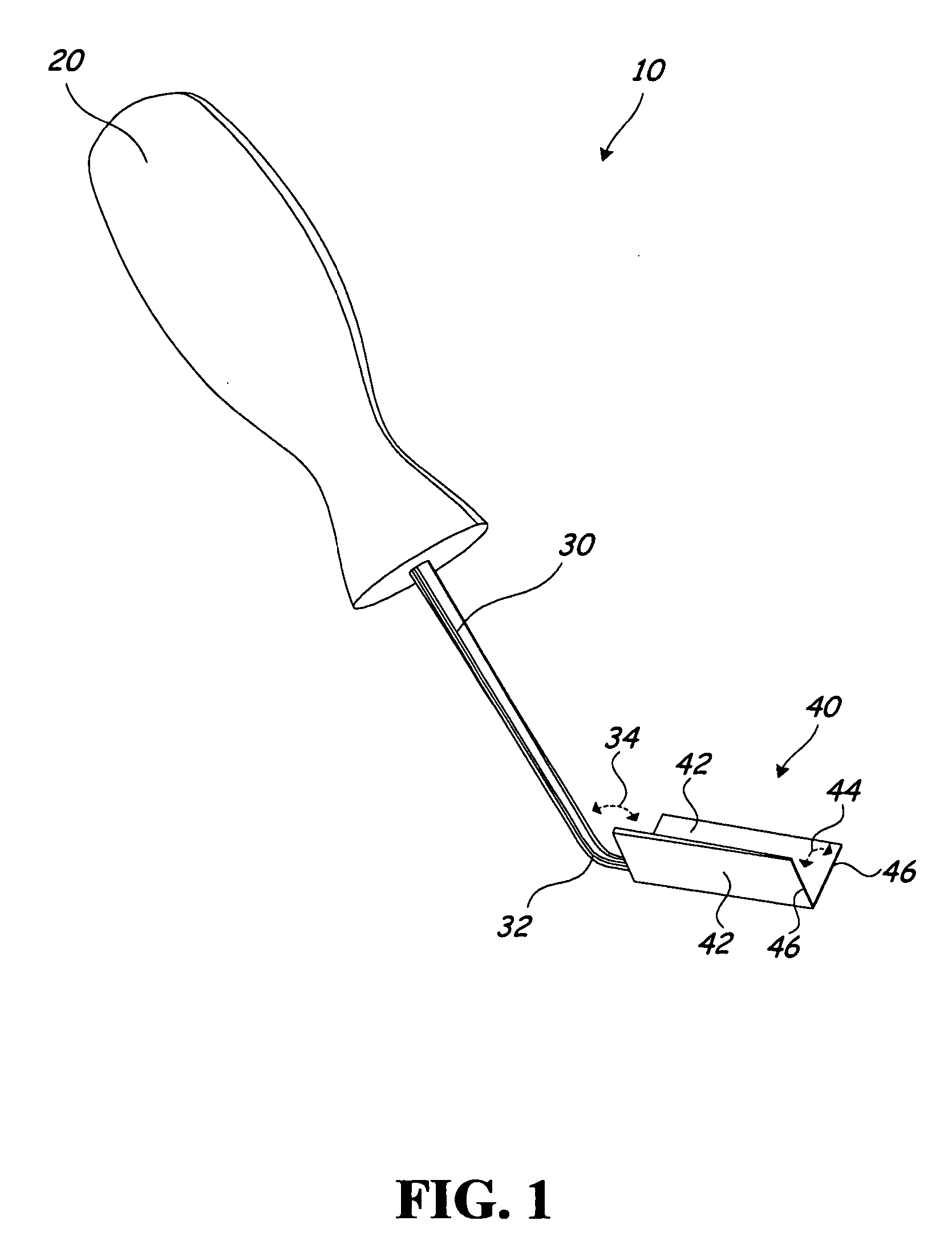

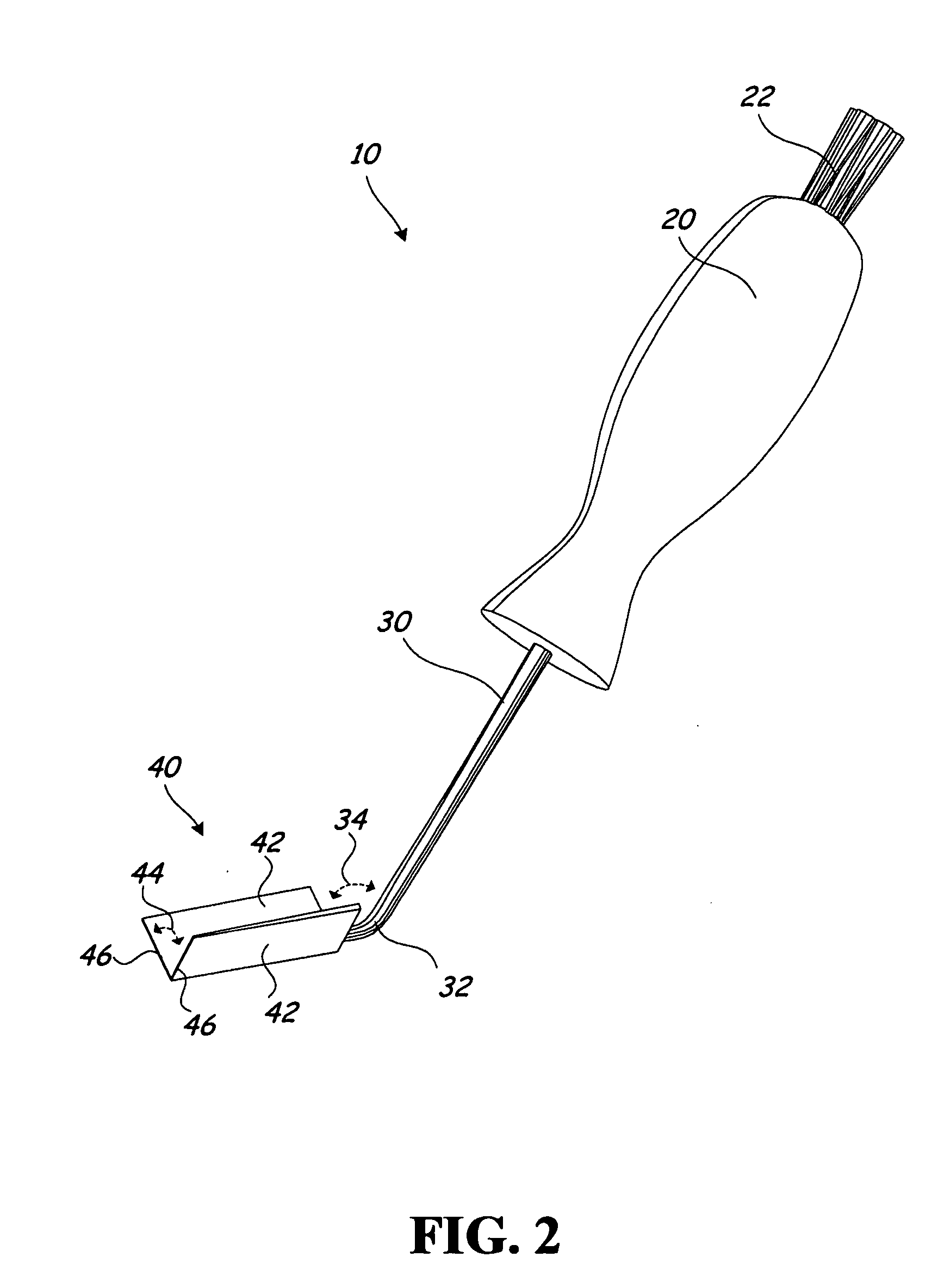

[0028] Referring now to FIG. 1, a front left perspective view of the corner caulk remover 10 of the present invention is shown. The corner caulk remover 10 includes a handle portion 20 fixedly or removably attached to an elongated shaft portion 30 fixedly or removably attached to an end angle portion 40.

[0029] The handle portion 20 is made of a metal, wood, plastic, fiberglass, or a similar substantially rigid material, such that it will securely, either fixedly or removably, hold the elongated shaft portion 30. Preferably, the handle portion 20 is sized and shaped such that it may be comfortably grasped by a user for an extended period of time.

[0030] The elongated shaft portion 30 is made of a metal, plastic, or similar substantially rigid material such that it is strong enough to endure pressure from the user while in use removing caulk. Additionally, the elongated shaft portion 30 and the handle portion 20 may be integrally formed as one piece by means of injection molding or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com