System and machine for strapping articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

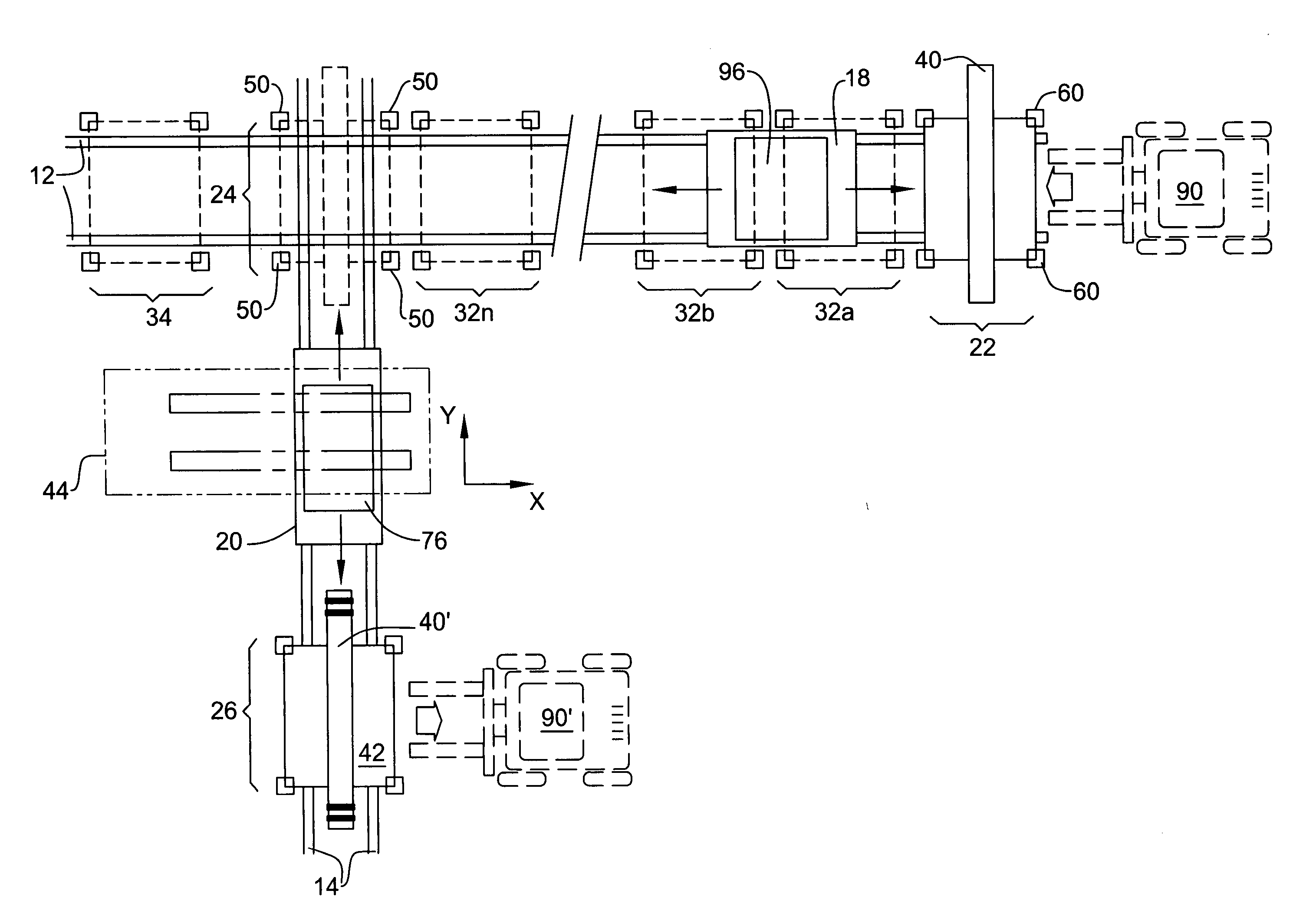

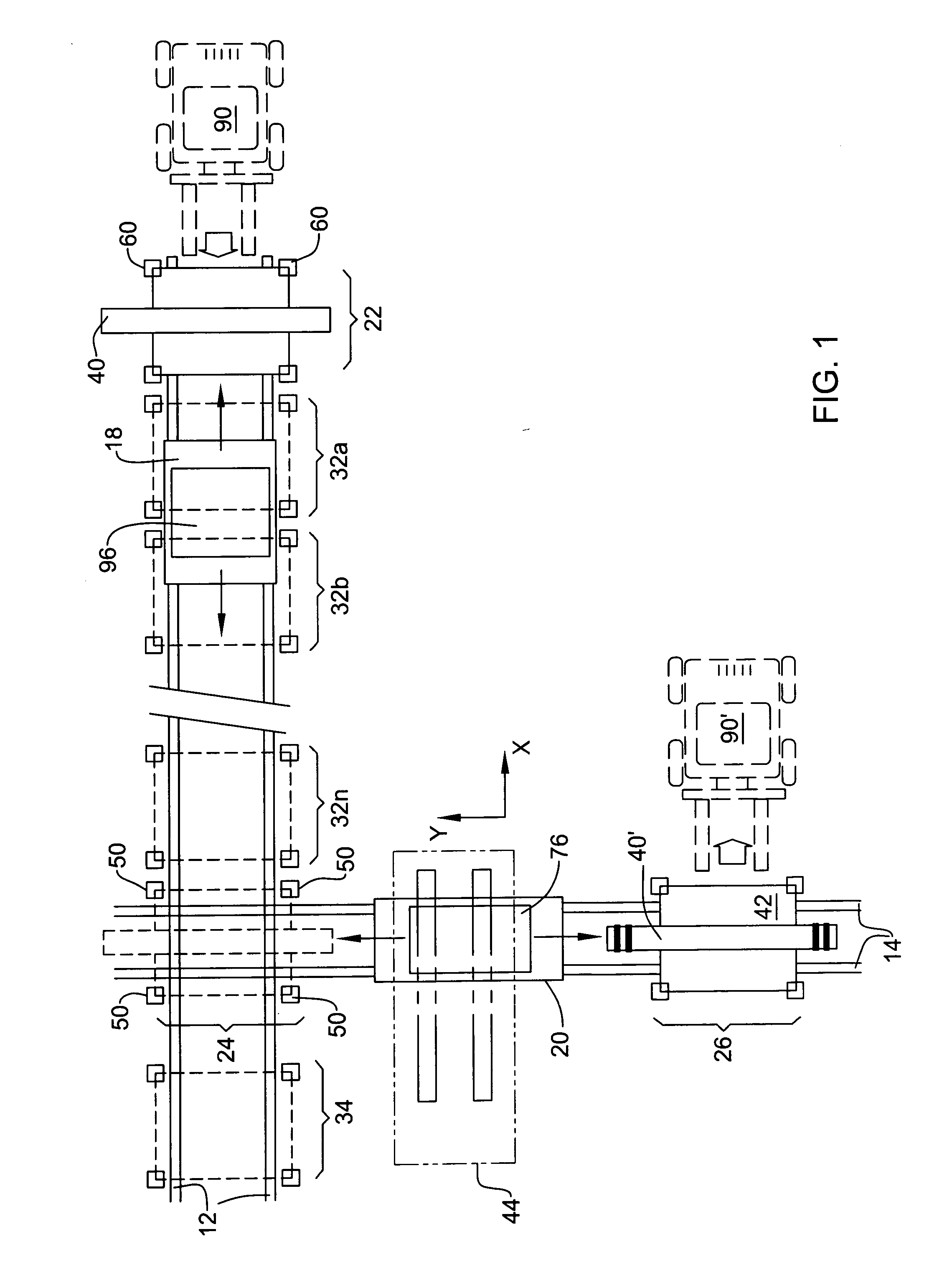

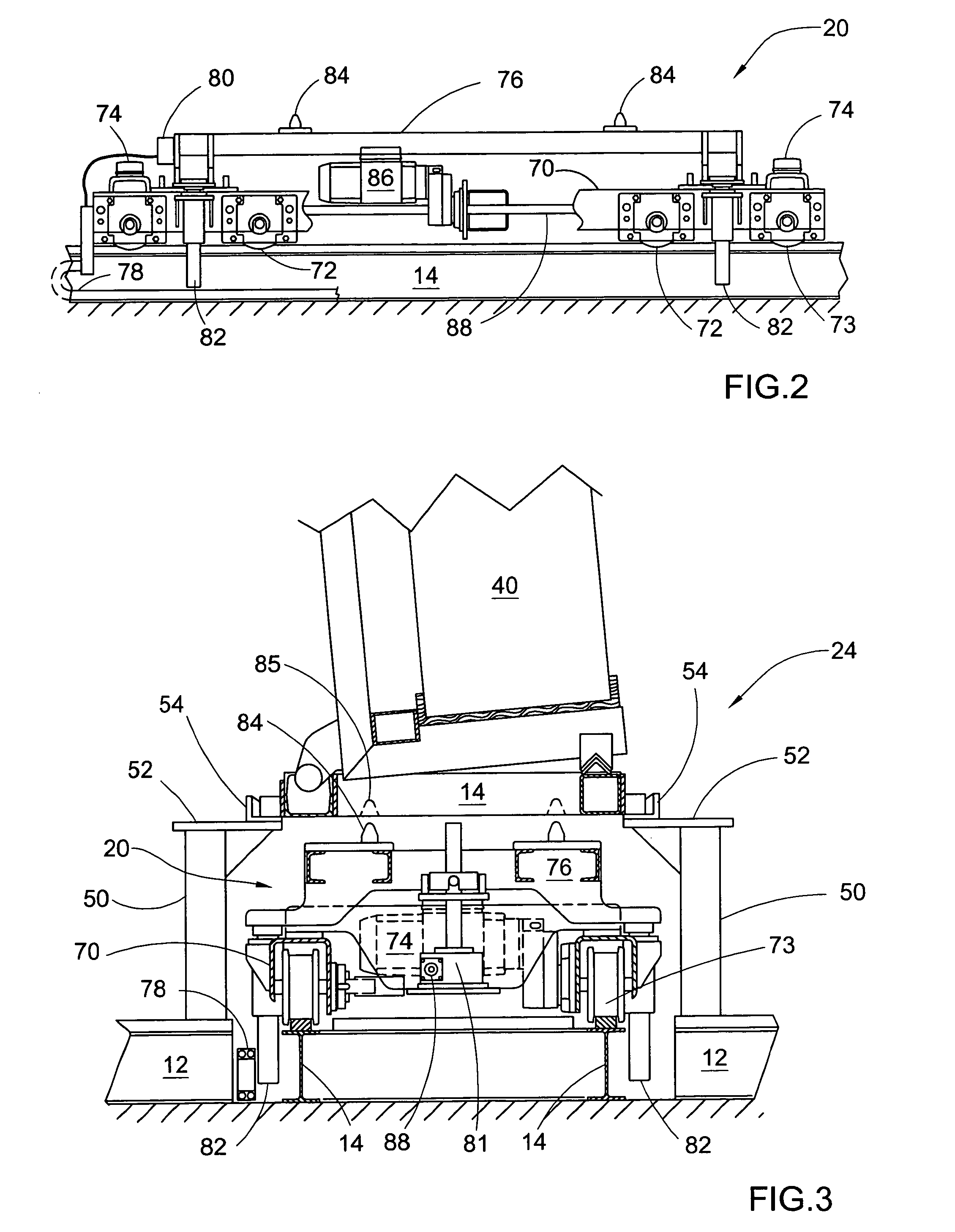

[0042] With reference to FIG. 1, the feeding system 10 of the present invention comprises a supply railway 12 and a feeding railway 14 intersecting at a crossroads 16, a supply carriage 18, a feeding carriage 20, a supply (loading) stand 22 and a crossroads stand 24. Optionally, the system may have an unloading stand 26 and a plurality of additional supply stands 32a, 32b, . . . 32n and 34, etc. A computerized control system (not shown) including positional sensors, velocity sensors, load sensors, etc. controls the operation of the carriages 18 and 20.

[0043] The feeding system 10 is used for inserting (feeding) and positioning stacks of glass sheets 40 supported on pallets 42 in a strapping machine 44. The stacks are typically flat, e.g. their width is considerably less than their length and height (the length and the width are seen in the plan view of FIG. 1). The stacks are encased in wooden cases or frames embracing their width.

[0044] The strapping machine 44 requires feeding a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap