Condom with male genital desensitizer lubricant

a lubricant and desensitizer technology, applied in the field of condoms, can solve the problems of high undesirable exposure and inconvenient use of compositions, and achieve the effects of high viscosity, low viscosity, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

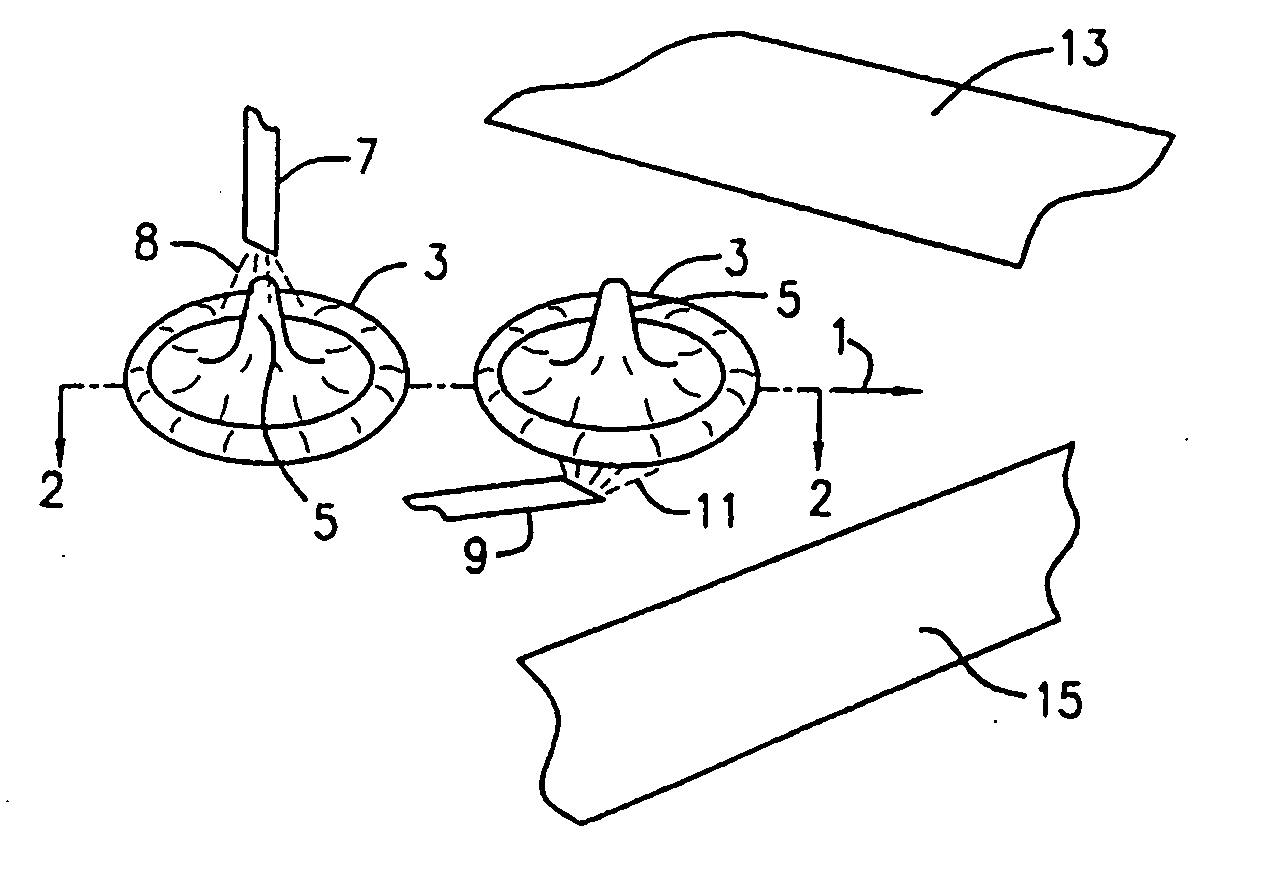

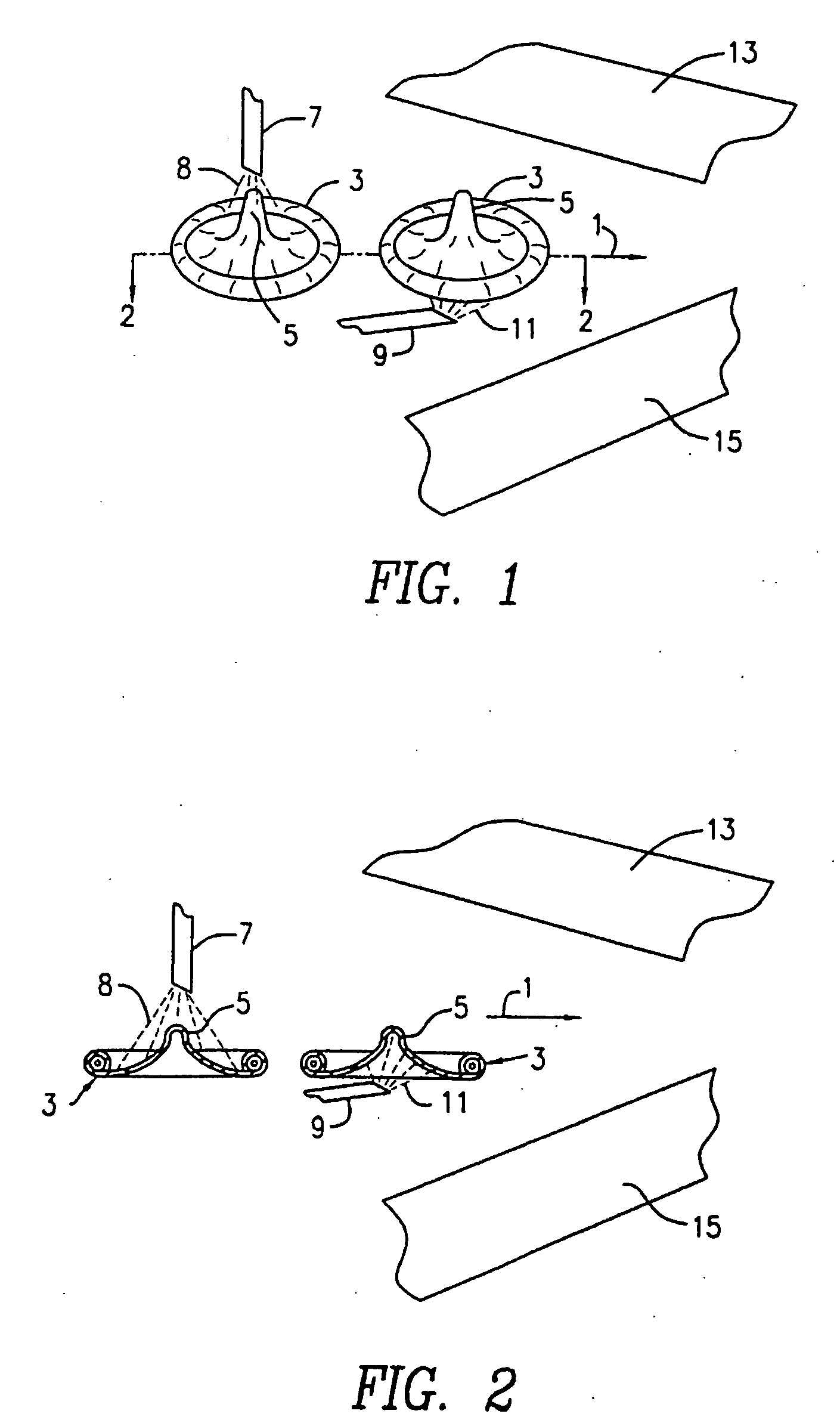

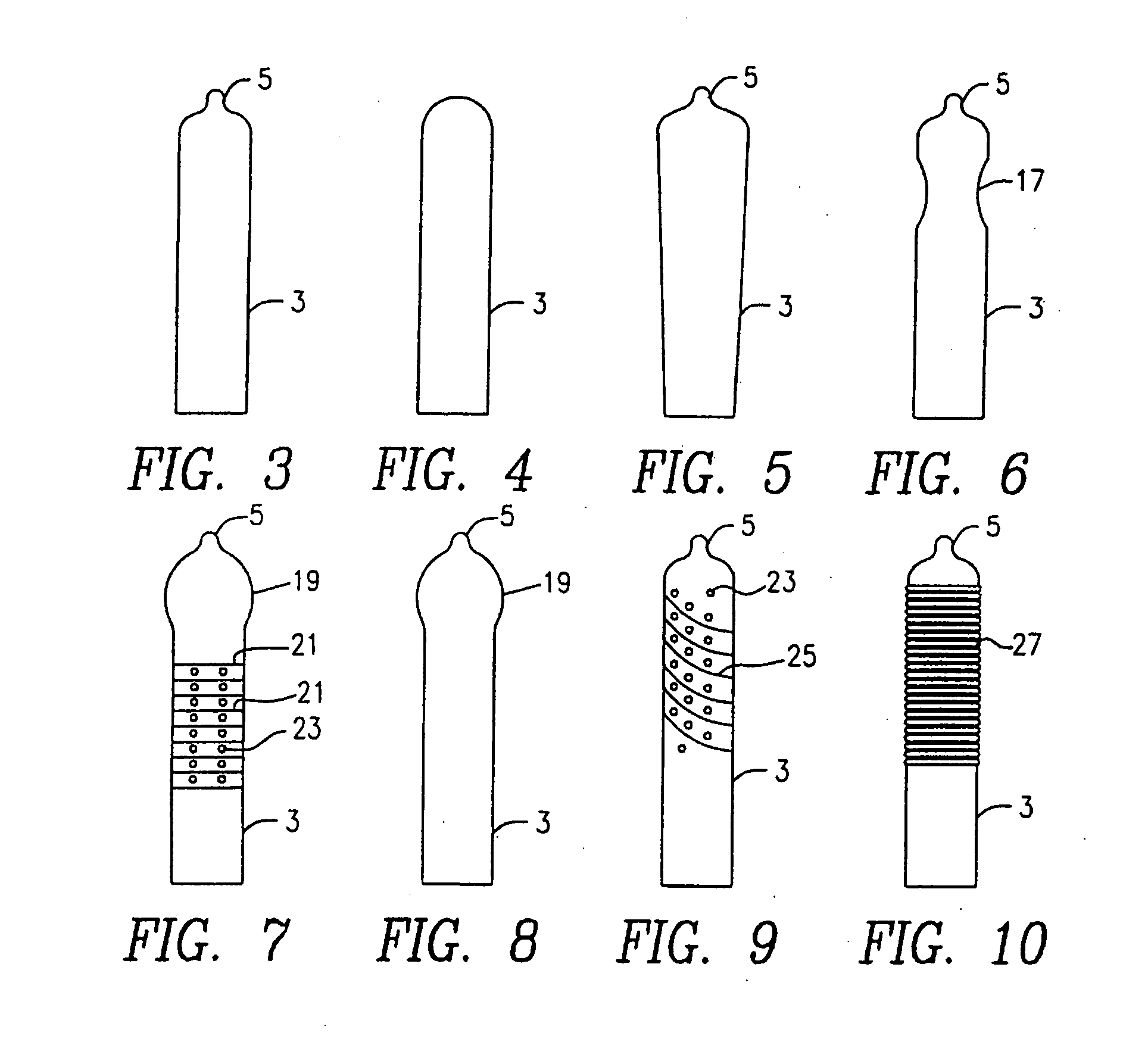

Image

Examples

example 1

[0029] Preparation of a First Lubricant Composition

[0030] A first lubricant composition in accordance with the present invention having the formula shown in Table 1 was prepared as follows:

TABLE 1IngredientPercent w / wPropylene Glycol44.0%w / w.Polyethylene Glycol 40015.0%w / w.Lubrajel ®CG*35.0%w / wBenzocaine USP6.0%w / w100.0%

*Lubrajel ® is a registered trademark of Guardian Chemical Corporation, Hauppauge, New York and contains glyceryl polymethacrylate, propylene glycol and water.

[0031] A method for manufacturing the first lubricating composition shown in Table 1 is now be described, with reference to FIG. 11. A hemispherical jacketed kettle 31, is provided with heating and cooling equipment. The kettle is equipped with a variable speed counter current sweep scraper, and a variable speed air mixer with propellers, as known in the art, to provide proper agitation. Three pumps, represented by numerals 33 through 35, are used to charge the kettle 31 with the particular components of th...

example 2

Preparation of Second Lubricating Composition

[0034] A second lubricating composition containing no desensitizing agent and having the formula shown in Table 2 was prepared in the following manner:

TABLE 2IngredientPercent w / wProplylene Glycol68.20Polyethylene Glycol 4006.80Lubrajel ® CG*25.00100.00%

*Lubrajel ® CG is a registered trademark of Guardian Chemical Corporation and contains glyceryl polymethacrylate, propylene glycol and water.

[0035] For the preparation of a batch of about 1,400 kg (kilograms) of the second lubricating composition shown in Table 2, the pumps 33-35 are operated to discharge 954.8 kg of propylene glycol, 95.2 kg of polyethylene glycol, and 350 kg of Lubrajel® CG into a 400 gallon capacity kettle 31 from a storage container (not shown), respectively under stirring with a variable speed counter current sweep scraper, and variable speed airmixer with propellers. The contents of the kettle are heated to between 75° C. and 80° C. During heating the air mixer u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com