Cooling arrangement for a portable air compressor

a portable air compressor and cooling arrangement technology, which is applied in the direction of positive displacement liquid engine, pump components, piston pump, etc., can solve the problems of single fan, common cooling configurations that do not supply dedicated cooling air to the head area of the compressor, and air ducting configuration(s) that are not optimized to control the distribution of all the air flow, so as to increase the cooling flow and facilitate the transition. , the effect of efficient air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

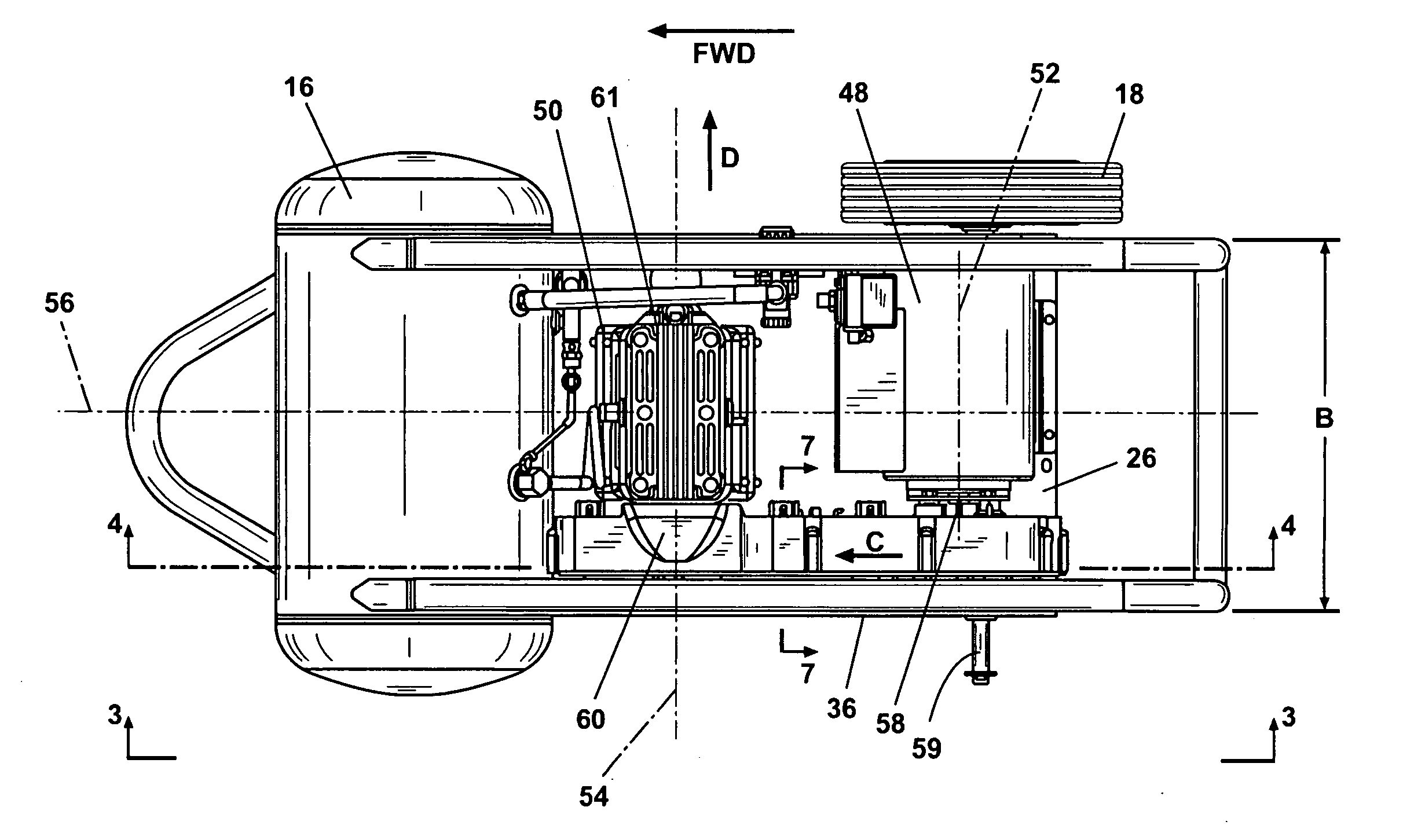

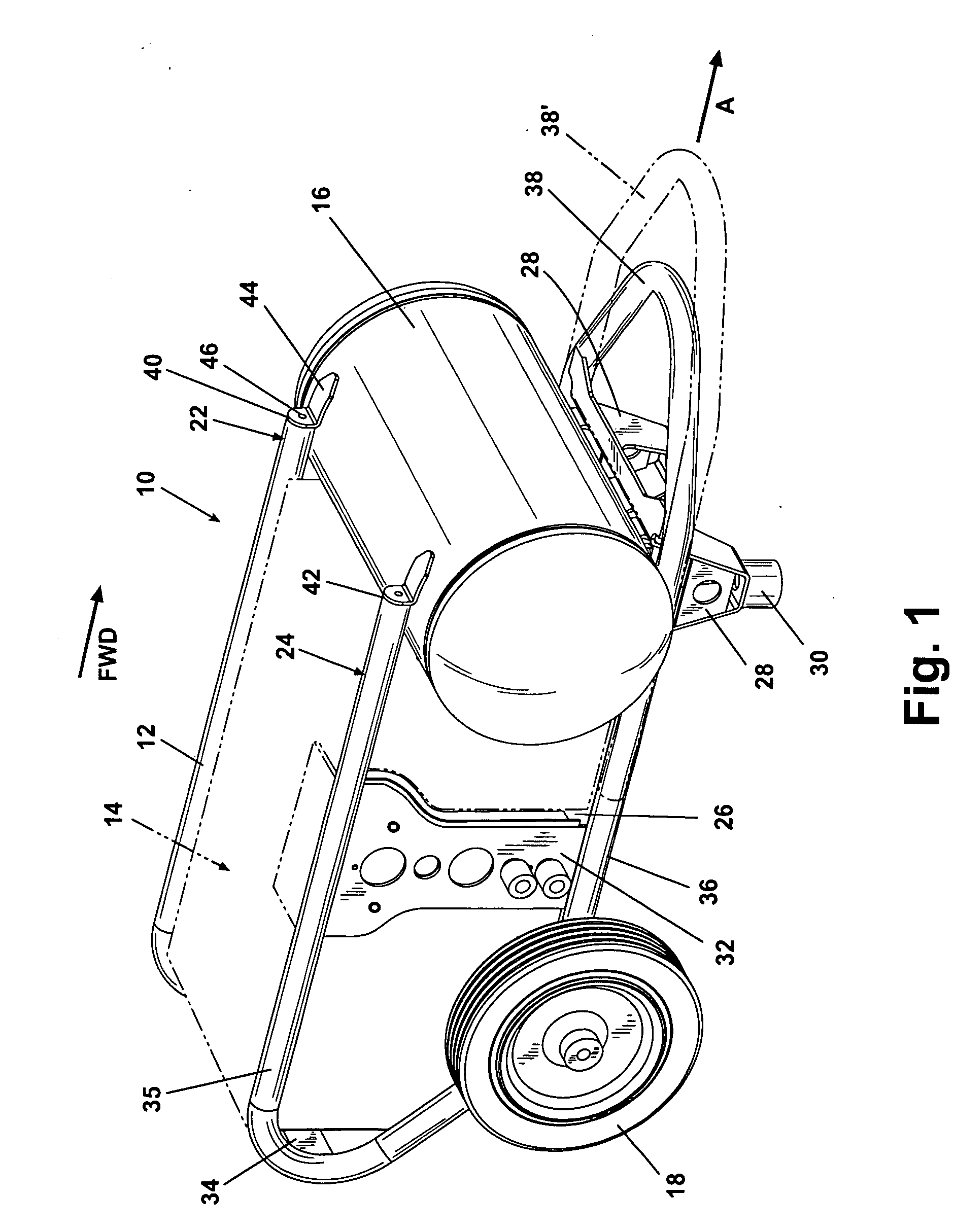

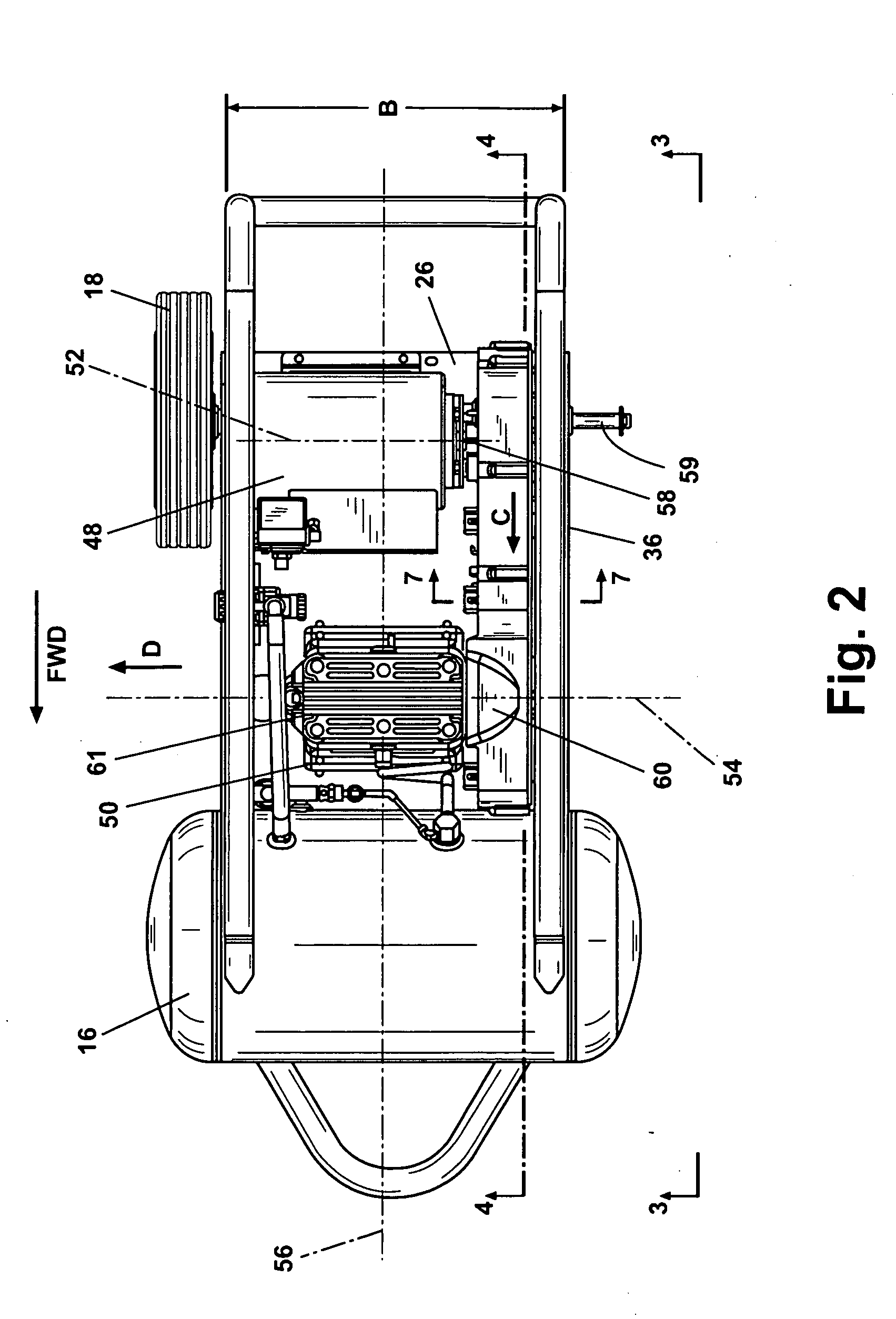

[0022]FIG. 1 identifies an air compressor assembly 10 according to one preferred embodiment of the present invention. The air compressor assembly 10 includes a frame 12, a component group 14, and a pressurized fluid containment tank 16. A first wheel 18 and a second wheel 20 are rotatably supported from the frame 12 at an aft end of the air compressor assembly 10. The frame 12 includes a first side 22 and a second side 24. The first side 22 and the second side 24 are generally tubular shaped frame members substantially formed in a parallelogram configuration having rounded corners. A support plate 26 is provided at a lower portion of the frame 12 and is mechanically joined to the first side 22 and the second side 24, respectively. A pair of support feet 28 are mechanically joined to a forward end of the frame 12 at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com