High-throughput screening with multi-through hole testing plate

a multi-through hole, screening technology, applied in the direction of laboratory glassware, instruments, chemical/physical/physicochemical processes, etc., can solve the problems of increased overall cost of testing procedure, difficult operation of special delivery systems, and difficult filling of wells in these testing apparatuses, so as to simplify the construction of testing apparatus, easy identification, and simple testing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

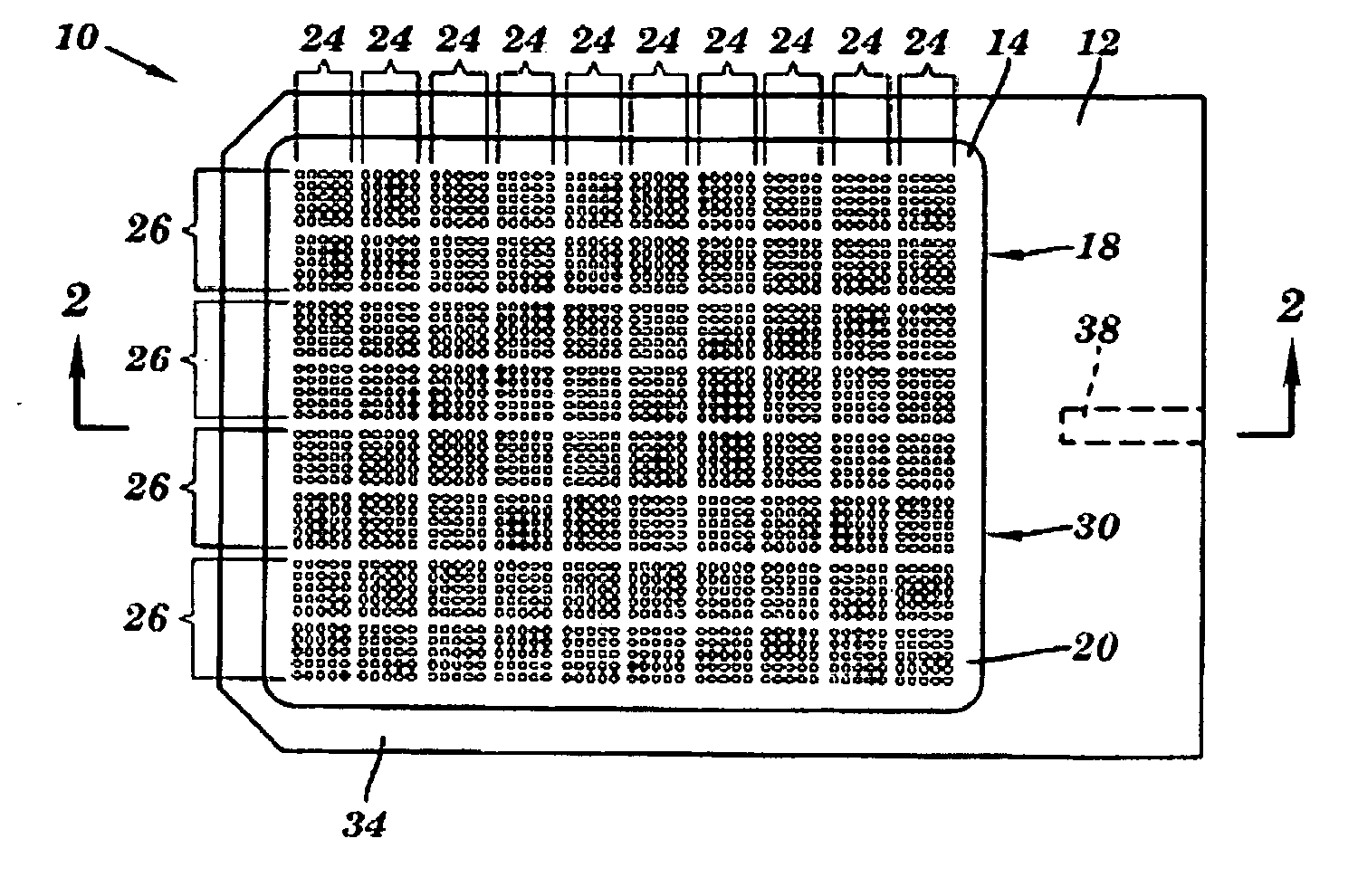

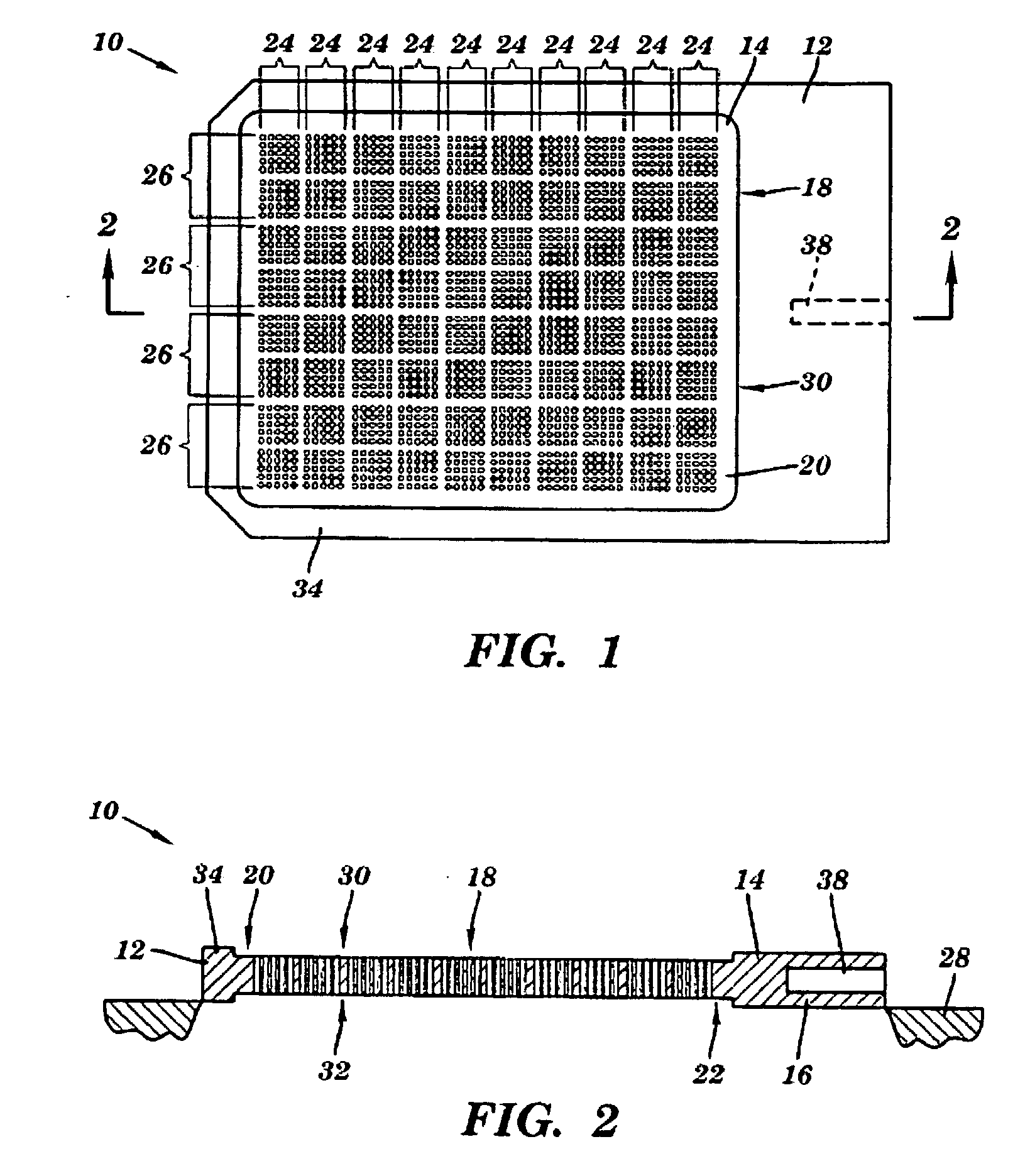

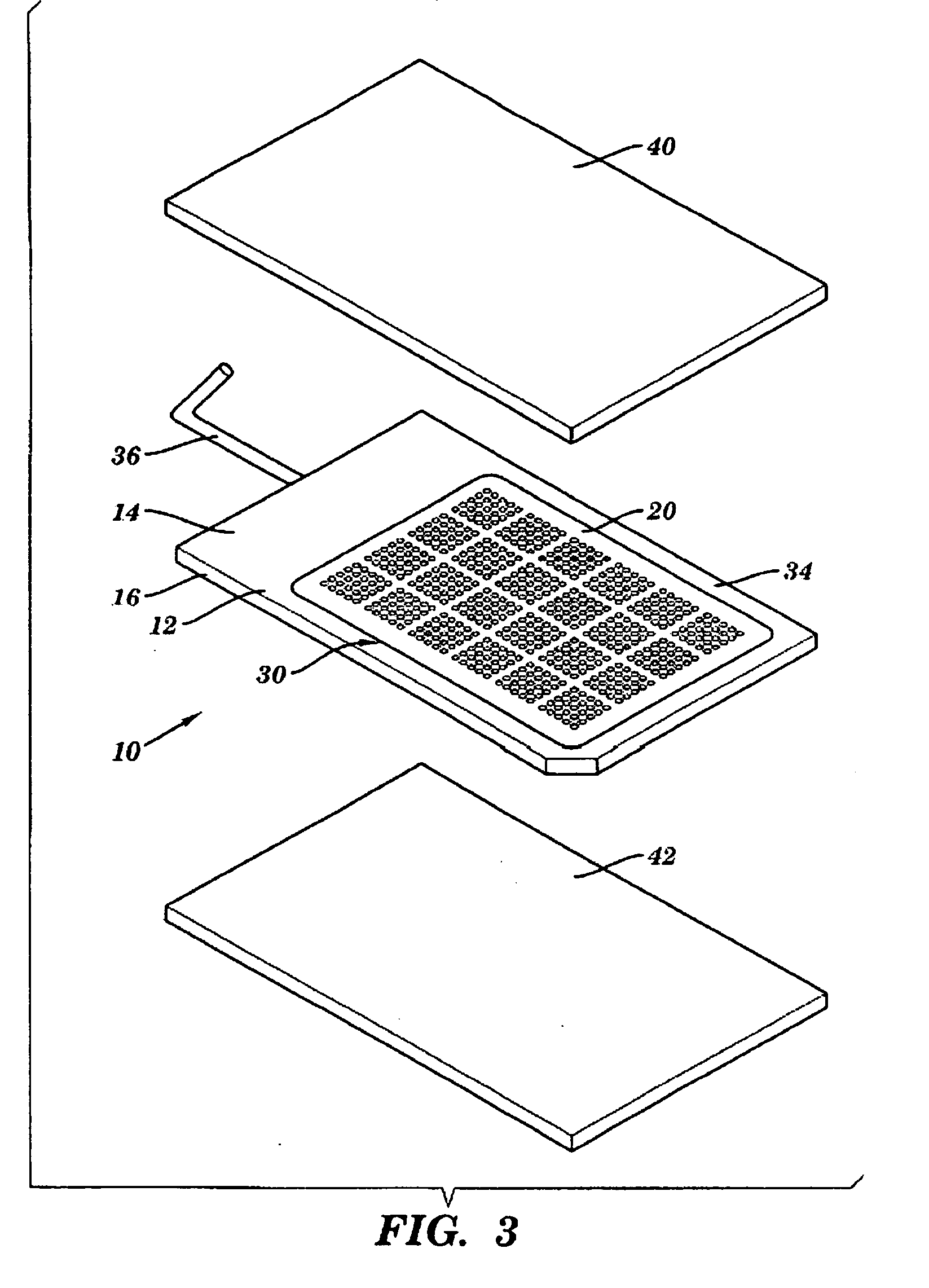

[0025] A testing apparatus 10 in accordance with one embodiment of the present invention is illustrated in FIG. 1. The testing apparatus 10 includes a testing plate 12 with a pair of opposing surfaces 14 and 16 (surface 16 is shown in FIG. 2) and a plurality of through holes 18. The through holes 18 are located in recessed portions 20 and 22 on each side of the testing plate 12. The through holes 18 are also arranged in groups 24 of at least two columns and two rows of holes 18 and in sets 26 of two or more groups of holes 18. The testing apparatus 10 provides a number of advantages including simplifying the procedure for loading samples of solution S into the holes 18 in the testing apparatus 10, simplifying the construction of the testing apparatus 10, and making the identification of a particular hole 18 filled easier for an operator.

[0026] Referring to FIGS. 1 and 2, the testing apparatus 10 includes the testing plate 12 which in this particular embodiment is made of a non-tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| constant diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com