Modular muffler

a module and muffler technology, applied in the field of mufflers, can solve the problems of inefficiency and cost, and achieve the effects of enhancing the level of sound reduction, reducing the cost of operation, and being strong and effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

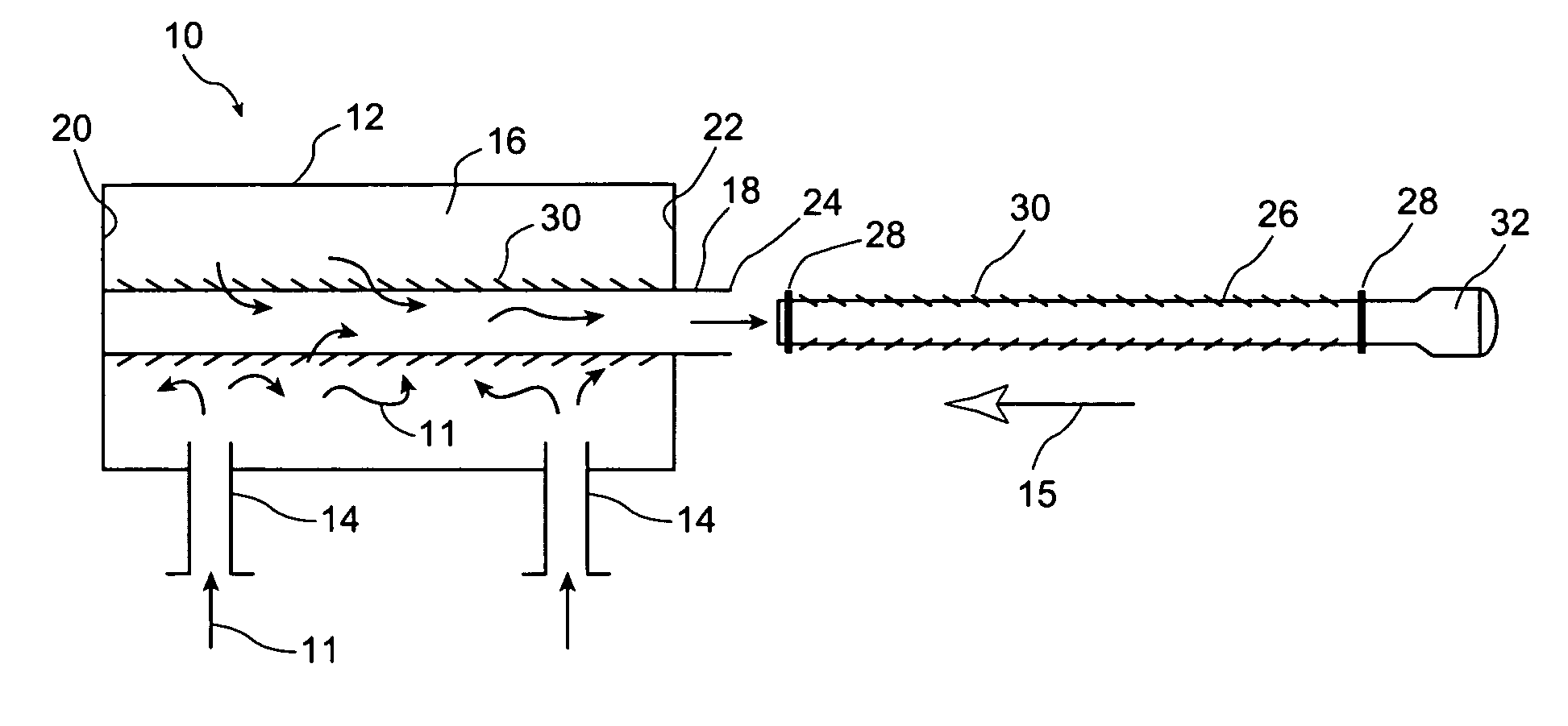

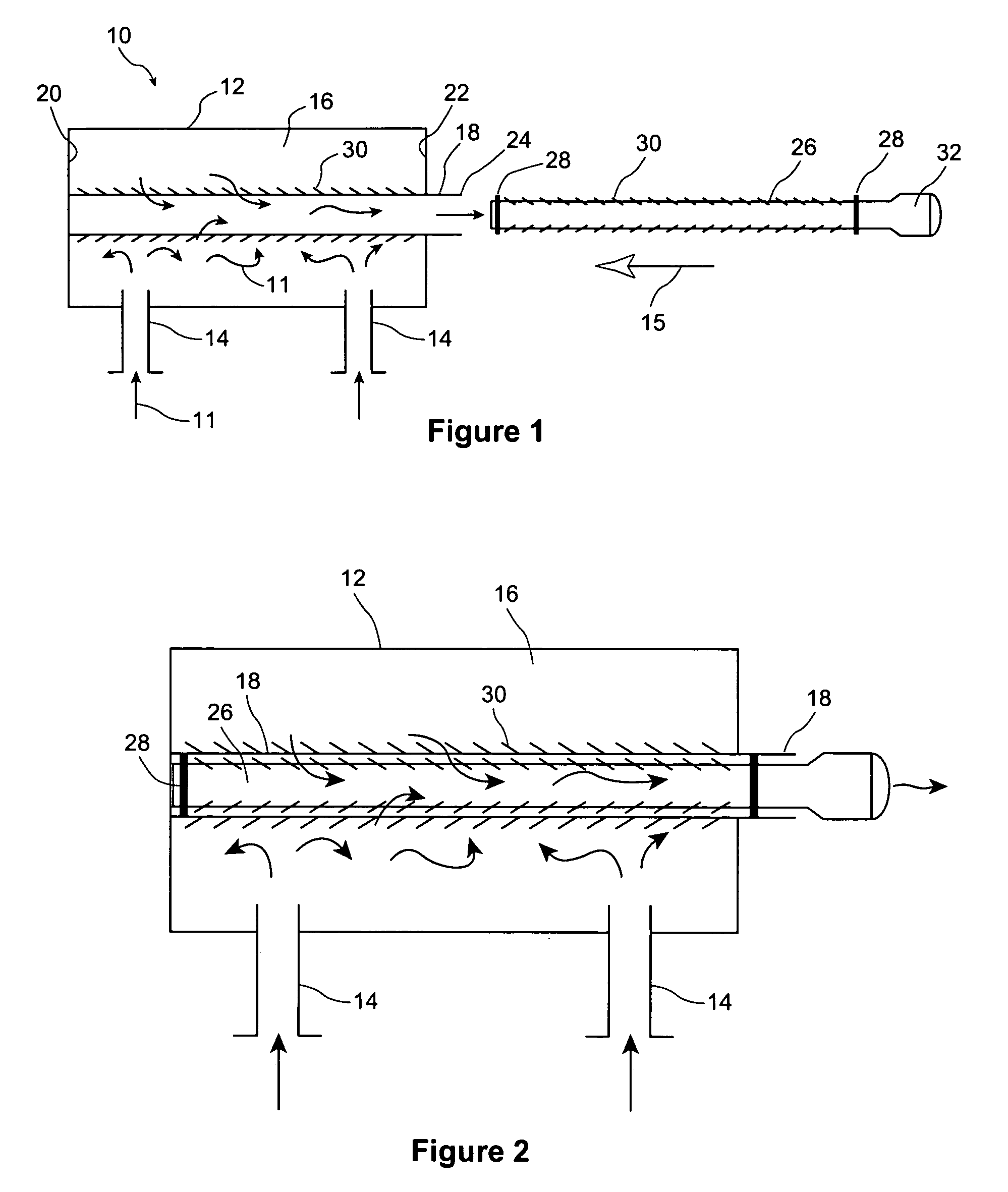

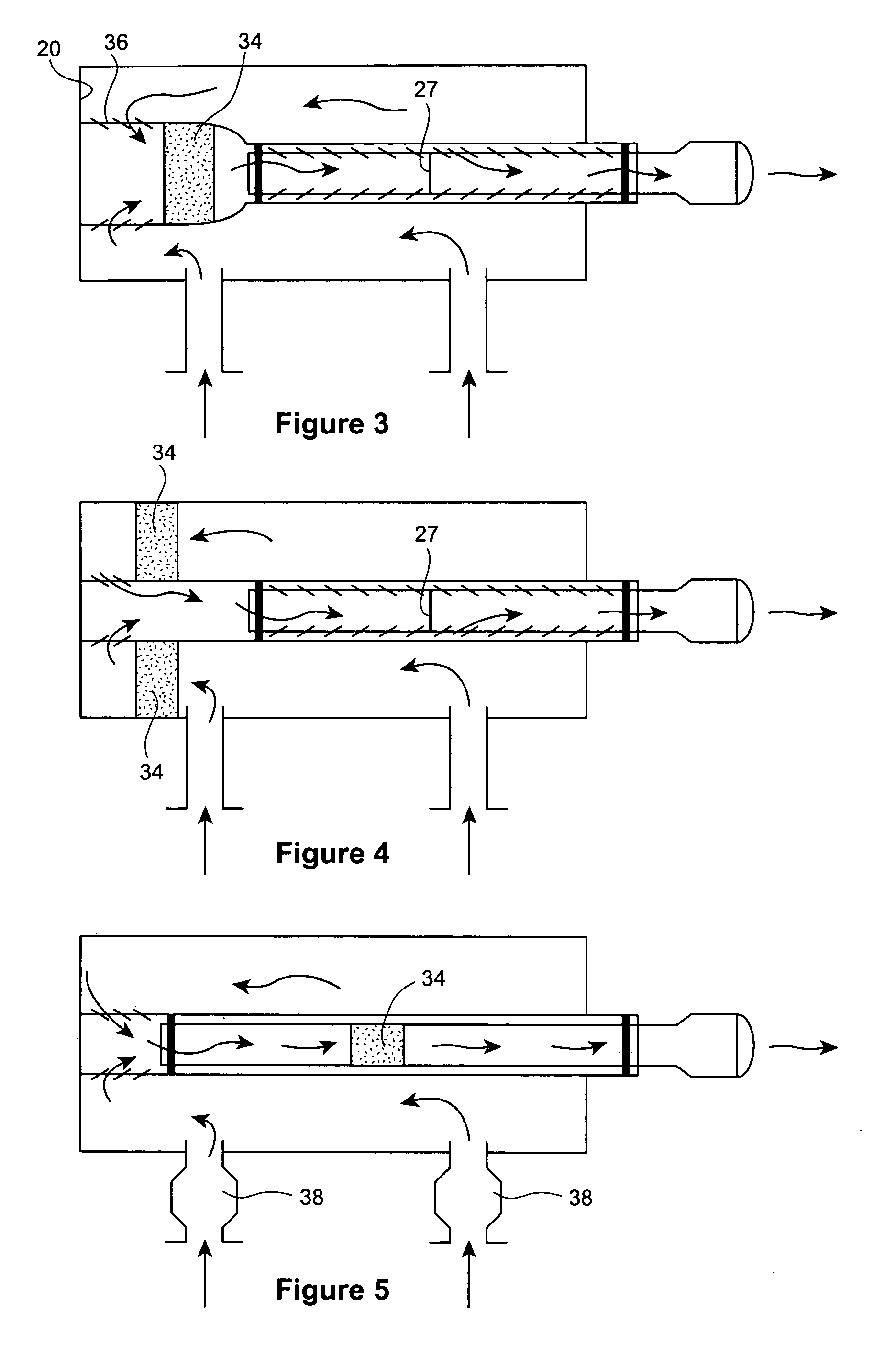

[0019] The modular muffler or exhaust gas muffler of the present invention is shown in a side view in FIG. 1 and generally designated as 10. The muffler 10 receives exhaust gas 11 from an engine (not shown). The muffler 10 generally comprises a base muffler or body 12 having at least one exhaust gas inlet 14, an internal chamber 16 to receive the exhaust gas 11 from the inlet 14, and at least one exhaust gas outlet or tailpipe 18 to vent the exhaust gas from the chamber 16. In the embodiments shown in FIGS. 1-5 there are two exhaust gas inlets 14. The chamber 16 has a first or back wall 20 at one end and a second or front wall 22 at the other end. In the figures the tailpipe 18 is attached to back wall 20, and extends the length of the chamber 16 past front wall 22 to a termination point 24 outside of body 12. The tailpipe 18 is usually configured as a tube or conduit, although other embodiments are also comprehended by the present invention.

[0020] The muffler 10 also includes a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com