Method and system for enhanced radiation detection

a radiation detection and radiation detection technology, applied in the field of radiation detection systems, can solve the problems of limiting the spatial resolution of the imaging system, increasing the complexity of the system, and imposing constraints on the minimum size of the detector, so as to improve the detection of specific objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The word “exemplary” is used herein to mean “serving as an example, instance, or illustration.” Embodiment described herein are “exemplary” and are not necessarily to be construed as preferred or advantageous over other embodiments.

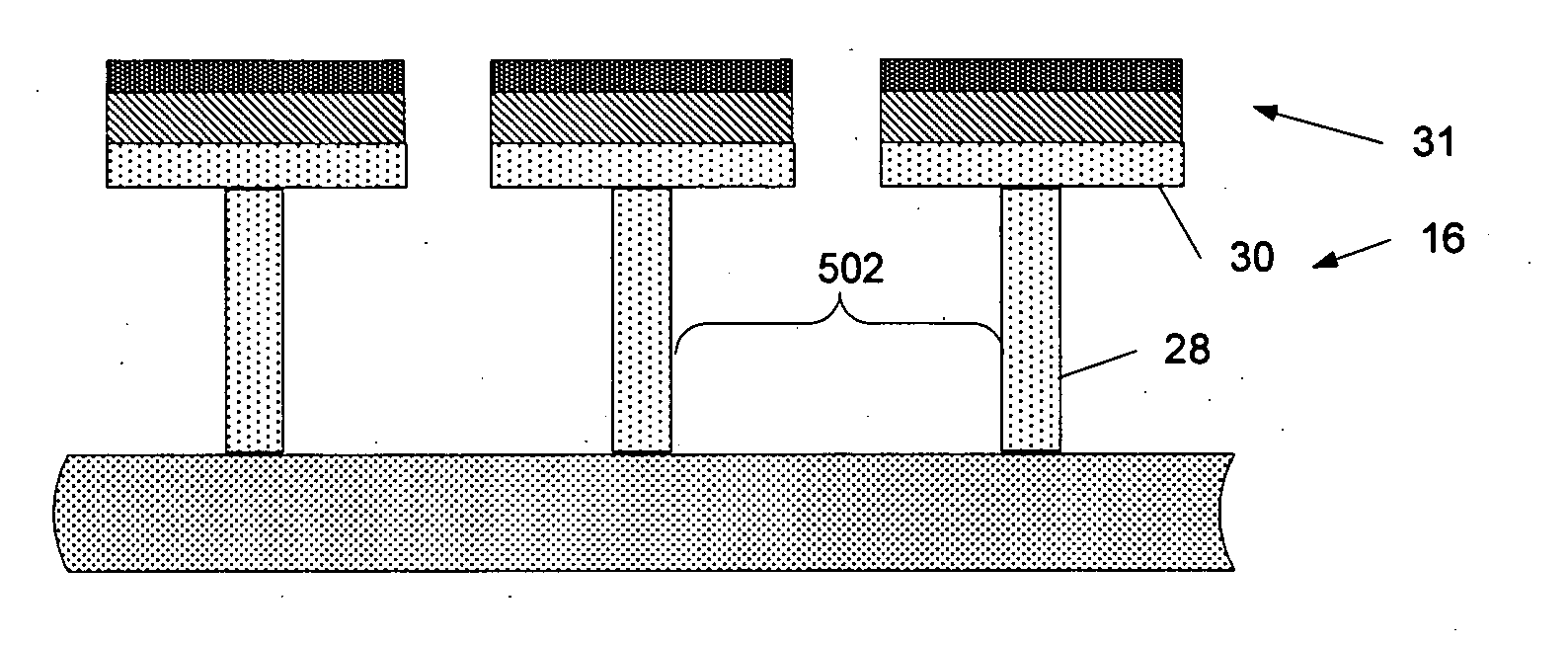

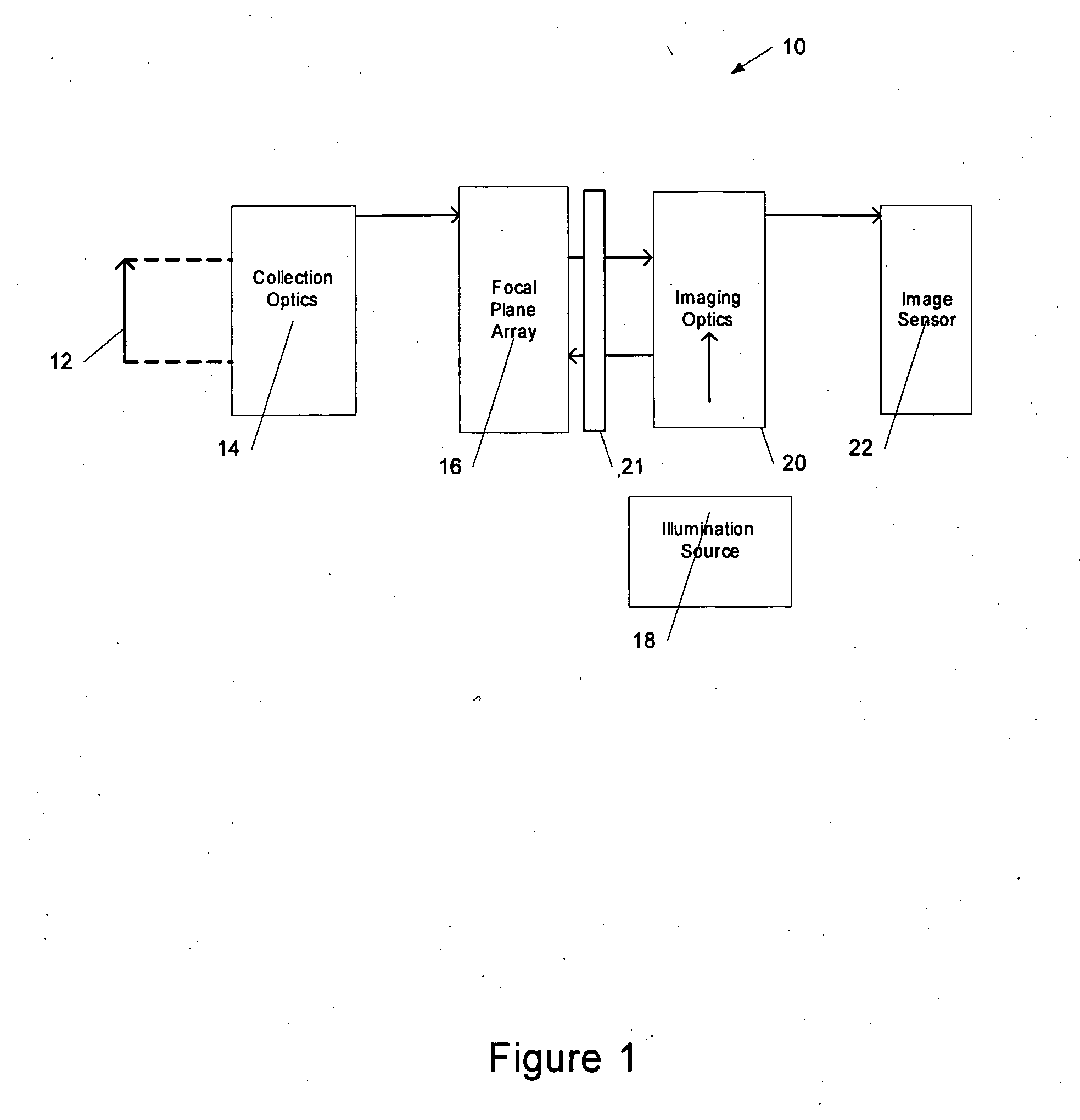

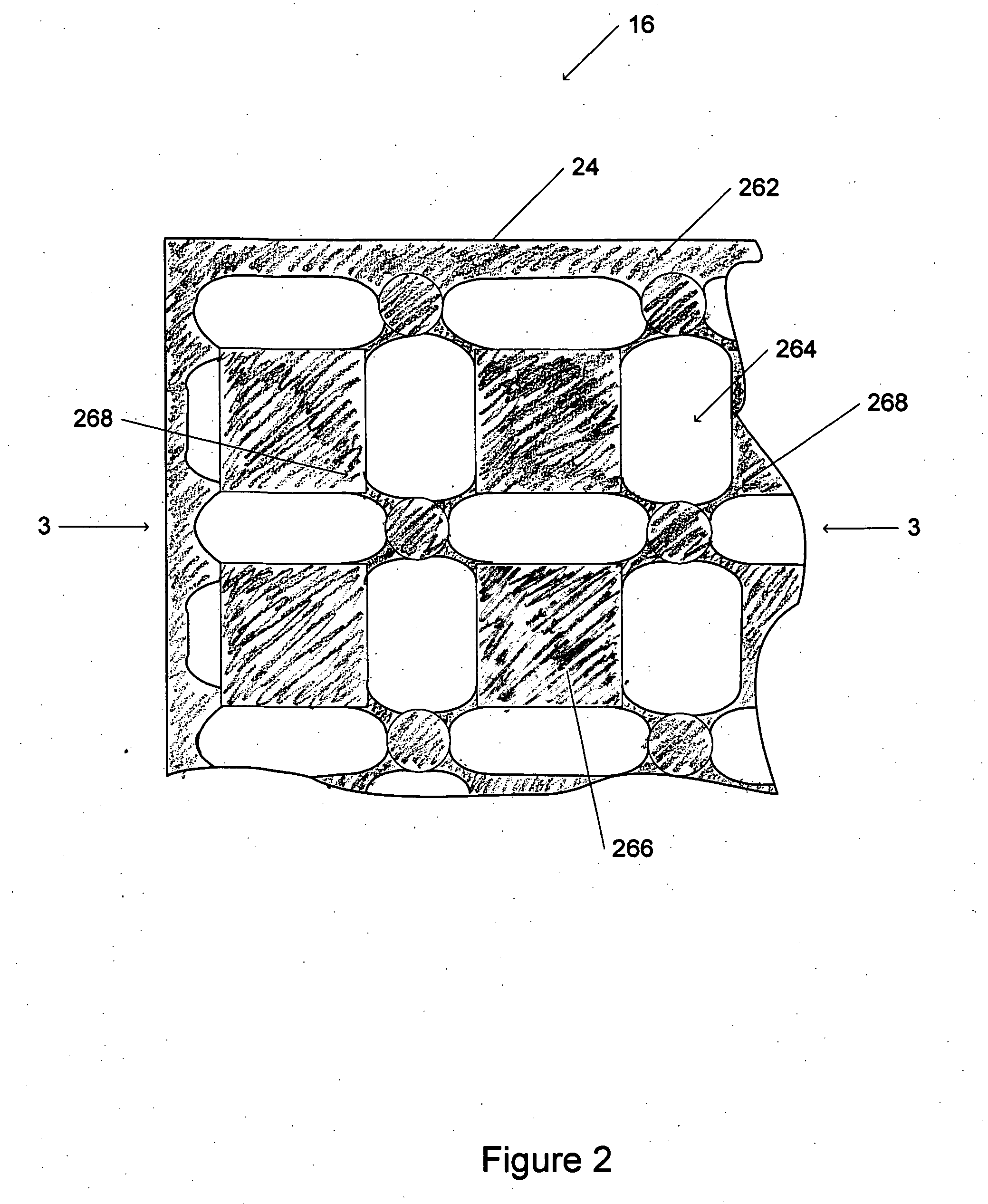

[0069] In accordance with the invention, a radiation detection sensor includes a radiation detector that is segmented into an array of mapping elements, also referred to herein as detectors. The mapping elements are substantially thermally isolated from each other and comprise pixels of a visual thermal energy map. The radiation detector receives thermal energy and generates the visual thermal energy map, which is provided by the sensor for viewing. The mapping elements of the radiation detector may be minimally connected to adjacent mapping elements, or the mapping elements may be substantially physically isolated from each other. The mapping elements may be micro-disposed, such that individual mapping elements are substantially thermally isolate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com