Pumping unit driven by a linear electric motor

a linear motor and pumping unit technology, applied in the field of pumping units, can solve the problems of large volume of pumping units driven by rotating motors, high electrical energy consumption, complex structure, etc., and achieve the effect of reducing potential safety hazards, high pressure, and simplifying the structure of pumping units driven by linear motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

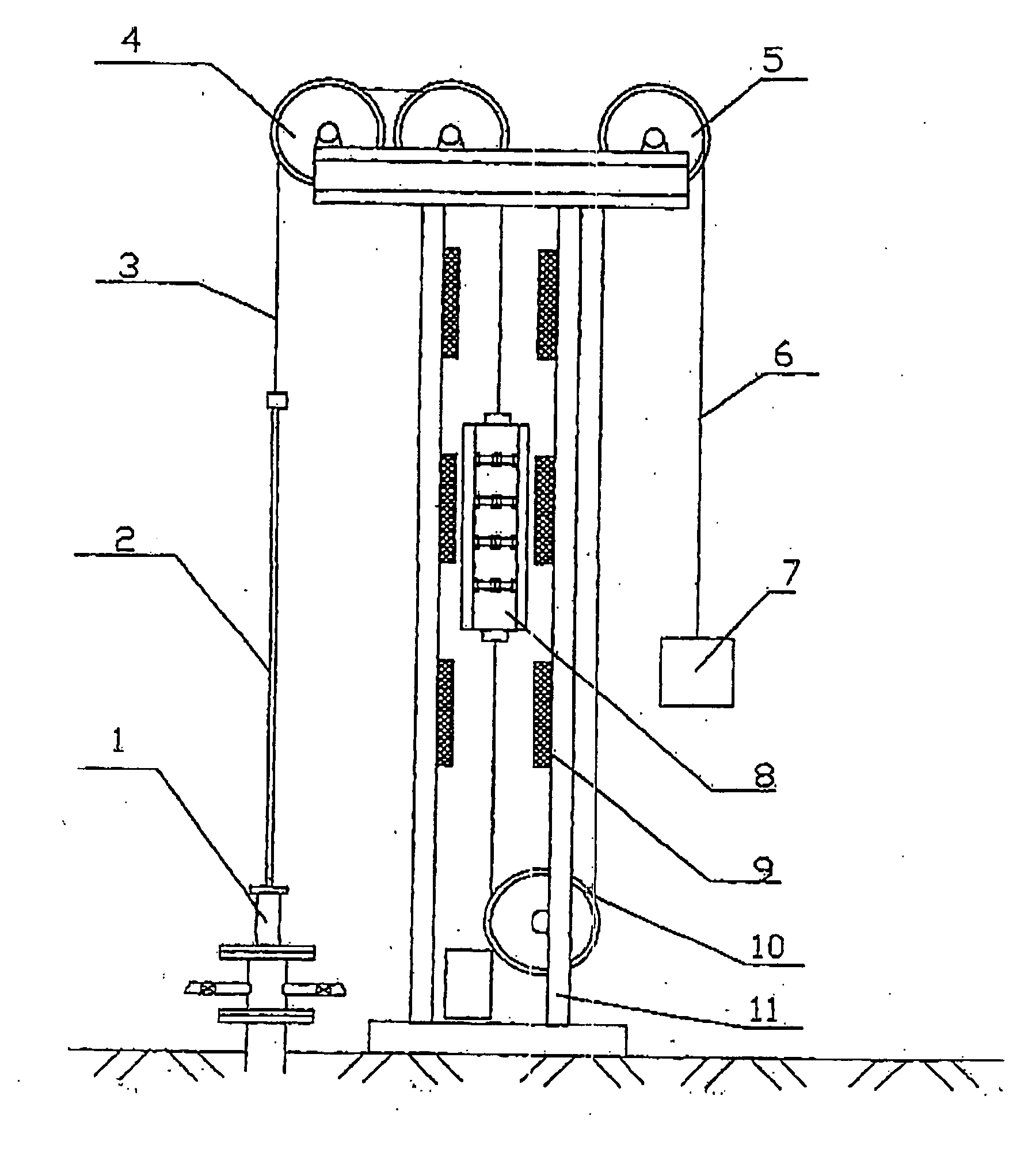

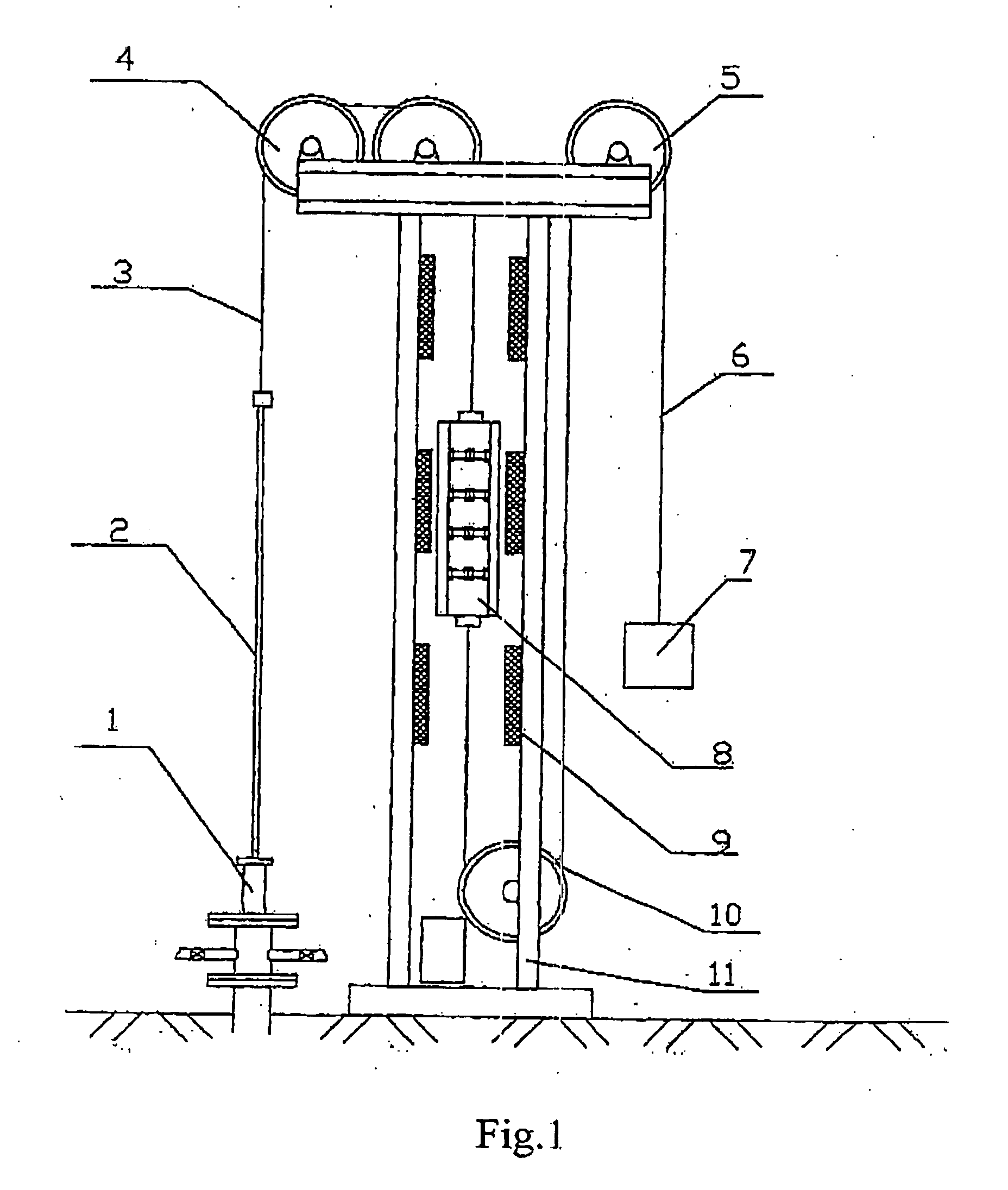

[0013] The guide rail support 11 of the pumping unit driven by a linear motor is formed by two channel beams, between the channel beams are provided with crossbeams, thus forming a frame structure. The frame structure can be formed by the channel beams and the crossbeams through welding or screwed connection. In order to improve stability of the frame structure, the guide rail support can be formed by flanged beams and steel plates instead of the channel beams and the crossbeams through welding. Four guide slide ways formed by angle bars through welding are provided on inner sides of the guide rail support. The guide slide ways are used for controlling sliding movement of the mover 8 of the linear motor, the mover 8 is connected to one end of the counterweight chain 6 at a lower end thereof, and the counterweight chain 6 passes a bottom chain wheel 10 disposed at the bottom of the guide rail support and a top chain wheel 5 disposed at the top of the support sequentially and is then ...

embodiment 2

[0014] The guide rail support 11 of the pumping unit driven by a linear motor in the embodiment 2 is substantially identical with that in the embodiment 1, except for the following aspects: there are two pulleys 4 at the top of the guide rail support 11, the diameter of the pulleys is 500 mm, the chain 3 is replaced by a wire rope 3 whose diameter is 25 mm, and the counterweight chain 6 is also replaced by a counterweight wire rope 6. One end of the counter weight wire rope 6 is connected to a lower end of the mover 8 of the linear motor, and the other end thereof passes the bottom chain wheel 10 disposed at bottom of the guide rail support and the top chain wheel 5 disposed at top of the support sequentially and is then connected to the counterweight 7. In other words, in the embodiment 2, the chain and the counterweight chain in the embodiment 1 are replaced by wire ropes, and the chain wheel, the bottom chain wheel and the top chain wheel in the embodiment 1 are replaced by pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com