Rolling bearing, rolling bearing for fuel cell, compressor for fuel cell system and fuel cell system

a technology for fuel cell systems and rolling bearings, which is applied in the direction of roller bearings, liquid carbonaceous fuels, shafts, etc., can solve the problems of volatile content, deterioration of the life of the compressor and even the entire system, and similar problems of the ejector compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

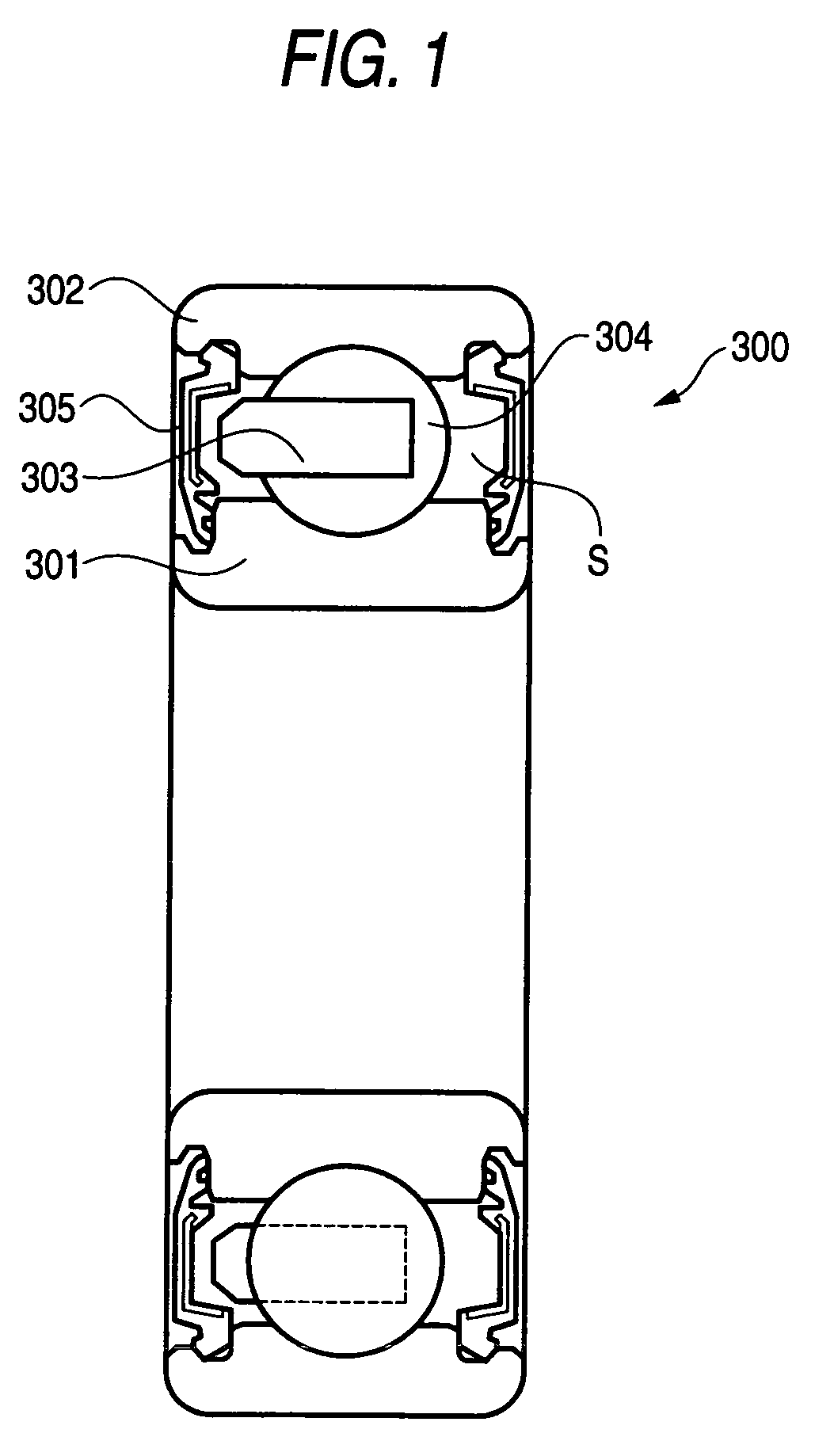

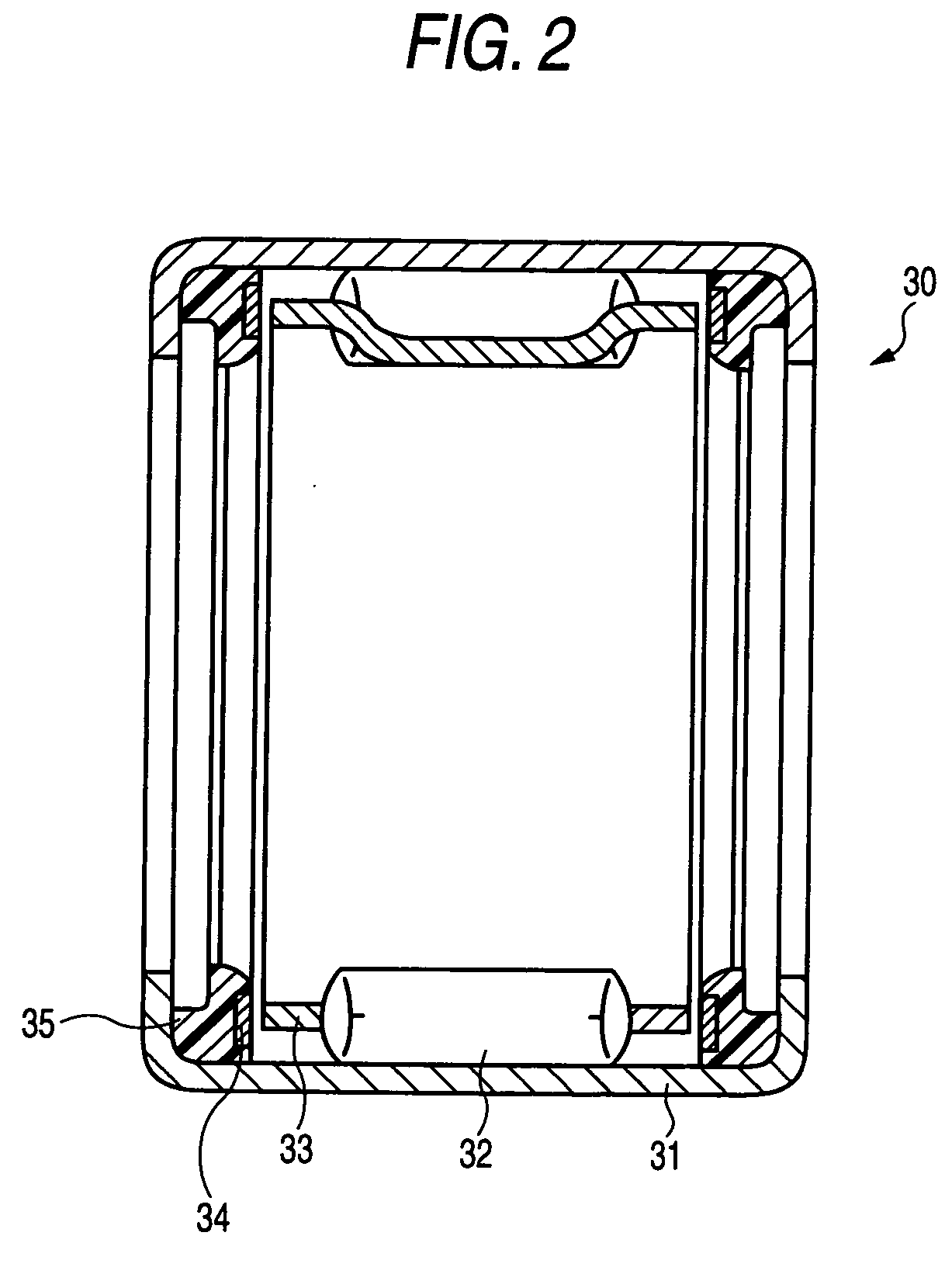

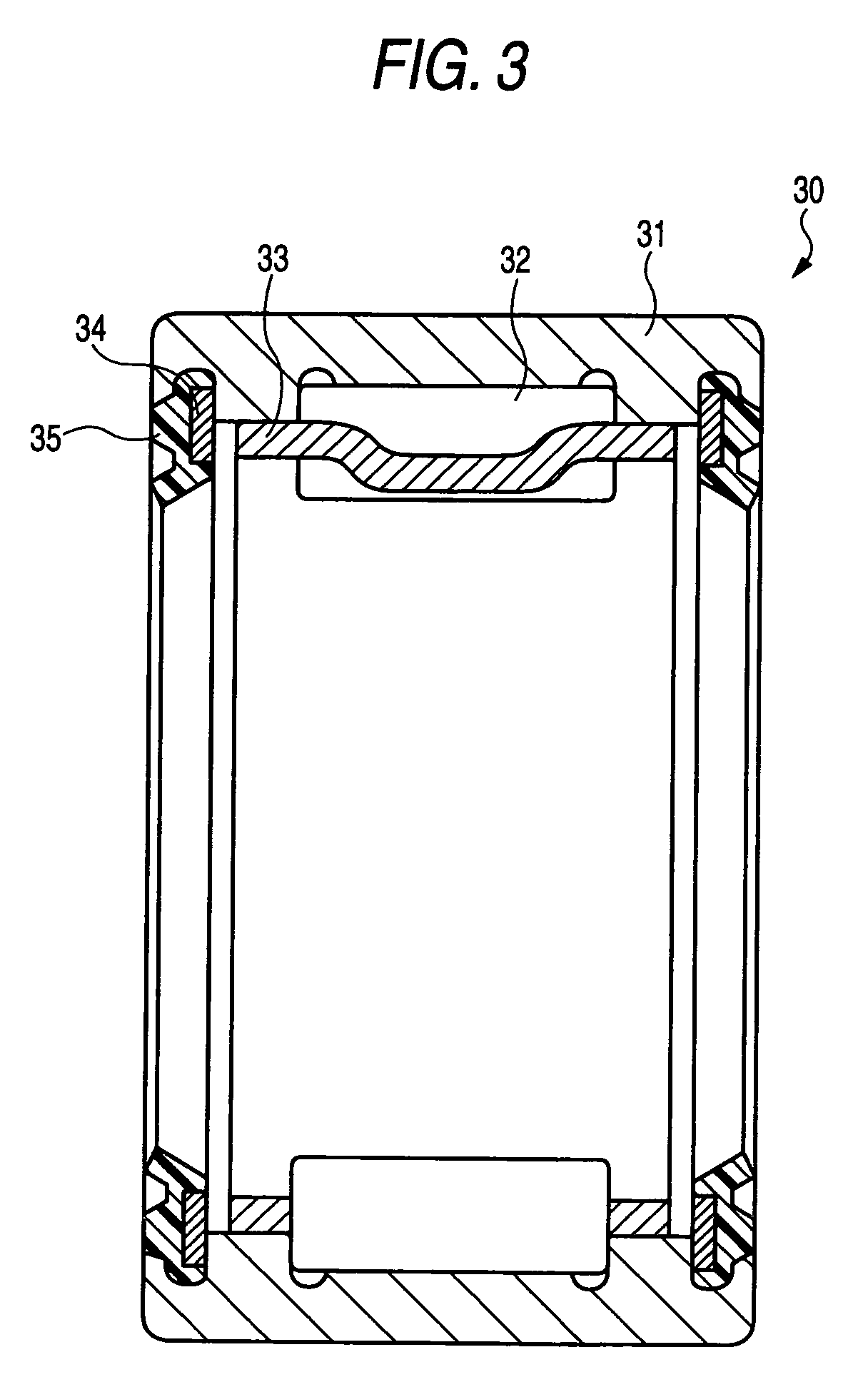

Image

Examples

examples

[0295] The invention will be further described in the following examples and comparative examples, but the invention is not construed as being limited thereto.

(Preparation of Test Greases)

[0296] Test greases A to G were prepared according to the formulations set forth in Table 1 below. For comparison, commercially available lithium soap-mineral oil-based greases and urea compound-mineral oil-based greases (grease C) were prepared.

(Moisture Durability Test)

[0297] A Type 6203DD contact type sealed ball bearing (produced by NSK Ltd.) was filled with the test grease to give a test bearing. The test bearing thus prepared was then rotated at a temperature of 120° C., a radial load of 100N, an axial load of 100N and an inner ring rotary speed of 2,000 rpm. Every 24 hours, rotation was suspended to inject 0.3 ml of water into the interior of the bearing through a syringe. When any unusual noise occurred, the bearing was not able to be started or the motor current rose beyond not small...

examples 1-1 to 1-7

; Examples 1-1′ and 1-2′

[0299] As set forth in Table 2 below, perfluoroalkylethers (PFPE) having a kinetic viscosity of from 270 to 300 mm2 / s at 40° C. were each subjected to thickening with a polytetrafluoroethylene (PTFE). To the perfluoroalkylethers (PFPE) thus thickened were each added a magnesium compound or a vapor phase inhibitor to prepare test greases of Examples 1-1 to 1-7. Further, a polyolester (kinetic viscosity at 40° C.: 270 mm2 / s) was subjected to thickening with a diurea compound. To the polyolester thus thickened was then added barium sulfonate as a rust preventive to prepare a test grease of Example 1-1′. Moreover, a polyolester oil (kinetic viscosity at 40° C.: 100 mm2 / s) was subjected to thickening with a lithium complex soap. To the polyolester thus thickened was then added barium sulfonate as a rust preventive to prepare a test grease of Example 1-2′. All these test greases were each adjusted to have a worked penetration of NLGI No. 2.

[0300] Subsequently, a T...

example 6-1

[0342] A base oil comprising a diisocyanate incorporated therein (ether oil: kinetic viscosity at 40° C.: 100 mm2 / sec) was reacted with the same kind of a base oil comprising an amine incorporated therein with stirring under heating to obtain a semi-solid matter. To the semi-solid matter was then added an amine-based oxidation inhibitor dissolved in the same kind of a base oil. The mixture was then thoroughly stirred. The semi-solid matter was then allowed to cool. To the semi-solid matter was then added carbon black (average particle diameter: 30 nm) in various amounts ranging from 0.1% to 10% by weight based on the total amount of the grease. The mixture was then passed through a roll mill to obtain various test greases having different carbon black contents.

[0343] During the aforementioned procedure, adjustment was made such that the sum of the amount of the urea compound as a thickening agent and carbon black was constant at 20% by weight based on the total amount of the grease...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| vapor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com