Hydraulic pump or hydraulic motor having a rotation speed sensor

a technology of rotation speed sensor and hydraulic motor, which is applied in the direction of pump parameters, positive displacement liquid engines, machines/engines, etc., can solve the problems of insufficient space for the rotation speed sensor and its fixing parts, not always the desired amount of space available, and increase production and assembly complexity. , to achieve the effect of space-saving solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

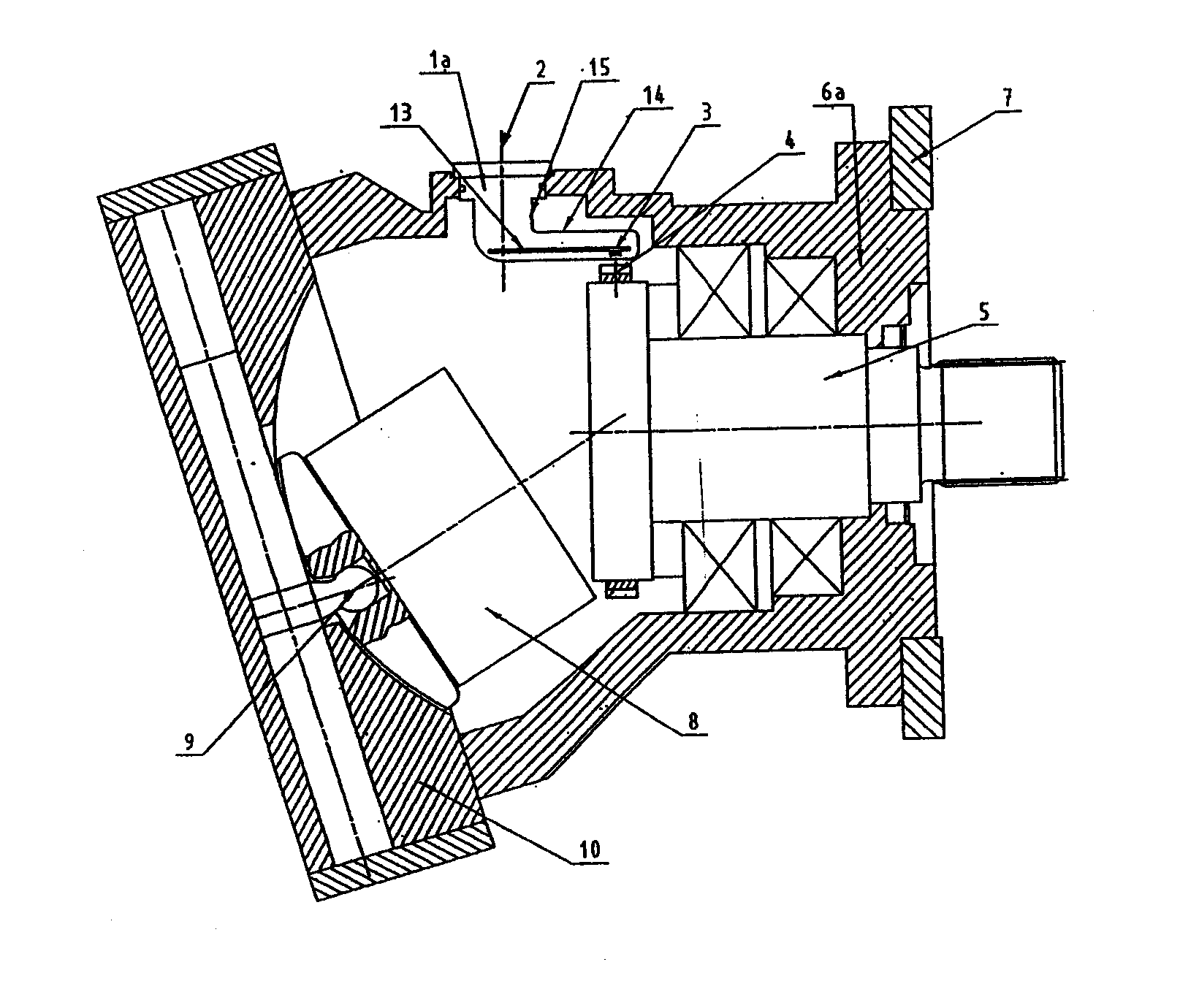

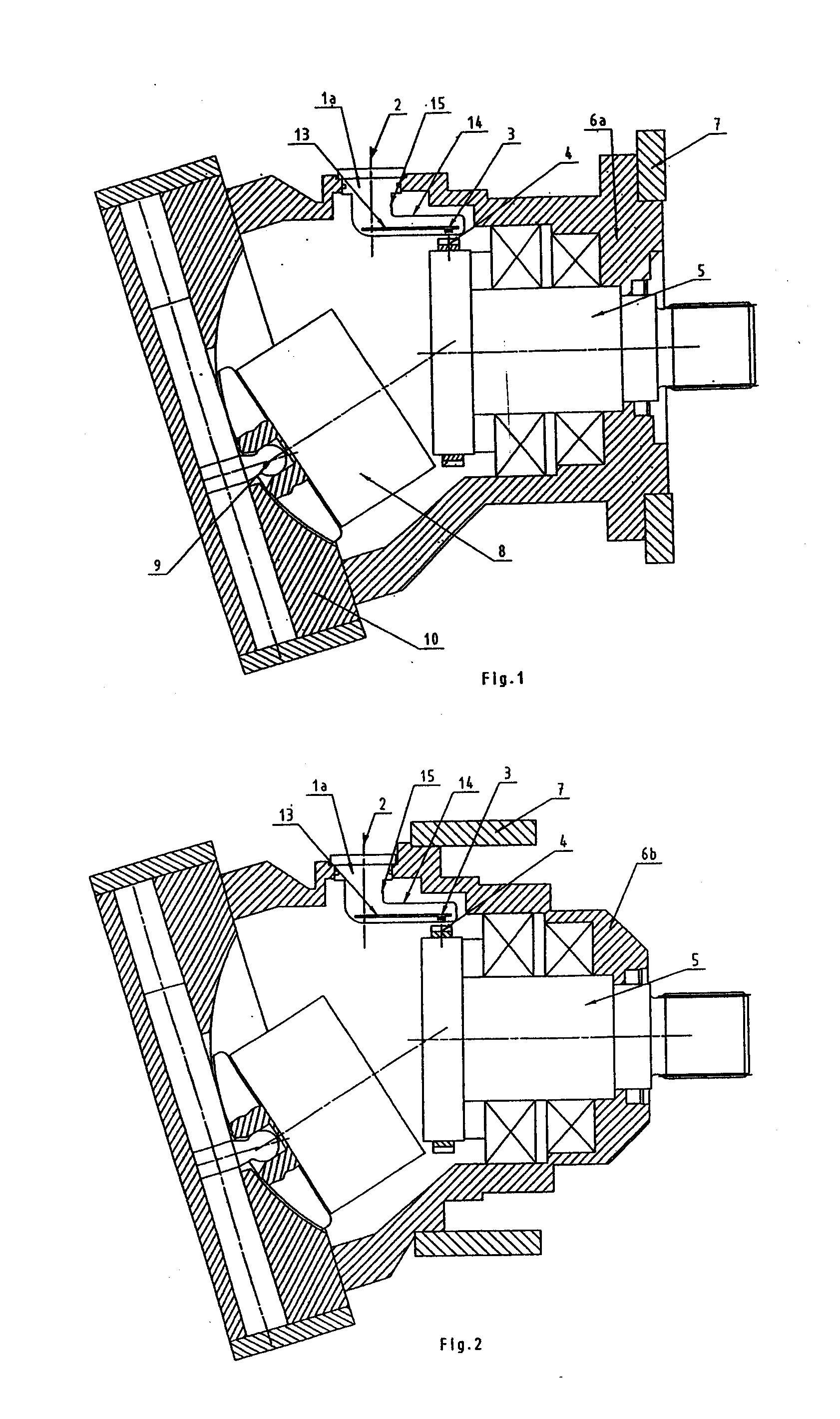

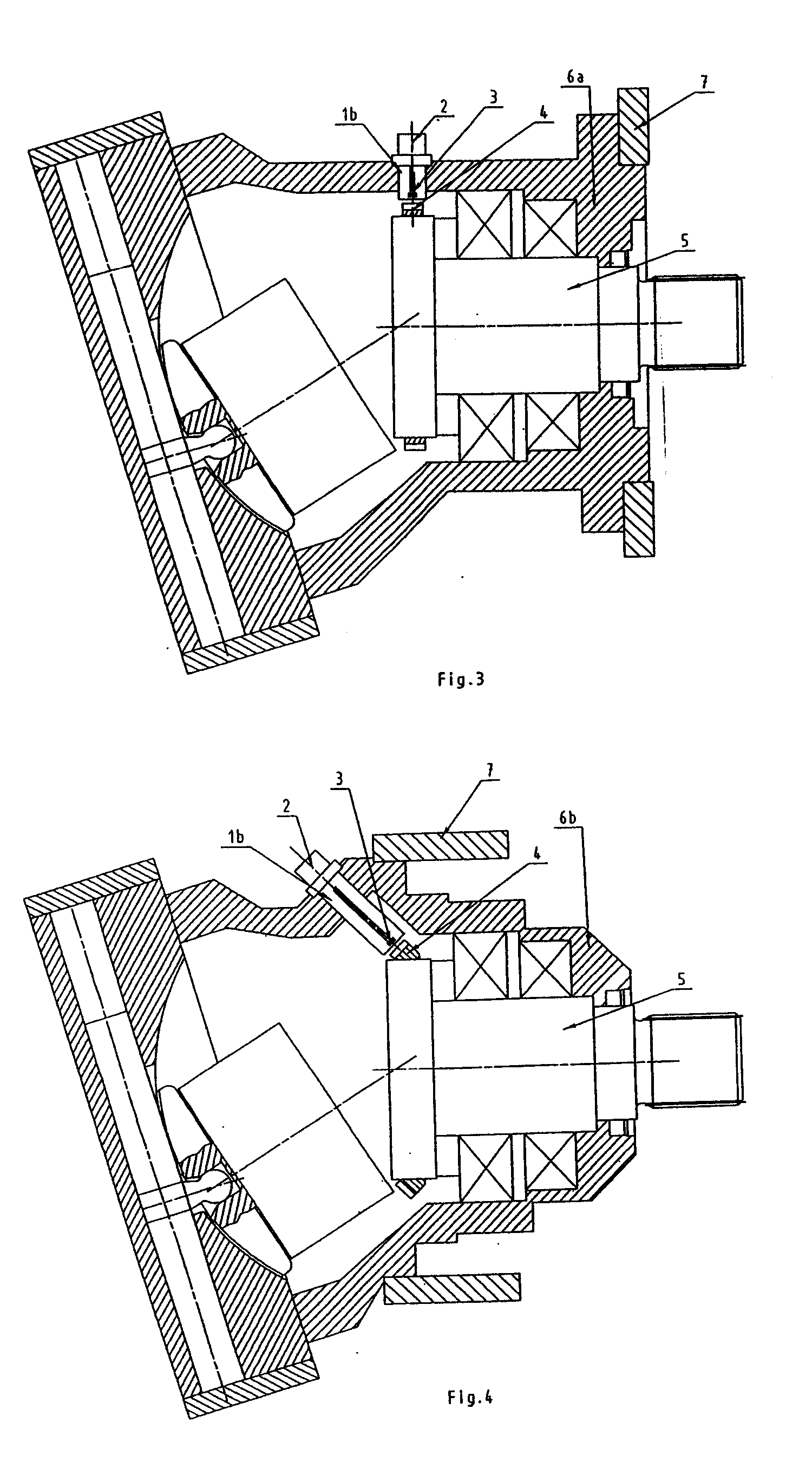

[0018]FIG. 1 illustrates an inclined-axis motor having a first housing variant 6a, in which the rotation speed sensor 1a according to the invention is installed. The housing 6a is connected to the gear mechanism 7 via a flange, only housing parts of said gear mechanism 7 being indicated here. The drive mechanism of the inclined-axis motor comprises in a known manner a cylinder block 8 and a pivoting mechanism 9, which are arranged in the region of the end housing 10.

[0019] The rotation speed is tapped off from the shaft 5, which is mounted in a fixed position in the housing 6a and on which an annular, magnetic pulse generator 4 is fixed, said pulse generator 4 producing corresponding pulses in the sensor element 3, a Hall probe, on rotation of the shaft 5. The Hall probe 3 is arranged on a printed circuit board 13, which extends along a first limb 14 of the L-shaped rotation speed sensor 1a. The limb 14 requires very little physical space. It can be matched optimally to the free sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com